What is better GVL or gypsum board

Having considered the main characteristics of gypsum plasterboard and gypsum fiber board, we will make a small verdict.

First, you need to decide on the purpose of purchasing a particular sheet. And know exactly what types of gypsum board and gypsum board there are. Types of gypsum plasterboard and gypsum board:

- GKLA is an acoustic plasterboard sheet, used as the final cladding of soundproofing sandwich panels. A unique development with increased sheet density and improved acoustic properties;

- GKLO – fire-resistant plasterboard sheet. Its production uses thick, flexible multi-layer paper, as well as a gypsum fire-resistant base;

- GKLV is a moisture-resistant plasterboard sheet.

- GVLV is a moisture-resistant gypsum fiber sheet that has excellent moisture protection due to the treatment of both sides with a water repellent and antiseptic agents.

If you focus more on quality and the budget allows you to realize your idea, then it is better to purchase gypsum fiber sheets (GVL), since their density is much higher, equal to 1250 kg/m³, therefore, the strength of walls and partitions increases. Another advantage of gypsum board is that it is uniform in structure and when cutting it, you can use any cutting tool without damaging the edges of the sheet, while when cutting drywall, the structure is damaged and uneven edges are formed.

If your choice fell towards the cheapness and simplicity of your ideas, then you can safely take ordinary plasterboard sheets (GKL). Despite the low cost, such sheets have their advantages, and it is easier to work with, since it is lighter in weight, the sheet can be given different shapes (pre-wetted), and in general it is better to use them in not the most critical projects, but to use GVL.

Each type of plasterboard is unique in itself, but if you take a broader look at the building materials market, you can find varieties of both plasterboard and fiber sheets. Plasterboard sheet can be made with additional additives that give it increased sound insulation and fire protection.

Comparative analysis in application areas

Strength

Gypsum fiber sheet (GVL), in which gypsum is reinforced with cellulose fiber, is a fairly strong building material, which cannot be said about gypsum board sheet (GKL). The compressive strength of the former is much higher, it is more rigid in processing, but is weak in bending and is not so suitable for constructing curved structures. Drywall is fragile. It may chip during transportation, loading, and is susceptible to moisture. Its use is not recommended in wet areas, except for the specially designed moisture-resistant type. This is one of the most important differences between GVL and GKL.

Environmental friendliness

GVL is more environmentally friendly compared to gypsum plasterboard. Its rigid structure prevents the destruction of the sheet mass, while plasterboard loses its declared strength over time due to the gypsum turning into dust, and therefore problems with the respiratory system may arise.

Moisture resistance

Gypsum fiber can be used without restrictions in rooms with high humidity, while plasterboard is not recommended for use in such rooms. But this material also has sheets containing special additives, the so-called moisture-resistant plasterboard (GKLV). They can be successfully used in damp areas.

Fire resistance

The physical properties of gypsum board prevent it from catching fire, whereas ordinary drywall requires coating with a special composition that prevents the cardboard from burning to achieve the same performance. It has a special marking - fire-resistant plasterboard sheet (GKLO).

Practicality

GVL is massive, durable and heat-intensive. It can be used for floor insulation as its basis. GCR does not have such properties; it has, first of all, a prop and decorative purpose. It cannot be used for flooring. At the same time, the lack of plasticity in the first one deprives it of the ability to transform the room.

Price component

Gypsum fiber sheet is much more expensive. The difference in price per 1 m² can be up to 200 - 300 rubles. But this is the price for quality.

Conclusion: which is better GVL or gypsum board? As we, of course, were able to see from the comparative analysis carried out above, it is clearly worth giving preference to the second option. Drywall has been replaced by a new building material - gypsum fiber, which has significant construction advantages.

It remains to add that the construction market, as it develops, offers more and more new building materials. For example, glass magnesite sheet (GML), which has a number of advantages:

- cheaper than GVL;

- high thermal conductivity, several times higher than that of gypsum fiber;

- fireproof;

- environmentally friendly;

- does not require special preparation for installation, unlike gypsum fiber boards and gypsum boards.

What do you think, will LSU be able to completely replace GVL or GKL? We are waiting for your opinions.

Author of the article

Evgeniy 47 years of experience in interior finishing work 21 years.

Where is moisture-resistant plasterboard used?

As mentioned above, this type is used in wet areas:

The most surprising thing is that the installation process of the two types is no different. That is, you can use technologies for the frame and glue. The joints of sheets are sealed in the same way using special reinforcing tapes, putty, etc. The only thing that can be noted is the ceramic tiles, which are installed in a moisture-resistant manner.

How to use GKLV

Anyone who constantly works with drywall knows that the light side of the sheet is its front side. The same goes for moisture resistant. But that's not the only distinguishing part.

Usually the chamfers of the panel are taken as a basis. Please note that the edges of the material may have different shapes. What is it for? It is no secret that drywall is sometimes combined with various finishing materials.

So, for each material, a specific sheet with different edges is used. What types of edges are there?

- Rectangular. If this type is chosen, then there is no need to seal the joints.

- Stepped. To seal the seams, you will need both a putty solution and reinforcing tape.

- Rounded. In this case, you can do without reinforcement, just putty.

Note! When sheet material is laid on a surface, its edge shaped part should face outward. This is the law.

Surprisingly, but not unfairly, the moisture-resistant type can be used in places where the usual one is used. But the opposite is not possible. Although, probably, no one will use gypsum plasterboard in the living room or bedroom. It's simply not economical.

Is there an alternative?

As a replacement for both options, a variety of slab materials are used:

- OSB. The products are distinguished by their rigidity and reliability, suitable for covering any base.

- LSU. Magnesium glass sheets with reinforcing layers are similar in characteristics to plasterboard.

- DSP. Cement boards with the addition of wood chips have excellent parameters that can be compared with gypsum fiber board.

GKL and GVL sheets are not the only materials for arranging various types of surfaces, they are no better or worse, it’s just that each of them was developed for a specific situation.

Such diversity allows you not only to choose the most suitable products, but also to successfully combine materials.

GKLV "Knauf": new designation, features, price per sheet

Moisture-resistant plasterboard from Knauf is now marked GSP-N2 (gypsum building board with additives that reduce water absorption). Manufactured in accordance with GOST 32614-2012 (EN 520:2009). By default, gypsum boards are equipped with a thin semicircular edge (marked PLUK), which promotes the formation of a tight joint. To order, the manufacturer produces sheets with other types of edges.

The durability of the structures being erected is ensured not only by the high quality of the material, but also by compliance during installation with the conditions specified in SNiP 02/23/2003 “Thermal protection of buildings”. Knauf gives the following recommendations:

- The temperature in the room being repaired must be above 10 °C.

- Drywall sheets are left to rest at the installation site for at least a day. This will allow them to acclimatize and not change their linear dimensions in the future.

- The edges of the ends of the GSP-N2 plasterboard are rectangular, therefore, for high-quality sealing of the seam after installation, they are first chamfered. Its angle of inclination is approximately 45˚, and its depth is 1/3 of the sheet thickness.

Cost of GKLV from Knauf in Moscow:

- for a standard sheet 2500 × 1200 × 12.5 – from 280 to 350 rubles;

- per sheet 2500 × 1200 × 9.5 – from 275 to 350 rubles.

USEFUL INFORMATION: How much does one sheet of drywall weigh: table of dimensions, area and weight

Comparison of GVL with analogues

First, let's figure out what GVL is. It differs from standard drywall mainly in its manufacturing technology. If the sandwich principle is used in the production of plasterboard (that is, two layers of cardboard and a gypsum layer between them), then in the case of gypsum board, manufactured fibers are mixed into the gypsum mixture and pressed into the form of a sheet. This results in increased strength and excellent fire performance. An analogue of GVL SML is a fairly new finishing material made in China. The glass-magnesium sheet contains in its structure magnesium oxide, finely dispersed shavings, perlite, magnesium chloride and binder composite materials. One of its good qualities is its non-flammability. In this regard, none of the currently known materials can compare with LSU. GVL is also inferior to it in fire resistance.

It is impossible not to note the moisture resistance. LSU perfectly withstands high humidity conditions. Test results have proven that even after immersion in water for several hours, the LSU does not lose its shape. It is also not susceptible to mold, deformation, does not contain harmful substances, flexible, durable, lightweight and quite easy to use. But in our country this material has not yet been studied enough, so not everyone risks getting involved with it, preferring GVL or GCR. GCR is the most common option. This is a composite finishing material that is traditionally used for finishing residential and office premises. Drywall is environmentally friendly and does not contain any harmful impurities. Excellent soundproofing characteristics and non-flammability make it the most common and versatile material for constructing interior partitions, leveling walls and installing ceilings. property is interesting

when the humidity in the room is high: the material absorbs excess moisture, and when the air is dry, it releases it. GVL is, in fact, an improved version of gypsum plasterboard, superior to it in some respects. For example, increased strength and fire resistance. In general, GVL has a huge list of advantages:

- Excellent heat and sound insulation.

- Environmental friendliness and safety.

- Increased strength.

- Easy to use.

- Low amount of waste during installation.

- Possibility of mounting on both wooden and metal frames.

- Another quality that can be noted is the ease of processing of joints.

- It is not necessary to use special tools to cut gypsum fiber board.

The list of shortcomings is not so impressive. It is limited by a large mass that prevents deformation and stretching. You won't be able to bend it like drywall. And the second drawback is the high cost compared to the same drywall.

Types of drywall used in finishing

There are many types of drywall depending on the activity and where it will be installed. One of the important details that drywall offers is the presence of tapered edges on the long edges of the drywall sheets. These tapered edges, when joined together, create a shallow recess for the drywall and joint, allowing invisible finished joints to be seen. There are other options, but not as common as the previous ones. There is an ECO board made from recycled material using waste material to create drywall that looks like concrete. It can be made from 20 different by-products, and one of the most important benefits is that it prevents mold and termites due to its composition.

Green gypsum board is also known as moisture resistant drywall. It has a green coating that makes it more resistant to moisture than regular drywall. The cost is slightly more expensive than regular drywall, but keep in mind that it is not waterproof, so do not use it if it will come into contact with water. Also used as a finish in confined wet areas such as bathroom and basement walls, as well as kitchens, laundry and utility rooms. Blueboard drywall is also known as plaster baseboard. Blue board is used for plaster cladding, and the surface of the paper has special absorption qualities. It is waterproof and mildew resistant. Blue board drywall is resistant to dirt, tape and paint and works great in bathrooms or areas with a lot of moisture. In addition, this type helps reduce noise levels and ensures low emissions. Good choice for overall performance. Purple Drywall is an advanced moisture resistant product that offers the same benefits as regular moisture resistant drywall, but with superior moisture and mold characteristics. It can be installed in all wall and ceiling applications and is ideal where increased resistance to moisture and mold is required. If it will be in contact with water, this is the type to use.

The relevance of the use of drywall.

Today, all over the world, including in Russia, the construction business is developing at a rapid pace. And this is not without reason. Construction has always been one of the main crafts. It's hard to imagine life today without it. Every day hundreds and thousands of different houses and structures are built all over the world. But construction is not only a large-scale activity that brings profit to the state or private entrepreneurs. You can also do construction at home, equip your own apartment, house or cottage. Currently, a variety of building and finishing materials are used for this purpose: brick, concrete slabs, cement, tiles, paving stones, wood, lining, block house and others.

Parameters and elements of a drywall sheet.

A special place among finishing materials is occupied by plasterboard and other materials based on it, for example, gypsum fiber and plasterboard sheets. This material is widespread and in great demand among buyers and customers. Unlike lining and block houses, it costs much less, almost 2 times. In addition, it has a number of valuable properties: it is an environmentally friendly and safe product, fire resistant, easy to use, and so on. Let us consider in more detail the main technical characteristics and application of plasterboard and gypsum fiber sheets. Which is better: GVL or gypsum board?

GVL for the ceiling: device, installation rules, step-by-step instructions

However, this is too expensive a method. It is expensive both in terms of funds and labor intensity. Therefore, if you want to carry out repairs quickly, easily and cheaply, then the second method is more suitable for you. The lathing of the structure can be made of wooden beams, but the best material for its manufacture is considered to be a galvanized metal profile - it is more reliable and durable.

The frame must be assembled in such a way that its elements are located at a distance of no more than 400 mm from each other. It is important to remember - using the first (frameless) method of surface cladding, it is necessary to maintain a certain width of the gap between the plates (6-8 mm), seal the joints with a special gypsum putty and use special glue for gypsum plasterboard. Any type of wallpaper, paint or tiles can be used as materials for finishing the coating. Let's talk about tile cladding

First, you need to determine a step-by-step scheme for performing installation work.

It should consist of surface treatment and marking, preparation of tiles and adhesive, laying itself, as well as subsequent grouting. Along with the use of GVL slabs for finishing walls and ceilings, this material is often used when installing dry floor screed. Any finishing coating can be laid on top of it - durable gypsum fiber will provide an absolutely flat, reliable surface.

To carry out such work, it is not at all necessary to hire professionals; the sheets can be laid independently and very quickly. Gypsum fiber without a paper shell is a high-density fabric that is homogeneous in composition. Moreover, the thinner the canvas, the higher its density. The material is successfully used in conditions that require increased structural rigidity - sports, gymnastics and fitness halls, courts. Next, the ceiling is marked and installation of the metal profile frame begins.

The technique for constructing a frame for gypsum plasterboard is similar to working with drywall. The difference between gypsum fiber and drywall lies in the composition of the materials. GVL board consists of a homogeneous mixture of loose cellulose fibers with gypsum, which is pressed using a special technology, if necessary, reinforced with fiberglass, and then cut and sanded to a smooth surface.

The composition provides the material with increased density and improved performance characteristics. To level the floor under the floor covering, only gypsum fiber boards can be used - the rigidity of the material and its high bending and compressive strength ensures its resistance to serious loads. The performance of gypsum boards according to these parameters is much lower, they are more fragile, and therefore are not used for finishing floors. For partitions.

The choice of material depends on the design. Simple partitions with a rectangular opening can be assembled from gypsum fiber board. The sheets will provide rigidity and good sound insulation. If you plan to install an arch with complex decor, it is better to choose gypsum boards.

Drywall is easier to process. The cost of plasterboard is lower, since it is easier to produce and has slightly inferior characteristics to gypsum fiber. In some cases, for example, with increased surface loads and high humidity, the price of gypsum fiber board is completely justified and is paid for many times over by its properties.

Distinctive features of GKLV

Moisture-resistant plasterboard (GKLV) is a sheet material consisting of two layers of special cardboard and a gypsum core.

The facing shell protects the fragile inner filler from crumbling. The coating treated with antibacterial and hydrophobic compounds is suitable for residential premises and is the basis for subsequent finishing.

To make the inner layer, viscous gypsum with reinforcing and moisture-repellent additives is used. The plasticity of the resulting composition provides increased flexibility to gypsum board panels, which allows the installation of structures of any shape.

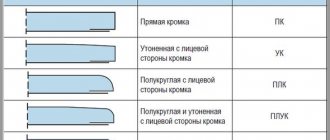

The edge of each GKLV plate is rolled with cardboard of the front layer. The method of sealing joints between sheets during installation depends on the edge profile.

The edges of plasterboard panels are of the following types:

- PC – straight longitudinal.

- UK – thinned longitudinal.

- PLC – longitudinal semicircular on the front side.

- PLUK – semicircular thinned universal longitudinal.

- ZK – rounded longitudinal.

Note! You can visually distinguish waterproof plasterboard from standard panels by the green color of the front cardboard layer.

Important! When purchasing, you need to evaluate the appearance (uniformity and color saturation), as well as the integrity (presence of breaks and cracks) of the sheets.

Overview of gypsum board and gypsum board

Gypsum fiber sheets and plasterboard "Knauf" are very popular for wall decoration. They are also used for finishing industrial buildings, residential interiors and public buildings. But since there is a high probability of stumbling upon a fake in the building materials market, it is always worth familiarizing yourself with the Knauf plasterboard certificates of conformity, which every decent seller should have.

Plasterboard and gypsum fiber sheets from this manufacturer have different structures.

The difference is determined in operational and technical characteristics:

- gypsum fiber has an even structure, which allows you to cut the material without chipping. Therefore, GVL can be used for parts of different sizes;

- the use of GVL is required where high impact resistance is required;

- plasterboard is characterized by excellent plasticity, which allows it to be made into structures of various shapes;

- GVL and gypsum plasterboard from this company also differ in the degree of frost resistance. In this case, drywall is designed for 4 cycles of thawing and freezing, and gypsum fiber for 15 cycles.

The table below shows approximate prices for different types of gypsum fiber boards and gypsum plasterboards from Knauf:

| Photo | Kinds | Description | Prices, rub. |

| GVL sheet Knauf floor element | 200x600x1200 mm. Superpol | 337 | |

| Knauf super sheet GVL | 2500x1200. With straight edge. | 487 | |

| Knauf plasterboard sheet | 300x1200x12.5 mm Used for the construction of light partitions. | 279 | |

| Knauf plasterboard moisture resistant | 2500x1200. Used for suspended ceilings and as a covering for walls. | 336 |

Knauf gypsum board Knauf gypsum board moisture resistant

Product characteristics and dimensions

Let's consider the main dimensions of the Knauf gypsum board sheet:

| Kinds | Dimensions |

| Standard, 12.5 mm thickness, 2 meters length. | 1200×2000 |

| Thickness 12.5, length 2.5 meters. | 1200×2500 |

| Thickness 12.5, length 2.7 | 1200×2700 |

| Thickness 12.5, length 3 meters | 1200×3000 |

If you are looking for a suitable material for a bathroom, toilet room or swimming pool, then you can consider the products of moisture-resistant GVL for flooring 1200x600x20mm "Knauf" Superpol. You can also use the sheets presented in the table.

| Kinds | Dimensions |

| Moisture resistant, length 2 meters, thickness 12.5 mm | 1200×2000 |

| Thickness 12.5 mm, length 2.5 meters. | 1200×2500 |

| Thickness 12.5, length – 3 meters. | 1200×3000 |

The table shows prices for gypsum fiber sheets from this manufacturer depending on size

GKL Knauf: special characteristics

It also offers acoustic gypsum boards. This material has the following properties:

- reduces the level of background noise;

- improves perception;

- reduces boominess.

Acoustic plasterboard allows you to create a comfortable indoor environment. Therefore, finishing with such material is required in cinemas, classrooms, recording studios and meeting rooms. This material is also used in apartments.

No less popular are the types of moisture-resistant gypsum board "Knauf". It is used in the kitchen, bathroom and in places where high humidity is expected.

Features of installing partitions using Knauf products. Installation of gypsum plasterboard and gypsum board sheets is carried out using these methods.

Related article:

Watch this video on YouTube

Watch this playlist on YouTube

Previous Building materials Brick-like tiles for interior decoration: price, choice of materials and installation technology Next Building materials Chipboard: what is it and how to choose what is really profitable

Comparison of technical characteristics of drywall and gypsum fiber

The rationality of using gypsum plasterboard and gypsum fiber board is determined by the features and performance characteristics of the materials. Knowing how gypsum fiber differs from plasterboard in terms of basic parameters, you can determine how wise it is to use one or another option during repair work.

Density

The density of gypsum plasterboard, regardless of waterproofing and thermal protective components, is approximately 850 kg/m2. In this parameter, gypsum fiber is noticeably superior to plasterboard - its density is on average 1200 kg/m2, which is equivalent to expanded clay concrete. Thanks to its homogeneous and dense structure, nails can be driven into the gypsum plasterboard sheet and screws can be screwed in without using dowels, as is the case with plasterboard. At the same time, the hardware installed in the GVL can withstand a 30-kilogram load hung on them.

Strength

Gypsum fiber sheets have greater strength than plasterboard. This is achieved primarily due to the higher density of GVL. This also determines the areas of application of these materials. Gypsum plasterboard sheets are used for cladding light structures - partitions, suspended ceilings, wall cladding at home. Gypsum fiber sheets have increased strength, which allows them to be used in industrial facilities and in rooms where higher loads may be placed on the walls. The bending strength of GVL is more than 5.5 MPa, gypsum plasterboard does not reach this value.

Flexibility

When wetted, gypsum boards soften somewhat and acquire a certain flexibility, which makes it possible to produce arches, figured ceilings and radius structures for interior decoration. Gypsum fiber slabs are distinguished by their unchangeable rigidity; it is almost impossible to bend them without breaking them, and therefore they are used exclusively for finishing and constructing linear structures.

Difficulty in installing and processing sheets

Features of installation and processing of plasterboard and gypsum fiber according to some parameters are shown in the table below:

| Parameter | GKL | GVL |

| Installation of partitions | On a metal or wooden frame using technology generally accepted for gypsum products. | On a metal or wooden frame using technology generally accepted for gypsum products. |

| Cutting | You can cut it with a knife by trimming the top layer of cardboard and breaking the gypsum core. | Cannot be cut with a knife; sawing is required. |

| Fastening | Screws type TN or TB, according to the usual technology for gypsum products. | TN type screws, according to the usual technology for gypsum products. |

| Seam processing | Each seam must be covered with reinforcing tape, followed by putty with a special mixture. | The use of reinforcing tape and preliminary putty at the joints is not required. |

| Processing corners (internal and external) | Reinforcing tape is required to create an ideal internal corner, and special metal corners are required for external corners. | Does not require the use of special corners and mesh. |

| Surface treatment before painting | A layer of putty followed by priming is required. | It is possible to putty only the joints of the sheets and subsequent priming. |

| Painting | The use of silicon-based paints and whitewashes is unacceptable. | Any whitewash and coloring compositions can be used. |

| Preparing for wallpapering | It is necessary to apply a wallpaper primer. When removing wallpaper, there is a high risk of damaging the surface of the plasterboard. | Primer is optional. The surface of the plasterboard retains its integrity even after the wallpaper is removed. |

Environmental friendliness

In this case, it is extremely difficult to determine which is better - gypsum fiber board or drywall. Both materials are environmentally friendly and do not contain toxic components.

Flammability

Drywall has a certain heat resistance - even an ordinary sheet can withstand about 25 minutes of open fire before destruction begins, while the cardboard surface chars. Some manufacturers use special flame retardants to impregnate sheets, due to which the fire resistance of gypsum boards increases to 60 minutes. The composition of gypsum fiber eliminates any possibility of fire, and therefore it is safer. However, both of these materials are classified as flammability group G1.

Material weight

The standard size of gypsum fiber sheet is 2500X1200 mm. Such a sheet, depending on its thickness, can weigh from 39 to 42 kg. Drywall is much lighter - the weight of a slab of the same size with the greatest thickness is 33 kg, which makes carrying and working with the material somewhat easier, and the weight of the manufactured structures is less.

Final comparison of materials

| GKL | GVL | |||||||

| Density, kg/m3 | 850 | 1250 | ||||||

| Strength | below | higher | ||||||

| Thermal conductivity, W/(m*K) | 0,1 — 0,2 | 0,22 — 0,35 | ||||||

| Bending strength, MPa | less than 5.5 | more than 5.5 | ||||||

| Sound insulation level, dB | 27 — 30 | 30 — 35 | ||||||

| Flammability class | G1 - low-flammable | G1- low-flammable | ||||||

| Weight | easier | heavier | ||||||

| Environmental friendliness | high | high | ||||||

Key materials for interior decoration: SML, GVL and GLK, what is the difference

In appearance, GVL panels are very similar to ordinary sheets of plasterboard and glass-magnesium finishing materials. Standard plasterboard slabs are labeled as GLA. The inner part of the panels consists of gypsum, and the outer surface is made of cardboard.

Like the previous material, GLA is divided into several subgroups:

- GLKO – fire-resistant plates;

- GKLV – meaning “moisture-resistant plasterboard sheet”.

There are also combined boards containing polystyrene foam for insulation. The material is intended for external and internal work. Gypsum fiber and plasterboard have many similar properties: they are moisture resistant, fireproof and suitable for decorative cladding.

To understand which is better - GVL or GLK, you need to familiarize yourself with the main differences between the panels. Thus, drywall consists of several autonomous layers of cardboard and gypsum, while gypsum fiber board is a solid fiber, which makes the sheets stronger and more reliable. There is another material with similar characteristics - LSU, the so-called glass-magnesium sheets, the main disadvantage of which is the content of chemical elements such as magnesium oxide and chloride.

If you choose between gypsum plasterboard or gypsum plasterboard, you need to take into account that fiber panels are better able to resist damage, because many who have worked with drywall note that the sheets are extremely fragile. In the case of gypsum fiber sheeting, you should not worry that it will easily lose its integrity in the event of a pinpoint impact

Another important advantage of gypsum fiber board is that, unlike gypsum plasterboard, it can be used to decorate floor coverings

If plasterboard is used to finish the walls, it is recommended to make as few joints as possible so that the surface does not lose strength. In the case of fiberglass, there is no such problem: the number of joints does not affect the reliability of the wall.

Other differences in materials are shown in the table:

| Criterion | GVL | GLK |

| Ability to bend | It bends very badly | Easily make complex curved shapes |

| How does it behave when cutting? | Can be cut in any way, because the edges remain smooth | It crumbles and cracks at the cut points |

| Resistance to temperature changes | Does not change its properties even when frozen | Doesn't like changes |

| Humidity resistance | They tolerate exposure to high humidity well, especially if moisture-resistant GVL or GLA is used for walls. | |

| Installation features | Can be attached directly to the surface or to the sheathing |

It should also be taken into account that the cost of gypsum plasterboard sheets for walls is higher than the price of conventional plasterboard panels. When decorating a room, many people prefer to combine slabs depending on the surface.

What is the difference between moisture-resistant drywall and regular drywall?

- By appearance, or more precisely, by the color of the cardboard layer. For ordinary plasterboard, the color of the shell is grayish, while for moisture-resistant plasterboard it is greenish. So, when choosing GKLV, you can’t go wrong, that’s for sure.

- By marking. GKL – plasterboard sheets, GKLV – moisture-resistant plasterboard sheets. For information, let’s add one more type - GKLO - fire-resistant plasterboard (how far progress has come).

- According to the degree of processing of the cardboard layer. The moisture-resistant analogue is treated in several layers with various preparations. Which ones exactly? Antifungal, waterproof and impregnated compounds. It is these solutions that provide increased stability when using the material in wet areas.

- By weight. All additional protective compounds add a little weight to moisture-resistant drywall. True, not by much, but still there is such a difference. The approximate discrepancy in the mass of one sheet is two to three kilograms upward.

- Dimensions. Sheet thickness can vary from 6.0 to 22.0 millimeters. But companies mainly produce drywall in two thicknesses: 9 and 12.5 millimeters (other sizes can be ordered). The same applies to the length and thickness of the sheet: length - 2500-4800 millimeters, width 1200-1300 millimeters.

- Price. GKL is cheaper than GKLV.

- All other technical characteristics are identical to conventional gypsum boards.

Features of gypsum plasterboard and differences with gypsum board

There is a building material that does not require advertising. Anyone who has at least once attempted to do repairs with their own hands or turned to specialists is familiar with it. This material is called drywall. The structure is a dense gypsum layer onto which two cardboard layers are glued. In terms of composition, it is filled with gypsum by 93% (inner layer), cardboard by 6% (outer layer), and organic matter by 1%.

Distinctive characteristics

Environmentally friendly. The content of hazardous substances is zero. Endowed with impeccable sound-absorbing characteristics. Fire resistant (GKLO). It has sufficient moisture capacity, allowing it to absorb moisture when there is excess in the room and return it when there is a lack of it. The price per square meter reaches 100 rubles.

Practical use

Drywall is used for the construction of partition walls, cladding and leveling of walls, and installation of ceilings. This finishing material is easy to install. Its use allows you to create cosmetic cleanliness in the room by hiding the communications available in the room under it.

Drywall makes it possible to realize various construction and finishing fantasies, for example, niches, arches, columns, built-in lighting. If there are deficiencies in the design of the room, unevenness, curved walls, corners, plasterboard construction allows you to easily eliminate these errors.

Its surface is very practical, which makes it easy to prepare for wallpapering, painting, or replacing some part of the structure. Possibly formed errors during the installation of drywall (chips, seams, holes) can be easily repaired with a related material - gypsum putty.

Purchase of gypsum fiber and plasterboard sheets

Experts advise purchasing gypsum fiber and drywall from well-known international KNAUF dealers. In this case, the quality of the product is practically guaranteed. After all, this international company was founded, without exaggeration, on the best business principles and has managed to maintain them even in our time, with fierce competition and the current global scale of activity. The company has earned undoubted success with its responsibility and work.

Let's study further in more detail how gypsum board differs from gypsum board.

Choosing moisture-resistant drywall: 6 main features

When choosing moisture-resistant drywall, you need to pay attention to whether the GOST quality certificate meets the requirements. It is he who guarantees the safety of the material for human health. Such drywall must necessarily have fire-resistant properties. Waterproof gypsum fiber board is suitable for finishing walls in unheated rooms.

The choice of material for finishing indoor surfaces largely depends on the microclimate in the room. Sometimes it can be difficult to choose a material that will not become unusable due to sudden changes in temperature, increase or decrease in humidity levels. One of the materials that is not afraid of water is moisture-resistant drywall.

- The slabs are light green or pink in color.

- The marking is applied to the back of the sheet using blue color.

- When producing sheets, a special impregnation is used, which performs a protective function against the penetration of moisture and fungi into the material.

Hydrophobic drywall is designed specifically for rooms with high humidity. It contains a layer impregnated with water-repellent agents. The material is easy to install.

You can finish the room yourself, after reading the instructions first. The material can be covered with a variety of decorative and finishing materials.

GVL for the furnace. Performance

As a rule, when choosing a material, the buyer is not interested in “dry” numbers, but in the advantages and disadvantages of the product. Therefore, we will further familiarize ourselves with the performance qualities of GVL.

On the forums, many people ask experts whether the gypsum fiber board actually burns or not? Despite the assurances of the manufacturers, the fire resistance of this material can be discussed with some reservations.

GVL does not ignite

According to GOST 30244-94, the material is classified as G1, i.e. is slightly flammable. According to GOST 30402-96, it belongs to flammability class B1 - does not ignite. But how does this happen in practice?

When exposed to open fire, the surface of the material chars, but does not catch fire. Moreover, when exposed to high temperatures, the crystals contained in the structure of the gypsum fiber disintegrate. This releases water, which resists the flame.

As a result, the fire resistance of gypsum fiber board in minutes, as tests show, averages 90 minutes or more. Those. This is how long the material resists the spread of fire on the surface located behind it. This allows the use of gypsum fiber for fire protection of wooden and other combustible structures.

The fire resistance limit of GVL depends on its thickness. The thicker the material, the correspondingly higher the fire resistance limit.

Gypsum fiber sheets are securely fixed with self-tapping screws

So, whether gypsum fiber burns or not - we figured it out, now let’s get acquainted with other important qualities of the material:

- high density, which is comparable to the density of expanded clay concrete. This allows you to screw self-tapping screws into the gypsum fiber without dowels and even drive nails into it;

- the material does not crumble. Thanks to this, gypsum fiber sheets can be processed with the same tools as wood;

GVL can be used as a flooring material

high strength (twice as much as plasterboard) - this allows the material to be used not only for finishing walls or ceilings, but also for floors. In particular, GVL sheets are often used in the construction of so-called dry screed.

In addition, they can withstand high mechanical loads. Thanks to this, quite heavy pieces of furniture, for example, shelves, can be attached to the sheets;

GVL is able to withstand large mechanical loads

- the low coefficient of thermal conductivity allows you to insulate the room to some extent. The sheets always remain warm to the touch;

- frost resistance - this quality allows the material to be used for finishing unheated rooms. In particular, it can be used in country houses, on balconies, in vestibules, etc.;

- high hygroscopicity - this property allows you to regulate the level of humidity in the room. Those. At high humidity, the material absorbs moisture, and at low humidity, on the contrary, it releases it.

GVL can be used for finishing vestibules and balconies

Of course, along with the advantages, GVL also has some disadvantages:

- the weight is higher than that of gypsum boards, which somewhat complicates transportation and work with the material;

- As a result of its high density, gypsum fiber board is not able to deform. In other words, the sheets do not bend. Therefore, it is more difficult to finish radius surfaces with them;

- the material is more fragile than drywall, so you need to work with it carefully. This is especially true for the thinnest sheets.

In addition, the price of gypsum board is slightly higher than that of drywall. You can verify this from the following table:

In order for gypsum fiber sheets to last a long time, they cannot be coated with silicate paints and putties, as well as compositions based on liquid glass.

Thus, gypsum fiber sheets are a good alternative to plasterboard, especially in cases where high strength or fire resistance is required from the material.

Main characteristics of moisture-resistant gypsum fiber sheet (gvlv)

The very concept of “plasterboard” is quite broad, since it includes several types of this material. They differ significantly in operating conditions, and, accordingly, in their composition. In addition, there is such a thing as a “fiber supersheet”. Such material has a number of advantages compared to gypsum board and, according to the Knauf classification, is divided into:

- superlist (gvl),

- moisture-resistant supersheet (gvlv),

- small format supersheet.

Each of the above options is characterized by increased mechanical strength, excellent sound insulation, fire resistance and has a special fibrous structure. The latter property allows you to carefully cut drywall and process edges without much effort.

Technical characteristics of gvl (gvlv)

Gypsum plasterboard supersheet has special properties that allow it to be used not only for covering walls, ceilings, but also for floors! Thanks to a high-quality mixture of fiber and gypsum, as well as a special anti-chalking impregnation, supersheet can be used in buildings and premises for any purpose. The only fundamental difference in the use of gypsum board and moisture-resistant gypsum board is the possibility of installing the latter in places with high humidity. All main parameters of the sheets are given in Table 1.

Table 1. Characteristics of gvl supersheet (gvlv)

The moisture-resistant material differs from standard gypsum plasterboard in that its surface on both sides is treated with a special water-repellent agent. This allows it to be used in rooms with any degree of humidity.

If we talk about the properties of the materials, they are very similar. The dimensions and weight of moisture-resistant gypsum board are the same as those of a standard super sheet. The following characteristics are also identical: humidity, Brinell hardness, flexural strength and thermal conductivity gvl and gvlv. At the same time, the range of applications for moisture-resistant drywall is wider than standard, since even in the bathroom it will “stand idle” for its entire service life.

Advantages and application of moisture-resistant supersheet

Fibrous gypsum board has all the advantages of conventional drywall:

- environmental friendliness,

- high heat and sound insulation,

- non-flammability,

- mechanical strength and abrasion resistance,

- ease of installation.

It has only two drawbacks: price and significant weight of the gvl (gvlv) sheet. The first problem can be solved by minimizing waste, and the second can be solved by using a good assistant during the installation process.

Moisture-resistant plasterboard can be used in almost any type of building. Main use cases:

- in places with a high fire hazard as wall and ceiling cladding,

- for cladding attics, balconies and basements (if ventilation is available),

- for the construction of partitions in apartments with high humidity (for example, in bathrooms),

- for unheated rooms,

- for prefabricated floor subfloors.

In the bathroom, it is recommended to additionally treat the surface of the wall made of glvv from Knauf with special moisture-resistant decorative coatings (paint) or cover it with ceramic tiles.

Installation of gvlv on the floor

The slabs can be laid on almost any base: reinforced concrete or wood. For these purposes, the best option would be to use a 12 mm thick gypsum board sheet. The order of work will be as follows:

- Attaching a special edge tape.

- Filling with expanded clay or installing insulation.

- Laying a standard size gypsum board (gvlv) sheet on the floor.

- Treat the surface of the first layer with glue or mastic.

- Installation of the second layer.

- Tightening the layers with screws.

- Primer.

- Installation of covering (most often linoleum).

If you need to install bathroom floors, you should definitely treat the joints with waterproofing tape. This will help avoid moisture ingress and protect the structure from premature destruction.

Of course, gvlv is a “new word” in the development of the construction business. It is especially convenient to use this material during DIY repairs, as it is very easy to process. Moreover, the market offers gypsum board sheets of various thicknesses and sizes, which significantly optimizes marking and installation work.

The only important point is that you should not purchase materials from dubious manufacturers whose reputation on the market is not confirmed by real documents. After all, compliance with GOST sheets gvl and gvlv is the main guarantee of the quality and safety of the entire structure. Nobody wants to redo most of it a couple of tapes after the repair. I would like to hear the opinion of experienced drywall craftsmen on how to avoid the most common mistakes.

Advantages and disadvantages

The choice is always easier if you know the strengths and weaknesses of competing materials. This allows you to avoid unpleasant surprises, both during operation and during operation.

GKL

Many years of experience in using gypsum board have formed a complete list of the advantages of the material, where nothing is superfluous, nothing is missing:

- affordable price for mass buyers. This plus is one of the most important for families on a limited budget. At the same time, the quality of work and durability do not suffer;

- low thermal conductivity coefficient - 0.30-0.34 W/ (m×K). According to this indicator, the material is comparable to wood. In combination with insulation, an excellent thermal insulation layer is obtained;

- Easy to install: no experience required. The main thing is to know the principles of working with the material, which can be easily found on the World Wide Web;

- flexibility. Many will be surprised. After all, the material easily crumbles upon impacts or strong bends. On the one hand, this is true. On the other hand, with the help of gypsum plasterboard you can make any semicircular arches and complex installations (as evidenced by the photo below);

Methods for bending gypsum boards.

- fire resistance. The gypsum itself does not burn, but only melts at +1450°C. Only cardboard can burn. But after it is treated with fire retardants, it becomes difficult to burn (painted pink);

- moisture resistance. In fact, gypsum absorbs moisture very well. However, processing sheets with special compounds makes it possible to use the material in rooms with high humidity (kitchen, bathroom);

- high level of maintainability - dents, cracks, and through holes can be easily repaired. As a last resort, the damaged area is replaced;

- versatility. Can be mounted in any room (residential, non-residential) under any finish (wallpaper, paint, ceramic tiles);

- environmental cleanliness. The material contains no additives harmful to health;

- the ability to easily and simply hide communications. But the main thing here is not to overdo it and arrange inspection hatches at the points of connections or adjustments.

The list of advantages of drywall is impressive, but the disadvantages :

- fragility is the main problem of gypsum boards. Sheets may crack during handling (carry only vertically), transportation, or installation. Therefore, special care is needed when working with slabs;

- low strength under weight loads - you can’t hang anything heavy on gypsum plasterboard partitions. It is necessary to provide embedded OSB or plywood boards at the fastening points in advance. You can also use molly dowels. But their weight is limited - for a slab with a thickness of 12.5 mm, such a mount can withstand from 16 to 25 kg of load. This way you can hang a cornice and a TV, but there are no kitchen cabinets or shelves;

- low level of sound insulation, which is important for partitions - even a whisper is perfectly audible. Exit in mineral wool insulation (not polystyrene foam) between sheets of plasterboard.

Another drawback, although common to the materials being compared, is the reduction in space. This is especially noticeable in small rooms or apartments (houses) with low ceilings.

Important: some experts consider the impossibility of covering walls in dachas with gypsum sheets to be a disadvantage—in winter, due to the lack of heating, it will tear. It's hard to agree with this. Firstly, gypsum board is afraid not of frost, but of high humidity (frost tears away sheets that have accumulated moisture). Secondly, you can use moisture-resistant modifications of drywall (GKLV). Thirdly, indoor humidity is lower in winter than in summer. Therefore, after a wet autumn, you can dry the room well and close it for the winter.

GVL

GVL also has its advantages

- high strength allows you to hang heavy objects on vertical structures (a simple self-tapping screw holds up to 30 kg of load), and on the floor to use it as a base under linoleum, parquet, laminate or tiles;

- the presence of viscosity, firstly, allows you to cut the material without dust - it does not crumble, and secondly, you can tighten the fasteners without dowels - it will hold like in wood;

- low heat transfer coefficient, which allows the material to be used as insulation;

- good level of sound insulation - perfectly absorbs air and shock sound waves. This is confirmed by measurements: the noise level drops by 35-40 dB;

- fire resistance - does not burn, but only chars. Therefore it is used as protection for wooden structures;

- the moisture resistance of sheets treated with special compounds (GVLV) is the same as that of cement-sand mortar;

- high frost resistance makes it possible to use it in the country and in unheated rooms;

- hygroscopicity allows, like wood, to regulate the humidity in the room. When the amount of vaporous moisture increases, it is absorbed by the GVL, and when it decreases, it is easily released;

- can be used in a “warm floor” system, but only from below;

- the material is safe in all respects - when heated, it does not emit harmful substances and does not contain allergens;

- there are no restrictions on use: private houses, apartments, cottages, unheated rooms, horizontal and vertical surfaces;

- easy to install - the work can be performed by a home craftsman without the help of specialists;

- not subject to deformation (change in linear dimensions) under the influence of temperature and humidity fluctuations.

There are also disadvantages that you need to pay attention to:

- the price is prohibitive for some segments of the population;

- high specific gravity, as a result of which an assistant is needed during installation. Even though they are smaller in size than drywall, the sheets are much heavier;

- moisture-resistant gypsum fiber sheets can be affected by rot in places with constant high humidity;

- does not bend - can only be used on flat surfaces.