Tools and materials

Sealing the seams on the ceiling will require the preparation of tools and materials. They should be prepared before starting work on the ceiling slabs.

Spatula with flexible elastic blade

How to seal the seams on the ceiling between the slabs? This type of work requires:

- deep penetration primer, better concrete contact. The soil is intended to improve the adhesion of the concrete surface and the material with which it is planned to seal the cracks;

- cement brand NTs, it is used to eliminate deep recesses. The main difference from the standard composition is the ability to expand and fill holes during the solidification process;

- for wide cracks, thermal insulation material is useful; the filler is construction foam, polyurethane or polyethylene foam;

- putty with elastic material (latex);

- sealant;

- reinforced mesh with a width of 4-5 cm, if the width of the crack allows you to place a metal base inside;

- starting and finishing putty.

When treating the ceiling, as well as the floor and walls, you will need basic electrical appliances. The type of tool depends on the seam sealing technology; usually it is enough:

- spatulas of various sizes;

- metal brush;

- spray bottle;

- construction knife;

- hammer drill, easy to replace with a drill with impact mode;

- sandpaper.

What tools will be useful to us

Before closing the joints of the slabs on the ceiling, you should take care of personal safety: eye protection glasses, a respirator, comfortable gloves and overalls.

Work technology

Stage 1

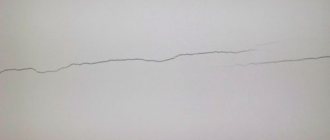

Ceiling seam

The seams on the ceiling are most often sealed simultaneously with the repair of the entire ceiling. This is much more convenient, since such repairs are quite labor-intensive and dusty. Therefore, it is better to do this as a whole.

- First you need to prepare the surface. To do this, you need to remove old whitewash or remaining water-based paint from the ceiling. This is done very simply. Using a spray bottle, water is sprayed onto the ceiling. It is necessary to thoroughly spray the entire ceiling so that there are no dry areas left. Then, you need to let the surface absorb the water for 15 minutes.

- After this, using a spatula, preferably a wide one, remove the layer to the plaster. If there are traces of paint, rust or other materials on the ceiling, they must be removed with a chemical solution. You also need to ensure that the surface is free of chips and holes, as this can interfere. You need to work especially carefully on the seams. They need to be embroidered, removed from old putty, plaster, paint and whitewash. It is better to clean with a narrow spatula to get into all areas of the seam.

- If you cannot remove the solution manually, you can use a hammer drill. The most important thing is that the seam ends up being U-shaped, so the adhesion to the putty will be stronger.

- After the seam is ready, it needs to be cleaned of dust. This can be done with a brush. You also need to blot it with water.

Stage 2

Sealing ceiling joints

When the preparation of the ceiling is completed, you need to inspect it and decide how to remove the seams on the ceiling, that is, which method to use. If the seam width is more than 3 cm, and the recess is not very large, then such a seam can be sealed using ordinary polyurethane foam.

- To begin with, you need to slightly moisten the seam with a clean liquid, and then apply foam and spray. You need to wait several hours for the foam to expand and harden.

- After drying, it is necessary to very carefully cut off excess foam. It is better to cut with a stationery knife, because it has a thinner blade and the cut will look more accurate. You need to make sure that there is a small depression in the shape of a triangle left at the cut site. But, this recess should not be more than 0.5 cm. If the seam on the ceiling is deep enough, but not very wide, then it is better to reinforce it with polystyrene foam, and polyethylene foam will also do.

- Before this, the seams must be thoroughly treated with a primer and dried. This is important because if you apply the material to a wet surface, it will not stick and will soon fall off. You can secure the seal with a sealant; be sure to choose a moisture-resistant one. Remember that the surface must be dry. The sealant is placed in the seam of the slab, and then the seams are sealed from the outside with cement mortar. At the joints, you should get a small depression, just like in the first case. After this, the cement must be allowed to dry thoroughly.

Stage 3

Sealing ceiling seams with your own hands

- As mentioned earlier, it is better to choose latex putty on a recess in which a layer of putty is applied on hardened foam or cement mortar. It is necessary to carefully level the solution with the surface of the slab. This is not an easy task, so you have to work hard. It is important that there are no unevenness, because otherwise the ceiling will be uneven.

- It is better to apply putty using large and narrow spatulas. Apply a sufficient amount of solution to the large one, and spread it onto the seam with the narrow one. At the same time, do not forget to strengthen and smooth the mortar inside the entire seam. You need to make sure that there is no empty space left in the seams, as this could cause the solution to crumble and fall out.

- After this, use a wide spatula to smooth the surface and remove excess putty.

Stage 4

Plastered seam on the ceiling

- The seams must be allowed to dry for 15-20 hours. And only after this you need to start re-puttying.

- The first layer of putty is applied to the seams and the area next to the seam. On top of the layer it is necessary to glue serpyanka or a special mesh. You need to glue using force so that the mesh is pressed into the layers of putty. This is done to strengthen the surface, so there is a greater chance that the putty will not fall off over time. The layer of putty and mesh must be carefully ironed to get rid of unevenness.

- After this, the surface should be allowed to dry. As soon as the putty has dried, you need to go over it with sandpaper or a special mesh. This is done to get rid of roughness and unevenness. When sanding the ceiling surface, you should use a face mask and special glasses, as this is a very dusty job. And dust from putty is very harmful to the human respiratory system.

- After the surface has been cleaned, you need to apply a second layer of putty, but this time to the entire area of the ceiling. The principle of application is the same. Using a large spatula, apply a layer to the ceiling and level it. After drying, go over the surface with sandpaper.

- Then comes the final stage - applying the finishing layer of putty. It is applied in the same way as the preliminary one. Only after drying it should be sanded with a special fine-grained mesh so as not to scratch or damage the surface. After this, the ceiling can be painted or wallpaper glued to it.

Serpyanka sticker

How to remove seams on the ceiling: preparatory stage

Before sealing the seams on the ceiling, it is important to carry out the coating preparation stage. The surface should be durable and primed. It is better to remove any coatings with weak fixation: old putty, paint, wallpaper, cement, lime, etc.

It is better to seal the seams of floor slabs in a clean room (after wet cleaning). To achieve better adhesion and normal mineralization of the working solution, the room must be dry. Primer is applied on top of the cleaned ceiling surface.

Before proceeding to apply the next layer, it is important to wait until the previous one has hardened. The amount of time depends on the temperature and type of material.

Sealing seams between floor slabs: two ways to get rid of annoying seams

In almost all apartment buildings built in the last century, the same problem arises during the process of repairing ceilings - the seams between the floor slabs. No matter how hard the builders try, seams still form between adjacent slabs, and in the worst case, height differences between them. Previously, this problem was practically unsolvable, but today, in the world of developed construction technologies, it can be solved in no time. We’ll talk about this in this article, in which, together with the site stroisovety.org, we will deal with the question of how to seal the seams between floor slabs. We will study various materials that allow this work to be done, as well as the technology itself for eliminating such a “misunderstanding.”

Working with a wide, shallow joint

If there are shallow cracks between floor slabs with a width of 3 cm or more, it is better to use filler, polyurethane foam.

Repairing a seam is quite a labor-intensive job that must be done scrupulously, otherwise the bad work will be visible later

How to seal a seam between ceiling tiles using foam? For this:

- A mounting gun is inserted into the recess and the hole is filled with foam.

- Wait for the foam to dry, usually takes about 2-4 hours.

- All protruding parts are removed with a construction knife; it is better to make a recess of a few millimeters for better grip, but the depth should not exceed 5 mm.

- The recess is treated with elastic putty. It is convenient to use the material using 2 spatulas: narrow and wide. The mixture is stored on a wide tool, and the putty is applied with a narrow spatula.

- Cover the seams on the ceiling with a wide spatula, removing excess and other defects.

Repairing cracks in floor slabs

There are situations when, when removing worn plaster from the ceiling, cracks are found directly in the floor slabs. Such damage may be a signal to take more serious measures than cosmetic sealing of cracks, so let’s take a closer look at how to repair a crack in a ceiling slab, and whether it is possible to do it on your own.

The formation of a crack in a reinforced concrete structure indicates a release of stress that has accumulated in this place due to various factors. The occurrence of cracks is caused by tensile forces arising in the structure from the total impact of internal processes in the product and external loads on it.

According to SNiP 2.03.01-84* “Concrete and reinforced concrete structures”, cracks with identical parameters may be allowed on one type of reinforced concrete products, but not allowed on other structures. Let's consider the situation with floor slabs in order to guide us in assessing the possibility of repairing them on our own.

In addition to the shrinkage (hairline) cracks described above, there are also the following types of cracks:

- technological - from temperature deformations or insufficient vibration when pouring concrete into a mold, uneven prestressing of reinforcement, resulting in delamination of the finished product;

- deformation – mechanical damage during transportation, installation and operation.

Cracks in monolithic reinforced concrete floor slabs, with the exception of hairline cracks, are very rare. But, even if they appear, if the width of the cracks in the ceiling is up to 2 mm, they are simply sealed independently with a cement solution using a construction syringe - to prevent moisture from accessing the reinforcement.

Important! When preparing to seal a crack in a floor slab, jointing it with a grinder, wall chaser or other power tool is not allowed - only superficial expansion of the crack using manual means (trowel, steel wire brush) is allowed.

Hollow and multi-hollow slabs are more susceptible to cracking and require more careful inspection when repairing ceilings.

Small longitudinal cracks on them are acceptable and must be sealed with cement mortar.

If there are transverse cracks on the slab, then it is necessary to carry out a construction examination of the floor by specialists, since such damage is serious and may require strengthening or replacing the entire concrete element, which cannot be done by the residents.

To determine the dynamics of a longitudinal or diagonal crack, use the installation of control beacons; they can be made with your own hands from a strip of paper or a plaster lintel indicating the installation date (a paper beacon is less accurate).

After sealing small cracks in the slab, the ceilings are primed, puttied and painted, as after sealing cracks in plaster.

Working with a wide joint of great depth

If you have to seal a seam between tiles on a ceiling with a width of more than 3 cm and a relatively large depth, you should not use foam.

Work algorithm:

- Filling the recess with heat-insulating material. Foamed polyethylene and polyurethane foam are suitable for this purpose.

- Fixing the insulation using a sealant with maximum resistance to moisture.

- After sealing the crack, the gap is sealed with NC cement, but a small groove with a depth of up to 5 mm is left.

- After the cement has completely hardened, a latex type of putty is applied on top, and the plane of the slab is leveled with it.

- Using a spatula, remove the excess layer of preliminary putty and level it as much as possible.

Instead of foam, you can use ceramic tile adhesive to seal deep cracks.

How to seal a hole in the ceiling

It happens that after cleaning the old grout, not only a crack, but a large hole appears. You can seal it in two ways:

The first way is as follows:

- We clean the crack and prime it twice. Each time you need to let the material dry.

- Fill the hole with foam. We wait until it dries. After which all excess is cut off, a cone with a hole must be cut inside, the height should be 40–50 mm.

- We lay the cement mortar, level it and leave it to dry.

- We apply putty to the place where the hole was and to an area 50–70 mm from it. Leave to dry.

- After which the same work is carried out as when rubbing seams.

The second method is used in cases where the hole is very large:

- You need to take a piece of plywood, you can also use a piece of laminate. The size should be 100 mm larger than the hole itself.

- We attach a wire grid to the hole. For this, a sealant or cement solution is used. After the solution has dried, the mesh should be firmly fixed. It will create reinforcement for the mortar. And together they can create a kind of slab.

- Concrete is poured onto the plywood. The concrete must be mixed until smooth and not too thick.

- We lift the plywood seal and press it firmly against the hole along with the mortar. This is necessary so that the solution completely fills the hole. For a while, it is necessary to make a support that can hold the plywood until the composition dries completely. You can use a block or a thick branch.

- After drying, you will get a smooth surface.

- After this, you can begin work to bring the ceiling surface to normal condition.

It is worth noting that you can update the joint between the slabs yourself. But it will be difficult to bring the entire surface of the ceiling back to normal. But if you have the desire and perseverance, you can handle this work yourself .

So, we have figured out how and with what to grout the seams between the tiles on the ceiling. You can do this yourself. The main thing is to follow all stages of finishing and use high-quality materials.

If you live in a panel multi-storey building, then the appearance of gaps between the floor slabs or the appearance of seams that were unsuccessfully sealed is a common occurrence. That is why if the first signs of this phenomenon appear, you need to immediately take radical measures. After all, if this is an apartment located on the top floor, then when there are cracks in the ceiling, it can drip, causing dampness, fungus and mold to form. This phenomenon is not entirely pleasant. Therefore, the problem needs to be solved. And to do this, you need to have the necessary skills and knowledge. Few people know how to seal a ceiling seam, so the job will seem difficult for them. However, do not rush to call specialists.

However, the seams can crack, regardless of whether the apartment is on the top floor or on the first floor. It all comes down to the fact that the house can shrink. Therefore, in this article we will look at how to eliminate the problem and seal the seams between the slabs.

Working with deep and narrow joints

It is better to seal narrow but deep seams between floor slabs using the same method as in the previous case.

How to seal the seams on the ceiling between the slabs? The sequence of work is as follows:

- A sealant is applied to a piece of insulation and placed inside the groove. The material should be pushed firmly into the recess.

- After high-quality compaction with insulation, there should be about 1 cm of depth left for adding NC cement. It is important to leave a 5mm recess.

- Latex putty is applied to the hardened cement mortar and leveled with a spatula.

Sealing small seams

If the seam is narrow but deep, sealant is applied to one side of the polyethylene insulation and tightly tucked into the prepared joint with a spatula. After this, the surface is sealed with a special solution and plastered.

After waiting for the solution to dry, elastic putty is applied to the seam with a spatula. It is advisable to use a wide and narrow tool at the same time - the first one is filled with mortar, and the second one is applied to the seam, after which the material is compacted and leveled. If there is excess putty, it is removed immediately.

Figure 3 Seal the joint on the ceiling.

It takes about 2 days for the solution to harden properly, after which you can begin reinforcing. Apply a small layer of putty to the seam and the part of the ceiling adjacent to it, attach the sickle mesh to it, pressing it into the solution. Excess material is removed with a spatula. When the solution is completely dry, apply two layers of primer to the entire ceiling with a roller, then allow the composition to dry and proceed to the next stage - plastering the surface.

Two layers of plaster are applied to the ceiling. After applying the primary plaster and drying it, the main, final layer is applied to it. It is recommended to use a wide spatula for this purpose, which is convenient for applying and leveling the plaster. After waiting for it to dry, apply whitewash, paint or wallpaper to the surface.

Next steps

Sealing the seams between the panels is not completed in the previous steps. It is important to carry out the entire processing complex so that defects do not appear in the future. Otherwise, when the soil and the base of the building move, the floor seams will crack again, and all work will be in vain.

The reason for the appearance of cracks may be incorrect calculation of the load on the structure or neglect of construction technology, which causes the building to shrink. At the stage of building a house, it is important to take into account the weight of the house’s insulation and lay the water supply system in advance to prevent the destruction of load-bearing walls and foundations later.

Latex putty. This kind of putty is more suitable for sealing seams.

Protection of joints between floor slabs from destruction is carried out in stages:

- Wait for the latex putty to harden; complete drying takes about 2 days.

- Preparation for reinforcement of the recess. Apply a starting layer of putty, it is laid with a small protrusion beyond the edges of 4-5 cm.

- A reinforcing mesh is pressed into the material; a roller or narrow spatula will do.

- Use a spatula to run along the putty to remove excess.

- After the material has hardened, the surface should be treated with fine or medium-grain sandpaper.

- Repeated application of the starting putty will help create an ideal plane; cleaning is done with fine-grained sandpaper.

- A finishing putty coating is applied on top.

- After hardening, re-treat with sandpaper.

- The final stage is painting or gluing the ceiling.

Plastering

If, parallel to the damaged seams, there is a significant slope in the ceiling in any direction, it should be leveled. The best method is plaster compositions; their installation is preceded by the installation of the mesh. The entire working surface is covered with concrete contact soil; it contains hard, large particles to improve adhesion to concrete. To cover the ceiling, a mixture of cement and gypsum is prepared.

The seams on the ceiling are most often sealed simultaneously with the repair of the entire ceiling

Closing the hole

As a result of ignoring building codes, defects may appear on the ceiling; one of the most dangerous is a hole. Sealing ceiling joints between slabs is done using one of two methods.

First way:

- Use a brush with an extended handle to clean the hole from the inside.

- It is important to remove loose dust, creating a strong adhesion; to do this, thoroughly spray the entire surface with a spray bottle containing soil.

- Polyurethane foam is blown inside.

- After complete hardening, cut off areas with excess material using a sharp knife.

- Cut out a cone-shaped recess with a height of 4-5 cm.

- The recess is sealed with NTs grade cement and the material is allowed to harden.

- The surface is leveled with a layer of putty, and a sickle mesh is placed inside.

- Subsequent operations are no different from sealing the seams on the ceiling between the slabs.

There is a second method for sealing the joints of floor slabs with holes:

- An improvised frame is created that fits flush into the hole, and it is placed inside the defective area. Any metal wire can be used.

- The frame is fixed using sealant; it is better to use one intended for repairing plumbing fixtures and walls in wet rooms. If the purpose of the material is damp walls, its use for ceiling repair often leads to a better result.

- After hardening, a lattice is formed in the cavity; it will ensure strong fixation of the solution.

- Prepare a mixture of NC solution; you can use the classic composition, but it is better to add an additive that will improve the setting of the solution. To prevent the cement from falling out, it is supported from below with a piece of plywood.

- The plywood is secured from below with a support; it will hold the cement in the required position until it dries.

- The wooden board is removed only after hardening, then finishing is carried out.

The most important thing is to strictly follow the sequence and be careful

Technology for sealing seams between floor panels

One of the main stages in the construction of a floor made of reinforced concrete slabs is the sealing of rustications - the seams between them and holes with mounting loops (if any). It is better to do this immediately after laying the products, so that the narrow cracks do not become clogged with construction debris, which is problematic to remove from them. The technology of work directly depends on the overall dimensions of the seam.

Tools and materials

As a rule, with high-quality sealing of joints immediately after laying the slabs, no problems are observed in the future. But there are situations when this work is done “anyhow” and during operation, cracks appear at the joints and the solution begins to crumble. We will discuss the issues of filling joints when installing slabs and repairing crumbling areas.

Mortar seams

To seal the gaps from above immediately after installation, you will need the following materials and tools:

- cement-sand mortar;

- corrugated reinforcement for reinforcing wide rustications;

- materials for formwork when filling large joints and concreting missing areas;

- Master OK;

- deep vibrator for concrete compaction – recommended for concreting wide gaps and monolithic areas.

Sealing seams on the ceiling between floor slabs, which can open during operation, is a much more labor-intensive and complex process than filling directly during installation. Cement-sand mortar is also used for work, but depending on the opening width, other materials can be used. The tools you will need are a spatula, a trowel, and a wire brush for cleaning gaps.

Sealing joints on the ceiling

How to seal a seam between floor slabs?

Sealing the seams between the floor slabs after their installation can be done using the following methods, depending on their size:

- Rust up to 20 mm wide is filled with cement mixture and carefully compacted with a trowel.

Filling a small joint with mortar Cracks with a width of 20 mm or more are sealed with a thick mortar; it is additionally recommended to perform longitudinal reinforcement.

Filling middle joints

Large gaps and missing fragments of floors are reinforced and concreted. The areas are laid with a sagging reinforcement frame, formwork is constructed from below, concrete is poured, followed by compaction.

Reinforcement scheme for the missing fragment

The technique for repairing crumbling seams on the ceiling between the slabs is discussed below. But before repairs, it is mandatory to clean the surface from crumbling areas and provide high-quality priming.

Priming the joint between the plates

Wide shallow seam

Shallow joints between floor slabs with a large width (from 30 mm) are usually sealed using the following technology:

- Filling the gap with foam.

Filling the gap with foam

- Removing the remaining foam and deepening it by 5 mm after it has dried.

- Application of elastic putty.

- Embedding a fiberglass mesh into the freshly applied compound.

- Filling the gap with thermal insulation material - polyethylene foam is best suited for this purpose, but polyurethane foam can also be used.

- Sealing using moisture-resistant sealant.

- Filling the gap with self-expanding cement of the NTs brand, but it is important to leave a small depression of up to 5 mm.

Then the repaired joints of the floor slabs are carefully smoothed with a wide spatula to remove excess putty and level the surface.

Wide gap deep depth

A deep seam between floor slabs with a width of more than 30 mm is sealed without the use of polyurethane foam. The sequence of work is as follows:

Filling the gap with self-expanding cement

Deep and narrow joint

Deep, but narrow seams between the floor slabs on the ceiling are sealed using the following technology:

- Filling the gap with foam - it is important to ensure penetration of the product to the full depth. To do this, you can use small diameter tubes that are put on the gun and pushed into a narrow slot. After filling, approximately 10 mm of depth should remain for subsequent sealing.

- The next approximately 5-7 mm of the joint depth is sealed with self-expanding cement.

- The remaining 3-5 mm are covered with latex putty reinforced with fiberglass mesh.

Technique for filling and reinforcing the seam between the slabs

After the measures described above, you can begin finishing with the selected material

Joint between wall and ceiling: sealing methods

Characteristically, there are not only noticeable defects in the joints between the floor slabs, but also in the walls. It will not be possible to properly finish the surface without eliminating cracks.

To remove defects it is recommended to use:

- construction foam;

- gypsum mortar;

- synthetic putty;

- putty for exterior use.

The simplest and most effective material is foam, which expands during the hardening process and fills voids.

If the joints are quite large, it is worth taking care of further protection against cracking. Reinforcing mesh and alternative materials - cotton, linen fabrics that are soaked in an adhesive solution will help prevent the appearance of cracks. The fabrics are laid over the hole. At the final stage, a layer of plaster is laid.

What to do if joints are visible on the ceiling: final leveling of the surface

Regardless of the method used to remove defects, it is important to create a high-quality finishing coating. Abrasive mixtures are used to level the surface.

The process of applying latex putty

To create a perfectly smooth and even surface, it is recommended to use non-woven fabric. It is glued to the ceiling up to the finishing layer of putty. The material helps eliminate small irregularities.

It is important to cover the ceiling with primer after the final leveling layer; this will help prevent the destruction of the coating and increase the durability of the putty layer. Now you can paint the ceiling, paste it over or whitewash it.

Recommendations

Construction of a building and creation of an attractive appearance is a complex task that requires taking into account many factors:

- creating a reliable foundation will prevent cracks from appearing at corners and between floor slabs. Before making a slab foundation, it is important to carefully carry out the preparatory work: examining the soil, studying the level of soil freezing, creating the correct markings and compacting the surface. The construction of the foundation slab ensures a service life of up to 150 years only if the laying technology is followed;

- To maintain heat in the room, it is worth eliminating the leakage of thermal energy through the floor. One of the best ways is a USHP foundation;

- in multi-storey buildings, it is better to first study the plan of the floor slabs, this will help to identify potential vulnerabilities of the structure and eliminate them at the repair stage;

- when building housing, it is better to use composite concrete, it has high technical characteristics and is absolutely safe for health;

- working with concrete in the cold season with a standard cement composition is unacceptable by the manufacturer, but not all companies are ready to stop construction for the winter. So is it possible to pour concrete in winter? – Yes, but you will need to add special mixtures to the composition or electrically heat the concrete;

- if you plan to build a house from aerated concrete, be sure to reinforce it every 2-3 rows. The reinforcement is placed inside the block recesses that are created by the wall chaser for aerated concrete;

Holes of various sizes can be sealed if the technology is followed correctly. It is recommended to choose one of the existing methods for eliminating ceiling defects; they are easy to use and durable.