Drywall and unheated cottage

We use moisture-resistant plasterboard in the bathroom.

Almost every building material has many different varieties, differing in certain characteristics. Moisture-resistant plasterboard is often used for finishing arches, ceilings, walls and other surfaces.

Drywall is called a building material. consisting of several layers: the plaster itself in the middle and two cardboard sheets. Reinforced material, which is strengthened with metal mesh, fiberglass and other means, has greater strength.

A distinctive property of waterproof plasterboard is that it can be used in rooms with an unstable microclimate. While non-moisture-resistant materials, like a sponge, absorb moisture and gradually collapse.

Before you give preference to a certain material. its performance characteristics should be studied in detail. Properties of moisture-resistant drywall.

As a rule, the color of the product is light green - this feature helps to distinguish moisture-resistant material from ordinary gypsum board. Some companies also produce pink sheets.

The gypsum layer is impregnated with special substances that provide the material with moisture resistance.

Gypsum is treated with substances that protect the material from the effects of mold and mildew, so it can even be used for arranging basements.

The dimensions of gypsum boards are extremely varied. You can choose sheets of literally any size with a constant thickness, the value of which can vary between 7-24 mm.

Moisture-resistant plasterboard, the thickness of which is more than 12 mm, can be used for cladding unheated rooms: for example, a kitchen, a summer house, a bathroom.

Drywall: pros and cons.

A very good solution would be to use plasterboard under the tiles in the bathroom. After all, this material is universal and easy to install. Of course, when decorating wet rooms such as a bathroom, you should use only a moisture-resistant type of material.

Drywall in winter! incredible!

After all, only such products are not damaged due to exposure to liquids and high humidity. When buying drywall for a bathroom, you can easily distinguish it from many other materials: the sheets of the product are painted green and have blue markings with the abbreviation “GKLV” and an indication of the dimensions. The demand for gypsum in the field of rough finishing is also due to many other advantages.

Wide scope of application and versatility. This material can be used for the construction of various partitions, suspended ceilings and wall cladding in any rooms with high humidity.

Excellent water-repellent characteristics.

Sound-absorbing properties, thanks to which it can also be used as sound insulation.

Ease of installation and processing.

Good flexibility, due to which the sheet can be installed on a curved surface.

An excellent basis for all types of finishing: for example, tiles, decorative plaster, wallpaper.

Of course, moisture-resistant drywall, like any other material, also has some disadvantages, so it should not be idealized either. For example, due to prolonged exposure to water, a sheet can absorb it, swell and become significantly deformed. In addition, you need to take into account that drywall cannot withstand strong impacts and heavy loads. That is, it is not recommended to fix such bulky things as a boiler and cabinets on drywall.

It is also important to adhere to the technology of installing moisture-resistant ceiling plasterboard in order to preserve all its characteristics. It is best to entrust the installation of a plasterboard ceiling in a bathroom to professionals. But laying tiles in the bathroom on gypsum plasterboard is not at all difficult and, perhaps, anyone can do it.

Installation of moisture-resistant drywall.

The scope of application of moisture-resistant drywall is truly extensive: it can be glued, cut and mounted on external surfaces, floors, ceiling structures, walls and arched openings. Unlike ordinary plaster, the moisture-resistant product can even be washed.

Direct installation of moisture-resistant gypsum boards is carried out in stages.

preparation of the surface to be finished.

installing the frame or lubricating the surface with glue.

The material can be placed on a frame or in a frameless manner. Each of these options is worth considering separately.

Installation diagram of moisture-resistant drywall without frame.

Frameless method of installing drywall step by step.

First of all, you should prepare the surface on which the sheet will be installed. First you need to remove the old finish from the surface: remnants of paint, plaster or wallpaper. Then the surface must be treated with a primer. It is the primer mixture that will help protect the material from fungus and mold, as well as significantly increase the adhesion of the treated surface and glue. This stage is especially important when processing the ceiling.

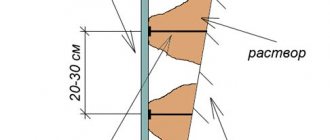

Taking into account the condition of the surface, the adhesive mixture can be applied in different ways: with slaps and around the perimeter. If you are covering a smooth wall without defects, glue can be applied around the perimeter. To do this, apply glue along the sides of the drywall and in the center of the sheet. Then place the product against the wall or ceiling and level it using a level. If the surface to be treated has any unevenness or roughness, it is best to apply the glue in splashes. This way you will cover the entire surface with an even layer. In some cases, builders apply glue not only to the drywall itself, but also to the wall. This is necessary to prevent the occurrence of voids between the surface and the material.

Before you begin the gluing procedure, check if there are any drafts in the room. Keep in mind that it is drafts that contribute to premature hardening of the glue. Under normal conditions, the composition hardens within 24 hours.

Then you need to cover the sheet with another layer of primer. The soil mixture dries in approximately 24 hours. After this, the surface can be coated with a universal primer.

Lastly, you can start decorating. However, please note that installation of tiles is only possible on drywall that is mounted using a frame method.

Installation of moisture-resistant gypsum board on the frame.

Of course, frame installation technology differs markedly from the frameless method.

First of all, you need to determine which side to fix the material. Keep in mind that both sides of moisture-resistant drywall are different: one is made of gypsum and the other is made of cardboard. The gypsum side has greater hardness and density - it should be mounted on the frame. And the cardboard side is considered the front side and must be subjected to additional lining, so it remains outside. The tiles are actually laid on the cardboard side.

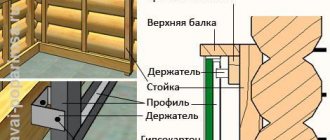

Considering where the drywall will be installed: on the floor, walls or ceiling, you need to find the lowest corners and mark them with dashes. The guide profile will be mounted along these lines.

Using a level and anchors, secure the drywall to the ceiling, floor or walls. Draw the plane, highlighting the pitch of the main profiles and racks. This characteristic depends entirely on the location of installation of the material.

In order to make the frame more rigid and durable, you need to supplement it with special hangers. The distance between the hangers should vary between 40-50 mm.

Only after this can you begin the direct installation of drywall on the frame. If you plan to create shaped details in the interior, use small-format plasterboard. Sheets of this material can be cut according to patterns and fixed on prepared profiles. Fortunately, waterproof drywall is flexible enough to allow it to be bent and adjusted to fit the desired openings.

As you can see, you don’t need any special skills when working with plaster - everything is quite simple and quick.

However, is it possible to completely rely on a rough finish with moisture-resistant plasterboard and at the same time be completely sure that nothing will happen to the material? In fact, absolutely every material has weak, vulnerable spots, and drywall is no exception! Now we are talking about the cut and unprotected ends of the plaster, as well as the back side adjacent to the existing walls. It is these areas that need additional protection during prolonged exposure to moisture.

Is it possible to protect moisture-resistant plaster from the effects of water? The answer is simple - it’s not easy, but it’s even necessary! Rest assured, absolutely any material, even one that is not resistant to water, can be easily adapted with the help of additional means. How to do it.

How to store drywall in an unheated room

Is it possible to attach plasterboard sheets instead of plaster directly to the wall of a brick garden house that is not heated in winter?

Answer: Of course, it is possible to secure it; there are frameless technologies. But in your case it is better not to do this due to the fact that gypsum boards are recommended for use in dry and normal rooms with relative humidity up to 70%. In an unheated room during winter and transitional periods, this requirement is practically impossible to fulfill. Even moisture-resistant cardboard is not designed for long-term operation in such humidity conditions. The drywall will peel and swell.

Where to start installing drywall from the walls or from the ceiling?

Answer: It is more convenient to start work from the walls. But there are no restrictions for starting work with ceiling cladding.

What determines the distance between the guides when facing walls or is it always standard?

Answer: First of all, the distance between the guide frame posts depends on the size of the sheet and a prerequisite for any cladding is the joining of the sheets on the edge of the profile. It is recommended to reduce the distance between the guides when installing facings with ceramic tiles or artificial stone, when the height of the structure increases to more than 3 meters and increased requirements for sound insulation. Strengthening the structure is also possible by installing a two-layer cladding or using high-strength plasterboard sheets (GKLU).

Is it possible to use drywall to cover an unheated balcony?

Answer: Experts do not recommend doing this. In unheated rooms with high humidity, drywall can delaminate and become moldy. It is better not to take risks and use a more reliable material for cladding the balcony, for example, wooden lining.

Is it possible to cover the ceiling of the first floor of a two-story house with wooden beams with plasterboard sheets?

Answer: Load-bearing wooden beams under loads during walking on the second floor are to one degree or another subject to sagging, which can lead to the formation of cracks. To prevent this process, it is necessary to choose a ceiling design that does not have a rigid attachment to the wall. I usually recommend this design for earthquake-prone areas. It represents a two-level ceiling, when the load-bearing and main profiles are located at different levels, and there is no ceiling side guide profile at all. The joint between the drywall and the wall is glued with corner reinforcing tape and puttied. When deflections occur, the ceiling sheet can move, but at the same time, with this design, a hairline crack forms only along the perimeter. Professionals call such a crack “organized.”

How thick should plasterboard sheets be for the ceiling, the same as for the walls?

Answer: The thickness of plasterboard ranges from 6 to 24 mm. For ceiling work, 9.5 mm sheets are most in demand. Finishing partitions requires a more serious thickness and very often specialists use gypsum boards of maximum thickness.

What to do if the length of the ceiling profiles is less than the length of the room?

Answer: They are simply extended using factory-made connectors. Everything is provided by the manufacturers.

Is it necessary to completely putty the surface of plasterboard sheets before painting?

Answer: The joints of plasterboard sheets must be puttied. It is theoretically not necessary to completely putty the surface of the gypsum board, but in practice it usually turns out that in this case the paint must take on all the “responsibility” and will need to be applied at least three times. In this case, it is very important to understand how the wall surface will be finished in the future.

Is it possible to sheathe an unheated room with plasterboard?

Dear forum users, please advise. Can waterproof plasterboard be used for interior decoration? Given - the veranda is glazed, we don’t go in winter, the house is not heated. I would like to paint the walls with “corrugated paint.”

If drywall is not suitable, what can be replaced? Thank you in advance.Lara, two years ago the second floor was partially covered with plasterboard.

The drywall was secured not with screws, but with a stapler. The joints were closed with slats. They stopped there, didn’t paint, didn’t glue wallpaper.

After the winter, marks and smudges appeared here and there, because a roof leak was discovered in one place. But the drywall did not deform. I don’t know what kind of drywall they used, it’s rough on one side and glossy on the other. The possibility of painting is also of interest. Wood is a warm and clean material. For many years, after construction is completed, it fills the inside of the house with its aroma.

To finish the walls, it is necessary to take into account the shrinkage of the new structure and the constant expansion of the logs with changes in humidity and temperature. Timber and boards play less. Our neighbors' house is lined with plasterboard inside.

Wallpaper is pasted on top. The house is about twenty years old. Nothing bad happened to the drywall during this time. Only the wallpaper is changed periodically. Yes, a “prefabricated panel” house.

At the dacha you can relax not only from the city noise and bustle. Clean air is an integral part of outdoor recreation. Many are tormented by the question of how to cover the walls of a dacha inside inexpensively and maintain comfort. For this purpose, an environmentally friendly material is used that can easily withstand the winter unheated period.

It is advisable to preserve the natural, country style of finishing.

Is it possible to sheathe the walls of an unheated cottage with gypsum plasterboard or MDF panels?

Question No. 145: A dacha was built from blocks and facing bricks, the walls are 40 cm thick, unheated. In winter, the usual air temperature is minus 10 degrees, sometimes lower. Is it possible to cover walls with plasterboard? Or is it better to use MDF panels? Thank you. Answer: As for plasterboard, I do not recommend that you use even moisture-resistant plasterboard for cladding walls in your house without heating. In any case, there will be a difference in temperature inside and outside the room, even rare visits to the dacha in winter will change the air humidity inside the room, and the dew point will shift to the inner surface of the walls. This means that the air humidity in the room will increase, the plasterboard sheets will absorb moisture, become covered with frost, freeze, and in the spring they will swell and crumble. Drywall itself does not belong to the family of frost-resistant building materials; its frost resistance is only eight cycles, but should be at least 35. Now about MDF panels. These are very good wall panels and are made from wood dust by pressing; the binder material in MDF boards is lignin, released from wood as a result of heating the wood dust during pressing. So MDF is the familiar fiberboard covered with a textured film. I would not recommend trying MDF panels to decorate the walls of your dacha. This material does not belong to the moisture-resistant class and is not recommended for use in unheated rooms. Over the winter, the panels will become saturated with moisture and begin to deform and swell. Consider panels made of PVC or natural euro lining or simple wooden lining for finishing the walls of your dacha. Good luck. PS If you don’t decide how to decorate the walls before winter, buy one MDF panel and leave it indoors in your dacha for the winter, and see how it behaves in the spring. Calculations show that at -12C your room will be +5C with your wall thickness, so anything can happen and the humidity in the room will be below 70%, and this will allow you to install MDF boards on the walls without fear that they will collapse.

Added: 02/13/2017 11:14

Discussion of the issue on the forum:

Storage rules

Any gypsum plasterboard manufacturer must include recommendations with the product regarding what storage conditions and rules must be followed by the buyer so as not to damage the material. However, not all sellers treat this issue responsibly. Therefore, if you are planning to renovate using drywall, you need to know the basic rules for storing it indoors. For gypsum boards there are the following storage rules:

- the room must be warm and heated. It can only be stored in an unheated room at a temperature of at least 10°C. The temperature should not fall below this mark. It should be noted that such a temperature regime must be maintained for 2 days after installing the sheets on the walls or ceiling;

- the room should be dry and closed;

- The shelf life of the product until it is installed on a metal frame in a heated room is at least 2-3 days;

- Stable temperature and humidity indicators are required.

In addition, there are requirements for the placement of the material itself:

- packages should be located away from heating sources;

Note! The minimum distance to batteries should be 1.5 m.

- The storage surface must be level.

Storing sheets

By following these rules, the purchased building material will remain in perfect condition until installation work begins. There are several ways to place drywall in a suitable room. Bundles of material can be stored either horizontally or vertically. The easiest way to place gypsum board packs is “lying”, i.e. in the plane of the floor. To avoid damage and deformation of the slabs, a certain structure made of boards should be built under them, or special pallets can be used.

Storage base

This design will help prevent product damage if moisture gets on the floor. Raising the pack above the floor level should be approximately 10-20 cm. If you have problems with space in the room, then the best way to place it would be to lean the pack on the wall (place it “on its edge”). But in this situation, it should be remembered that in order to prevent deformation changes in the slabs, we place the first sheet from the package in such a way that it is as close as possible to 90 degrees. Those. it should be almost parallel to the wall.

Note! Under no circumstances should sheets be placed “edge-on” with their narrow side. This position of the plates will lead to inevitable deformation under its own weight.

We place the remaining sheets close to it. This way they will be positioned vertically.

No matter how you decide to place the drywall, it must be covered with film. For vertical placement this is especially important. The film will protect the product from excessive contamination with dust, prevent moisture from entering from above, and also eliminate the possibility of damage from mechanical impacts of small forces.

Other publications in the “Interior decoration of the house” section

As we know from practice, renovating an apartment or house is an interesting, educational, and sometimes even eternal process. Therefore, many homeowners prefer to do repairs on their own. Of course, there are those who do their own repairs simply because they don’t have enough.

What are the risks of using conventional slabs in the bathroom? Let's consider the features of constructing partitions in the bathroom from tongue-and-groove gypsum boards. Each such slab is made of building gypsum and is a rectangular parallelepiped, the joining and supporting surfaces of which are .

The house is made of adobe, walls without lathing, sand-clay plaster, lime whitewash. How to properly approach the issue of leveling walls with putty (finishing) or how to properly prepare such walls for painting with water-based paint. Thanks for the answer Answer: If the house is old enough and there are .

Is it possible to sheathe the walls of an unheated cottage with gypsum plasterboard or MDF panels?

Question No. 145: A dacha was built from blocks and facing bricks, the walls are 40 cm thick, unheated. In winter, the usual air temperature is minus 10 degrees, sometimes lower. Is it possible to cover walls with plasterboard? Or is it better to use MDF panels? Thank you. Answer: As for plasterboard, I do not recommend that you use even moisture-resistant plasterboard for cladding walls in your house without heating. In any case, there will be a difference in temperature inside and outside the room, even rare visits to the dacha in winter will change the air humidity inside the room, and the dew point will shift to the inner surface of the walls. This means that the air humidity in the room will increase, the plasterboard sheets will absorb moisture, become covered with frost, freeze, and in the spring they will swell and crumble. Drywall itself does not belong to the family of frost-resistant building materials; its frost resistance is only eight cycles, but should be at least 35. Now about MDF panels. These are very good wall panels and are made from wood dust by pressing; the binder material in MDF boards is lignin, released from wood as a result of heating the wood dust during pressing. So MDF is the familiar fiberboard covered with a textured film. I would not recommend trying MDF panels to decorate the walls of your dacha. This material does not belong to the moisture-resistant class and is not recommended for use in unheated rooms. Over the winter, the panels will become saturated with moisture and begin to deform and swell. Consider panels made of PVC or natural euro lining or simple wooden lining for finishing the walls of your dacha. Good luck. PS If you don’t decide how to decorate the walls before winter, buy one MDF panel and leave it indoors in your dacha for the winter, and see how it behaves in the spring. Calculations show that at -12C your room will be +5C with your wall thickness, so anything can happen and the humidity in the room will be below 70%, and this will allow you to install MDF boards on the walls without fear that they will collapse.

Added: 02/13/2017 11:14

Discussion of the issue on the forum:

How to store drywall in an unheated room

DESIGN AND CONSTRUCTION OF SUSPENDED CEILINGS AND PARTITIONS FROM GYPSUM CARDBOARD SHEETS, SOUND ABSORBING AND DECORATIVE PLATES P1-01 to SNiP 2.08.02-89. 8.6 The temperature in the rooms where partitions are installed must be no lower than +10 С, and air humidity no more than 70%. 8.7 During the winter season, permanent or temporary heating must be connected to the rooms where partitions are being installed.

By the word INSTALLED, take it literally, as DURING INSTALLATION (work with the NK itself) or as not only installation but also subsequent OPERATION?

Actually, the question is: is it possible to finish the walls and ceiling with GC in a house that will not be heated in winter?

By the word INSTALLED, take it literally, as DURING INSTALLATION (work with the NK itself) or as not only installation but also subsequent OPERATION?

Actually, the question is: is it possible to finish the walls and ceiling with GC in a house that will not be heated in winter? I suppose it is possible. Well, my warehouse of plaster lay all winter in a cold garage, nothing happened to it. What's the difference with the ceiling? IMHO none. The main thing is that the humidity does not go off scale.

Other publications in the “Interior decoration of the house” section

As we know from practice, renovating an apartment or house is an interesting, educational, and sometimes even eternal process. Therefore, many homeowners prefer to do repairs on their own. Of course, there are those who do their own repairs simply because they don’t have enough.

What are the risks of using conventional slabs in the bathroom? Let's consider the features of constructing partitions in the bathroom from tongue-and-groove gypsum boards. Each such slab is made of building gypsum and is a rectangular parallelepiped, the joining and supporting surfaces of which are .

The house is made of adobe, walls without lathing, sand-clay plaster, lime whitewash. How to properly approach the issue of leveling walls with putty (finishing) or how to properly prepare such walls for painting with water-based paint. Thanks for the answer Answer: If the house is old enough and there are .

Is it worth using drywall for finishing?

Today, the basis for satisfying the information appetite is the Internet. It’s hard to argue with this, because if we need an answer to any question, we turn to Google and Yandex via a PC, tablet or smartphone, rather than going to the library. But here, in the fields of the electronic network, there are many pros and cons, myths and legends. But there are also truthful conclusions. It is with them, against the backdrop of a huge flow of information, that we need to understand if we need to study materials for the architecture and decoration of our own home. Next up is drywall - a popular and sought-after material that is practical and, one might say, somewhat universal. I will tell you in this article whether it is possible and whether it is necessary to use drywall in your own home!

Author: Alexander Kirichenko

Contents of the article:

There have always been disputes on the topic of this material. And their main participants are specialists in our specialized field: designers, builders, decorators, finishing specialists, and directly, the customers themselves. There are not even hundreds of opinions, but thousands and tens of thousands, so you need to sort out the issue, taking into account the recommendations of drywall manufacturers, the features of production and installation technology, building codes, and technical characteristics of gypsum boards!

Designers' opinion

One can agree with the voiced thoughts of most modern designers about the use of material. This is a practical and really good option for interior decoration and the production of decorative elements. But when using drywall, you should start from its direct qualities and purpose, and use it strictly in order to increase practicality, and not install gypsum boards wherever you just want. It is also worth understanding that today there are a lot of other technologies and materials that may better meet the requirements of the process where the customer decided to use drywall. We solve structural problems with gypsum boards and use the material where it is needed. we exclude him as much as possible from projects that bring chaos, thanks to rash and impractical decisions!

The main purpose of drywall

- There are several main manufacturers on the market - Knauf, Gyproc, Rigips and others;

- Drywall, different types and areas of work: GKL - standard, GKLV - moisture-resistant, GKLO - fire-resistant, GKLVO - moisture-fire-resistant, GVL - gypsum fiber sheet;

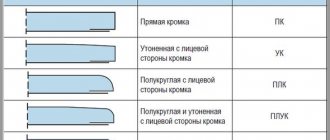

- Material by type of edge - straight, semicircular, rounded, thinned and others, combined;

- Drywall by type of work and purpose - wall, ceiling, arch!

Such a classification is necessary for the purchase of material, as are the dimensions of the sheet, its thickness, and accurate calculations of the area. But, first of all, you should understand the purpose of the material, where it can be used in rough or fine finishing, the production of architecture, and decorative compositions for interior design:

- The main direction is the production of wall structures and partitions. Drywall is used to construct lightweight frame walls for space planning;

- The next task for gypsum boards is leveling surfaces as an alternative to plaster. You can work with walls and ceilings, architectural structures, partitions. Drywall is installed on an adhesive base, wooden or steel frame;

- Drywall is an excellent material for filling niches and producing communication boxes. Under it and behind it you can hide any pipes and wires, highways and channels - water supply, ventilation ducts, etc.;

- And finally, gypsum plasterboard is popular in the production of suspended ceiling systems, classic and multi-level combined. The material can be used for standard ceiling leveling, but also serve as one of the elements of a modern combined ceiling made of gypsum plasterboard and wood, gypsum plasterboard and glass or mirrors, gypsum board and stretch ceiling!

These are the main areas of application where gypsum boards can be used to reduce pressure on the budget and increase the speed of work. Their quality does not depend on the material itself, but on a complex that combines the correct choice of gypsum boards and fastening systems, compliance with technology requirements, and compliance of the material with the assigned tasks!

Despite its main purpose, today drywall is used to solve the following problems:

- Creation of standard and curved arches for zoning rooms, as well as designing doorways;

- Production of storage systems in hallways and pantries, in the kitchen and living room. Difficult operating conditions should be avoided, as well as the production of open thin shelves;

- Production of through partitions and cabinets, special wall niches for placing equipment and equipment;

- Production of significant interior design items - false fireplaces, 3D figures, decorative lighting systems;

- Special overhead decorative items for walls and ceilings, design elements for built-in cornices;

- Bar counters, children's play complexes, special structures for pets, wall panels, screens for wide window sills and bathtubs, etc.!

Basic recommendations for choosing moisture-resistant drywall.

It is necessary to purchase drywall only from trusted suppliers. You can seek advice from a specialist, or trust the reviews of other consumers. Based on practice, buying a cheap analogue of moisture-resistant drywall leads to additional costs, since this material has a short service life.

Carefully inspect your purchase; this will allow you to notice a low-quality plasterboard board and immediately replace it in the store.

When broken, the core should not crumble too much; to do this, ask the seller for a fragment of moisture-resistant drywall.

The material is thin, not waterproof, and plasterboard, unlike gypsum fiber, has low strength - if you hang something heavy, you can collapse the entire wall.

Inside there is plaster with additives, outside there is a cardboard lining attached with a special glue. Depending on the properties of the drywall, dimensions may differ from standard ones.

Drywall weight and weight . Have you ever wondered - “how much does a sheet of drywall weigh”? The weight of drywall is no more than 1 s (kilograms per square meter). Fire-resistant plasterboard sheets - plasterboard is not so important, in the end it can be cut the way you want, the main thing is the thickness. It comes in different profiles - 6, 9, 12 mm, it does not depend on the place where we buy gypsum boards - on the market or in a specialized store. GKL 6 mm is used for bending sheets using the “wet method” - creating products with curves (designer fantasies, niches, arches). GKL 9 mm is usually used for ceilings, and is also used for bending sheets using the “dry method”. They make beautiful ceilings to reduce the weight of the structure. The thickest ones are used by builders to create partitions and wall cladding. They also create racks and columns, the height of which will indicate the status of the owner. There is little demand for other sizes; non-standard gypsum boards are rarely of interest to buyers.

Benefits of drywall

- Drywall is an inexpensive material for construction and finishing. Its cost is competitive in relation to other construction materials;

- GKL is easy to install - it is installed on a special glue, galvanized steel profile, wooden frame;

- A material with a high level of versatility - it can be cut with a standard construction knife and CNC to create straight sections and any other shapes, bent to produce geometric shapes and 3D elements;

- GCR is lightweight and highly portable. Delivery and lifting to floors is not a problem, as is replacing sheets in case of need for repairs or direct dismantling of the structure;

- It's easy to work with drywall yourself. Also, it will not be difficult to find craftsmen who can use the material in production and finishing work. In the case of complex structural work, the task becomes somewhat more complicated, since not every specialist is thoroughly familiar with the technology and is ready to use all its requirements;

- Wide target area is an additional advantage. You can build partitions from plasterboard, use the material as a base for any type of finishing, use the sheet for the production of boxes and niches, sewing communications, installing sections of multi-level ceilings, finishing slopes, etc.;

- A quick and inexpensive replacement for plaster - leveling the plane, creating levels, bringing corners together, improving the correct geometry of rooms;

- In most works, eliminating dirty and wet processes, as when using standard plaster mixtures;

- Increasing the speed of project implementation due to minimizing waiting periods for materials to dry - putty, primer, paint;

- Elimination of additional costs for special tools and equipment for material processing;

- Rapid production of thermal insulation packages, as well as soundproofing partitions using manufacturer technology, for example, Knauf;

- Reduced costs for the implementation of any of the projects, thanks to the advantages of drywall!

The general list of positive characteristics also includes the vapor permeability of the material, its environmental friendliness and safety, and high-quality geometry!

Making drywall and its base?

Drywall is a composite material in the form of individual sheets 2.4 - 4.7 m long, 1.2 - 1.4 m wide and about 8 - 23 mm thick. The basis of such a sheet is gypsum, while the outer planes are lined with cardboard. To achieve special strength, special components are added to gypsum, which improve its performance properties. In this case, cardboard simultaneously serves as a reinforcing frame and a basis for applying the finishing material, so the material is hard on one side and flexible on the other.

In fact, plasterboard appeared a long time ago, but only now has gained popularity and began to be widely used in construction and finishing work. Previously, plasterboard in the form of wide sheets was used for leveling walls and interior decoration. Much later, during the boom and huge demand for European-quality renovations, designers discovered a new quality of drywall - the ability to give the material any shape. Thus, plasterboard began to be used for the manufacture of arches, dome coverings, various columns and the design of complex transitions between different planes. The so-called “dry construction” method has also begun to be used, without the need to necessarily use “raw” plaster and wallpaper.

Physical properties and places of use of drywall?

Firstly, due to its physical and hygienic characteristics, plasterboard is ideal for finishing residential premises. This is due to the fact that drywall is an environmentally friendly material and does not contain toxic substances; this material also has good soundproofing properties, it is non-flammable and fire-resistant. Another invaluable quality of drywall is its ability to “breathe,” that is, to absorb excess moisture indoors. The acidity of drywall is similar to the acidity of human skin, due to which drywall is able to regulate the indoor microclimate naturally. In addition to standard plasterboard sheets, there are waterproof and fire-resistant ones. Waterproof sheets contain special components that destroy fungi; such drywall is used for finishing bathrooms, toilets and kitchens. Fire-resistant plasterboard is widely used in the finishing of communication shafts and air ducts. There are also tongue-and-groove slabs; during their manufacture, gypsum is fired, thereby increasing the strength of the material so much that it can be used as interior partitions. Such partitions can be used even in seismically hazardous regions, for finishing buildings of all degrees of fire resistance.

Today it is difficult to imagine repairs or construction that could do without the use of drywall. Drywall opens up enormous possibilities for designers; multi-level ceilings with lighting, various figured partitions with niches and shelves, and decorative elements are made from it. Drywall gives architectural expressiveness to rooms and allows you to create unique design projects that have no analogues both in their technological characteristics and in aesthetic indicators.

What is drywall made of (production technology)?

The main component of drywall is 93% gypsum, approximately 6% cardboard and 1% moisture, starch and other substances. Gypsum is a white material with a density of 2300 kg/mk ., in powder form, it has low solubility in water. There are medical and construction plaster. Their main difference is in the fineness of grinding. The following grades of gypsum are used in construction. In the range G-5 to G-25 fine grinding. Gypsum does not have any toxic impurities and is an environmentally friendly material.

Gypsum is fire-resistant, hypoallergenic, electrically neutral and has the same acidity as human skin. All these properties make gypsum one of the most popular building materials recently. Drywall sheets are somewhat reminiscent of the painfully familiar construction plaster. But this similarity is only external; the structure of these materials is different. The filler inside drywall is a foamed fiber composition made from gypsum.

There is also moisture-resistant drywall (GKV, GVL, GVLV) for use in rooms with high humidity. When used in rooms with increased requirements for fire resistance, it is advisable to use gypsum plasterboard sheets.

Application of plasterboard sheets.

Plasterboard sheets are mainly used for interior finishing work, cladding walls, partitions, and ceilings. Drywall is a very convenient material to work with; paint and varnish coatings, wallpaper and other coatings for decorative wall decoration fit well on it. Plasterboard sheets are easy to cut and saw. The only disadvantage of this material is that it is afraid of dampness (with the exception of moisture-resistant brands); plasterboard is also not recommended for use in rooms with high temperatures. Various decorative panels are created on the basis of plasterboard, for example, Decor and Decogypsum. Due to the fact that the structure of the material is porous, the soundproofing properties of plasterboard are increased. Soundproofing properties are affected by the thickness of the drywall, the depth of the space in the frame and the number of sheets installed. It is best to store drywall in a dry and warm room.

Popular questions about construction

Why do you need a construction project?

Design documentation is necessary to solve the following tasks: • assessing the compliance of a construction project with the requirements of technical norms and state standards. This assessment is made before the state examination of the project; • calculating the required amount of construction and finishing materials, drawing up estimates and determining the budget for the construction (reconstruction) of the facility; • coordination with government services and departments; • obtaining a construction permit; • development of working documentation necessary for construction and installation work. The project will also be required when handing over the finished object to the customer to check it for compliance with the stated requirements.

How to choose the right building materials?

To select the type and quantity of building or finishing materials, you must use project data or your own calculations. In this case, it is recommended to purchase goods with a small reserve, approximately plus 10-15% of the estimated volume. When purchasing, you should pay attention to the presence of labeling, expiration date and specific qualities of the product. Characteristics such as frost and moisture resistance of building materials and their maintainability will be important. We should not forget about additional consumables, such as fasteners, glue, mortars, etc. You shouldn't skimp on them. After the construction or repair project is equipped with the necessary material, you need to ensure that you have the tools to carry out all types of planned work.

Which building materials are better and which are not?

The quality of the work ahead largely depends on the choice of building materials. If financial capabilities allow, it is best to purchase goods from well-known brands that inspire confidence in the buyer. And you need to purchase them from official dealers so as not to purchase a fake. The cost of building materials in this case will be high, but the quality will also be excellent. If you have a limited budget, you can use cheaper analogues with a good price-quality ratio. You should not buy a product if its price is too low compared to a branded product. As a rule, these are low-quality and short-lived products.

How to distinguish high-quality building materials?

The packaging of high-quality building materials always contains all the information necessary for the buyer. It must have the manufacturer’s logo, a description of the purpose of the product, production and expiration dates, composition, and rules of use. Compliance of the product with the declared characteristics is confirmed by a certificate, which the seller is obliged to present to the buyer upon his request.

What construction work cannot be done by yourself?

You can carry out various construction and finishing works on your own. But their list is limited for a number of reasons. Firstly, the use of special machines, for example, a crane or excavator, requires not only the availability of special equipment, but also permission to operate it. Secondly, if it is necessary to carry out electrical and welding work, you will need to undergo fire safety training. Thirdly, not every type of work can be done alone. If you are installing rafters on the roof of a cottage or installing SIP panels, then you cannot do without helpers. Fourthly, some types of work require the use of special, expensive tools and equipment, which are not rational to buy for one-time use.

Why is it better to entrust engineering systems to professionals?

Engineering systems are complex objects that include lines for energy supply, water supply and sewerage, ventilation and air conditioning, gas supply, and heating. Their construction requires highly qualified contractors, since the comfort and safety of home residents or office workers depends on the quality of engineering networks. Therefore, the construction of such objects should be trusted exclusively to professionals.

Reviews about building materials

The professionalism of our employees allows the company to take on projects of any complexity. Work has to be carried out not only in warm rooms, but also somewhere outside the city in severe frost. The equipment must show stable operation in any weather. It is for this reason that it is important for us to use high-quality and reliable tools. In addition, it must have an autonomous power source.

Andrey Vladimirovich, construction company Novosibirsk

Yes! Finally, my wife and I managed to buy our own apartment. The layout suited me completely. But there was one problem in the bathroom. The strong humidity in this room literally ate away the surface of the walls. They suffered for a long time until I decided to cover them with moisture-resistant plasterboard (GKLV). We haven’t remembered the problem for 12 years now. And the appearance of the room did not deteriorate.

Vyacheslav, Moscow

I spent a long time choosing what material to use to build a house on my plot in a holiday village. Many friends began to recommend pine timber. I decided to take the risk at my own risk. As it turned out, I was right at all. This durable material can withstand any weather surprises. At the same time, excellent thermal insulation pleases. A lot of time has passed, but the timber is not going to rot.

Fedor Mikhailovich, dacha village

For many years our team has been famous for its painters. A team of professionals who were always rewarded by their superiors for good work. But what a disappointment I was when people began to openly complain about the poor quality of work. This was all due to poor quality materials. We switched to NC paints. Paintwork lasts long, colors remain vibrant, and we no longer receive unfair complaints.

Head of the construction team Ivan Aleksandrovich, Voronezh

We were able to buy a plot of land with a house at a good price. There is enough space for planting plants or trees. At the same time, you can safely stay with friends and have a barbecue when warm days come. The house turned out to be durable overall. The only thing that upset me was the plank and uneven floor. But the situation was quickly corrected with the help of high-quality wood slabs.

Alexander, Bogorodsky Village

I can say about my work in the words of one song: “Our service is both dangerous and difficult.” You have to visit different places and often make decisions in emergency situations. Usually extremely worried women call because the water from the tap is gushing under pressure or the faucet or its mechanisms have simply broken down. It will definitely not be possible to solve such problems without high-quality sealant, rubber bands and spare parts for the faucet.

Igor, “Husband for an Hour”, Krasnodar

If the time has come to replace the floor covering, I highly recommend paying attention to laminate flooring. Recently, this material has begun to receive more and more negative reviews. And there is only one reason for this - the high price. But in return you get a really beautiful and high-quality coating. Moreover, even a non-specialist in such work can install it.

Irina, Moscow region

Disadvantages of drywall

- The first of the disadvantages is the increased fragility of the material. It does not tolerate dynamic loads and mechanical stress;

- The second disadvantage is based on the first - instability of structures. When they are overloaded, cracks and chips appear, seams fall out at the junction points, and unprotected corners crumble;

- Lack of moisture resistance. Direct contact with high humidity and water quickly leads the material to a visually unusable state, which is complemented by a loss of strength. Therefore, for wet rooms it is better to use gypsum boards with additional protection with facing materials, or even other special materials that have a neutral reaction to moisture and direct contact with water. The recommendation applies more to bathrooms;

- Reducing the area and volume of rooms that are covered with plasterboard. The value is minimal and depends on the initial geometry of the premises, the type of structure and the method of its fastening, but it is still worth paying attention to this fact when performing calculations for the project;

- Hollow economical walls and partitions are structures with minimal sound insulation. Mineral wool and basalt fillers should be used, taking into account the technology of double cladding of the frame;

- GCR walls can hardly be called durable. They can be punctured, broken, damaged during the removal and installation of furniture, subsequent repairs, or during children’s games;

- GCR surfaces have minimal load-bearing capacity. Therefore, even decorative objects should be installed on them carefully!

Important: Having experience working with drywall, I recommend using special fasteners for gypsum boards - butterfly dowels, driva, Hartmut, umbrellas. Be sure to pay attention to possible loads when purchasing fasteners. In the case of installing or hanging heavy objects and equipment on the wall, it is better to mount directly into a galvanized steel profile, a profile reinforced with wooden beams, or special embeds, thought out at the start of work. Another fastening method is used when installing gypsum boards with glue to the wall. This is the installation of anchors through gypsum boards directly into a wall made of concrete or brick!

Considering the volume of areas where plasterboard is used today, one can cite many more advantages and disadvantages of the material in relation to each individual structure or process. But is it worth doing this if the main qualities and characteristics have already been announced?

Whether you use drywall in your own home or work with another material is up to you. The decision can be based on a body of knowledge obtained from various sources, strictly on the characteristics and features of drywall, but also on design requirements that are important to consider in repairs and decoration!

Structure of the material and principles of its storage

Drywall consists of two components, which appear in its name. The gypsum base is covered with a layer of paper, which tightens it and prevents it from cracking. This structure makes the gypsum sheet (gypsum board) resistant to serious longitudinal loads. At the same time, its lateral stability remains quite weak. Almost any pressure can lead to the formation of dents or even the appearance of through holes. Due to the large area of the sheet (2400x1200 mm), during the moving process its corners often suffer, breaking off or getting knocked down. According to building codes, the rules for storing drywall are based on the following principles:

- the storage temperature of the material should not fall below +10 degrees (the optimal values are 16–18 degrees);

- humidity in the premises should be 75–80%;

Subject to the above conditions, the shelf life of the material is unlimited. At the same time, failure to comply with at least one point can affect the quality of drywall or even lead to its damage. Particular attention must be paid to the level of humidity and the absence of leaks, since the main enemy of gypsum boards is water.

Drywall on wooden slats

It is best to store drywall in a room where you can organize all the necessary conditions for its safety. Storing material outside is a temporary measure and is carried out exclusively in the warm season. It is better to place it on the roof or attic, where it will be completely protected from precipitation.

It is not recommended to leave plasterboard outdoors for more than 1–2 days. In this case, the material must be hermetically sealed and placed according to all rules.

Do-it-yourself interior wall decoration at the dacha

In creating a cozy atmosphere in a country house, the decoration of the walls in the country house plays a significant role. Materials of varying costs can be used as final decorative finishing.

In the case where the work will be carried out in a seasonal house in which there is no constant heating, preference is given to budget options.

When purchasing a finishing material, it is important to understand whether it can be used in conditions of high humidity, which are inevitable in unheated rooms.

Finishing work to protect against high humidity

The screw caps must be puttied to protect against corrosion. It is clear that black self-tapping screws already have an anti-corrosion coating, but when they are used in the bathroom, it is better to additionally putty them. We don’t want rust stains to start appearing on the ceiling in a year.

Self-tapping screws are screwed in flush for ease of further finishing of the ceiling

Putty is applied to all joints, after which sickle tape is attached. As a result, the fastener heads, the joints between the sheets, and the joints between the sheets and the wall should be puttied. After the putty has completely dried on the ceiling, it is applied again in a thin layer. Now the surface is ready for the finishing coat.

As a finishing layer, you can use white water-based paint. It will have to be renewed every 5 years, because it will dry out in small pieces. Also, the plasterboard ceiling in the bathroom can be finished with decorative plaster with additional protection from a layer of wax. Whatever option is chosen, it will protect the ceiling from excess moisture.

Material selection criteria

In addition to the presence or absence of a heating system, when choosing decorative finishes, it is necessary to take into account the base material of the walls. The most suitable solutions for finishing a country house for seasonal use are recommended:

For enthusiastic and dynamic people, it is better to choose a finishing method that allows you to easily change the finish layer. For such owners, it would be more correct to choose plaster or gypsum plasterboard sheets as the interior decoration of the walls at the dacha. For a perennial option, it is better to choose a finish with a soft texture and color.

Technical characteristics of drywall: description of material features

There are plasterboard sheets of different parameters on the market.

It is necessary to know their properties, which play a decisive role in the choice. For example, by using ordinary drywall when decorating a warehouse for flammable substances, we risk, after the first fire, receiving significant damage inside the premises. And all because we did not know what characteristics drywall has. Read our article on how to recognize fire-resistant drywall and much more. What is this article about?

Preparation

Finishing is the final stage in the repair, therefore it is carried out after all the work on laying engineering and plumbing communications has been carried out. When deciding to purchase material, you should remember the specifics of unheated rooms.

If you plan to visit the house in winter, then raw materials should be selected that are resistant to possible sudden temperature changes. It is also worth considering how to insulate the walls from the inside.

Any finishing begins from the back room of the upper floor and is carried out towards the exit. If work is carried out with a high degree of soiling: plastering, painting, whitewashing, then the already treated surfaces should be protected with plastic film.

The necessary materials should be calculated and purchased in advance, and the working tools should be prepared.

Finishing with natural materials

There are many options for finishing brick or foam block walls and the inside of a wooden house. Modern technological finishing materials offer various cladding options, for example, wood wallpaper, which is made from natural wood. They are applied to the walls of the cottage indoors using a special adhesive solution. The main and very significant disadvantage is their cost.

A less expensive method would be to decorate the interior walls of a house with block-house material. Before installing the slabs, allow them to rest indoors at room temperature for 48 hours. The material is mounted on flat walls, on pre-stuffed wooden frame beams.

Fiberboard will be an inexpensive finishing material

The elements are screwed to the guides with self-tapping screws through the base of the tenon, which all boards are equipped with. The elements are connected to each other using a groove-tenon system. To give additional external gloss, upon completion of the work, the surface can be coated with varnish, wax or stain.

Lining is one of the easiest materials to work with, a way to inexpensively cover the walls of a country house with your own hands. This results in a completely environmentally friendly and clean finish. The lining is mounted by stuffing slats onto horizontal guides, fixed at a distance of 0.5 - 0.7 m from each other. For more information about how and how to decorate a country house, watch this video:

The wood must first be treated with antiseptic and fire-retardant compounds.