How to glue extruded polystyrene foam

So, let's look at one of the most important questions. If the manufacturer has not written that you need to glue it exclusively with glue and foam, or that installation needs to be done using silicone or bitumen mastics, cement glue, or liquid nails, then you can install it with the glue or foam you want.

The most popular of them are bitumen adhesive Bitumast, adhesive foam Ceresit, TechnoNIKOL, Tytan.

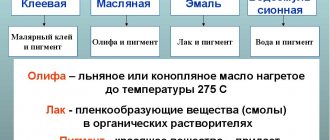

Today the following mixtures are in wide use:

- Multicomponent, consisting of diluted bitumen in a solvent, but have a bad effect on extruded polystyrene foam, since they are not suitable for this material, since they may contain gasoline, acetone and other substances that have a bad effect on this material, eating through small amounts over time holes. Used only for fastening polystyrene foam boards (not extruded).

- One-component adhesive foams do not contain solvents. Most often they contain polyurethane, which does not corrode the insulating material over time. This mixture is a foam that dries quickly in the open air. It is a universal fastener for any type of insulation. One of the highest quality examples of mounting foams from.

Not every building mixture is suitable for attaching extruded polystyrene foam. You need to look for a universal option and also do not forget to look at the composition, since the content of various solvents in the mixture is unacceptable.

Bituminous

Such products are produced on the basis of bitumen (an asphalt-like substance) with the addition of a solvent and plasticizers. The main advantage of bitumen glue is to improve the waterproofing properties of the base. The composition allows you to fix slabs of thermal insulation material, as well as glue polystyrene foam together. The name usually contains “bitumen”, for example, “Bitumast”, “Kerabit”.

High quality of insulation gluing ensures:

- preliminary drying of the base and sanding;

- applying a primer to the wall, thereby sealing unnecessary pores.

Advice! It is better to prefer a primer that contains an antiseptic and fungicides. This will prevent the development of mold and fungi under the slabs of thermal insulation material.

The glue is spread with a comb spatula in a continuous, thin layer. Within 20 minutes after connecting the wall surface and the insulation, additional pressure will be required, for example, using spacers.

Features of material installation

For insulation and thermal insulation of facades from the outside of the building, as well as rooms from the inside, different types of construction finishing are suitable. The finishing material is polystyrene foam boards, which are available in various parameters, dimensions and thickness. The slabs can be attached to various surfaces, including metal and concrete. For this purpose, special glue for polystyrene foam boards is used.

Note! A suitable adhesive composition for polystyrene foam must have properties that could ensure high-quality adhesion and durability of fastening between materials.

Both domestic and foreign brands are engaged in the production of adhesive for polystyrene foam.

There are special types of adhesive for polystyrene foam: for external use and for internal use.

The choice of a suitable installation adhesive for polystyrene foam insulation should be based on the following important features:

- Ensuring the quality and reliability of adhesion between polystyrene foam and the base, price is not the main indicator in this case.

- Construction adhesive, especially for exterior finishing, must be resistant to temperature changes, precipitation and other environmental factors.

- In terms of composition, the selected adhesive must be environmentally friendly, especially intended for interior decoration. If this feature of the product is not taken into account, then in the future, glue evaporation may negatively affect the health of people who live or are often in the room.

- Convenience and ease of installation and fastening of polystyrene foam boards with glue.

If you look at the products offered by construction stores, not all of them will meet the listed requirements. Therefore, often the installation of thermal insulation boards with the adhesive proposed by experts becomes significantly more complicated.

It is not enough to simply choose a suitable and high-quality composition; you need to take into account the specifics of working with glue for exterior finishing.

If a cement or bitumen mortar is selected, it is applied as a permanent layer over the entire area of the slabs. Before fastening, the base must also be prepared to increase adhesion. Therefore, it is necessary to eliminate any contamination, residues of other substances and materials, and apply a layer of primer.

If foam adhesive is chosen for the work, then it is necessary to apply the composition along the perimeter of the slab and in zigzag lines through the center.

Advice! If excess adhesive appears on the finishing surface, only after complete hardening is it carefully removed. If the chosen solution turns out to be long-drying, then it is better to secure the finish with supports.

How to apply glue

Cement adhesive mortar is applied to the surface of insulation boards in different ways, depending on the unevenness of the base. Beacon is used for wall unevenness of 5 mm or more. The mixture is distributed around the perimeter of the slab and laid out with several beacons in the center. Solid is used on surfaces with unevenness up to 5 mm, using a notched trowel. In both cases, the surface of the mineral wool insulation is pre-primed with a thin layer of the same adhesive solution. After installing the element, excess glue extending beyond its contour is removed.

After installing the slab in the design position, the adhesive contact area must be at least 40% of the bonded surface. Photo: KNAUF

To create a protective reinforced layer, the glued insulation is covered with a plaster-adhesive composition 2–3 mm thick. Then the fiberglass mesh sheets are embedded in it and the mixture is applied again to a thickness of up to 3 mm, smoothing it so that the mesh is not visible. Surface unevenness is leveled with an abrasive float after 24 hours.

The process of insulating a façade with finishing with a thin layer of plaster

7 photosThe base is cleaned, uneven areas more than 10 mm deep are filled with leveling solution. Photo: TECHNONICOL

Apply primer. Install the support base. Since the unevenness of the base is less than 3 mm, a continuous method of applying a plaster-adhesive composition to the insulation is used. The composition is distributed over the entire surface of the slab, with a distance from the edge of 20–30 mm, using a notched trowel (tooth size 10–12 mm). Photo: TECHNONICOL

The slab is applied to the wall, pressed with a long float, and checked with a level. Photo: TECHNONICOL

After the glue has dried, the insulation boards are fixed with dowels and the corners of window and door openings and the corners of the building are reinforced. Photo: TECHNONICOL

The insulation is covered with a layer of plaster-adhesive mixture, a reinforcing fiberglass mesh is embedded in it and smoothed with a spatula. Photo: TECHNONICOL

After the layer has dried, the surface is sanded, primed, and then decorative plaster is applied. Photo: TECHNONICOL

If necessary, paint. Photo: TECHNONICOL

Overview of adhesives

All adhesives are divided into two categories: for interior and exterior use. They differ in their constituent components and basic properties. Available in different forms: dry and ready-to-use. May vary in color and consistency.

But one common characteristic for any composition is the absence of solvents among the main components due to the fact that they, in contact with the insulation, can burn through it.

Adhesive foam is often used for outdoor work due to its maximum ease of use. The substance is made from successfully combined ingredients that allow high-quality, reliable and quick gluing of polystyrene foam. You need to take into account the speed at which the glue hardens when working and purchase it better for one-time use.

Dry compositions can be used repeatedly, simply separating the required portion as needed.

Important! According to experts, when there are various damages or unevenness on the surface for the installation of polystyrene concrete slabs and expanded polystyrene, it is better to choose dry mixtures.

Polyurethane foam adhesive in the form of foam is available in convenient cans and is suitable for outdoor work. Thanks to such cylinders placed in construction guns, it is much easier to apply the material to sheets of polystyrene foam.

The glue does not require the use of supports for the slabs, as it hardens very quickly. After a couple of hours, it gains the necessary strength.

Note! Among the numerous brands represented on the Russian market, products of the Knauf, Ceresit, and Berg brands are distinguished by their high quality and reliability. They managed to create a good reputation for themselves and win the trust of customers.

All adhesives intended for working with polystyrene foam are available in 2 consistencies - dry and polyurethane solution.

There are also universal products and highly specialized substances. The first type has the widest range of use. In addition to its main function, it can serve as an analogue of the substance for reinforcing slabs with mesh. But these compositions also have a significant drawback - the quality characteristics are at an average level. Thanks to its quite affordable price, this disadvantage is compensated. To ensure more reliable and long-term fastening, you need to choose adhesive mixtures for a specific purpose.

On the video: How to glue polystyrene foam boards, instructions for working with Ceresit CT 83.

For outdoor use

Bitumen adhesive is ideal for insulating facades with polystyrene foam. It contains a solvent, but it is not dangerous for polystyrene foam boards. The composition is sold ready for use; it must be applied to both surfaces, that is, to the base and the material itself.

The second most popular glue is cement, for working outdoors. It is used if the base is brick, concrete, or cinder block. It is also used for installing ceiling tiles.

Cement adhesive is sold in dry form and is diluted with water in appropriate proportions for use.

The disadvantage of working with cement glue is the loss of time diluting the composition to the required consistency. However, this does not reduce its relevance.

In room

If it is necessary to carry out finishing work indoors, then polystyrene adhesive is often used for interior work.

Adhesive for indoor use must meet the following requirements:

- High quality coupling.

- Absence of harmful and toxic components.

- Resistant to temperature changes.

- Thick consistency to eliminate the possibility of drips.

- High installation speed.

In those rooms where there is low humidity and above-zero temperatures, you can use PVA glue.

Which plaster should you choose to use:

When you begin work, you need to figure out what types of plaster you will use to complete the foam plaster work.

In construction practice, these types of solutions differ:

- Mineral plaster.

It is made of cement and various polymer additives. It practically does not absorb moisture, resists fungi and mold, is easy to work with new craftsmen, the price is low, which makes it an ideal finishing material. - Acrylic plaster - with a high degree of elasticity, excellent resistance to unpleasant environmental factors and ultraviolet radiation.

It is recommended that this mixture be used in areas with high humidity because cement does not withstand moisture.The price of acrylic is higher than cement.

- Silicate mixtures are effective, elastic, have good antistatic properties, vapor permeability, and resistance to precipitation.

It can be used for interior and exterior decoration.

Pay attention to the choice of gypsum, which is the best quality in acrylic compounds. The latter are resistant to silicate mixtures, even less resistant mineral ones. You should know that texture affects texture - more textured plasters that are environmentally resistant

You should know that texture affects texture - more textured plasters that are environmentally resistant.

alabaster

Popular plaster manufacturers:

The construction market offers a wide range of mixtures suitable only for penoplex.

In addition, one manufacturer may offer several items. Some of them serve to connect panels, while others perform protective functions

Your attention is drawn to the characteristics of the most famous manufacturers:

- The Ceresit mixture must be additionally colored.

The acrylic mixture is UV resistant and silicone durable. All products are of high quality and reliability. - Ecomics mixtures are designed for use indoors and outdoors. Resistant to high humidity, environmentally friendly. But the end cannot be completed during the cold period when the temperature indicator drops below 7 degrees. With their help you can eliminate cracks, marks and deformations.

- Stolit mixtures.

The products use the highest quality cement with the addition of stabilizers and modifiers, which allows the material to be used at low temperatures.

Characteristics and consumption

According to experienced craftsmen, polyurethane foam and adhesive putty for painting are considered the most economical in consumption.

Related article: Tile adhesive for exterior use: features, varieties and tips for quality installation

To calculate the required amount of glue for purchase, you need to know its average consumption, which is determined by many factors, including the type of product, purpose, and manufacturing technology.

Dry mixtures are consumed on average 0.5 kg per 1 m². Bitumen adhesive has a higher consumption of 0.8 kg per 1 m². Polyurethane glue is the most economical, 1 can is enough for 10 m².

Bergauf ISOFIX

Bergauf ISOFIX adhesive mixture consists of cement binder, mineral filler, sand and modifying additives.

Used for external and internal work, mixture consumption for a layer of 3 mm is 4-5.5 kg per m2 of insulation. The finished composition must be used within 90 minutes, and glued slabs must be adjusted within 25 minutes. The compressive strength of the adhesive after 28 days is 7.5 MPa, and the bending strength is 3 MPa.

The composition is suitable for almost all substrates, including drywall, bag weight 25 kg.

TechnoNIKOL No. 500 balloon adhesive is practically no different in its characteristics from Tytan Styro 753 GUN, although it costs a little less.

Use extruded polystyrene foam for the intended purpose provided by the manufacturer and do not buy unknown but cheap adhesives for its fastening - this is the road to losses, and not the path to savings.

Rating of the best adhesives for polystyrene foam

| Nomination | place | Name of product | price |

| Rating of the best adhesives for polystyrene foam | 1 | Ceresit CT 83 Strong Fix | 509 ₽ |

| 2 | Tytan Styro 753 GUN | 457 ₽ | |

| 3 | Knauf Klebenspachtel | 250 ₽ | |

| 4 | Prospectors Teploizol | 386 ₽ | |

| 5 | Ceresit Express CT 84 | 560 ₽ | |

| 6 | TechnoNIKOL Professional | 30 ₽ |

Ceresit CT 83 Strong Fix

Rating: 4.9

The first place in the ranking is occupied by a product from the German concern Henkel. It produces building materials and solutions under the Ceresit brand. The adhesive is designed for extreme conditions and has high adhesion. In reviews, users report that when checking the load-bearing capacity, the rupture always occurs in the material. The glue is prepared in 5 minutes by simply mixing with water. The solution allows steam to pass through, so moisture will not accumulate in the room. Excess traces of the mixture can be easily removed with water. Plastering the surface is allowed three days after installation. The substance can be used to create fire-resistant cuts, since it is not subject to combustion.

Our experts included the glue in the rating as the best for installing thick polystyrene foam slabs on the outside of the house facade. It is allowed to work with the mixture even at an outside temperature of 0 degrees, only then it is necessary to use warm water (+30 degrees) to prepare the glue. With this substance it will be possible to attach high-quality sheets of polystyrene foam, 200 mm thick, and strong winds will not tear them off.

Tytan Styro 753 GUN

Rating: 4.8

In second place in the ranking is adhesive in the form of polyurethane foam. It is produced in a cylinder with a capacity of 750 g. To apply it, construction guns are used, into which the cylinder is inserted upside down. With this technology, the process of installing polystyrene foam occurs 5 times faster than when diluting the solution and using trowels and graters. But the height of the foam does not exceed 5 mm, therefore, when installing polystyrene foam boards outside, where they will be exposed to wind and precipitation, additional fixation with dowels is required. But this can already be done 2 hours after gluing, which the craftsmen like in the reviews.

According to our experts, the product deserves a place in the ranking of the best for its cost-effectiveness. Unlike loose mixtures applied 50 mm wide along the perimeter of a sheet of polystyrene foam, glue in the form of a thin strip 10-15 mm wide is sufficient. Therefore, one balloon can fix polystyrene foam over an area of up to 8 m². It is also convenient to transport the sealant to the installation site due to the compact container.

Knauf Klebenspachtel

Rating: 4.7

The third place in the ranking is occupied by a product from a German manufacturer. The adhesive mixture is available in dry form and diluted with water to the desired consistency. The glue is supplied in packages of 25 kg. Has high adhesion to hard and soft materials. Can be used simultaneously for fixing expanded polystyrene and mineral wool (in areas protected from flame transfer). The solution is suitable for use inside the house or for finishing the facade. Buyers in the reviews like that the glue is suitable for any type of polystyrene foam, both regular and extruded. In the solution itself, air pores make up 13-15%, so the composition is durable and prevents it from falling off the wall.

We added the product to the rating because it can be machine applied to walls. For this purpose, G4 or Monojet pumps are used. This significantly increases productivity on large-area facades. Glue can be used to reinforce polystyrene foam, fixing a special mesh onto it for plaster mortars. The thermal conductivity of the binder itself is only slightly higher than foam plastic and is 0.047 W/m*K.

Prospectors Teploizol

Rating: 4.6

The fourth place in the rating is given to Russian glue for polystyrene foam, also produced in the form of a dry mixture. The package contains 25 kg of fine powder, diluted with water in a ratio of 250-300 ml per 1 kg. If you need to knead a large volume at once, then 6-7 liters of water per bag is enough. Glue can be used to fix foam of any thickness, as well as strengthen the surface for subsequent finishing. External use on facades is permitted. If repairs are not planned immediately, the product can be stored in its original packaging for up to 12 months.

Our experts included the glue in the rating for its reduced consumption, although this indicator depends on the skill of the master to apply the composition to the polystyrene foam board. With practice, you can reach a figure of 3-4 kg per 1 m² (with trowel teeth 1.0-1.2 cm), which is twice as economical as German brands. We also noted the viability of the solution for 3 hours. Thanks to this, wall finishing work can be carried out slowly and excess traces of glue can be easily removed with a wet rag.

Ceresit Express CT 84

Rating: 4.5

In fifth place in the ranking is another German product from the company Ceresit, but now in the form of polyurethane foam. The substance consists of polyurethane and flammable gas, squeezing the material out. The product can be used at air humidity up to 90%. The adhesion index to concrete is 0.3 MPa. But in terms of consumption, the glue is inferior to other participants in the rating - one cylinder is enough to cover about 6 m² with polystyrene foam. Buyers note in reviews the ease of use of the product - the glue is shaken for 30 seconds and screwed onto the gun. The application is carried out crosswise on the slab, as well as along the perimeter, with a strip width of 5-10 mm. You can adjust the insulation within 20 minutes. Excess traces can only be removed with solvent.

Our experts noted the product in the rating as the most resistant to low temperatures. Installation is allowed even at -10 degrees, which makes it possible to insulate the facade even in winter. Under such extreme construction conditions, curing takes 7-10 hours. In summer, the glue sets in 2 hours.

TechnoNIKOL Professional

Rating: 4.4

In sixth place in the ranking is a domestic product in the form of a sealant in a cylinder. The adhesive consists of one-component polyurethane foam and is suitable for all types of polystyrene foam. Installation can be performed at temperatures from 0 to +30 degrees. Experts in the reviews advise that after applying it to the slab, you need to wait a minute for the foam to expand a little, and then press the foam against the wall using a long profile. Once cured, the adhesive is resistant to water and mildew. The material has no aging effect. You can adjust the insulation within 20 minutes after fixing it in order to achieve minimal gaps between the slabs and ensure the evenness of the blocks.

Features of popular adhesives for penoplex

Extruded polystyrene foam is used for external and internal work. For exterior work, cement-mineral based adhesives are mainly used. To ensure that the material is securely fastened, special umbrella dowels are additionally used. For interior work, adhesive polymer and polyurethane compositions work best. We will tell you about some of them.

Penoplex glue “Fast fix” – polyurethane glue. It glues penoplex to any surface: stone, wood, concrete, aerated concrete, plaster. Metal cylinders with a volume of 750 ml, in which glue is produced, are very convenient for application using a mounting gun. The adhesive composition has high adhesion to any building material.

A 750 ml bottle is enough for sizing 6-10 square meters of extruded polystyrene foam. The adhesive is used for external work on insulating foundations, plinths, walls, as well as internal thermal insulation of premises and finishing balconies. The glue sets within a few minutes but dries within 24 hours.

One of the representatives of polyurethane glue is “Tytan Styro 753.” The glue dries within 2-3 hours. Economical consumption of glue is considered an important advantage of the adhesive composition. The glue does not emit toxic substances and is harmless. It is applied quickly and easily and does not require dilution. Adheres to any building material. Helps level the slab in three planes.

Before filling the cylinder into the mounting gun, you must shake it for at least 15 seconds. When pulling the trigger of the gun, hold it upside down. Apply glue to polystyrene foam boards along their perimeter: along the edges, retreating 2 cm and in the center. After spreading the adhesive, you need to wait 1 minute for it to set (but no more than 5 minutes). Next, press the extruded polystyrene foam onto the facade. The fastening to the walls will be reliable because the glue is of high quality.

TechnoNIKOL adhesive foam is intended for thermal insulation of house facades, basements, balconies, the inner surface of the roof, external walls and walls inside the building, sealing cracks between foam boards. A 750 liter can treats 10-12 square meters of polystyrene foam boards. Displacing gas is propane. Adhesive foam based on polyurethane foam reliably adheres to various building materials: wood, plaster, OSB boards. The glue is moisture-resistant, has antiseptic properties: it protects the material from mold, aging, and fungus.

To install extruded polystyrene foam, before using TechnoNIKOL glue, the surface of the structure is scratched with a notched trowel or a hacksaw for better adhesion. The glue is shaken about 20 times, loaded into a mounting gun and applied in strips along the contour of the board being glued and in the center, retreating 30 mm from the edge.

Important! Before applying the foam, both surfaces: the structure and the polystyrene foam board are moistened.

After applying the foam to the penoplex, you need to wait 5-10 minutes to increase its volume. Next, press the plate to the gluing zone. Dowels can be used for additional fastening only after the glue has hardened. Excess glue is cut off with a sharp knife. To ensure that the edge of the extruded polystyrene foam boards is even, beautiful, and smooth, the cut is cleaned with coarse sandpaper. TechnoNIKOL is inexpensive - only 325 rubles per cylinder.

"Ceresit TsT83" is used to strengthen the insulation of the external walls of the house. This is a mineral-cement adhesive mixture that has high quality adhesion of the material to various surfaces: concrete, aerated concrete, expanded clay concrete and ceramic blocks. It is stirred with water. Consumption of dry mixture is 5 kg per square meter. This adhesive composition is resistant to low temperatures.

Therefore, you can work with it at temperatures from zero degrees. The adhesive composition not only firmly adheres to the surfaces of the insulation and facades, but also protects against exposure to moisture and aggressive environments, including salts. The cost of a 25 kg glue package is 450 rubles.

Adhesive for extruded polystyrene foam "Bitumast" has high-quality properties. High adhesion with building materials such as concrete, brick, metal, wood and others allows you to thoroughly insulate a house with penoplex. The adhesive is based on modified bitumen.

It also contains a plasticizer, filler and a special solvent that does not destroy extruded polystyrene foam. Using this composition, especially bitumen, it is possible to glue thermal insulation blocks to external walls. And the absence of harmful and toxic substances in its composition makes it possible to process penoplex for cladding the internal surfaces of the house.

This glue also has waterproofing properties: it protects the joints of the building walls from moisture. Bituminous adhesive can be used on vertical, horizontal and sloping surfaces. Glue for extruded polystyrene foam "Bitumast" firmly glues polystyrene foam boards to each other. It has high strength characteristics and operates in any climatic conditions.

Glue consumption is half a liter per square meter. Work on gluing insulation can be carried out at a temperature not lower than +5 degrees. If you need to glue polystyrene foam at subzero temperatures, you must preheat the glue. Breeding "Bitumast" is easy. Just add water and stir the mixture for a few minutes.

No special tools or equipment are required. You can do without a mixer, but if you want the mixture to be free of lumps and have a uniform consistency, then it is better to use a mixer. The disadvantage of glue is its long drying time - within 24-48 hours. Therefore, to prevent the foam sheets from moving, you need to hold them with your hands or put a weight on them. "Bitumast" has a liquid consistency. It must be applied in a thin, even layer. In order for the foam boards to stick effectively, you need to thoroughly clean the surface of dirt, dust, ice, and rust.

The surface of the structure must be thoroughly dried. For better adhesion to the surface, it is better to treat it with a bitumen primer. If you apply glue to metal, you should use a special brush to remove rust from the surface or use a “Bitumast” rust converter.

If polystyrene foam boards are subject to loads, then it is better to use supports when gluing them for better and reliable adhesion of the surfaces to each other. Bitumen adhesive is packaged in 2l, 5l, 21.5l, 210l. The cost of glue is 2l - 150-250 rubles, 5l - 580-650 rubles. The price of a 21.5 liter package ranges from 1500 to 1700 rubles.

Types and brands of adhesives

For gluing are used:

- dry (powder, plaster-adhesive) and ready-made liquid mixtures;

- liquid Nails;

- adhesive foam (polyurethane);

- sealants.

Dry (powder)

These are plaster and adhesive mixtures. Packaged in large bags up to 30 kg per package. To prepare, the powder is diluted with water in the proportions specified in the instructions. The composition is based on the inclusion of cement, gypsum and polymer components. Externally, the powder is similar to putty or plaster, but the gluing result is more durable.

Suitable for indoor and outdoor use. Adhere well to concrete, wood and other substrates. Used as a seal for cracks, joints and seams. Consumption per 1 m2 ranges from one and a half to two kilograms.

For a reliable result, the walls are processed before gluing: they are cleaned of dirt, dust, dried and primed.

When diluting the powder with water, the liquid is added gradually in small quantities, and the water itself is constantly stirred. This will prevent lumps from forming. Application is possible in a continuous layer over the entire surface or in separate lines with a small distance between each.

Powder adhesives:

- Ceresit ST-83;

- Knauf Perlfix;

- Avangard-K;

- Primus;

- Volma";

- Armierungs-Gewebekleber.

Avangard-K allows gluing not only to concrete, but also to brick walls. Packaging 25 kg in one package. There is a frost-resistant option for the street.

Another Bergauf ISOFIX cement-sand mixture, which contains fillers and special additives, plasticizers. Apply a layer up to 3 mm thick. After mixing the solution, it can be used for one and a half hours, and the position of the EPS can be adjusted for a quarter of an hour. Can be used indoors and outdoors.

Polyurethane adhesive foam

Polyurethane adhesive in the form of foam (foam glue) connects all types of plastic, including polystyrene foam, with any substrate (OSB, metal, concrete, plaster, wood, aerated concrete and foam blocks). You can glue the foam together.

There are specialized formulations on the market. They are marked with an inscription on the packaging (for polystyrene foam).

The gluing plane is not important. Both horizontal and vertical surfaces are glued. The connection holds firmly both indoors and outdoors.

Installation is possible only with a construction gun, on which a cylinder is placed on top of the legs. The application technology is shown in the figure.

It is convenient to use foam adhesive. The work is done quickly. Has low consumption per sq. m. The cylinder is enough for 10-15 m2. Foam adhesives are resistant to moisture, do not freeze, and have high adhesion.

There is no need to prepare, the cylinder is ready to use. The maximum result of the coupling is evident after half an hour, while pressing the parts is enough for only 20 seconds.

Popular brands:

- Tytan Styro 753;

- Penosil;

- Ceresit CT-84 Express.

PVA

PVA is cheap, so it is often chosen for gluing extruded polystyrene foam (EPS). The reliability of the adhesion is not the highest, so it is more suitable for gluing crafts. It is better to give preference to specialized mixtures.

PVA fills voids in walls well. Additionally, foam plates are attached to dowels. Usually PVA is applied in two layers.

Suitable polyvinyl acetate adhesives include Moment Stolyar and PVA-MB.

- Moment Joiner. Universal composition for repair. Supplied in packages of different volumes, from 100 g to 30 kg. The drying time is fast and the seam is reliable. It does not destroy the structure of polystyrene.

- PVA-MB.The composition contains special plasticizers that improve the quality of adhesion. The hardening time of the seam is longer than that of conventional PVA.

Polyurethane foam

An effective composition, but it has another purpose - sealing seams, cracks, strengthening concrete structures.

If you glue with polyurethane foam, the following consequences may occur:

- the foam after complete drying increases in volume, which can damage the foam and deform the entire structure;

- Foam can increase in volume in different ways, so voids form in some places and the thermal insulation properties decrease.

Polyurethane foam has a high consumption per square meter. m of surface, which increases the cost of gluing.

Recommendations for use:

- make sure that the foam is suitable for gluing foam and does not destroy it;

- install the polystyrene itself with a different composition;

- seal the joints with polyurethane foam;

- the foam dries quickly, so you need to work in the same way;

- Reducing consumption is possible with a glue gun.

Liquid Nails

They have a high price, but the gluing result is very high quality. The best choice would be specialized polyurethane adhesives.

Liquid nails have an optimal balance of qualities (ease of use, service life, adhesion). Polystyrene foam attaches perfectly to polystyrene foam, metal, plastic, concrete, wood, and other materials.

Professionals recommend gluing metal using a combination of liquid nails and polyurethane mixtures.

Increasing adhesion to the surface is achieved by preparing it: cleaning, degreasing, priming.

the high price causes the use of nails only on small bases.

The most popular composition is “Moment Montage”.

Types of adhesive compositions for penoplex

There are the following types of glue for extruded polystyrene foam:

mineral (cement);- gypsum;

- polymer;

- composite;

- polyurethane;

- waterproofing.

Mineral and gypsum are the most popular types of adhesives because they are inexpensive and firmly adhere the flooring material to the insulated surface. This type of adhesive composition is used for both external and internal work. But they also have disadvantages. If the humidity is high, cement or plaster hardens quickly, so they need to be diluted in small portions and used immediately. The glue is applied to dry surfaces of any material: wood, metal, concrete and others.

Polyurethane and polymer adhesives are very viscous. They are in second place among materials in terms of adhesion to the surface; in terms of adhesion quality they are surpassed only by mineral adhesive mixtures.

Polymer adhesive mixtures are harmless and do not emit toxic substances. They can glue any materials for a long time. They have high strength characteristics. After the polymer glue dries, a dense crust forms. It is ideal to use polymer glue for exterior work and for gluing penoplex to the ceiling. The fact is that extruded polystyrene foam needs to be glued to concrete, and as you know, concrete adheres poorly to solutions.

Polymer adhesive has high adhesion to any building material, including concrete. Polymer adhesives harden quickly, making them difficult to use. It's important to have more glue just in case. It is best to entrust the installation of penoplex using polymer glue to a professional.

Such adhesive compositions are produced in finished form and distributed in tubes. If polymer adhesives are used for interior work, the room should be ventilated for 2-3 days due to the unpleasant pungent odor of the product. Polymer types of glue include “Moment” and “Emphikol.” They try not to plan interior decoration for the winter, because the pungent, corrosive smell does not disappear for a long time. And opening windows for a long time in winter is undesirable.

Polyurethane glue has a different structure, but is used for the same work. The glue has the form of foam. It is sold in cans. To use polyurethane adhesives, a mounting gun is used. The can is loaded into it and then applied to the stove.

Waterproofing adhesive is created on the basis of bitumen. Assembly bitumen adhesive is a plaster-adhesive mixture. Bitumen is added to it. It has astringent properties, so it reliably fastens polystyrene foam slabs, adhering them to the surface of walls, ceilings, and floors for a long time. The reflective hydrophobic properties of bitumen help protect the connections between the exterior walls of a home. The waterproofing properties of bitumen glue protect the walls of the house from moisture.

Bitumen glue is prepared quickly and easily. Water is added to the plaster-adhesive mixture and beaten using a mixer.

Polystyrene foam adhesive review

In this paragraph, we will consider popular construction adhesives for insulation from two manufacturers - Ceresit and Technokil. Since they were written about above, in this review we will consider only the advantages and disadvantages of both, as well as their prices.

Ceresit CT84 is a universal adhesive foam suitable for both the construction of new buildings with insulation and the insulation of existing ones. The best properties of this glue are its excellent adhesion to polystyrene foam and cement plastered walls, but they must first be degreased and cleaned of bitumen and dust. The glue has received excellent reviews among many builders due to its high moisture and frost resistance. The cost of one 0.75 liter foam cylinder is approximately 700-800 rubles.

TechnoNIKOL is an excellent foam for insulating rooms. Designed for fastening slabs of extruded polystyrene foam and ordinary polystyrene foam to the base for thermal insulation of external and internal walls of a building, roofs, basements, foundations. Just like Ceresit, it is suitable for both houses under construction and already built ones. Can be used at temperatures from 0 to +40 °C. The price for one cylinder is about 700 rubles.

Selecting adhesive for extruded polystyrene foam

How to glue polystyrene foam? To fasten the slabs, you can use different means that have different components. But there are specifics to using mixtures. So, it is better to use one for gluing to a concrete base, another for attaching to a brick wall, and another for winter work. There are adhesives that combine the properties of fastening material and insulation and have low thermal conductivity.

Before purchasing, it is important to clarify that the product contains no substances that corrode polystyrene foam. This:

- acetone;

- alcohol substitutes;

- toluene;

- esters;

- other solvents.

The ideal option is to purchase specialized formulations, because their manufacturers have already taken into account all the important points. There are three main types of products that are suitable for gluing material. This is a plaster-adhesive mixture of different brands, polymer adhesives and bitumen glue (mastic).

People often use “liquid nails” in a bottle, silicone sealants, frost-resistant tile adhesives, drywall and tile products for gluing materials. Can I use them? Experts say that the use of such adhesives is possible, especially if additional fastening of the structure with dowels is planned. But the cost of the work can be much higher, so it is better to buy products designed for XPS.

How to prepare glue

To prepare the glue, you need to have with you two buckets or any other container of similar sizes (one is needed for water, the other for glue), a special tool for mixing the glue or any available material suitable for this matter, and therefore the mixture itself for gluing polystyrene foam boards .

We will proceed from the calculation of 5 kilograms of glue; as an example, we take the mixture for gluing polystyrene foam boards.

This glue is also perfect for internal insulation.

So, now let's look at how this is done in more detail:

- We need to pour water into a bucket prepared in advance for this. Many will have a corresponding question - how much water is needed to prepare the adhesive mixture? To prepare bags of glue weighing 25 kilograms, only about 5-6 liters of water are needed. From this we can assume that 0.2-0.24 liters of water are consumed per 1 kilogram. Therefore, you need to pour approximately 1.2-1.3 liters of water into the bucket.

- Weigh 5 kilograms of dry glue mixture. For the first time, it is better to weigh it and pour it into a convenient container, so that later it will be more convenient to find the desired proportion using this container. Knowing how much glue is in the container, it will be easier for us to calculate the required amount for preparation. Afterwards, gradually add the dry glue mixture to the water and thoroughly mix the glue with water. The adhesive mixture must be mixed so that there are no lumps or various debris, otherwise the procedure will be of poor quality.

- Now you need to let the adhesive mixture sit for 5-10 minutes, but it is better not to keep it longer than this time, otherwise the adhesive mixture will begin to thicken. All this is necessary so that the remaining lumps completely dissolve.

- Mix the glue again just in case, since sometimes even after the above steps small lumps may remain.

How can I glue foam?

There are several proven adhesive compositions suitable for gluing foam parts to each other or to other materials. The choice of adhesive depends on the type of foam, as well as the desired strength of the seam after gluing.

For work, you should use adhesive compositions that do not contain organic solvents, since substances of this group destroy polystyrene.

List of adhesives for foam plastic:

- one-component polyurethane adhesive (“Titanium”, “Dragon”);

- dry adhesive mixtures (“Ceresit-CT83”);

- polyurethane foam;

- liquid foam (“Penosil”);

- polyvinyl acetate glue (PVA);

- hot melt glue (a heating gun is required to work with it);

- solvent-free liquid nails for latex-based polymer materials (LN-604 or Macroflex MF 190);

- two-component epoxy compositions (“Ceresit”);

- acrylic compositions (“Ultima”);

- bitumen mixtures (“Bitumast”).

How to glue foam parts together?

In practice, several means are used to glue foam or penoplex parts together. They differ in seam strength, polymerization period, and cost.

PVA glue is suitable in cases where a high-strength seam is not required, for example, when making foam plastic models or for children's creativity. It is very important to wait until it dries completely, which occurs within 24 hours.

Titan glue is several times stronger, so it can be used in construction and installation work for fixing penoplex blocks to the wall or to each other.

Other means for gluing foam plastic and penoplex: polyurethane foam “PUTECH”, “Slavia”, “Penosil Polystirol FixFoam”, as well as hot-melt adhesive heated with a glue gun. The advantage of these materials is quick drying, which allows you to shorten the period of fixation of fragments.

How to glue the material to paper or wood?

Sometimes you need to glue foam letters to paper or a wooden stand. A composition based on polyvinyl acetate is best suited for this. It is ideally compatible with wood, paper and foam. PVA glue dries slowly, so letters or other glued parts should not be touched during the day. Also, foam glues well to wood using wood glue. One of its options, casein glue, can be prepared independently from low-fat cottage cheese, guided by the material “How to make casein glue from cottage cheese with your own hands at home?”

Stages of work:

- sand the wood and foam in the area of future gluing for better adhesion;

- Clean the surfaces well from dust using a brush;

- apply glue around the perimeter of the part and in its center;

- combine the fragments and leave until completely dry;

- remove excess dried glue using a utility knife.

Bonding to metal

You can use expanded polystyrene to insulate a door or walls in a garage made of metal, as well as the inner surface of a roof made of corrugated sheets. Which fixation method is suitable for these purposes? Strong adhesion can be achieved using Dragon glue. This universal polymer glue costs about 70 rubles. for 500 ml. It is frost-resistant and does not contain flammable components. Before applying it, you should dry the surface thoroughly and make sure there is no condensation on it.

Foam blocks are smeared with glue and pressed against the metal for several minutes. This time is enough for the foam to stick to the metal, but complete stabilization of the adhesive composition occurs after about a day.

The gluing process will proceed faster if you use liquid nails. They set quickly, but the seam is less strong than when gluing with “Dragon”. This problem can be solved by using both adhesives at the same time. “Dragon” and liquid nails are applied pointwise to the insulation in different places. Due to the quick drying of liquid nails, the foam will quickly attach to the metal sheet, and it will not need to be fixed until the more durable “Dragon” has completely polymerized.

How to glue the fabric?

You can glue the fabric to the polystyrene foam or cover it with turns of twine or woolen thread using several compounds. PVA and hot melt adhesive are well suited for these purposes. Both materials, after drying, form a transparent and invisible seam. If immediate fixation is required, it is better to use hot glue. PVA takes longer to dry, about a day, but it allows you to achieve a stronger connection than hot glue.

Adhesive foam

The peculiarity of polyurethane foam is its very fast setting, which occurs within ten minutes. One can of foam adhesive is enough to cover an area of 10 m2 with insulation, which is equivalent to 25 kg of an ordinary mixture.

Popular compositions of this group:

- Tytan Styro 753;

- "TechnoNIKOL";

- Ceresit CT 84.

The foam must be applied to the thermal insulation, departing from the edges by approximately 10 cm, as well as diagonally across the slab. After this, the insulation must be placed on the wall. The same foam or joint sealant is placed in the remaining gaps between the plates.

High-quality adhesion of the material can be achieved if the surface is carefully prepared for application of the composition.

Consumption per 1m2

Calculation of consumption per sq. m. is needed to determine the required amount of material to purchase. It is impossible to calculate the exact amount. This is influenced by factors:

- material, its density and ability to absorb;

- consumption of a specific type and brand of mixture.

The average data is shown in the table.

Type of compositionConsumption

| Dry | 500 gr. / m² |

| Bituminous | 800-1000 gr. / m² |

| Polyurethane | 1 cylinder per 8-10 m² |

Useful tips

Several recommendations for choosing material and gluing technology:

- before purchasing, check the composition of the glue and make sure there are no components that destroy polystyrene;

- buy glue with a small reserve in case of possible overuse;

- pre-test the adhesive composition on an unnecessary piece of foam;

- for better adhesion, sand the surface of the polystyrene foam with sandpaper, walk over it with a needle roller or make notches;

- on large parts, glue should be applied around the perimeter and pointwise, in several places - along the inner surface;

- When gluing with polyurethane foam, leave the fragments under pressure until completely dry.

I hope the material presented is enough to glue foam in any situation. The next video is about how to use hot melt adhesive to join polystyrene foam.