Michel

6404 0 6

Michel September 28, 2016Specialization: plumber with 10 years of experience, computer repair specialist, powerlifting coach. I have extensive experience in construction, interior decoration, and making homemade furniture. Hobbies: sports

In this article I want to talk about the most popular building material, which is rarely necessary for rough finishing or remodeling of an apartment - moisture-resistant plasterboard sheet. Dear reader, you will have to find out how it differs from regular gypsum board, how it is installed and how it is processed for final finishing.

So let's get started.

Our hero is moisture-resistant gypsum board.

Markings and varieties

Waterproof plasterboard (GKLV) is a building material that was originally intended for finishing rooms with moderate or high levels of humidity. In appearance, it is an ordinary rectangular slab, which consists of two cardboard layers, as well as a gypsum layer between them. The latter contains reinforcing and antifungal additives.

There are also other abbreviations: GVL, GVLV. All these materials are similar in composition, but they are produced using completely different technologies. For example, drywall is formed using the sandwich principle, and the building material GVL is made by combining manufactured fibers with a gypsum mixture. The finished composition can subsequently be pressed. The result is a homogeneous material.

According to international standards, each type of drywall is assigned its own color marking, which helps to navigate the assortment Source tstn.ru

Laying tiles in the bathroom on drywall

You can decorate walls made of plasterboard for the bathroom in different ways: with waterproof paint or wallpaper, putty, artificial stone or cork. However, many people prefer to use ceramic tiles to decorate their bathrooms. It is easy to install on drywall, but you should follow some rules:

- Ceramic tiles are a fairly heavy finishing material that requires a solid base. For this reason, the bathroom is usually covered with waterproof plasterboard in two layers. The second sheet is laid “overlapping” in relation to the first. Ultimately, the wall should be solid and not respond to pressure. Otherwise, the decorative coating will not last long.

- The surface of the drywall does not have to be perfectly smooth. Experienced craftsmen use staples and glue to attach a special plaster mesh to it. Then the wall is primed twice (with a time interval of 40 to 60 minutes).

- To keep the tiles as secure as possible, use tile adhesive. Liquid nails are also sometimes chosen, which allow you to achieve not only strength, but also avoid the labor-intensive application of glue.

Attention! In this case, it is not recommended to use cement mixtures, since they do not provide high-quality adhesion of the tiles.

In general, plasterboard for the bathroom provides an opportunity to level the walls and insulate the room. When the sheets are selected at the proper thickness, ensure good waterproofing and fastening, they are excellent for tiling. At the same time, the low price of dry plaster makes it one of the most popular building materials.

Technical characteristics of GKVL

Moisture-resistant plasterboard should only be used in ventilated rooms. Additionally, it is extremely important to consider the labeling. Based on the number of surface defects, plasterboard sheets are divided into groups - A and B. The first includes products with a smoother surface. The putty layer fits better (fits tightly) on them, which means they will last longer. The cost of such elements is slightly higher.

What is the visual difference between moisture-resistant drywall and simple drywall? Only by color. Most manufacturers use a green tint to paint moisture-resistant products, but in rare cases pink panels are found. This material can additionally be fire resistant.

The sizes of waterproof gypsum plaster boards are standard: from 60x200 to 120x400 cm. The first number indicates the width of the element, the second the length. In this case, the pitch is only 50 mm.

Regular plasterboard sheets are gray in color, while moisture-resistant ones are green, which meets international requirements Source g-stroy.biz.ua

In addition, drywall comes in different thicknesses. The latter varies between 6.5-24 mm. Sheets with a thickness of more than 1.25 cm are suitable for building walls in houses; when creating arches, it is possible to use material with a transverse dimension of 6.5-12.5 mm.

Quality products always have markings. With its help, you can find out the following important information about the building material: sheet type, group, edge type, dimensions. Also contains a reference to the standard.

All high-quality plasterboard products have markings indicating their main characteristics Source stroybaza-kmv.ru

Application

- Is it possible to use drywall as a base for tiles??

Yes. Any cement-based tile adhesives adhere perfectly to it.

Laying tiles with cement tile adhesive.

- With what finishing can gypsum boards be used in a bathroom or toilet??

The coating must prevent prolonged direct contact of the material with water. Here are some examples of such finishing:

- Tile. In this case, it is worth paying serious attention to the grouting of the joints: it must be impervious to water;

- Thick vinyl wallpaper. In the bathroom they are glued not with ordinary wallpaper glue, but with PVA, which is more resistant to dampness. To reduce glue consumption, it can be diluted with water;

- Waterproofing “rubber” paint. It is a fully washable coating that is resistant to moderately strong mechanical stress, dry and wet wear.

Rubber paint reliably protects walls from splashes and dampness.

When decorating the bathroom in my attic, I settled on a combination of a tiled splashback over the bathtub and painting the walls and ceiling with rubber paint. Three years of operation of the bathroom have shown the viability of this solution: the appearance of the walls has not changed at all; There are no signs of wear or other defects.

It’s curious: I glued the apron tiles not with cement tile adhesive, but with a spot-applied silicone sealant. It was also used as grout for joints. No leaks were found, the tiles are holding up great.

Tiled splashback over the bathtub and rubber-painted ceiling.

- Is it permissible to use regular drywall for a bathroom??

Permissible if two conditions are met:

- The room is provided with effective ventilation that keeps air humidity within 80-90% even when taking a shower;

- The finished finish is absolutely impermeable to water. I considered options for such finishing a couple of paragraphs above.

- What thickness of sheet to use for a suspended ceiling - 12.5 or 10 mm?

If the ceiling does not experience mechanical stress from the word “at all”, you can safely buy ceiling gypsum plasterboard with a thickness of 9.5 mm and even arched gypsum plasterboard (6.5 mm). The lighter the skin, the less load the frame will experience during operation. In my case, however, I preferred a sheet with a thickness of 12.5 mm: the sloping ceiling of a bathroom in the attic is easy to hit, and it is better that there are no holes left in it that were not provided for by the design.

The low ceiling near the wall of the attic bathroom forced the use of 12.5 mm thick sheets.

- How to cut gypsum boards?

Just like regular drywall. Curvilinear parts are best cut with a jigsaw with a wood saw or a regular hacksaw; This work involves a lot of dust covering all surfaces in the room.

Attention, comrades: gypsum dust is destructive for active cooling systems of computer equipment (CPU, video cards and power supplies). When I was a computer service worker, I was often faced with their refusal after repairs in the apartment. Plaster clogs the bearing bushings and stops it; Moreover, it acts as an abrasive, leading to accelerated wear of open bearings.

Cutting gypsum board with a jigsaw: fast, convenient, but very dusty.

KGLV cannot be sawed along straight lines, but breaks after cutting with a knife to a quarter of the thickness. To break off a sheet evenly, you need to place it on the edge of a table or any other elevation and press on the hanging edge. After the gypsum board breaks off, you just need to cut the cardboard from the back side with a knife.

If you cut a sheet a quarter of the way through, it will break exactly along the cut.

- Is it possible to use a moisture-resistant sheet to level the floor??

Yes, gypsum plasterboard is one of the materials used to construct dry screeds. Expanded clay screenings are poured on top of the ceiling and leveled according to the beacon rule; then two layers of plasterboard are laid on it with a mandatory overlap of the edges between the layers of at least 50 mm. The top sheets are attached to PVA glue and attached to the bottom sheets with 25 mm long drywall screws.

Dry screed with moisture-resistant plasterboard over expanded clay screenings. The sheet of the first layer is laid.

- What kind of frame is needed when arranging a partition with your own hands??

In wet rooms it is better to use not a block, but a galvanized profile for gypsum boards. CW rack profiles are used as racks; along the perimeter of the partition to the floor, ceiling and adjacent walls, UW guide profiles are hemmed with self-tapping screws and plastic dowels. The minimum thickness of the partition is 50 mm, however, with a ceiling height of 2.5 meters and above, I strongly advise you to buy a more rigid profile with a thickness of 75 - 100 mm.

The step between adjacent posts is 40 - 60 cm. The distance is measured not from edge to edge of the profile, but between their longitudinal axes. The edges of adjacent sheets must be attached to a common profile.

Partition frame for gypsum board cladding. The distance between the posts is 40 centimeters.

It is better to select the length of the sheet such that it covers the height of the partition with a minimum margin. If you have to cut additional gypsum board sheets, a transverse profile is mounted at the junction with them, to which both sheets are again attached.

The seams are reinforced with serpyanka (self-adhesive fiberglass mesh) and puttyed directly through it with gypsum putty; The heads of the self-tapping screws are also hidden using putty.

Seam reinforcement with serpyanka.

I was pleasantly impressed by Eurogips and ABS Saten putties, but I liked Fugenfüller from Knauf, which is very popular in Russia, much less: it is inferior to its competitors in its tendency to form lumps and has a shorter lifespan of the mixed mixture.

- Is it possible to install gypsum boards on walls without a frame??

Yes, just like any other drywall. For this purpose, gypsum glue is used (for example, Perlfix from Knauf); it is successfully replaced by gypsum putty or plaster. The wall must first be cleaned of dust and treated with penetrating primer.

The glue is applied to the wall or drywall in separate patches; a continuous bead of glue is needed only at the level of the baseboard: this greatly simplifies attaching the latter to the wall.

By the way: this same technique is convenient to use when finishing door and window slopes. GKLV strips are pressed on top of the putty spread on the wall and leveled with light blows of the palm while controlling the position using a building level or plumb line.

The doorway slopes are made of moisture-resistant plasterboard mounted on gypsum putty.

How to turn ordinary drywall into moisture-resistant

In order for a simple gypsum board to become highly resistant to moisture, it must be treated with the following preparations:

- Deep penetrating soil. It is recommended to apply two to three times, starting with the first layer.

- Antifungal, anti-mold compounds.

- Water-repellent paint. Suitable only in cases where the base is not planned to be finished with tiles.

- Water repellent. Replaces the primer, but at the same time serves as waterproofing. The panels are processed with a roller on both sides.

The use of the above products significantly improves the moisture-resistant properties of simple drywall. At the same time, it is impossible to obtain a material in this way that is identical in quality to the factory one. Therefore, it is advisable to use real waterproof panels.

To obtain moisture-resistant drywall, ordinary sheets should be treated with a special impregnation, which limits the absorption of moisture inside and does not prevent water vapor from evaporating. Source howtofixaholeindrywall.com

Moisture-resistant drywall - what are the properties and advantages?

The properties of GKLV include the following:

- high-quality sheets are green, less often pink;

- the marking must be highlighted in blue on the back of the product;

- since the material can be used both as a main material and as a finishing (decorative) material, here you need to decide on its thickness. So, you can choose either thin sheets (from 6.5 mm) or, on the contrary, thick ones (up to 24 mm);

- It is possible to individually order a product with the required dimensions (if non-standard sheets are needed);

- in order for the material to retain all its beneficial properties for as long as possible, it must be treated (during the creation process) with special substances that rid the surface of mold, various fungi and excess moisture;

- GKL sheets can belong to different classes, for example, class “A” indicates that the products are moisture-resistant, and class “B” is more suitable for lower priority work.

Also, moisture-resistant drywall has several advantages, which attracts experienced craftsmen and specialists:

- high levels of water repellency and fire resistance;

- good flexibility and ductility, which allows you to create structures of different shapes;

- reasonable prices;

- non-toxic and safe;

- multifunctionality and versatility;

- creates, provides and maintains the desired microclimate of the room;

- the material is very convenient and easy to install and assemble, which allows you to work alone without involving strangers in the work;

- moisture-resistant drywall has excellent sound insulation properties;

- Any component or paint for finishing or decoration is good for this material.

Is it possible to use GKLV outdoors, in a bathhouse?

A significant difference between moisture-resistant drywall and regular drywall allows it to be used when decorating a bathroom. But the purchase of this material for finishing bath rooms is not always approved: it is allowed to cover only the washing room. Many experts argue that the use of waterproof plasterboard boards inside a steam room is undesirable. Otherwise, it will have to be repaired after five years.

When carrying out repair work in rooms with high levels of humidity, it is important to adhere to the rule: the holes between the panels should be sealed with waterproof putty, covered with fiberglass tape, then apply an additional layer of putty mixture. Moreover, this must be done regardless of the standard recommendations for one or another type of edge. In addition, it is important to putty the screw heads to prevent their corrosive destruction.

Even high-quality moisture-resistant gypsum boards should not be used outdoors. It will quickly lose its characteristics, which is why it will soon have to be replaced.

When setting up a washing room, tiles are often laid on moisture-resistant plasterboard Source elmin.ru

Drywall

The material is a layer of gypsum placed between two smooth cardboard sheets. The gypsum solution makes up 93% of the total volume, reinforcing cardboard 6% and 1% are additives that impart certain properties. GCR is ideal for budget repairs, its prices are low.

From this material you can make:

- arches;

- columns;

- cabinets;

- design of doorways;

- niches;

- cabinets;

- change design;

- sound insulation.

Restrictions on use

In cold rooms it is necessary to organize additional heating. Correlate the task with the thickness of the sheets, their moisture resistance or fire resistance.

Kinds

The entire range of plasterboard materials can be divided into:

- moisture resistant;

- refractory;

- ordinary.

Mixed modifications have moisture-resistant and fire-resistant properties. The variety of modifications makes the gypsum board universal.

Color

The production produces sheets of the following colors:

- green;

- blue;

- grey;

- pink;

- red.

Coloring depends on the properties and type of material. The standard color is gray for normal conditions and work. Yellow gypsum board is intended for finishing facades and is resistant to weather changes. The white core inside the sheet indicates its high quality.

Installation process

Once it has become clear how waterproof drywall differs from regular drywall, you can begin installing it. The installation process itself is identical for two different materials: you need to mount a metal frame consisting of rack-mount guide profiles. To carry out this procedure, you must first prepare plasterboard, screws, dowels, and a set of tools:

- drill;

- screwdriver;

- grinder;

- plumb line;

- building level;

- rule;

- roulette;

- metal scissors;

- hammer.

When installing moisture-resistant plasterboard sheets, it is recommended to take into account the following nuances:

- Ventilation must be provided in the room where repair work is being carried out.

- The pitch between the lattice elements should be slightly smaller than when installing conventional material.

- The frame should only be aluminum, wood cannot be used.

- All seams must be carefully sealed.

To understand which side to attach the plasterboard sheets, you need to look at the location of the groove. It appears if the end is placed at a certain angle. The color of the products is not important here.

Installation requires self-tapping screws; they are fastened at a distance of no more than 20 cm. Moreover, small gaps should be left in the places where the panels touch. Subsequently, this will ensure high-quality putty of the entire base. After priming, the treated surface must be puttied again. Then it is allowed to begin painting with waterproof compounds.

Moisture-resistant plasterboard can be used for finishing cold balconies Source stroy-podskazka.ru

Rating of the best drywall modifications

Gypsum boards are used not only in the construction of partitions, ceilings and finishing works, but also for frame-sheathing structures and leveling.

Moisture resistant

The product sheets have a greenish color and additional protection from moisture.

Aqua Strong Gyproc

A Russian brand manufacturer from Sweden produces gypsum boards for installation in rooms with humidity exceeding 70%.

Gyproc boards are of superior quality, in particular they are softer and have better installation properties. The absence of cracks when installing fasteners, without the formation of dents, indicates good elasticity of the material.

plasterboard Aqua Strong Gyproc

Advantages:

- can withstand up to 65 kg under dowel load;

- with excellent sound protection;

- unsurpassed impact resistance;

- installation is carried out in one layer;

- water-repellent internal impregnations;

- with additional processing of the paper layer;

- ideal size for standard apartments;

- parameters of possible loads allow you to equip the premises with a large number of shelves, mirrors, and other equipment;

- long service life;

- used for the construction of partitions, ceilings, walls;

- belongs to the low-flammable group;

- with a thinned edge type;

- with an increased cross-section of 15 mm;

- in accordance with GOST.

Flaws:

- price is above average;

- additional volumes of putty for sealing ceiling joints due to the size of the sheet.

Volma

Decent quality material from a domestic manufacturer is indispensable in the manufacture of boxes, niches in shower rooms and swimming pools, and columns.

Volma moisture resistant plasterboard

Advantages:

- suitable for ceiling installation;

- thinned and semicircular type;

- belongs to the non-flammable group;

- with a hygienic anti-fungal base;

- shock-resistant modification;

- with high-quality packaging on pallets;

- budget price;

- the presence of antifungal additives;

- does not change after repeated wetting;

- sheets are not subject to changes due to strong temperature changes.

Flaws:

- there are no reinforced internal fibers;

- selection of torque is complicated by the rigidity of the structure;

- requires additional protection when exposed to direct water.

KNAUF GSP N2

Products from a well-known brand labeled GSP N2 have hydrophobic impregnation with the unique property of evaporating excess moisture accumulated in the room.

plasterboard KNAUF GSP N2

Advantages:

- piece and wholesale sales on pallets;

- suitable for creating curved ceilings;

- the presence of a semicircular edge ensures the creation of sealed joints;

- low price;

- with protection against counterfeiting by applying a logo on each surface of the sheet;

- with markings for self-tapping screws;

- belongs to the low-flammable type;

- with a thinned semicircular edge;

- does not crumble during operation.

Flaws:

- there are no guarantees on the exact wall thickness;

- the structure contains air bubbles that prevent accurate cutting to size;

- additional costs for purchasing a needle roller for making bends.

Magma PlastV

Resistance to moisture is ensured by hydrophobic additives.

plasterboard Magma PlastV

Advantages:

- Refined design and low weight allows for suspended structures;

- indicated for residential premises, is non-toxic;

- increased strength is provided by internal reinforcement;

- clear joining along semicircular edges;

- average price;

- Recommended for bathrooms, showers.

Flaws:

- not suitable for massive elements.

| Moisture resistant sheets | |||

| Modification | Size, mm | Weight, kg | Area, m² |

| Aqua Strong Gyproc | 15*1200*2500 | 34.5 | 3 |

| Volma | 15*1200*2500 | 24.3 | 3 |

| KNAUF GSP N2 | 12,5*1200*2500 | 25 | 3 |

| KNAUF GSP DFH2 | 12,5*1200*3000 | 25 | 3.6 |

| Magma PlastV | 12,5*1200*2500 | 3 |

Fire-resistant modifications

The building material has a pink and red tint, which means increased fire resistance, thanks to impregnations and reinforcing components.

Volma

The gypsum board modification from a Russian manufacturer has fire protection and belongs to flammability group B2.

plasterboard Volma

Advantages:

- prevents smoke;

- resistant to destruction under the influence of fire;

- a double layer with a 5 cm mineral wool filling guarantees containment of the spread of fire for 1 hour;

- compliance with EI604 standard

- maintaining visibility in the event of a fire in a room made of this material;

- recommended for use in buildings with a high density of workers or population in the building;

- the ability to breathe during a fire is not lost;

- belongs to the non-flammable group;

- suitable for interior work;

- the edge has a semicircular shape.

Flaws:

- a porous structure is allowed;

- not allowed when working with high humidity;

- slightly wavy structure of the leaf surface.

KNAUF GSP DF

The GSP DF modification belongs to the fire-resistant class.

plasterboard KNAUF GSP DF

Advantages:

- the production process is based on pressing G4 binder gypsum;

- the presence of internal reinforcing components;

- compliance with GOST;

- with a thinned semicircular edge;

- guarantee against cracks;

- ideal for making curved shapes;

- certification compliance;

- recommended for the construction of cinema halls and supermarkets.

Flaws:

- does not tolerate sudden mechanical impact;

- the price is above average.

Magma PlastO

Fire-resistant gypsum plasterboard from a domestic manufacturer is intended for interior finishing work.

plasterboard Magma PlastO

Advantages:

- belongs to the class of low-flammable;

- preventing the spread of fire;

- for ceiling and wall finishing;

- with a thinned edge;

- neat joints without cracks;

- maintains microclimate.

Flaws:

- not found.

| Fire resistant sheets | |||

| Modification | Size, mm | Weight, kg | Area, m² |

| Volma | 12,5*1200*2500 | 37.5 | 3 |

| KNAUF GSP DF | 12,5*1200*2500 | 30.6 | 3 |

| Magma PlstO | 12,5*1200*2500 | — | 3 |

Regular gypsum boards

A characteristic parameter of the type is its moderate thickness and height of 2, 5 or 3 meters. The material serves:

- for finishing walls with subsequent wallpapering;

- for the construction of ceilings of several tiers;

- to provide insulation;

- for insulation;

- making openings.

KNAUF GSP A

The GSP A modification sheet for interior work belongs to the low-flammability class.

plasterboard KNAUF GSP A

Advantages:

- with rounded, straight, thinned, semicircular edges;

- recommended for walls with subsequent placement of lighting fixtures;

- resistant to point impacts up to 5.5 MPa;

- small thickness;

- easy to install;

- acceptable price;

- thermal insulation;

- without the threat of delamination;

- with a density of 800kg/m³;

- with a strong gypsum core;

- Great for leveling ceilings;

- easy to install;

- used for multi-tiered structures.

Flaws:

- the possibility of condensation forming in rooms with high humidity.

KNAUF GSP DFH2

To provide protection against fire and moisture, gypsum sheet is produced in a large area of 3.6 m².

plasterboard KNAUF GSP DFH2

Advantages:

- recommended for catering kitchens with several hot surfaces;

- meets the requirements of fire safety standards;

- high strength is ensured through reinforcing additives;

- the presence of impregnations to preserve the structure when wet;

- with tight fit of joints;

- good strength under static load;

- impact resistance;

- high sound insulation properties;

- Online ordering and delivery available;

- effective adhesive elements for bonding cardboard and plaster;

- low-flammability class;

- with a semicircular thinned edge.

Flaws:

- high price.

Gyproc Light

The lightweight and durable sheet is suitable for making hanging decorations; many tiers are possible.

plasterboard Gyproc Light

Advantages:

- mechanically strong;

- no gaps at the joints;

- saving on putty;

- order via the Internet;

- perfectly flat surface;

- creating a favorable microclimate with regulation of the percentage of humidity;

- protection against fungi and mold.

Flaws:

- No.

GKL KG Stroy Systems

A universal sheet of the usual type for finishing is characterized by simple fastening and accessible processing.

plasterboard GKL KG Stroy Systems

Advantages:

- flexible and durable;

- ideal for work on curved structures;

- minimized waste thanks to large sheets;

- economical option for leveling surfaces;

- moderate thermal conductivity, energy saving;

- low-flammable class;

- environmentally friendly materials.

Flaws:

- none.

KNAUF Safeboard

Acoustic-type gypsum plasterboard for increased sound insulation is intended for indoor use.

plasterboard KNAUF Safeboard

Advantages:

- with a straight edge and installation without seam processing;

- has protection against x-rays;

- does not contain lead elements;

- low price;

- belongs to the class of low-flammable;

- suitable for medium and large structures;

- easy to process and install.

Flaws:

- Use in rooms with high humidity is not permissible.

Gifas

OJSC "Sverdlovsk Plant of Gypsum Products" as an industrial group has high-tech equipment, thanks to which its products can withstand competition with foreign analogues. Regular type gypsum board is used for interior decoration.

Gifas plasterboard

Advantages:

- invisible joints along the thinned edge;

- low-flammable class;

- microclimate support;

- sufficient bending strength;

- suitable for walls, floors, ceilings;

- low thermal conductivity.

Flaws:

- not found.

Aksolit

GKL for wall and ceiling decoration of high quality belongs to the group of low-flammable materials.

Aksolit plasterboard

Advantages:

- with semicircular and straight edge;

- regular type;

- recommended for finishing in private homes and businesses;

- excellent insulation;

- reasonable price;

- hypoallergenic components;

- easy to process.

Flaws:

- No.

Belgyps

A lightweight 3.6 m² sheet of plasterboard, convenient for large-scale finishing, allows you to quickly decorate large spaces.

plasterboard Belgips

Advantages:

- the light shade will not affect the main color of the wallpaper or paint;

- is characterized by increased strength;

- low-flammability class;

- regular type;

- tapered edge for a seamless joint;

- thickness provides sound insulation.

Flaws:

- none.

| Gypsum regular sheets | |||

| Modification | Size, mm | Weight, kg | Area, m² |

| KNAUF GSP A | 9,5*1200*2500 | — | 3 |

| KNAUF GSP DF | 9,5*1200*2500 | 17.5 | 3 |

| Gyproc Light | 9,5*1200*2500 | 20.4 | 3 |

| GKL KG Stroy Systems | 12,5*1200*2500 | 24.9 | 3 |

| KNAUF Safeboard | 12,5*625*2400 | 25.5 | 1.5 |

| Gifas | 12,5*1200*2500 | — | 3 |

| Aksolit | 12,5*1200*2500 | 25.5 | 3 |

| Belgyps | 12,5*1200*3000 | — | 3.6 |

How to choose the right one

Confidence in the need to purchase waterproof material will appear only when it is clear how moisture-resistant drywall differs from simple drywall. Having decided on the type of sheets, you can select them by size, weight, and edge. In addition, it is recommended to pay attention to the following points:

- The cardboard should never peel off (especially at the corners).

- When transporting, plasterboard panels must be securely fastened, otherwise they may be damaged.

- The thickness of the material is selected according to the purpose of purchase, the type of object, and the characteristics of its operation.

Installation of drywall is carried out using frame or frameless technology. The main advantage of the latter is its lower cost. But the first one is more common because it allows you to hide any defects and lay utility lines.

What to look for in the store?

When choosing moisture-resistant drywall, you should take it responsibly. The final result, service life and appearance of the work will depend on the correct choice. Therefore, first of all, learn the following nuances:

- Buy only from large construction stores or trusted suppliers. If you don’t have the necessary purchasing experience, you should be puzzled by looking for recommendations.

- Give preference to well-known, time-tested manufacturers. Such brands always cost a little more, but in return you will receive excellent quality, confirmed by a certificate. Accordingly, high-quality material will last longer than cheaper analogues.

- Take the time to carefully inspect each sheet of drywall. This will avoid purchasing defective or broken sheets. Also pay attention to the surface - it should not have deep grooves or grooves.

- It is ideal to obtain a sample of moisture-resistant drywall - a small piece of sheet. This way you can examine its internal structure - it should not be too loose and crumble too much.

Considering these factors, you will receive excellent material that will delight you for many years.

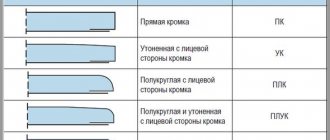

Sheet edge view

Regardless of the manufacturer of drywall, each sheet of this material has its own edge, which is suitable for a specific finish:

- rectangular edge - characterized by the presence of taped edges and is used for finishes where no further putty is required;

- edge with a longitudinal bevel - requires mandatory putty, and the seams are sealed with reinforcing tape;

- rounded edge - requires putty, but there is no need to seal the seams;

- longitudinal seam type of edge - in most cases it is present on gypsum-fiber sheets; after its installation, it is necessary to glue the sickle and putty.

Sanding seams and corners

If the layer is well leveled when sealing seams on drywall, sanding can be kept to a minimum. Why is it better to sand less? Because firstly, it’s long, and secondly, it’s dusty. Moreover, the dust is very fine, floats in the air for a long time and rises again from any movement. To reduce the amount of flying dust, wet rags, wet sawdust, etc. can be placed on the floor. Doors leading out of the room are covered with a wet cloth; it should be larger than the size of the door - so that dust does not fly into other rooms.

To begin with, you can go over it with a sharp, even spatula and cut off all the most protruding irregularities. Next is the sanding process. Since corners and seams at this stage do not need to be sanded to perfect smoothness, take a sanding mesh with a mesh size of 180-200 and a wooden block. A mesh is attached to the block (you can use staples from a construction stapler, but the staples should not stick out). This device levels the surface. When working, it is advisable to highlight it with oblique light - this way all the irregularities are more visible. But you can’t putty plasterboard under wallpaper so carefully.

There are special holders for the mesh, but you can get by with a block

One thing - it’s better to grind in a respirator and safety glasses. Gloves will be a good idea. The dust is very fine and penetrates literally everywhere. After the seams and corners are sanded, the surface is primed again. Moreover, all of it, since dust has also settled on the untreated areas, and it worsens adhesion.

The most inconvenient places for puttying and sanding are the inner corners. For the secrets of fast, high-quality grinding of corners, watch the following video.

Sheet sizes

When choosing drywall, you need to pay attention to the size of the sheet; they come in the following types:

A sheet with a thickness of 6.5 millimeters is considered the thinnest, therefore, if artistic deformation is necessary, it is the most pliable. It is used for the manufacture of arches and multi-level ceilings, where the main role is played by lightness and plasticity.

The sheet thickness of 9.5 millimeters is perfect for creating a flat ceiling. Among the characteristics of this drywall are lightness and strength.

Sheets with a thickness of 12.5 millimeters are widely used for walls, although they can also be used for single-level ceilings.

Material with a thickness of 14 to 24 millimeters is suitable for creating interior partitions. Drywall with such a thickness guarantees high-quality sound insulation, can withstand heavy loads and is quite resistant to damage.

What are the stages of the whole process?

After installation is completed, the HA sheets are prepared for finishing work. The very first step is to prime the plasterboard surface. After fixing the slabs to the frame, priming begins.

To apply the primer layer, prepare:

- pre-purchased mixture;

- roller with brush for treating the surface of the structure;

- containers for the primer composition (you can purchase special plastic containers for paint and varnish compositions with corrugations on the walls and a recess);

- protective equipment for personal safety - a respirator will help protect the respiratory organs from damage by harmful fumes, and gloves will protect the skin of your hands. This point should not be neglected, since the soil can cause poisoning of the body.

First of all, apply the primer as described in the manufacturer's instructions. The mixture is prepared based on water. The resulting solution is placed in a separate container.

Using a clean roller, the soil is distributed evenly over the surface. If a composition with color indexing has been chosen, then it becomes easy to control the areas where the solution is applied during work, as well as the completion of its drying period.

Some structural elements (joints, corners, etc.) are not easy to prime with a roller. Therefore, a brush is used in “difficult” areas. Their high-quality sealing is very important; it will affect the strength characteristics of the putty and the resistance to cracking of the finishing of the entire surface.