Technical characteristics of the glue

The above-mentioned composition for laying ceramic tiles contains polymer additives, mineral fillers and cement among its ingredients.

In order to obtain a ready-made solution, you should take 0.24 liters of water per 1 kg of mixture. If you additionally plan to use an emulsion, then for 0.14 liters of water you will need 0.08 liters of Ceresit CC 83 brand emulsion. It is important to consider that “Ceresit CM 11”, the technical characteristics of which you can find out in the article, has a certain consumption time after preparation . Therefore, it is necessary to mix the composition in such an amount that you have time to produce within a couple of hours. The mixture can remain open for 20 minutes. You can change the position of the laid tiles for another 10 minutes.

When applying, it is important to adhere to a certain base temperature, which varies from 5 to 30 °C. The sliding of tiles from a vertical surface will not be more than 0.5 mm. You can work on the seams after a day. Before purchasing Ceresit SM 11 glue, its technical characteristics must be studied first.

After reading them, you can find out that the solution has a certain level of adhesion to concrete bases. If operation is carried out in air, the mentioned parameter is 0.5 N/mm or more. When soaking in water, the parameter can be equal to 0.7 N/mm. With alternate freezing and thawing, the adhesion of the solution to the concrete base remains the same for 50 cycles.

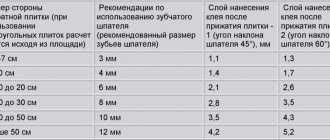

It is also important to take into account the operating temperature; it varies from -50 to 70 °C. Naturally, it is very important to know what technical characteristics a composition such as Ceresit SM 11 has. But the manufacturer also mentions the tools that should be used to distribute the adhesive composition.

If the tile has a side of 10 cm, the size of the tooth side should be increased to 4 mm, and the product consumption will be equal to 2.6 kg/m2. As the tile sizes increase to 20 and 40 cm, the side size of the float tooth should be 8 and 10 mm, respectively. In this case, the material consumption under the mentioned conditions will be equal to 5.2 and 6.5 kg/m2, respectively. When the tile size increases to 40 x 40 mm, the tool tooth should be 12 mm. You will need more glue - up to 7.8 kg/m2.

For tile work, the SM series of adhesives from Ceresit is used. Most products are sold in 25 kg packs, some are also sold in small packs of 10 kg.

Ceresit CM 9

This material is one of the most inexpensive among analogues; it has an average degree of adhesion to the surface. Used for gluing tiles, glazed tiles, terracotta up to 30*30 cm in size on floors and walls. Ceresit CM9 adhesive has sufficient moisture resistance, so it can be used in damp rooms.

Thanks to polymers and mineral components, the product will reliably hold the brickwork and can become a substitute for standard cement mortar. It cannot be used for outdoor work; it has low frost resistance. The adhesive works best on concrete bases; it can also be applied to cement-lime, cement-sand plasters that have been cured for at least 28 days.

Technical characteristics of SM 9:

- packaging – 25 kg bags;

- density of the dry mixture – 1.4 kg/cu. dm;

- tile sliding – up to 0.1 mm;

- adhesion – 0.5 MPa;

- temperatures during work - 5... 30 degrees, operation - 0... 70 degrees;

- humidity during work – up to 60%;

- solution viability – 2 hours;

- tile adjustment time - 10 minutes;

- Grouting period is 2 days.

Material consumption per 1 sq. m depends on the size of the tile and the trowel tooth, it can be 2-4.2 kg/sq. m.

Ceresit CM 12

Special Ceresit adhesive for porcelain stoneware and tiles up to 60x60 cm in size - CM 12. It is suitable only for interior work on non-deformable substrates (frost resistance up to −30 degrees). When adding elasticizer СС 83, it can be used for laying on warm floors, outdoors, unstable bases (chipboard, OSB, plasterboard, fresh screed more than 1 month old).

For convenient work with large-format tiles, the mixture has a fluid, plastic consistency. This allows you to apply glue only to the mounting base of the tiles; it is not necessary to go through the floor with glue “to tear off”.

Specifications

| Mixing proportions | 6-6.25 liters of water per 25 kg bag. When using an elasticizer: 2 liters C 83, 4.25 liters of water per 25 kg bag. |

| Time to use the mixture after mixing | Minimum 2 (1.5*) hours |

| Conditions of use | Base and air temperature from +5 to +30, air humidity less than 80% |

| Opening hours | From 20 minutes |

| Tile adjustment time | From 30 minutes |

| Sliding tiles | No more than 0.5 mm |

| Grouting joints | After 24 (48*) hours |

| Adhesion to concrete after 28 days | More than 1 (1.3*) MPa |

| Frost resistance | At least 100 cycles |

| Operating temperature | From −30 to +70 |

| Package | 25 kg bag |

| Flammability according to GOST 30244-94 | NG (non-flammable material) |

* When using elasticizer CC 83.

Consumption

| Tile length, cm | Comb tooth height, mm | Consumption, kg/m² | |

| Ceresit CM12 | SS 83* | ||

| < 30 | 10 | 4,2 | 0,34 |

| < 60 | 12 | 6 | 0,48 |

* When using elasticizer CC 83.

Preparation of glue

The Ceresit company offers consumers a fairly wide range of tile adhesives, so you can choose a fixing mixture based on the nature of the work. There are several categories of material:

- standard material - without additional impurities to protect the base from moisture, external atmospheric influences and other factors;

- elastic composition - suitable for fixing all types of tiles, for work inside and outside the building;

- special products - suitable for laying marble, granite, mosaic or dimensional tiles.

The material is selected depending on the type of application. The composition also affects the method of dilution, consumption and method of application.

Modern manufacturers of building materials offer several types of mixtures intended for facing work. These include:

- universal adhesive - made on a cement base using additives that give the composition the necessary functional characteristics;

- reinforced – capable of reliably fixing heavy cladding elements;

- moisture resistant – suitable for finishing work in rooms where high levels of humidity remain;

- polymer - intended only for interior finishing work, as it does not tolerate temperature fluctuations and ultraviolet radiation;

- modified - a plastic mixture characterized by increased performance characteristics due to the addition of additives.

According to the method of preparation, all mixtures are divided into adhesive mastics and dry mixtures. Mastics do not require preliminary preparation - they are produced in the form of a paste, ready for use.

Dry mixtures in powder form require precise and careful dilution to obtain high-quality, homogeneous glue.

The simplest is considered to be dry cement glue with the addition of antifreeze and moisture-retaining additives. The base is Portland cement, and quartz sand is used as a filler. PVA glue is also added to “handicraft” mixtures for laying tiles, which increases the elasticity of the solution.

We suggest you familiarize yourself with: B-7000 brand adhesive - the best analogues and instructions for use

Reference! Portland cement is a type of cement with increased binding properties and the ability to quickly harden both in air and in water.

More complex varieties of glue contain:

- latex – serves as a binding component, giving the composition plasticity;

- epoxy – suitable for working with wood, ceramics and metals;

- polyurethane – provides a high degree of adhesion to any surface;

- synthetic resins – promote rapid setting and drying, suitable for finishing moving substrates;

- synthetic rubber (neoprene) - included in liquid nails.

The specifics for diluting the glue will depend on how quickly it sets and hardens. Quick-drying mixtures must be prepared immediately before the installation process and in small quantities.

If the adhesive is too thick, it will adhere worse to the surface and create unevenness and voids. Most often these are simple two-component cement compositions.

More plastic mixtures take longer to set, so you can prepare them in advance and work slowly. In any case, you must follow the manufacturer's instructions, which should accompany each package of glue.

Quite often, consumers wonder how to dilute Ceresit SM 11. You should know that the mixture is mixed with clean water, the temperature of which can vary from 15 to 20 °C. For 1 kg of composition you will need approximately 0.24 liters of water. The resulting solution is mixed to a homogeneous consistency, which should not have lumps. For this you should use a low-speed drill with an attachment. Some craftsmen use a stirrer.

The resulting material should be left for 5 minutes, and then mixed again. It can be used within 2 hours. Before using Ceresit SM 11, you should read the instructions. From it you can find out that the composition is distributed in a thin layer using a grater, spatula or spatula. Application should be carried out on the surface to be coated, and then the mixture is leveled with a grater with teeth or a spatula.

CERESIT CM 11 / CERESIT CM 11 tile adhesive (25 kg)

Main characteristics

| Brand: | Ceresit |

| Weight: | 25 |

Price 320 rubles/piece

The appearance of the product may differ from that shown in the photograph.

Description

Dry mixture, tile adhesive based on cement, sand, with the addition of modifying additives, intended for gluing tiles made of natural stone and ceramics when carrying out facing work inside and outside buildings.

Scope of application:

cladding of non-deformable mineral bases (concrete, brick, cement plaster) exposed to constant and periodic exposure to water, installation of “warm floor” systems. Designed for laying ceramic and stone tiles with water absorption from 3% (size up to 30x30 cm).

Specifications:

The water consumption for 1 kg of mixture is 0.24 l or for 25 kg of mixture (1 bag) - 5 l. The recommended thickness of the mortar layer is 6 mm. The viability of the solution is 180 minutes. Opening hours: 15 minutes. The permissible time for adjusting the position of the tiles after laying is 20 minutes. Grouting of joints is possible 24 hours after finishing work. Ambient and substrate temperatures during operation are from +5°C to +30°C. Operating temperature - from -50°С to +70°С. Frost resistance - 100 cycles.

Preparing the base:

The surface of the base is cleaned of dirt, dust and oil stains, as well as peeling areas. Irregularities are removed using plaster. Before facing, the base is treated with a primer.

Preparation of the solution:

The dry mixture is poured into a container with clean water and thoroughly mixed until a homogeneous mass is obtained, wait 5 minutes, then stir for five minutes - the solution is ready for use.

Mode of application:

The solution is evenly applied to the base and leveled with a notched trowel. Lay the tiles on the glue and carefully press them to the base. The position of the tiles can be adjusted within 20 minutes after gluing.

Package:

The adhesive mixture is supplied in paper bags weighing 25 kg.

Shelf life:

In a closed container, the glue can be stored for 6 months from the date of manufacture indicated on the package.

Tile adhesive CERESIT 11 – advantages

- There is no slipping of CERESIT 11 tile adhesive when used on a vertical base.

- Tile adhesive Ceresit 11 can be used at sub-zero temperatures.

- There are no restrictions on the use of Ceresit 11 tile adhesive in conditions of high humidity.

- Tile adhesive CERESIT cm-11 has economical consumption when applied.

- Ceresit 11 glue is convenient in preparing the solution and applying it.

- CERESIT cm11 tile adhesive is harmless to humans because it does not emit toxic and harmful substances.

Recommendations for limiting the use of CERESIT 11 tile adhesive

- Tile adhesive Ceresit 11 on newly constructed concrete bases and cement screeds (as well as plasters). Ceresit 11 adhesive can be used on cement screeds and plastered surfaces older than 28 days and concrete bases older than 90 days.

- Deformable substrates are not suitable for using CERESIT cm-11 tile adhesive on them.

- Ceresit 11 adhesive cannot be used for laying slabs whose water absorption is less than 1%.

- You cannot use CERESIT cm-11 tile adhesive on “warm floors”.

- For cement, CERESIT cm11 tile adhesive can only be used if the humidity is less than 4%. However, tile adhesive CERESIT cm11 can be used for bathrooms and showers, where the humidity increases periodically and there is good ventilation.

- On foundations with large potholes or cracks, it is necessary to carry out preliminary work to seal and level them. You can use mineral putty or plaster for this, after which it will be possible to apply Ceresit 11 glue.

Documentation

Technical description ()

Certificate (

)

Certificate ()

Consumer Reviews

"Ceresit SM 11", reviews of which are recommended to be read before purchasing the product, has special polymer additives. They, according to consumers, improve the technical characteristics of the product. The material is frost and water resistant. According to buyers, it has many advantages, among them the following should be highlighted:

- high adhesion;

- environmental safety;

- high level of moisture resistance;

- resistance to tile sliding;

- convenience and ease of use.

Substrate preparation and instructions for use

In order for the tile to adhere securely to the surface, it must be provided with optimal load-bearing capacity. It is important to remove all fragile areas, sand them, and completely clean them of traces of paint and plaster. Then the unevenness must be smoothed out using plaster and allowed to dry completely before gluing the tiles (usually the process takes 3 days). The floors are leveled with a suitable floor mortar.

Also, all contaminants that potentially reduce the adhesion of the composition should be removed from the base:

- dust;

- dirt;

- fat;

- bitumen;

- oil.

If a cement screed is used on the floor, you need to wait at least 28 days until the humidity reaches 4%. Only then is priming and laying of the tiles carried out. Wooden bases are primed with special means 1-2 times. Do the same with various slabs and drywall. OSB boards and paint coatings are treated with coarse sandpaper and removed from dust.

To apply the glue, use a notched trowel or a grater with square teeth. Use a trowel to pick up glue, place it on the base, and level it with a spatula. Press the tile as hard as possible and repeat the work further, not forgetting about the tile seams. Laying tiles end-to-end is not permitted. When installing large-format objects, stone, and facade work, glue is applied to the surface of each tile and to the base. The thickness of the adhesive joint is from 3 mm, it depends on the complexity of the work and the size of the tile.

Traces of glue from the front side of the tile are removed immediately using a wet rag. After they harden, you will have to do mechanical cleaning. Grouting of joints is carried out after the time recommended by the manufacturer. Do not allow the solution to come into contact with the skin or eyes. To do this, it is important to follow preventive measures, wear gloves, protective clothing and goggles. Following all the tips guarantees excellent results when working with tiles and other types of finishing materials.

Home craftsmen emphasize that the glue adheres well even to absorbent and smooth surfaces. Even if you plan to use large tiles when carrying out work, they will be firmly held on a vertical surface without sliding down. Ceresit tile adhesive, according to users, is also popular for the reason that the composition is environmentally friendly. It is moisture resistant and easy to use.

Having received an answer to the question of how long it takes for Ceresit SM 11 to dry (this was discussed above), you can begin preparing the surface. It is important to clean the base where the tiles will be laid from materials that impede adhesion; among them, bitumen and grease should also be highlighted. When concrete is used as a base, it is important to ensure that its age is more than 3 months and its humidity is not higher than 4%.

Ceresit CM 17

The main feature of Ceresit CM17 is high elasticity and good adhesion. Due to this, it can be used for laying deformable bases: warm floors, plasterboard, chipboard. It is not afraid of moisture or frost, and can be used for lining swimming pools, for interior and exterior work, tiles and large-format porcelain tiles (with the exception of marble).

Ceresit 17 is available in two versions: regular and low-dust (marked “Stop Dust”).

Specifications

| Mixing proportions | When laying on walls: 8.5-9 liters of water per 25 kg of dry mixture. When laying on the floor: 9-9.5 liters of water per 25 kg. |

| Time to use the mixture after mixing | Minimum 2 hours |

| Conditions of use | Base and air temperature from +5 to +30, air humidity less than 80% |

| Opening hours | From 30 minutes |

| Tile adjustment time | From 30 minutes |

| Sliding tiles | No more than 0.5 mm |

| Grouting joints | In 24 hours |

| Adhesion to concrete after 28 days | More than 1.3 MPa |

| Frost resistance | At least 100 cycles |

| Operating temperature | From −50 to +70 |

| Package | Bags 5 and 25 kg |

Consumption

| Tile length, cm | Comb tooth height, mm | Consumption, kg/m² |

| < 10 | 4 | 1,5 |

| < 15 | 6 | 2,1 |

| < 25 | 8 | 2,7 |

| < 30 | 10 | 3,2 |

| < 40 | 12 | 4,1 |

How to choose the right glue?

Even glue called universal is not suitable for performing all types of finishing work. When choosing an adhesive, you should focus on the following conditions and nuances:

- sizes of tiles, their texture and base material;

- the type of surface that is planned to be coated;

- finishing operating conditions.

To hold heavy tiles, you will need an adhesive with increased astringent properties and adhesion values of at least 1 MPa.

If the ceramic elements are small, an adhesive with an adhesion of 0.2-0.3 MPa is suitable. The floor tiles will be reliably held in place by glue containing a high concentration of plasticizers and elastanes.

We suggest you familiarize yourself with: Exiting the chimney through the roof

You should choose the adhesive especially carefully if you plan to cladding the outside of the building. The product must not only withstand increased load, but also be resistant to frost, heat and temperature changes.

The cladding of stoves and fireplaces is carried out using heat-resistant glue. An elastic adhesive composition that can withstand linear expansion of the screed is ideal for installing a heated floor.

In dry interior spaces, ordinary cement glue will work perfectly. It is also suitable for the bathroom, but in this case the composition must include fungicidal additives that prevent the appearance of mold.

Advice! It is recommended to cover drywall with elastic adhesives after thoroughly priming the surface.

Instructions for use

Dry building mixtures "Ceresit" are produced by Henkel and are used for external and internal work, for walls and floors, and various types of foundations. The range of tile adhesives is huge; there are universal and specialized products on sale. All Ceresit compositions differ in their scope of application, and for ease of determination of their purpose they are marked as follows:

- SM – building mixtures for fixing ceramic tiles;

- SV – adhesives for fragmentary repair of lined surfaces;

- ST – mixtures for installing external (facade) thermal insulation.

The purpose of the funds is different, the user can always find the right solution. Standard SM brand adhesives have high adhesion to brick and concrete and are used for laying tiles, tiles, mosaics, porcelain tiles indoors and outdoors (example: Ceresit SM 110). Due to their moisture resistance, some adhesives can be used in the bathroom and other wet areas. Elastic adhesives will help secure the finishing material on surfaces prone to vibration and shrinkage. There are also special SM series adhesives for:

- large format floor tiles;

- mosaics and marble (white adhesives);

- clinker;

- facade tiles.

The ST line includes ready-made products and dry mixtures for dilution for outdoor use. The most popular compositions among builders are:

- CT 84 polyurethane adhesive for polystyrene foam (used when installing external thermal insulation of facades);

- CT 190 plaster-adhesive mixture (CT190 is used for installation of mineral wool boards and the base plaster layer for facade thermal insulation);

- CT 85 plaster mixture for polystyrene foam boards (for interior and exterior use).

Before you start using glue, you need to prepare the base. It must be strong and dry, without obvious damage. Before you start using the composition, the surface should be cleaned of sagging, dust and oil stains. It is also necessary to remove other substances that could reduce the adhesion of the mixture to products and surfaces.

Uneven areas must be removed, and then leveled with the same mortar mixture a day before the start of work. If there are irregularities on the surface of more than 20 mm, then they should be leveled with a solution, which must be laid in two or more layers. When working with gypsum bases, they must be coated with a primer.

Ceresit CM16 Flex

Ceresite CM 16 has good elasticity, water and frost resistance, so it can be used for interior and exterior work, laying on heated floors and other deformable substrates.

Specifications

| Mixing proportions | 7.5-8 liters of water per 25 kg bag. |

| Time to use the mixture after mixing | Minimum 2 hours |

| Conditions of use | Base and air temperature from +5 to +30, air humidity less than 80% |

| Opening hours | From 25 minutes |

| Tile adjustment time | From 25 minutes |

| Sliding tiles | No more than 0.5 mm |

| Grouting joints | In 24 hours |

| Adhesion to concrete after 28 days | More than 1 MPa |

| Frost resistance | At least 100 cycles |

| Operating temperature | From −50 to +70 |

| Package | 25 kg bag |

| Flammability according to GOST 30244-94 | NG (non-flammable material) |

Consumption

Approximate consumption of dry mixture CM 16 per square meter, depending on the size of the tiles and the height of the comb teeth:

| Tile length, cm | Comb tooth height, mm | Approximate consumption, kg/m² |

| < 10 | 4 | 2 |

| < 15 | 6 | 2,7 |

| < 25 | 8 | 3,6 |

| < 30 | 10 | 4,2 |

How to mix tile adhesive correctly?

Only at first glance it seems that diluting the glue is as easy as shelling pears.

There are many nuances, failure to comply with which can not only make the glue unusable, but also completely ruin the cladding.

Experienced builders recommend following these rules:

- the mixing container must be clean, the remnants of the previous glue or solution must be scraped off the walls, otherwise they will disturb the composition;

- the water must be clean and match the temperature of the dry mixture and the environment (it will need to be heated or cooled);

- the mixture must be poured into the liquid, and not vice versa, otherwise it will be more difficult to get rid of lumps;

- It is better not to use industrial water due to the presence of impurities that can react with the glue;

- if the cement mortar in the container begins to set, diluting with water will not help, it is better to prepare a new mixture;

- Do not exceed the permissible volume of water, otherwise the solution will turn out liquid and will not hold the tiles.

Advice! If there is any doubt about the consistency of the glue, the mixture should be left for 5-10 minutes. If the texture remains unsatisfactory, you can add a little water or dry powder.

If you have to prepare 10 or less liters of glue, it will be convenient to mix the components using a long rectangular trowel.

This steel spatula with a curved handle can be used by hand, trying to lift dry particles from the bottom so that there are no lumps.

Preparing large volumes of glue by hand is problematic. You will need a drill with a paddle attachment - only it should be designed for mixing the solution, not paint. Experienced craftsmen use a construction mixer with a whisk for this purpose.

The rotation speed of the nozzle should not exceed 300 rpm.

In this case, the blade must be completely immersed in the solution, otherwise bubbles will appear in the texture, deteriorating the quality of the glue.

Work order:

- Pour water at the desired temperature into a clean, prepared container. According to the instructions, add the dry mixture to the liquid. To begin with, it is better to take ⅔ water, and if the mixture turns out thick, dilute it with the rest of the liquid to the optimal consistency.

- Measure out the required amount of dry mixture planned for the first batch.

- Add the first portion of dry glue, stirring the solution. Add the entire prepared mass in small doses, stirring to achieve a uniform consistency.

- Leave the solution for 10-15 minutes so that the particles are well hydrated.

- Stir again to break up any remaining lumps and separations. The glue is ready for use.

The mixture should be quite thick and elastic. It’s easy to check its quality - just scoop up the glue with a trowel and turn it over. A high-quality solution should not drain or fall off in pieces. During the process of laying tiles, it is recommended to stir the solution periodically so that it maintains its plasticity and does not dry out.

We suggest you read: An effective remedy for mold and mildew

Advice! The longer the glue is mixed and whipped, the more liquid it turns out. The situation can be corrected by adding a small portion of the adhesive mixture.

For interior work in a house or apartment, where complex mixtures for laying tiles are not required, you can use a solution prepared yourself. Materials you will need:

- fresh cement grade not lower than 300 – 1 part;

- fine-grained sifted sand - 5 parts;

- water - on request;

- plasticizer – 1/25 part.

PVA glue, slaked lime, silicate glue or liquid soap are suitable as a plasticizer. First, cement and sand are mixed, then the mixture is brought to the desired plastic consistency with water. At the last stage, when all the lumps disappear, add any of the plasticizers.

Beginners should know that the solution prepared from the dry mixture must be used as quickly as possible, but without haste. You cannot leave the glue on the next day - even if it does not completely harden, its beneficial properties will be lost.

Execution of work

The low water absorption of tiles and climatic conditions complicate the work of the tiler. So, if when laying ordinary tiles in a house you need to apply glue to only one base (the tile itself or the surface), then when finishing the exterior - on both.

Ceresit SM 11

This is the most common mixture that is used to fix tiles indoors and outdoors. Glue is also used for laying porcelain stoneware, but in this case only internal use is possible. The main thing here is to follow the manufacturer's recommendations. The size of the tiles should not exceed 40x40 cm, and also absorb more than 3% of moisture. Can be laid on a warm floor.

| Working time after dilution, h | Up to 1.5 |

| Conditions of use | Surface and atmospheric air temperature 5-30°C, humidity – up to 80% |

| Proportions of water and glue | 6 l per 25 kg dry consistency |

| Time interval for cladding adjustment, min. | 25 |

| Sliding of finishing material, mm | Up to 0.5 |

| Rubbing joints | After a day or 72 hours in the case of using an elasticizer |

| Adhesion of adhesive to concrete after 28 days, MPa | 0,8 |

| Frost resistance, cycles | More than 100 |

| Packaging, kg | 5 and 25 |

Material consumption depends on four factors - the size of the tile, the height of the comb scars, the use of an elasticizer and the experience of the craftsman. Approximately it varies from 1.7 to 4.2 kg/m2. For example, when laying tiles up to 15 cm long with a trowel with 6 mm teeth, you will need about 2.7 kg per 1 m2.

Ceresit SM 117

Ceresit 117 belongs to the category of elastic adhesive bases; the product is suitable for installing various types of tiles except marble type. Installation can be done on the surface of cement screed, plaster, etc. The material has increased frost and moisture resistance, so it can be used both indoors and outdoors. The cost of tile adhesive for pools, plinths, facades for 25 kg is 600 rubles.

SM-117 5 kg for natural stone Flex

| Operating time of glue after dilution, h | More than 1.5 |

| Operating conditions of use | Base and ambient air temperature 5-30°C, humidity – up to 80% |

| Proportions of water and mixture | 7.5 l per 25 kg of dry mixture |

| Time interval for cladding adjustment, min. | 15 |

| Sliding of finishing material, mm | Up to 0.5 |

| Rubbing joints | In a day |

| Adhesion of adhesive to concrete after 28 days, MPa | 1 |

| Frost resistance, cycles | More than 110 |

| Packaging, kg | 25 |

When installing tiles measuring 25x25 cm using a comb with 8 mm teeth, the consumption per 1 m2 will not exceed 3.4 kg.

The tile is laid on the applied mixture and pressed. The maximum permissible layer under the tile should not be more than 10 mm. The tiles are not pre-soaked. It is recommended to lay it without seams. The distance between adjacent products should not be less than 2 mm.

Spacers are installed between the tiles to ensure the same joint width. However, you can refuse this process, because the tiles do not slide. Under normal conditions, which are characterized by a temperature within 20 °C and a relative humidity within 60%, the finish must be laid within 20 minutes of applying the mixture.

If work is carried out outside the building in summer in windy weather, then installation must be completed in 15 minutes. The remaining mortar mixture is removed with water until it hardens. Under normal conditions, jointing is carried out after 24 hours. To fill the seams, you can use materials from the Ceresit CE group.

Ceresit CM 14 Extra

The technical characteristics of Ceresit SM 14 make this adhesive suitable for laying tiles and porcelain tiles up to 45x45 cm in size on indoor floors and walls, including wet rooms and heated screeds.

Only strong concrete and cement screeds are acceptable as a base.

For exterior use, it can only be used for gluing decorative cement stone to walls.

Specifications

| Mixing proportions | 6-6.25 liters of water per 25 kg bag. |

| Time to use the mixture after mixing | Minimum 2 hours |

| Conditions of use | Base and air temperature from +5 to +30, air humidity less than 80% |

| Opening hours | From 20 minutes |

| Tile adjustment time | From 20 minutes |

| Sliding tiles | No more than 0.5 mm |

| Grouting joints | In 24 hours |

| Adhesion to concrete after 28 days | More than 0.8 MPa |

| Frost resistance | At least 100 cycles |

| Operating temperature | From −30 to +70 |

| Package | 25 kg bag |

Consumption

| Tile length, cm | Comb tooth height, mm | Consumption, kg/m² |

| < 15 | 6 | 2,7 |

| < 25 | 8 | 3,6 |

| < 30 | 10 | 4,2 |

| < 45 | 12 | 6 |

Scope and variety of adhesives

Ceresit SM 11 adhesive is used when facing non-deformable surfaces with cement or ceramic tiles. Work can be carried out outside or inside buildings. The tile can be artificial stone, the water absorption of which is 1% or less. In this case we are talking about internal work.

Ceresit SM 11 adhesive can be used for gluing tiles whose dimensions do not exceed 0.25 m2. In this case, we are talking about a square-shaped product with a side of 50 cm. An alternative solution is tiles with dimensions equal to 60x40 cm.

Work can also be carried out in utility rooms, namely:

- in drying rooms;

- storerooms;

- basements.