Hi all! I think most of you are well aware that special tile adhesive is used to lay tiles inside a house or apartment. But not everyone has heard about its use for work on external walls. As you understand, today I’ll tell you about tile adhesive for exterior use.

This material is distinguished by special properties that make it possible to create beautiful and durable cladding using natural and artificial stone, as well as porcelain stoneware and tiles.

Exterior finishing can lose strength and eventually collapse under the pressure of precipitation, solar radiation, and temperature changes. Therefore, for external work, frost-resistant tile adhesive is required.

Main properties and characteristics

Now to the question of what adhesive for porcelain tiles should be for outdoor use. Not only frost-resistant, but also has a number of other important properties and characteristics.

As practice and experience show, tile adhesive for exterior work differs in the following nuances:

- Increased adhesion of tile adhesive

. Tile adhesive must firmly cling to the surface and also provide reliable adhesion between the adhesive layer and the finishing material. Ordinary glue is not capable of withstanding the load of porcelain stoneware; - Long curing period

. Special frost-resistant tile adhesive used for outdoor use should take longer to harden. This allows you to adjust the position of the slabs after they have been laid; - Temperature resistance

. Although this is a frost-resistant tile adhesive, the mixture must withstand not only low temperatures, but also extreme heat. There are also heat-resistant compounds that are used for heated floors; - Low moisture absorption

. That is, the composition must be moisture resistant. This prevents mold from forming on external walls.

It is worth adding that tile adhesive for exterior use is safe from an environmental point of view. This is due to the absence of asbestos and other harmful impurities in the composition.

Types and features of choosing glue

Each type of adhesive for porcelain tiles has certain characteristics. The following types of adhesives are distinguished:

- Fast-hardening . The composition hardens within 1-4 hours after application, the surface can be used almost immediately after work. However, it is mainly suitable for small areas. Most often the composition is used for cladding walls indoors.

- Universal . The adhesive can be used with different types of tiles for interior and some exterior areas. Not suitable for complex materials and large porcelain stoneware.

- Elastic and highly elastic . The adhesive is used in conditions of temperature changes, as well as when arranging heated floors and walls. Can also be used in damp areas, when mounted on wood or drywall.

- Reinforced . The glue provides maximum fixation of porcelain stoneware. Suitable for large materials for horizontal and vertical cladding.

- Leveling . The composition is used when finishing uneven walls and floors. Smoothes out minor depressions. Can be used on ground floors, when finishing attics and balconies.

- Heat resistant . The composition is used for finishing stoves and fireplaces. Capable of withstanding up to 600 degrees.

- Thick layer . Used when laying large-format porcelain stoneware slabs. Mostly on the floor. The adhesive layer in this case is from 10 mm. There are varieties for interior and exterior use.

- Frost-resistant. A type of adhesive for external cladding. Withstands frost and temperature changes. Can be used for paths.

ValeraThe voice of the construction guru

Ask a Question

If the composition is universal, in most cases it is not suitable for finishing rooms with high humidity or sudden increases in temperature, as in fireplaces and stoves. Elastic adhesives can be used almost everywhere: indoors and outdoors, in swimming pools, ovens, for bonding to concrete, wood and drywall.

Choice depending on the location of work

It is necessary to take into account the purpose of the glue - for external or internal work.

External work areas include terraces, loggias, balconies and verandas, as well as garden buildings and paths. The adhesive for these areas must be frost-resistant and elastic, as well as resistant to moisture. Exterior adhesive must be able to withstand heavy weights to protect against shifting and sagging. Protection from exposure to sunlight will not be superfluous.

Interior adhesive must meet parameters such as strength and elasticity, especially when finishing stairs, corridors and common areas. In humid areas, it is necessary to use compounds with high moisture resistance and protection against fungus and mold. Heat-resistant compounds are chosen for finishing stoves and fireplaces.

When using glue for interior work, it is important to pay attention to environmental friendliness, the absence of harmful substances and asbestos.

Selection criteria depending on tile size

Porcelain tiles are available in sizes from 5 x 5 cm to 60 x 60 cm and more. When using small parts, high-strength and elastic adhesives are rarely selected. Adhesive for large-format porcelain tiles from 30 x 30 cm should provide high adhesion and fixation. Otherwise, the tile will not stay on the surface.

Choice depending on the base

When arranging floors of different types, select appropriate adhesive bases:

- for heated floors – with high elasticity;

- for cladding buildings and paths - adhesive with good frost resistance and resistance to temperature changes;

- for indoor floors - you can use universal glue 0.2-0.5 MPa;

- for complex substrates made of plasterboard, glass, plastic and wood - glue with increased adhesion from 1 MPa.

For rooms with high humidity, as well as for the kitchen, you can use moisture-resistant or universal compositions with moisture-repellent properties.

Varieties

Using tile adhesive for exterior work, you can use it to clad walls with decorative stone, use porcelain stoneware, hyper-pressed brick for cladding and many other materials.

The façade is even finished with tile adhesive followed by decorative plaster. But this is a rather expensive solution, since a lot of mixture will be required. And it's not the cheapest.

When choosing tile adhesive for exterior cladding, pay attention to what type it is. Mixtures are classified according to the following principles:

- Universal

. This is an adhesive for tiling work that is carried out using small tiles. Quite frost-resistant, but in terms of this indicator it demonstrates an average level in comparison with analogues; - Reinforced

. This is a good adhesive for base tiles and heavy trim elements. Characterized by improved adhesion. Can be used when laying in a vertical and inclined plane. Suitable for flooring indoors and outdoors. The coating has increased mechanical strength; - Moisture resistant

. If you are thinking about which tile adhesive is best to use for lining pools, choose this option. The mixture does not swell in water and does not peel off. But it cannot be used under normal conditions; - Frost-resistant

. Has the highest frost resistance. Suitable for external walls, terraces and fences. It is divided into several subtypes, depending on the working surface. These are metal, plastic, wood and concrete; - Heat resistant

. It is used in cases where it is necessary to line a stove with ceramics, or to create a heated floor system; - White

. A special variety that is used for decorative laying of tiles and mosaics.

Based on what work needs to be done, choose the appropriate type of tile adhesive.

Rules for working with tile adhesive

How to calculate the amount of glue

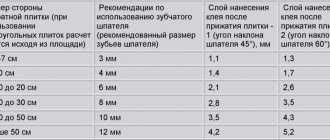

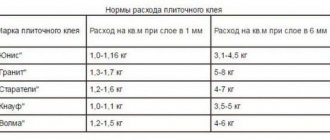

To calculate the adhesive consumption for laying tiles, you need to take into account its size.

| Tile size, mm | Consumption per 1 m², kg |

| up to 25×25 | 1,5 |

| 50×50 | 1,7 |

| 100×100 | 2 |

| 100×200 | 2,2 |

| 150×150 | 2,3 |

| 250×150 | 2,7 |

| 250×200 | 3 |

| 300×300 | 3,4 |

| 450×450 | 4 |

| 600×600 or more | 5,2 |

The required amount of glue is calculated using a simple formula:

y⋅S=x

x – the amount of glue we need (kg);

y – glue consumption per m², depending on the required layer thickness (kg/m²);

S – coverage area (m²).

How to properly dilute and knead glue

To prepare the right tile adhesive you need to know three rules:

- work is carried out strictly at temperatures from +6 to +25°C;

- water should be at ambient temperature;

- the mixture is poured into water, and not vice versa.

The proportions of water and dry mixture differ depending on the composition and manufacturer. The solution should be thick and elastic.

The quality of the solution is easy to check: place the finished glue on the trowel and turn it over - the solution should not drip or fall off.

How to apply tile adhesive correctly

To apply the adhesive to the substrates, you must use a spatula with a serrated edge:

- for small tiles (up to 100×100 mm), use a spatula with a V-shaped tooth measuring 3–5 mm,

- for medium tiles (up to 250×250 mm) – with a square tooth measuring 6–8 mm,

- for large tiles (from 300×300 mm) - with a U-shaped tooth measuring 10–12 mm.

The glue is applied evenly with the smooth side of the spatula with a minimum thickness of 2.5 mm. Then the layer is “combed” with the jagged side at an acute angle (45–75 degrees) to the base. It is important to maintain the same angle throughout the entire area.

Important! There is no need to apply glue to the entire base. The solution dries quickly, so it is applied in parts (under 1–4 tiles).

What thickness of tile adhesive is considered optimal?

The adhesive layer depends on the size of the tile: the larger and heavier the tile, the thicker the layer.

| Tile size, mm | Layer thickness, mm |

| 100×100 | 2,5 |

| 200×200 | 3 |

| 300×300 | 3,25 |

| 600×600 | 4 |

| more than 600×600 | 5 |

Working with tile adhesive is a simple process, but requires skill. By choosing the right composition and following simple rules, even a novice specialist will cope with the task if he works carefully and without haste.

Good luck with your work!

Composition of tile adhesive

As you understand, ordinary cement adhesive is not suitable for laying facade tiles. It can be used, only the consequences of such work will be obvious. And the result is short-lived.

Therefore, it is better to take special glue for concrete tiles, porcelain tiles and other facade finishing materials.

Frost-resistant compounds are divided into 3 categories:

- one-component;

- two-component;

- mixed.

In the first case, everything is clear. This is a ready-made dry mixture, which is diluted with water, based on the manufacturer’s proportions, and used for its intended purpose.

Two-component analogues are created with the addition of polyurethane or epoxy glue. The components are mixed immediately before use. Such additives significantly enhance adhesion performance.

Mixed mixtures may contain various additives, which allows them to obtain certain properties.

When planning to organize a facade using tile adhesive, it will not be superfluous to find out what is included in its composition.

Most mixtures contain:

- Portland cement grade not lower than M400;

- slaked lime;

- fillers;

- cellulose thickeners.

Limestone, quartz sand, as well as dolomite, etc. can be used as fillers.

To further improve the characteristics, the composition includes various plasticizers, water repellents, as well as porosity regulators, additives for controlling the rate of hardening, sealants, etc.

How to choose the right glue

See also

DIY block house: home production technology

When choosing a composition for outdoor work, you should not take the first tile adhesive for outdoor work that you come across.

Be sure to read the information on the packaging. The following criteria are considered key:

- application area;

- Terms of Use;

- type of frost-resistant external glue;

- compound;

- adhesion indicators;

- period of use after mixing;

- number of frost resistance cycles;

- hardening speed;

- instructions for using the finished composition.

Also, some manufacturers write how thick the glue can be.

Additives and additives play an important role. In the best frost-resistant compositions, the proportion of additives and additional components can reach 40% of the total mass.

Here are a few more points you need to know when choosing:

- take into account the cladding material used, as well as the surface on which the mixture will be applied;

- if you take porcelain tiles or stone, use only reinforced glue;

- when using porcelain tiles on an inclined and vertical surface, make sure that the tile adhesive is thixotropic, that is, non-slip;

- for heated floors, it is recommended to take mixtures characterized by increased elasticity;

- the presence of the letter F in the marking indicates the maximum frost resistance of the mixture.

This directly determines how well the purchased tile adhesive for exterior work will cope with the assigned tasks.

Recommended parameters and characteristics

See also

Tile adhesive for exterior use: which is better, composition

I will give an example of what numbers the glue used for outdoor work should correspond to.

This is a kind of norm, below which it is not recommended to fall.

In numbers, the recommendations are as follows:

- suitability of the composition after preparing the mixture from 1 to 8 hours;

- Drying time up to 24 hours;

- temperature operating limits from -50 to 70 degrees Celsius;

- the number of frost resistance cycles is at least 50;

- adhesion when laying on concrete surfaces is not less than 1 MPa after 28 days;

- time for adjusting slabs after laying is 15-30 minutes.

Just keep the following in mind. When work is carried out at outdoor temperatures above 15 degrees Celsius, it is recommended to choose mixtures with a long drying time. If the temperature outside is low, then take a mixture with a minimum hardening rate.

Examples of quality compositions

See also

How to properly furnish a house in the Art Nouveau style: photo

I won’t go into detail about each mixture. But I want to offer a list of high-quality tile compositions that are excellent for external cladding work.

We are talking about the following types of tile adhesive:

- Unis Granite;

- Ceresit CM117;

- Vetonit Ultra Fix;

- Kreisel Schnell Fix 106;

- Rusean Fixator;

- MKU Standard SM5;

- Knauf Fliesenkleber;

- Ivsil Classic;

- VOLMA-Ceramic;

- Bergauf Keramik, etc.

Moreover, each composition has its own characteristics, purpose, and scope of application.

Types of tile adhesive

There are three main types of tile adhesive. They differ in composition:

1. Cement based. The classic composition (as in the USSR, when there was “no glue”): sand, cement and water. What’s new in it are various plasticizer additives, the brainchild of modern industry. These components adapt the adhesive to the difficult conditions in which it must hold the tiles.

2. Epoxy. It consists of two components (epoxy resin plus hardener), which must be mixed and only then will a composition with the desired adhesive properties be obtained. Therefore, when preparing it, you must strictly follow the instructions. This glue has increased adhesion, elasticity and is recommended in rooms with high humidity and for outdoor use.

3. Dispersive. It is a mixture of acrylic base, various binders and artificial resins. It spreads well and has a good grip. Suitable for difficult surfaces: previously painted, with old coatings that were not removed before repair.

Based on these three types, more highly specialized options are already being produced.

- Universal tile adhesive. Suitable for most simple repairs in apartments and private houses. The surface for its use must be prepared as standard: leveled, primed, possibly additionally covered with concrete contact. It is advisable that the size of the tiles does not exceed 30 cm on one side.

- Reinforced, for outdoor use. It is primarily intended for large (size on one side is longer than 30 cm) and heavy tiles. If it is intended to be used outdoors, it must withstand all the vagaries of the weather.

- For use in conditions of high humidity (for example, in high-traffic showers, saunas and baths, car washes). It not only prevents the tiles from falling off under the influence of steam and water, but also contains additives that protect against fungus.

- For the floor . More liquid than that for walls, because it is advisable to lay floor tiles on a mass that spreads well and fills all the voids in the floor, otherwise the new floor will move apart.

- For heated floors. Able to withstand sudden temperature changes, which means it can expand and contract without damaging the tiles lying on top.

- For transparent tiles , mosaics, glass blocks. White or transparent. It is valuable because it provides great design opportunities.