Drywall is a material that is now present in almost every home, and not a single renovation can be done without it. It is perfect for preparing walls for finishing, in particular for leveling them, it is not hazardous to health, does not burn and is quite cheap. That is why almost everyone chooses it. However, many of the performance characteristics of the material and its quality depend not only on its type, but also on the manufacturer. For you - the top 6 manufacturers of wall plasterboard, whose products can be bought on the Russian market.

Leveling walls with plasterboard

Scope of application of gypsum boards

GKL or drywall is a material created on the basis of gypsum and cardboard or special construction paper. It was invented in America back in the 19th century, so it is far from a new type of building material. During production, gypsum undergoes special preparation: it is heated to high temperatures, due to which all excess moisture is removed from it. As a result, the manufacturer receives a calcium-based composition, which is used directly to create gypsum board sheets. Then sheets of material are formed, which are subsequently covered with cardboard or special paper.

The main advantages of gypsum boards:

- non-toxic;

- hypoallergenic;

- mold rarely forms on it or fungus develops;

- perfectly isolates sound;

- easy to use.

Drywall is suitable for various types of work.

GKL cuts perfectly and is very easy to work with. Most often, sheets are used for finishing walls and leveling them. Fixing the material on a concrete base occurs through the creation of a special lathing, as well as with glue or special mastic - the choice of method depends on many factors. Often the material is also used to create interior partitions - this is simple, quick and safe and allows you to reduce the time spent on constructing partitions from other materials. Also, using drywall, you can implement interesting design solutions - create arches or niches, false columns, shelves, etc. GCR is often used to decorate ceilings.

On a note! GCR bends quite well if you moisten it a little before bending. After giving it the desired shape, it needs to be dried well. The dried leaf will retain its shape.

Top 6 drywall manufacturers

| Photo | Name | Rating | Price | |

| #1 | Knauf | ⭐ 4.95 / 5 3 - votes | Find out the price | |

| #2 | Gyproc | ⭐ 4.9 / 5 | Find out the price | |

| #3 | Lafarge | ⭐ 4.85 / 5 | Find out the price | |

| #4 | Volma | ⭐ 4.8 / 5 2 - votes | Find out the price | |

| #5 | Gifas | ⭐ 4.75 / 5 2 - votes | Find out the price | |

| #6 | Rigips | ⭐ 4.7 / 5 | Find out the price |

Which drywall did you choose or recommend?

Take the survey

Many properties of a material directly depend on the quality of its production, which in turn depends on the manufacturer. This list presents the best gypsum board manufacturers whose products can be purchased on the Russian market.

No. 1 - Knauf

Drywall Knauf

This company has been a permanent leader for many years. The manufacturer is European, but it also has factories in Russia. And everyone has definitely heard about it, even people far from the field of construction and repair. Knauf products are created using modern technological equipment and are characterized by durability and high quality. GKL sheets from this brand are smooth and neat, they have standard sizes. The weight of one sheet varies between 12-30 kg depending on its thickness - and this is relatively small compared to sheets from other manufacturers. By the way, the company produces both premium and budget versions of gypsum boards.

pros

- big choice

- durability

- smooth geometry

- relatively light sheet weight

- excellent flexibility and strength

- We have all the certificates confirming the safety and environmental friendliness of the products

Minuses

- not detected

Prices for Knauf drywall

plasterboard Knauf

No. 2 - Gyproc

Gyproc drywall

It is interesting that the name of this English brand has become a household name for drywall. Quite often you can hear a phrase using the Russified name “gyprock” in relation to this material. The brand itself has French roots - it “spun off” from the French company, which produces gypsum-based materials. The main advantage of this company's products is their environmental friendliness. Contains only natural ingredients, no additives. The range also includes very light sheets, 20% lighter than standard ones. They are suitable for creating lightweight structures. By the way, the company has a plant in the Russian Federation, which means the price for the sheets is quite reasonable, since there are no extra costs for logistics.

pros

- 100% environmentally friendly

- lightweight material

- European quality

- perfect geometry

- small sheets, easy to transport

Minuses

- no acoustic material

- costs more than Knauf

Prices for Gyproc plasterboard

Gyproc plasterboard

No. 3 - Lafarge

Lafarge

This is a company from France that sells good HA at extremely low prices for a material of this level. The low cost is ensured by savings on material transportation, because Lafarge has enterprises in many countries around the world. A lot of products are produced per year, but their quality does not suffer at all. One of the main advantages of gypsum boards from this brand is the ideal geometry of the sheets, since during their production special attention is paid to the processing of edges.

pros

- budget cost

- ideally shaped sheet edges

- environmental friendliness

- widespread

Minuses

- not found as such

Lafarge drywall prices

plasterboard Lafarge

Reviews of Lafarge drywall

No. 4 – Volma

Drywall Volma

This is a Russian manufacturer of gypsum boards, whose products, due to their favorable price and good quality, are in great demand everywhere. This is the first brand in the Russian Federation that began to produce material with an increased level of moisture resistance. And, in addition, the material meets all European standards, as it is created taking into account all the innovations in this area of production. At the same time, the cost of Volma GC sheets is quite pleasant for the consumer. By the way, for reference, the company’s history began in the 40s of the twentieth century, and it has been on the market for quite a long time. The main disadvantage of Volma sheets is their heavy weight compared to analogues, and the material itself is quite rigid.

pros

- low cost

- Russian brand

- compliance with European standards

- a large assortment

Minuses

- the sheets are very heavy

Prices for plasterboard Volma

plasterboard Volma

No. 5 – Gifas

Gifas plasterboard

The history of the brand began with the extraction of gypsum and quartz, but then the company opened enterprises for the creation of dry building mixtures, as well as plasterboard. The assortment includes a large selection of materials, both ordinary and moisture-resistant, fire-resistant, etc. When it comes to sizing, everything is manufactured in accordance with industry standards. Among the advantages of gypsum plasterboard from Gifas, buyers note a pleasant price compared to some other materials. However, Gifas sheets are very heavy and are not suitable for creating lightweight structures.

pros

- large assortment of different gypsum boards

- high strength

- low cost

Minuses

- heavy sheets

Prices for Gifas drywall

Gifas plasterboard

No. 6 - Rigips

Drywall Rigips

This is from the French concern Saint-Gobain, like Gyproc. The main production facilities are located in Poland, but the brand has a lot of factories in other countries. The product has excellent geometry and also has a reasonable price. Users choose gypsum boards from this company for their durability and high quality.

pros

- excellent geometry

- European quality

- compliance with all European parameters

- Polish production

- nice price

Minuses

- not the most popular brand in the Russian Federation

Rigips drywall prices

Rigips drywall

Reviews of Rigips drywall

Types of drywall

GCR is used for a variety of jobs, but is most often used for covering walls, frames, and finishing ceilings. It likes fairly dry conditions of use, but in fact there are now options on the market that are suitable for use in waterlogged areas or where there is a high risk of fire. Based on this, 4 groups of drywall can be distinguished.

- Standard - an ordinary thin sheet containing gypsum and pasted with paper. A budget option in white and gray color. It is used only indoors, and in those where the humidity level is low or within normal limits. It cannot be used where it is excessively humid - it will quickly become unusable in just a few weeks.

- Moisture-resistant or gypsum plasterboard is a material that is more expensive than the usual option, but it is stronger, more versatile and can be used where the humidity is higher than standard. It has these properties thanks to a special additive. It has a greenish color and special markings. It can be used in the bathroom, on the balcony, in the kitchen.

- Fire-resistant or GKLO is a material that is resistant to fire. Pink or red in color, has a special marking and is treated with a fire retardant. It costs more than a standard sheet. Its main advantage is its high resistance to open fire for almost an hour of exposure. It is used where there are high temperatures in rooms and there is a risk of fire, as well as for finishing fireplace niches or where heating appliances are located.

- GKLVO is a drywall that is waterproof and fireproof at the same time. Green, with special red markings. It is rarely used at home, but is indispensable when arranging offices and industrial premises. It's quite expensive.

On a note! You can also find a special acoustic gypsum board on sale. It is perforated and is used to provide soundproofing for rooms. It can usually be seen in recording studios, radio rooms, radio stations, etc. Perfectly removes unwanted noise and extinguishes all echoes.

In addition to these types, reinforced HA sheets can also be found on sale. They have additional reinforcing elements that increase the strength of the material. Their weight increases because of this - remember this aspect if you plan to attach it to the sheathing.

You can also now find a laminated version in some stores. It is used to decorate walls, has a decorative coating and does not require additional finishing, perfectly replacing wallpaper. Installation is carried out using special fittings - the material is not attached to self-tapping screws. The joints between individual sheets are covered with special overlays.

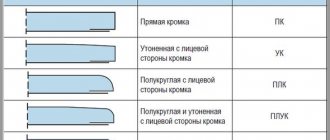

Also, all plasterboard sheets can be divided into several types depending on the type of edge.

Table. Types of gypsum board edges.

| View | Description |

| Direct (regular) or PC | Sheets with such an edge are used for dry installation. when the material is laid in multilayers. |

| Refined or UK | Such an edge on the front side of the sheet is thinner and during installation necessarily requires strengthening and sealing the seam formed between the two sheets. Usually putty is used for this. |

| Semicircular or PLUK/PLC | There are two types here: PLC, that is, semicircular on the front side of the sheet, and PLUK - semicircular, but thinner on the front side. Both the first and second require mandatory filling of the seam and reinforcement. |

| Rounded or ZK | Such a sheet has a completely rounded edge and does not need additional reinforcement - the seam is simply covered with mastic or putty. |

Calculation of the required number of panels

Knowing the dimensions of the panels is required in order to correctly determine the number of panels for carrying out certain planned repairs. The size of the sheet is determined after taking all measurements. For example, for rooms where the wall height is 2.7 m, three-meter panels are purchased. A 0.3 m strip is cut from them. It is incorrect to use 2.5 m panels with the addition of 0.2 m strips. This only increases the number of seams, profiles and, accordingly, costs.

Correct calculation of ceiling panels Source sdelaipotolok.com

Correctly sized panels ensure correct installation of the frame, strengthening the structure and reducing the time of repair work.

It is necessary to avoid in every possible way a large number of seams when working with this material. This means that when purchasing panels, it is necessary to correctly determine the required length, as well as correctly place them on the frame and the plane as a whole.

You can purchase sheets based on the area of the entire surface that will be processed. But in this case, you will need to take approximately 10-20% of spare panels. These are additional and unreasonable costs that can be avoided if you know the dimensions of the sheets and make the appropriate calculations.

How to choose drywall

Drywall is a great help in renovations. However, in order to fully appreciate all its advantages and not be disappointed in the quality of the material, you need to choose it correctly. And first of all, to do this, you need to assess the conditions in which the HA will be used after repair. For example, where the humidity will be high, you need to use a moisture-resistant type of material; where there will be high temperatures or heating equipment will be located, install a fire-resistant type. Regular HA is suitable for rooms with normal humidity levels (usually residential premises).

It is also important when purchasing to pay attention to the integrity of each sheet. All of them must have the correct geometric shape and be free of kinks and other damage.

Important! Do not buy sheets marked “packing slip”. Usually the manufacturer gives them away for free, because this sheet is the base on which other sheets are laid during transportation. And such a sheet is often severely damaged during transportation.

Be sure to take into account the size of the sheets: the choice depends on the room in which you will work, and even on the presence of a freight elevator in the house, because the material itself will somehow need to be lifted into the apartment where the renovation is underway, and not every sheet will fit into the standard passenger elevator. And yes, remember a simple rule: the smaller the sheet, the more joints there will be on the finished surface, but working with a small gypsum board is more convenient and easier.

As for the thickness of the material, gypsum board with a thickness of 12.5 mm is sufficient for walls. Where you plan to make any bends, you can use material 6-9 mm thick. Also, if possible, before purchasing, evaluate the conditions in which the plasterboard was stored. This will allow you to understand whether the material is damp.

Panel weight

The weight of the panel depends on the thickness, length and width. In this case, the thickness of the plasterboard for the wall (as well as other options) depends on the purpose of the panels. According to the standard, the weight of a fire-resistant panel sheet should be 1.6 kg per 0.8 mm; for moisture-resistant and ordinary sheets, this figure should be a maximum of 1 kg per 1 mm of panel.

The thickness of the panel determines its weight and purpose Source izgipsokartona.com

It is necessary to know the weight of the slab to calculate the load force of the installed structure. It is very important to know the maximum weight the panel you are using can support. This will avoid any defects or even collapse of the structure when operating conditions change. When working with material, it is necessary to correctly calculate the load on each square meter. This is especially true in cases where it is necessary to install blind panels or mount heavy elements. You can achieve a load of up to 150 kg/1m2.

Video - How to choose drywall

Drywall is a relatively inexpensive material that will help you easily level your walls, making them almost perfect. It is quite easy to install, provided that special fasteners are used and installation technology is followed. And it is not surprising that it is used in a variety of conditions and quite often. The main thing is that before you buy the material, choose the right type of gypsum board and select the optimal manufacturer whose products will meet the required level of price-quality ratio.

Briefly about the main thing

The dimensions of the gypsum board sheet are a very important indicator when working with drywall.

It is very important to choose the right panels to get a high-quality and durable result.

Some panels are interchangeable, but they may not give the required result.

Always follow the recommendations of manufacturers and craftsmen.

Try to avoid a large number of seams, plan the placement of sheets correctly.

Ratings 0