Composition and properties

When choosing any building mixture for high-quality repairs, the consumer usually pays attention to its properties and chemical composition. The quality and durability of the finish will directly depend on this. The fact is that not all substances can contact each other and provide strong adhesion.

The presented tile adhesive is well suited for finishing both outside and inside a building, but it should not be used when tiling a floor with an integrated heating system. Otherwise, it is ideal, but requires certain conditions to be met for the repair to be durable. Able to withstand moderate physical stress and has high adhesion.

The tile adhesive in question is made on the basis of cement, mineral additives and water-repellent components that prevent water from penetrating into the thickness of the installation layer, protecting it from destruction.

There is also a special plasticizer that makes the finished solution elastic and pliable. Easily applied to the surface using a comb, grater or spatula.

Strengthened composition

The presented product for tiling walls and floors with tiles or porcelain stoneware is highly durable, so it is recommended by specialists when installing finishing with a total weight of 1 square meter. m up to 45 kg. Moreover, the material can withstand up to 50 cycles of complete freezing, which indicates relative durability.

The reinforcing properties are ensured due to the presence of special polymerizing components in the composition, so it is ideal for laying floor coverings in rooms with high traffic.

Advantages and disadvantages

Trademark tile adhesive has a wide range of advantages. For example, it can be used to work with different types of bases. It is suitable for cladding concrete, cement, brick, stone and other bases (gypsum plasterboard, gypsum board, gypsum plasterboard, SML, TsSP). You can also apply cladding with this glue to cement plaster. In addition, the composition is easy to prepare: if you follow the instructions on the product packaging, preparing it will not be difficult.

This composition is plastic, which allows it to be used when finishing the base with a height difference of up to 2 mm per 1 m2. The diluted mass is convenient, does not flow or slide off vertical planes, and therefore does not increase the degree of inclination of each upper laid row. The solution has a long life cycle, so there is no need to dilute it in small portions.

The company's adhesive is resistant to high dynamic loads. It can be used for laying not only ceramic tiles and porcelain stoneware, but also for tiles, mosaics in the form of individual fragments and on a grid, natural and artificial facing stones. This is a modern adhesive that allows you to finish surfaces at a professional level. Convenience for buyers is the presence of modifications, due to which you can choose a special type of glue for a specific material.

There is no need to pre-soak the tiles. Due to its high plasticity, the solution not only fits well on the base, but also allows you to correct its minor unevenness. It will cover small holes and rid the rough base of microcracks. This is a material with a long service life. If the dilution and installation technology is followed, surface cladding with trademark glue will last for decades without needing repair.

Due to its high resistance to moisture, the mixture can be used for finishing rooms with a high humidity coefficient. The adhesive is a waterproofing agent for hygroscopic and mineral floors. An additional advantage is the fact that this composition is suitable for laying over previously installed tiles. In addition, every buyer is pleased with the price of the material.

However, with a lot of advantages, glue also has disadvantages. For example, it will not hold the cladding well if the base is not properly prepared. In addition, if you do not maintain the temperature conditions during operation, this may affect the quality and durability of the coating. If the air in the room is too dry, the life cycle of the finished solution will be shortened.

Specifications

Knauf Fliesen is ideally suited to work with any tiles up to 30x30 cm in size, which is ensured due to the special chemical composition and characteristics to which it meets.

| Characteristic | Meaning |

| Level of adhesion to concrete base, MPa | 0,6 |

| Operating temperature | +5…+25 |

| t °C operation | -45…+80 |

| Drying time before grouting, days | 1 |

| Drying time before use, days | 2 |

| Time for complete drying before applying high mechanical loads, days | 7 |

| Viability of the mixture, h. | 2,5 |

| Time period during which the tile position can be adjusted, min. | 10 |

| Thickness of the adhesive seam, cm | 0,2-0,6 |

| Frost resistance, freeze/defrost cycles | up to 50 |

| Moisture absorption coefficient, % | No more than 3 |

| Expiration date, year | 1 year in undamaged original packaging in compliance with the manufacturer's requirements |

Scope of application and characteristics of glue

The scope of application of Knauf Flizen tile adhesive is quite wide. It is used to cover walls and floors inside and outside the building. Not recommended for finishing plinths and laying on heated floors. Creates a durable mounting layer that will hold the tile for an unlimited period of time.

Fliesen glue is produced by the German company Knauf. This is a loose building mixture that, after dilution, turns into a solution for laying tiles, porcelain stoneware, clinker, tile blocks and mosaics.

The composition is suitable for tiles of any shape, but it is best used with the following materials:

- tiles 300x300 mm with moisture absorption more than 3%;

- porcelain stoneware 600x600 mm;

- any ceramic floor covering.

Knauf adhesive has proven itself well when attaching bases made of polystyrene, foam plastic, glass wool, polyurethane, and when installing glass-magnesium sheets. Due to the high adhesive parameters, they are used to glue finishing and insulating materials to concrete, cement, silicate surfaces and brickwork, and to plasterboard. Fliesen is used for gluing tongue-and-groove slabs.

Due to its resistance to temperature changes, the adhesive composition is used when laying heated floors and other heated structures. Fliesen is used for gluing external and internal cladding.

Scope and features

Knauf Fliesen glue from the Knauf company (country of origin – Germany) is a dry construction mixture, which, after dilution, turns into a high-quality solution. This product can be used for tiles of any size, clinker and porcelain tiles, mosaics and tile blocks (depending on the specific type of adhesive). The composition has proven itself best for tiles up to 30*30 cm in size with water absorption above 3%, porcelain stoneware up to 60*60 cm, and any ceramic floor covering.

The product is also well suited for fastening the following insulating and finishing materials:

- polystyrene;

- Styrofoam;

- glass wool;

- polyurethane;

- glass-magnesium sheet.

The adhesive has a high degree of adhesion to various substrates: concrete, cement, limestone coatings, tongue-and-groove and cement-bonded particle boards, silicate materials, brickwork, as well as to plasterboard, gypsum fiber. The versatility of the glue is confirmed by the ability to use it for external and internal work. Also, Knauf glue is suitable for installing heated floors and other types of heated cladding, since it easily withstands temperature fluctuations. A special feature of Knauf Fliesen is its fairly low consumption per m2, which is due to the possibility of applying it in a thin layer.

Specifications

Knauf Flizen glue has all the necessary certificates, which reflect its main characteristics. Here are the technical parameters of the product:

- degree of adhesion with a standard concrete base – 0.6 MPa;

- temperature when applying the solution – from +5 to +25 degrees;

- operating temperature – from -45 to +80 degrees;

- time for complete drying of the solution before the start of operation - 2 days, before troweling - 1 day, before the possibility of high mechanical loads - 7;

- solution pot life – 2.5 hours;

- period for adjusting the position of the tile – 10 minutes;

- possible thickness of the adhesive layer is 2-6 mm;

- frost resistance – up to 50 freezing/thawing cycles;

- Shelf life – 1 year in the absence of damage to the integrity of the packaging and compliance with the conditions recommended by the manufacturer.

Composition and properties

The Flizen glue from Knauf is based on cement and fine sand (the latter acts as a binding component), which give the powder a gray color. To improve the quality and performance characteristics, special additives, fillers - polymers, additives, anti-mold and antiseptic components were introduced into the composition. The adhesive is designed in such a way that it is ideal for moisture-absorbing materials and relatively flat substrates. If the tiles do not absorb moisture well, you should choose a different composition from Knauf.

Main properties of glue:

- Thanks to its thickness, the product does not slide off the wall and can hold even heavy slabs, blocks, and stone elements. However, to ensure the declared level of adhesion, it is important to comply with the temperature regime recommended for work and subsequent operation.

- The adjustment time is short, so you cannot immediately apply the product to large areas. If you place tiles on already dried glue, the quality of adhesion will decrease.

- The adhesive is flexible, easy to apply and can be used on substrates with small pits and defects. The elastic structure will not allow the product to deteriorate over time, and also promotes uniform filling of problem areas with glue.

- Due to its high frost resistance, the Knauf Flizen composition is widely used for outdoor work. After thawing, the adhesive joint will retain its characteristics and will not begin to deteriorate faster. The glue is even suitable for laying tiles on terraces, steps, balconies, and verandas.

- Moisture resistance makes it possible to use the glue in rooms with high levels of humidity. It is suitable for laying tiles in the bathroom, kitchen, etc. In addition, the adhesive layer provides waterproofing of hygroscopic mineral substrates and protects them from infection by fungus, mold, and bacteria.

To dilute the glue you do not need to have special knowledge; all instructions are written in detail on the packaging. It is only important to follow the proportions recommended by the manufacturer, and then use the resulting solution correctly.

Advantages and disadvantages

The advantage of the glue is its suitability for a wide variety of substrates and excellent compatibility with most insulating materials. The product is also suitable for various types of tiles and mosaics. Standard Flizen adhesive is not suitable only for glass and transparent tiles due to its gray color.

Other advantages of the mixture:

- You don’t need to be a master to work; just read the instructions carefully;

- thanks to the self-leveling effect, gluing tiles to the floor is easy;

- due to the low fluidity, there will be no problems with gluing elements to the walls either;

- the product allows you to level surfaces with height differences of up to 2 mm, which helps reduce the list of repair work;

- the glue hides microcracks in the screed, perfectly corrects the plane, and promotes the formation of a monolithic surface;

- the product has a long service life, the tiles do not have to be changed often, even those located outdoors and in unheated rooms;

- under intense loads (including dynamic ones), the finishing material will not deteriorate and the adhesive layer will not collapse;

- the solution is plastic, so the tiles do not need to be soaked in water before work.

The glue is sold in convenient packages, and a bulk pack (25 kg) has a more favorable price, and is often used by craftsmen to save money when carrying out a large volume of work. The solution has few disadvantages. It requires preparation of the base before work, as well as compliance with a certain temperature regime, otherwise adhesion is reduced. The adjustment time is also quite low (10 minutes). This can cause problems for beginners, especially if the product is applied to several square meters of base at once.

Advantages of glue

- Can be used with a variety of substrates and combines well with insulating materials.

- Various types of tiles and mosaics are glued. Due to the gray color it is not recommended for clear or glass cladding.

- A non-professional can work with the composition; to prepare it, it is enough to accurately follow all the instructions.

- Low fluidity allows Flizen to be used for gluing cladding to vertical structures.

- The mixture levels surfaces with height differences of up to 0.2 cm, due to which the number of repairs is significantly reduced.

- Forms a monolithic surface, correcting it, hiding microcracks in the screed.

- The adhesive joint has a long service life; the tiles will last a long time on any surfaces in heated, unheated rooms and outdoors.

- The seam is not affected by intense, dynamic loads, it does not deteriorate or collapse.

- The finished mixture is very plastic, which is why there is no need to soak the tiles before gluing.

- Sold in convenient packaging. Packaged in packs of 25 kg. The price is affordable, unlike analogues from other manufacturers.

Advantages and disadvantages

An important advantage of Knauf glue is its compatibility with various types of substrates. This allows the tiles to be glued to concrete, cement, stone, brick walls and floors

Facing materials adhere well to moisture-resistant plasterboard, cement-bonded particleboard, tongue-and-groove, plasterboard, gypsum fiber boards and glass-magnesium sheets. The composition firmly adheres tiles, mosaics and porcelain tiles to cement plaster.

The advantages of Knauf Fliesen glue include:

Easy to prepare - to make the solution, just follow the instructions on the package. The mixture is easy to work with - the paste-like product has low fluidity, a self-leveling effect, and lays down in a thin layer. The high plasticity of the substance allows you to work with surfaces with differences in height up to 2 mm per square meter. The high strength of the dried mortar ensures a long service life of the coating even under intense loads. The absence of fluidity and slipping is an important property when applying Knauf glue to vertical planes. The long viability of the prepared solution gives the master the opportunity to carefully adjust the tile laying. After complete curing, it demonstrates high resistance to dynamic loads. Frost resistance of the mixture is achieved by including special additives and can withstand 25-30 cycles. The versatility of the glue allows you to glue ceramic tiles, porcelain stoneware, tiles, mosaic fragments, and stone.

Fliesen tile adhesive is supplied as a dry powder in strong paper bags weighing 10 kg and 25 kg. Several products in the Knauf Fliesen line allow you to choose the most suitable composition for a particular facing material. Due to the good plasticity of the solution, the tiles do not need to be soaked in water before laying.

The composition fits well on imperfectly level but well-prepared bases, corrects the plane in height, and hides microcracks in the cement screed. The long service life of the composition ensures the durability of the masonry, and the waterproof properties of Knauf glue contribute to the formation of a monolithic surface that is resistant to contact with water.

The disadvantages are the need for careful preparation of the base before applying the solution. A prerequisite for using Flizen adhesive for tiles is maintaining the temperature within +20+25 degrees.

Flaws

- If you do not prepare the base before gluing or violate the temperature conditions for working with the composition, its adhesion will deteriorate.

- The glue has a fairly short correction time. Beginners sometimes find it difficult to complete in 10 minutes. install the facing coating correctly and use the entire prepared composition.

Types and forms of release

Knauf adhesives differ in layer thickness and caliber of facing material with which they work. All types are packaged in durable paper bags with several protective layers of 10, 25 kg.

It is recommended to store packages on wooden pallets in rooms protected from moisture.

Universal glue

Knauf Fliesenkleber presents a universal composition for interior work on gluing tiles with water absorption up to 3%. It can be used for external cladding, but the water absorption rate of the tile must be above 5%.

Fliesenkleber adheres well to concrete, plaster, cement-sand bases and plasterboard.

Not used for gluing low-porosity tiles, which have a low water absorption coefficient.

Flizen Flex

Knauf Fliesen Flex tile adhesive has increased elasticity and ductility. Effective when working with porous, medium-porous tiles, stone tiles and porcelain stoneware. Adheses well to any substrate, including insulating materials. Knauf Flex can withstand significant dynamic loads. They are used to cover surfaces made of wood, chipboard, and install heated floors.

Flizen Plus (reinforced)

The composition of Knauf Fliesen Plus is supplemented with mineral fillers and polymers that enhance the strength of the seam. It has good adhesion to concrete and cement bases; tiles are glued to drywall.

The reinforced composition is not afraid of low temperatures, therefore it is used in finishing work on the facades and plinths of buildings. It is used to glue materials with low water absorption, including not only tiles, but also various types of stone.

Fliesen Marble

Knauf Marble is based on minerals, polymers and white cement, which is why its color is white. They can be used to glue natural and artificial stone, granite, porcelain tiles, mosaics, ceramics, and glass tiles. Has a high level of adhesion. When gluing large-sized Fliesen elements, Marble is applied to the base and the reverse side of the material.

Description

Knauf Fliesen tile adhesive (Knauf Fliesen, formerly Fliesenkleber) is used for laying ceramic and porcelain tiles in rooms with low and medium humidity levels on floors and walls.

It is durable and has good adhesion to most traditional building substrates. Suitable for laying tiles up to 330 mm in size on either side, on concrete, cement and gypsum plasters, cement and anhydrite screeds, walls made of brick, foam blocks, aerated concrete, cinder blocks, gypsum blocks, plasterboard, gypsum plasterboard. It consists of high-quality cement, a complex of special additives, fractional fillers and quartz sand. Can be used for cladding facades, balconies and terraces; Knauf Flizen tile adhesive cannot be used for cladding the basement and blind area of a building. When carrying out work on complex substrates, such as drywall or gypsum plasterboard, for external work, it is recommended to prepare the adhesive with the addition of a latex plasticizer.

Comparison with other analogues of the line

Tile adhesives from Knauf differ in the additives they contain. They are responsible for the properties of the glue and its purpose.

- To install heated floors, only those mixtures are used that are not afraid of temperature changes, for example, Flizen Flex. It is optimal for laying industrial floors and surfaces subject to dynamic loads.

- The universal Knauf Flizen is rarely used for gluing porcelain tiles; it is more often used when installing regular tiles.

- Fliesen Marble is used when working with decorative or artistic tiles.

- Knauf Flizen Max is applied in a layer of up to 3 cm, it helps to strengthen the strength of the masonry, levels the floor and walls, and is used on surfaces with large differences in height, but it cannot be used to attach cladding to a warm floor.

- Flizen Plus is used to glue low-porosity porcelain tiles.

An analogue of other manufacturers is CERESIT SM-11 tile adhesive

Application and consumption

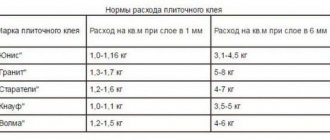

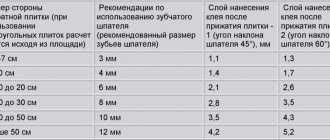

Apply Knauf Fliesenkleber adhesive solution using a notched trowel, trowel or similar tool. In this case, the thickness of the applied layer is selected in the range from 4 to 8 mm when installing tiles measuring 30x30 mm.

It is not advisable to apply more mortar, because it can deform under its own weight and the tiles may move out. Based on the manufacturer's recommendation, the glue consumption is 1.7, 2.2 and 2.9 kg/m2 when applying a layer with a thickness of 4, 6 and 8 mm, respectively.

Required Tools

- Notched trowel with the correct height and shape of the teeth.

- Master OK.

- Level, level.

Breeding

To properly prepare the adhesive composition for covering walls and floors with ceramics or porcelain stoneware, you will need to maintain the proportion. It is 1:4 with a little, that is, for 1 bag weighing 25 kg you will need 7 liters of water, or for 10 kg - no more than 3 liters.

The solution is constantly stirred until smooth. To obtain the required homogeneity, it is recommended to use a mixer with a power of at least 800 W. After mixing, the solution must be allowed to stand for 5 minutes.

Preparatory work

The composition is applied only to a prepared, dust-free surface, pre-treated with high-penetration primers. The result is maximum adhesion and reliable fixation of heavy tiles on surfaces with any roughness.

Recommended for use on surfaces that have been cleared of contaminants: brick, concrete, PGS, gas silicate, expanded clay block, cement plaster, gypsum plasterboard, gypsum fiber board, gypsum PGS glazes and other bases.

If the surface has poor water absorption, then KNAUF-Tiefengrund soil is used. For porous substrates it is better to use the KNAUF-Mittelgrund treatment. If the finishing is done in the bathroom, then the surface must be impregnated with a waterproofing compound before laying the tiles. Knauf recommends Flachendicht.

Application of the solution

The adhesive is applied using a notched trowel and trowel. It is spread in a thin, uniform layer on one of the surfaces to be fastened, on the facing material. If there are some irregularities, then in this place it is applied in a thicker layer.

When spreading the composition, maintain an angle of inclination of the spatula of at least 60 degrees so that uniform grooves of equal thickness are formed.

When laying tiles indoors, mortar should be applied to them to cover 80% of its surface. This is necessary so that later it will be easier to unstitch the seams for decorating them with putties. If the finishing is done outside, then it is spread completely in order to maximally seal the seams between the wall finishing elements.

We also recommend watching - How to cut tiles without a tile cutter: a selection of simple methods

After laying the finishing element on a fresh solution, it can be moved from its place within 10 minutes. You can start sealing the seams with various fugues after 24 hours, but you can fully load the surface only after a week. The seams are cleaned with gentle movements along the tile, without undermining it.

Application

Preparatory work

- To ensure the maximum level of adhesion of the base under the cladding, the surface to be finished should be carefully prepared. To begin with, it is cleaned of dirt, dust and grease, grease stains, peeling and other defects are removed. Old waterproof paint, varnish and any glossy areas are sanded, non-waterproof paint is washed off.

- The cleaned surface is thoroughly dried.

- If the base is made of highly absorbent materials, for example, cement or gypsum plaster, it is pre-primed using Tifengrund Knauf and left to dry for three hours. The temperature of the base should not be less than 5 °.

- When finishing a heated floor, it must be turned off for a day before starting finishing work.

On a note

During the cold season, you can limit yourself to reducing the floor temperature to 15˚.

Preparation of the solution

Dry Flizen mixture and clean water are mixed in a ratio of 5 kg per 1.4 liters. A construction mixer is used for mixing. The ready-to-use composition must have a homogeneous structure. It is recommended to prepare the solution in two stages:

- mix until smooth;

- let the mixture sit for 5–10 minutes;

- mix again. If necessary, the consistency can be adjusted by adding water or dry mixture.

On a note

The finished composition can be used on average within three hours. If the facing work requires more time, and the mixture has already thickened, it can be mixed again without adding more water.

Applying Knauf glue

The mixed dry mixture is not applied immediately - it is necessary to soak the solution for 10-15 minutes. To apply the binder mixture, use a notched trowel, which is selected taking into account the caliber of the tile. The size of the teeth should be such that the back side of the tile is in contact with the adhesive layer on at least 80% of its area. In the case of external cladding, the back side must be in full contact with the adhesive.

| Glue brand | Tile caliber, mm | |||

| up to 100 | 100–200 | 200–300 | from 300 | |

| Fliesen | 6 | 8 | 8 | |

| Fliesen Plus | 4 | 6 | 8 | 8 |

| Flex | 6 | 8 | 10 | |

| Marble | 6 | 8 | 8 |

Selection of spatula by tooth height (in mm)

It is recommended to first evaluate the choice of spatula. This is done simply:

- remove freshly laid tiles;

- examine it from the back;

- if the glue does not cover the tile enough, the spatula is replaced with another, larger one;

- You can choose another option: apply the adhesive mixture to the tiles as well.

- The adhesive composition is evenly distributed over the surface of the base, using a spatula on the smooth side. Then the smooth surface of the adhesive layer is “combed” with its serrated side, holding the tool at an angle of 60 degrees. In the area of the upper level of the cladding, a horizontal broach is performed approximately to the height of the tile.

- For external cladding and tiles that have a grooved texture on the side, the composition is also applied to the back side of the tile.

- After fixing the tiles, it takes 10 minutes for full adhesion. During this time, if necessary, it can be adjusted.

- If a crust has formed on the surface of the laid binder mixture, this layer is removed and replaced with a fresh solution.

| Glue brand | Tile caliber, mm | |||

| up to 100 | 100–200 | 200–300 | from 300 | |

| Fliesen | 2,2 | 2,9 | 2,9 | |

| Fliesen Plus | 1,7 | 2,2 | 2,9 | 2,9 |

| Flex | 2,2 | 2,9 | 3,7 | |

| Marble | 2,3 | 2,9 | 2,9 |

Glue consumption, kg/m²

Important

The glue contains cement, so when working with it,

- put on gloves

- protect your eyes from contact with the solution. If this does happen, you should immediately rinse your eye and seek medical help.

- After finishing installation, the tools are immediately washed with water.

- Adhesive stains are removed without delay, without allowing them to dry.

Consumers who have personally used the composition leave extremely positive reviews about Knauf Flizen tile adhesive. They note excellent characteristics: low consumption, ease of preparation and application of the composition, convenient price.

Recommendations

- As the ambient temperature rises, the time spent working with the mixture decreases.

- During operation, avoid drafts and direct sunlight.

- In damp rooms, the working time with the composition increases.

- The mixture must not be diluted with any liquids other than water.

- For exterior work or when gluing large areas, it is recommended to provide expansion joints.

- After work, the entire instrument is washed with water before the solution hardens.

- All work with tile adhesive is carried out wearing protective equipment.

How to store

Tile adhesive should be stored only in dry, ventilated areas. The bags must be placed on wooden pallets or other devices, and the shelf life of the adhesive composition in intact packages does not exceed 1 year from the date of production. If the bag has been damaged, it must be used first.

Release forms

Depending on the area of tile masonry, consumers can choose Knauf adhesive in 25 kg packaging, which is economical for work, or in 10 kg bags, which are less common on sale. Dry powder must be stored on a wooden platform, otherwise the cement will “pull” moisture from the floor. If the original packaging is damaged or deformed, this bag should be used first.

Price Knauf Fliesen

| Name | Bag volume, kg | Price, rub |

| Fliesen | 25 | ~235 |

| Flizen Plus | 25 | ~300 |

| Fliesen Max | 25 | ~290 |

| Flex | 25 | ~550 |

| Fliesen Marble | 25 | ~495 |

The price depends on the seller and the country's currency. The table shows the cost of glue from Yandex Market.