Primer TechnoNIKOL based on bitumen No. 1

The products are represented by various brands, but the leading position is occupied by bitumen primer Technonikol 01, the technical characteristics of which are as follows:

- the content of non-volatile substances averages 50%;

- It takes approximately 12 hours for the film to dry completely;

- the temperature limit for maintaining strength is +70 degrees Celsius;

- the conditional viscosity of the bitumen primer is in the range of 15-40 units;

- The thermometer's operating indicators range from -20 to +40 degrees Celsius.

The composition contains only organic solvents without inclusions. After the applied film has completely dried, the odor and toxicity of the material are completely eliminated. Technically, the product is a deep penetration primer with resistance to temperature and humidity changes.

Surface treatment with bituminous primer on the outside of the buildingSource venterma.ru

general description

This composition is a homogeneous black liquid, which is a solution of petroleum bitumen. To soften them, conditions are required, characterized by a temperature of 80 degrees or more, and organic substances act as a solution. There are no foreign inclusions in the mixture, and there should be no inhomogeneities. The mixture does not contain toxic solvents such as toluene. Roofing and waterproofing work will be made easier if you use a bitumen primer. With its help, you can reduce the time of manipulation, improving the quality of waterproofing.

Video description

You can see how to apply bitumen-based primer using a gun from the video:

Consumption of bitumen primer TechnoNIKOL per 1 sq.m. depends on the substrate being treated and the method of application. So, if you pour and distribute with a spatula, you will need approximately 0.5-1.2 times more liquid than if you use a roller or brush.

When processing metal products per sq. m. you have to spend about 0.2 liters of soil. If the base is represented by a mineral composition, then the consumption is 0.25-0.45 l/sq.m, depending on the absorbency and porosity of the object. Solid wood will require 0.3-0.35 l/sq.m.

Calculation of primer consumption per 1 m2

Calculating bitumen consumption is easy; you just need to calculate the area of the base. And also find out the consumption indicator of a specific primer. This information is available on the Internet. The manufacturer’s website also often contains an online calculator, with which calculations are not difficult.

Calculating bitumen consumption is easy; you just need to calculate the area of the base.

Bitumen primer is a reliable product that will help to carry out high-quality waterproofing of various structures. To carry out repair work, craftsmen calculate in advance the number of kilograms that will need to be purchased to cover the entire area. The article described in detail the rules for conducting independent calculations.

Bitumen composition with polymers

Technonikol's products for priming surfaces are presented in three options. These are compositions numbered 1, 3 and 4. Thus, the bitumen-polymer mass (No. 3) has the following characteristics:

- the share of non-volatile substances from the total mass averages 27%;

- Complete drying time takes approximately 11 minutes;

- when heated, the polymer film does not soften;

- conditional viscosity is in the range of 10-30 units;

- The operating indicators of the thermometer are indicated in the range from -20 to +40 degrees Celsius.

Bitumen composition TechnoNIKOL No. 3Source uralint.ru

Primer types

There are several types of this product, the cheapest is simple primer. Bitumen-polymer material is much more expensive; it contains special substances that promote rapid drying, while at the same time isolating the surface much better from the effects of nature. Primer, bitumen emulsion – used for interior work, diluted with water.

Application and positive aspects of bitumen-based soil

Bitumen primer is similar in properties to plaster, and is intended to protect porous materials, only, unlike gypsum mixtures, it can be used for metal surfaces and in roofing work.

Impregnation of the base with bituminous soil is intended as a starting coating before using various waterproofing materials.

Due to its dense composition, the primer clogs all the pores of the material, making it resistant to moisture. Waterproofing of various structures using a bitumen primer becomes better.

Let's consider in which areas it is most preferable to use bitumen primer.

Scope of application

Primer is a primer designed to fill the pores of the material, level out small roughnesses and irregularities, and remove dust from the material. It is used for primary treatment and improving the adhesion of the waterproofing material to the base.

The material can also be used as independent surface insulation, in cases where the base is not constantly exposed to moisture.

Many builders use emulsion primers to coat surfaces in the bathroom and kitchen, where air humidity is high.

Now there are many types of this material on the market, which are used:

- for roof treatment;

- floor coverings;

- basements;

- foundations;

- sewer pipes and water supply systems.

The performance characteristics of each type of bitumen primer differ from each other, and you only need to use the material that is suitable for a particular type of surface.

Characteristics of bitumen impregnation:

Types of bitumen primers

Manufacturers of this type of primer for waterproofing produce a wide range of materials with different properties, for example, different brands of product:

- Primer intended for deep impregnation of concrete surfaces, foundation blocks, self-leveling floor coverings, sand-cement plasters.

- For insulating wooden decks or walls.

- Material for processing pipes and metal spans when waterproofing work is planned.

- Emulsion primer that can be applied to a damp surface indoors.

All impregnations can be applied with a brush or roller. Before treatment, the surface should be thoroughly treated - cleaned of old coating and degreased.

Universal formulations

In addition to specialized formulations, manufacturers produce universal acrylic-based materials that can be diluted with water.

A universal bitumen primer primer, used in residential premises, while its composition contains antiseptic additives and has antifungal properties.

This material can be applied to any surface:

- brick;

- aerated concrete;

- plaster;

- concrete;

- Fiberboard;

- drywall;

- chipboard;

- DSP.

Universal foundation primers are used for exterior work, when it is planned to apply decorative plaster to the base plaster layer. The material is vapor permeable, while protecting the surface from adverse weather conditions.

Universal bitumen soil has the following advantages:

- high adhesion of the base and material;

- allows air to pass through;

- makes the base waterproof.

Bitumen composition without organic solvents

Bitumen solution No. 4 does not contain organic solvents. The product is presented as an aqueous emulsion with technological additives. The technical specifications are as follows:

- the proportion of non-volatile substances in relation to the total volume is 25-40%;

- It takes 60 minutes to dry completely;

- when exposed to more than 75 degrees Celsius, the film begins to soften;

- conditional viscosity is 5-30 units;

- the operating temperature range is from +5 to +30 degrees Celsius.

The soil is used only inside the building. Concrete structures made of cement with sand and foam blocks are subject to treatment before installing a waterproofing coating. Consumption of bitumen primer TechnoNIKOL No. 4 per 1 sq.m. is 0.25-0.35 liters.

TechnoNIKOL bitumen solution No. 4 Source www.tn.ru

Tips for use

- Clean the surface from sand, dust and dirt.

- Select the solvent and its volume in accordance with the instructions on the primer packaging.

- Before use, the solution is mixed with an electric drill or a construction mixer at low speeds.

- The layer thickness should be in the range of 0.5-1.5 mm.

- Use a spray bottle when treating vertical surfaces.

- It is allowed to spill the composition on a horizontal plane, and then carefully distribute it over the entire area.

- Be sure to wear protective gloves and a respirator.

- Do not use a foam roller. The solvent included in the primer will corrode it.

Can be used after the expiration date. But the efficiency and technical parameters will be partially lost (the quality of the protective film coating decreases).

Briefly about the main thing

Bitumen-based primer from Technonikol is presented in three versions: 01 – universal, 03 – temperature-resistant and 04 – for interior work.

Primer TechnoNIKOL 01 – consumption per 1 m2 depends on the surface being treated and its absorbency. The indicators range from 0.2 to 0.45 l/sq.m.

Primer No. 1 from TechnoNIKOL is used to protect metal from corrosion and indoor structures from moisture penetration. The composition is also used to prepare the base for installing a hydraulic barrier or designing a roofing covering. It is permissible to glue roll insulation and mineral filler as a substrate on a road surface or foundation.

Which primer should you choose?

The most versatile and popular composition is TechnoNIKOL 01. Today it costs about 1,600 rubles for a container of 20 liters (16 kg).

It is ideal in consistency, price and quality. Suitable for poor surfaces, absorbs quickly and provides additional protection against moisture. The roof stays on it for a very long time if it is laid in accordance with GOST.

The cheapest option is the TechnoNIKOL 04 primer. It is fluid and excellent for an even and high-quality screed. But if there are microcracks in the screed, or the surface is uneven, then it is no longer enough. No. 4 is a primer in the full sense of the word, with a minimum of waterproofing properties.

TechnoNIKOL 03 is the highest quality primer that is on sale. It contains polymer substances that create an additional protective barrier. Well suited for rainy areas, foundations, processing concrete in contact with water. But the price is appropriate.

For roof repairs, it is best to choose the 01st primer model. It is the most common, reliable, and easy to work with due to its fluidity, whether on vertical walls or on a horizontal surface.

Waterproofing with bitumen. Step-by-step instruction

Waterproofing work consists of the following stages:

- Surface cleaning.

- Preparation of material.

- Diluting a small portion of bitumen.

- Surface application.

- Ensuring complete drying of the material.

First, the surface is cleaned with a stiff-bristled brush, then with a clean, damp cloth and left to dry. After this, a bitumen mixture is prepared. If you use the method of cold application with a solvent, then you need to follow these instructions: pour the mixture into a container, pour in the solvent, stir. The solution should be quite thick, like jelly. For dilution, you can follow the instructions indicated for a specific mixture.

Then the diluted mastic is applied with a brush to the prepared surface. A brush is used in hard-to-reach places, but when applying material to a large flat surface, it is better to use a roller.

Surface application

The material should be applied in strips and spread in one direction if a vertical area is being processed. But when waterproofing a horizontal surface, you can simplify your work: pour a small amount of the mixture from a metal ladle onto the surface and level it with a roller.

When working with cold-applied mastic, you don’t have to rush, because this material completely hardens within a day. Therefore, this kind of work can be done alone.

Cold applied mastic can significantly reduce labor costs, because this method does not require additional heating of the mixture. But the disadvantage of this method is that it contains a large amount of solvents that evaporate after hardening. Therefore, cold applied mastic is consumed more than hot applied one.

If you use hot applied mastic, the work will become more complicated because it will have to be done many times faster. After heating the material, it must be instantly applied to the surface and leveled, because such bitumen hardens in 2 minutes. It is better to work with this mastic together: while one melts the material, the other should apply it to the surface.

When applying hot bitumen mastic, you must follow the following rules:

- Apply the mixture to vertical areas from top to bottom.

- The strips are overlapped with a margin of 100 mm.

- Do not melt large amounts of material, otherwise it will quickly dry out in the ladle and need to be re-cooked.

To melt the material, you need to place crushed bitumen in a ladle, then stir it until completely dissolved.

Application Features

For small volumes, rollers are most often used.

The procedure for working with bitumen primers is quite simple. The instructions do not require special knowledge or skills; it is enough to follow its points:

- The base on which the composition is applied must be cleaned of dust and loose parts.

You should take the preparation of the foundation seriously.

- According to the manufacturer's instructions, the composition must be prepared. This may be by heating or diluting with a solvent. As a rule, mastics are diluted for spray guns.

Prepare the material according to the manufacturer's instructions.

- When working with roofing, the substance is poured and smoothed with rubber squeegees. During large-scale construction, spray guns are used;

The composition can be poured onto a flat roof.

- Then rubber, polymer or bitumen materials are glued, depending on the specific work;

Roll material is glued onto the mastic layer.

- If the composition is used independently, it is often necessary to apply a second layer;

Despite the fact that the price of the material can be high, several layers are often required.

- At the end, it is necessary to create conditions for normal hardening of the primer layer . They are described in the instructions for the specific substance.

Allow the composition to dry properly.

When working with solvent-based mastics, be sure to use gloves, goggles and respirators. Do not work near open flames and do not smoke while doing so.

How to prepare your own bitumen primer ↑

The technology for preparing bitumen compositions is not complicated; any developer can master it. The primer is prepared immediately before use so that it does not harden and adheres well to the surface to be treated. It is not advisable to prepare the composition in reserve, much less freeze it, because... this may affect its properties.

The first method is cold ↑

There are two main ways to prepare primer - cold and hot. The first is used if the developer has nowhere to rush and has at least 1-2 weeks. Low-octane gasoline can be used as a solvent; grades AI-80 or AI-72 are suitable. It is poured into a large tank and pieces of bitumen are placed. The rest is a matter of time.

Bitumen dissolves in gasoline in about 7-12 days. This largely depends on the ambient temperature. To speed up the process, it is advisable to mix the bitumen

It is very important to tightly seal the container in which the mixture is located so that gasoline vapors do not escape. A sign that the primer is ready is complete dissolution of bitumen, transformation of the composition into a homogeneous mass.

Applying primer to concrete floor

The second method is hot ↑

Most often they resort to the hot method of preparing the primer. To do this, pieces of bitumen are placed in a container and “cooked”, i.e. heated to a boil. A regular fire can be used as a fire source. When the bitumen boils, it is slowly and carefully poured into a tank with gasoline.

Recommended proportions of bitumen and gasoline:

- for concrete – 1:2;

- for metal – 1:3.

Heated bitumen

When preparing the primer, be sure to pour boiling bitumen into gasoline, although many do the opposite. The finished mixture must be thoroughly mixed until smooth. The composition should not contain solid pieces.

How long does it take to dry?

The drying time of the bitumen primer layer directly depends on the ambient temperature: the colder it is, the longer the composition will harden. The hardening period declared by the manufacturer is 12 hours . The material is considered dry when the surface stops sticking to your hands.

The operating temperature range of the material varies from -10...+40 degrees . If work is carried out at temperatures below +5 degrees , the composition for at least 24 hours .

Consumption of bitumen mastic per 1m2 * ABuildic

Bitumen mastic is one of the fairly common modern materials used for waterproofing. It can be used for waterproofing the foundation and roof of a building, as well as in preparing individual structural elements, for example, for pillars that form the basis of barriers or small architectural forms.

Types of bitumen mastic

There are several dozen trade names of bitumen mastic, but, in fact, there are only a few types of mastic, or more precisely, three. They differ in the method of application, as well as in composition. The first version of mastic is used together with aggressive chemical solvents.

They are most often based on synthetic materials, which, when mixed, produce a solution that can be applied to the surface to be treated without preheating it.

A distinctive feature of such mastics is their high danger, therefore it is necessary to work with them only when using means that protect the respiratory system.

The second option, unlike the first, although it consists of synthetic materials, however, ordinary water acts as a solvent for it. This greatly increases the safety of its use. The only difficulty in using them is the need to comply with environmental temperature parameters. They should not go beyond the range from +5 to +30 degrees.

The third option of mastic has been used for quite a long time. It is traditional, but at the same time such mastic creates a lot of difficulties. To apply it, it needs to be heated and special tools are used for this. Hot applied mastics are dangerous for craftsmen when working with them, since their melting point is quite high, which increases the risk of thermal burns.

Consumption of bitumen mastic per 1 m2 when waterproofing the foundation

When waterproofing the foundation, all of the listed main types of bitumen mastics can be used. However, their consumption rates are somewhat different. Cold application mastics are consumed in a volume of 1-1.5 kg per 1 m2, provided that the thickness of one layer is about 0.5-1 mm. Consumption increases proportionally with increasing number of layers.

Hot mastics, due to technological difficulties, are applied in a thicker layer - 2 mm. Therefore, the consumption of raw materials, accordingly, increases and amounts to 2 kg per 1 m2. It is worth considering that the number of layers when waterproofing a foundation cannot be less than two, that is, the consumption must be at least doubled.

Consumption of bitumen-polymer mastic per 1 m2

Bitumen-polymer mastics are often used not just for waterproofing, but for gluing the waterproofing layer to the base, so their consumption is somewhat different from the main parameters. Depending on the manufacturer’s brand, chemical composition and purpose of such mastic, its consumption can vary from 0.8 to 3 kg per 1 m2.

Consumption of TechnoNIKOL bitumen mastic per 1 m2

TechnoNIKOL bitumen mastics also differ in their composition, and accordingly, their consumption is different.

For example, a bitumen-rubber mastic called Technomast, which is used to treat roofing, can be consumed in an amount of 1 to 3.5 kg per 1 m2.

Bitumen-polymer mastics produced by Technonikol, namely Vishera and Fixer, are consumed in a volume of at least 0.8 kg per 1 m2.

Consumption of bitumen rubber mastic AquaMast

Another type of mastic produced by Technonikol is the bitumen-rubber mixture AquaMast. It is used not for external, but for internal waterproofing of premises, for example, for treating bathrooms. Its consumption varies from 0.5 to 1.5 kg per 1 m2

Bitumen primer: what is it and what does it consist of?

- Preparing the base. The surface intended for treatment is completely cleaned of dust and construction debris.

- Preparation of the composition. It was mentioned above that primers are ready-to-use and highly concentrated. In the first case, the composition is mixed using a construction mixer and applied to the surface. In the second, the composition is diluted with organic solvents, observing the proportions specified by the manufacturer.

- Application. The processing method may vary depending on the type of base and application technology. In most cases, the composition is evenly distributed over the surface using a nylon brush or roller. If we are talking about a large area, the primer is poured and then leveled with rubberized scrapers.

It is more convenient to treat vertical structures with spray guns.

It is important to understand that organic solvents included in the primer require mandatory safety precautions. All work is carried out only in well-ventilated areas, using personal protective equipment

Many people confuse bitumen primer with mastic and sealant. In fact, these are completely different mixtures with their own composition and purpose. Bitumen primer is a primer in the form of a water emulsion of petroleum bitumen with the addition of white spirit, kerosene and other components that give the mixture certain properties.

In simple words, the primer is not solid, but liquid bitumen. It is a composition of resinous hydrocarbons, which are classified as organic substances. They are characterized by viscosity and a very dark, rich black color. Various materials are made from bitumen: roofing felt, stekloizol, linokrom, ondulin, parchment, etc.

Please note: primer is a broader concept. It is not only bitumen, but also alkyd, phosphate, acrylic, epoxy and shellac

Applying primer with a brush

Treatment with a bitumen primer increases the adhesion of the base to the materials that are laid on it. Unlike a primer, this composition no longer strengthens, but glues, seals and makes the surface resistant to moisture. Due to such effects, the following can be achieved:

- Increase the insulating properties of the materials used.

- Speed up the finishing process.

- Reduce overall costs by 1.5-4% and costs for further maintenance.

- Extend the service life of treated coatings.

The main criterion for classifying bitumen primers is consistency. The method of application of impregnation also depends on it. According to this criterion, the following are distinguished:

- Ready primers. There is no need to carry out any manipulations with them before starting work. Such impregnations can be immediately applied to the base. It is enough just to thoroughly mix the contents of the container.

- Concentrated. Before use, be sure to dilute them, for example, with diesel fuel, white spirit or gasoline.

Many people, before starting waterproofing work, are faced with a choice between primer and mastic. Both compositions are produced on the basis of bitumen. Their purpose also coincides - protecting the roof and other structures from moisture. What, then, is the difference between primer and mastic, and which composition is better to choose?

We recommend that you study in more detail: “What is bitumen mastic: what does it consist of, properties and characteristics, advantages over roll materials and application technology.”

It is impossible to answer this question unequivocally. Mastics are more viscous than primers. They may contain plasticizers and various types of crumbs to give the composition a certain thickness. If the main task of the primer is to create a high-quality base into which moisture will not penetrate either from above or below, then the mastic is intended directly for waterproofing.

We prime the foundation with primer correctly

Before applying coating waterproofing or gluing roll materials, it is necessary to perform a number of preparatory operations and apply a bitumen foundation primer to the entire area of the base. The general scheme of work is as follows:

- First of all, it is necessary to ensure an approach to the work site. To do this, the soil is removed from the foundation at a distance of at least a meter.

- Next, the concrete base must be allowed to dry completely. This is especially true if the foundation was not covered with waterproofing materials in a timely manner.

- The next stage is cleaning the foundation surface from loose concrete particles, soil residues and other debris. For this purpose, various brushes with both metal and synthetic bristles are used.

- After all the preparatory work has been completed, the foundation is directly waterproofed with a primer. To do this, the composition is applied in the manner indicated above, trying to cover the entire surface of the base of the house or bathhouse without gaps. Many of today's bituminous primers have a very short drying time. This allows you to apply three or four layers of primer during daylight hours, with each layer completely drying.

- After the last layer has completely dried, which is checked by touching it for tack, you can apply the previously selected type of foundation waterproofing.

Primer application

Why prime the surface for waterproofing?

Separation of the waterproofing layer and depressurization of the roof often occur due to the difference between the coefficients of thermal expansion of the base and the deposited roll material. Under significant wind loads, a waterproofing carpet laid directly on concrete or metal without the use of a bitumen primer comes off the base.

Bitumen primer prevents such situations, preventing depressurization of the roof. When using IKOPAL products for priming surfaces, the adhesion force between the roofing covering and the metal or concrete base is so great that depressurization does not occur even with constant sudden changes in temperature or strong gusts of wind. The negative consequences of this cannot be described.

Primers TechnoNIKOL

TechnoNIKOL Corporation is one of the Russian market leaders in the production of bitumen mixtures for various applications.

Tenonicol 01

Bitumen primer TechnoNIKOL 01 is considered one of the most popular universal waterproofing materials. This is a classic version of a ready-to-use bitumen mixture based on organic solvents. Widely used in roofing work, and as an independent waterproofing for concrete and cement surfaces.

Primer TechnoNIKOL 02 is a concentrated analogue of TechnoNIKOL 01. The concentrate is more convenient for transportation and when used in large volumes. Before use, the mixture is diluted with white spirit or kerosene in a ratio of 1:1.5 – 1:2 by volume and mixed thoroughly. It is acceptable to use gasoline solvent.

TechnoNIKOL 03

Bitumen-polymer primer Technonikol 03 has increased adhesive and hydrophobic properties due to the additives included in its composition. The composition is used for processing metal and non-uniform surfaces, pipelines and bridge structures. It is sold as a ready-to-use bitumen primer.

TechnoNIKOL 04

TechnoNIKOL 04 is an emulsion bitumen primer, i.e. ready-to-use aqueous bitumen emulsion. It is used for interior work (for example, for treating the floor in the bathroom). Since the composition does not use organic solvents, the mixture does not have a strong odor and does not emit harmful fumes. Drying time for the primer at room temperature is no more than an hour.

The water base allows you to apply Technikol 04 primer to wet surfaces.

AquaMast

Primer AquaMast is an environmentally friendly primer based on organic solvents for pre-treatment of surfaces. A special feature of the AquaMast composition is that it can be used both in combination with roll materials and when installing coating waterproofing.

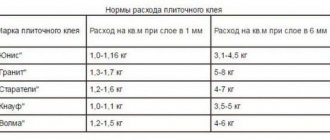

| Indicators | 01 | 03 | 04 | AquaMast |

| Primer consumption, l/m2 | 0,25-0,35 | 0,25-0,35 | 0,25-0,35 | 0,35 |

| Drying time at 20 C, h | 12 | 10 minutes | 1 | 12 |

| Application temperature, C | from -20 to +40 | from -20 to +40 | from +5 to +30 | from -10 to +40 |

Table 1. Technical characteristics of TechnoNIKOL primers

Healthy competition for the TechnoNIKOL corporation comes from the Vitumast company, which offers its line of bitumen primers with similar technical characteristics.

When choosing a universal primer, the golden rule “price – quality” applies. It is better to ask your sales consultants in more detail about the properties of special-purpose mixtures.

"TechnoNikol 01": material characteristics ↑

"TechnoNikol 01" is a primer made from high-quality solvents and bitumen. In its standard form it is ready for use and does not require the addition of additional chemicals. Organic solvents do not emit toxins and are harmless to health. This material can be classified as environmentally friendly, which distinguishes it favorably from toluene analogues offered by other manufacturers.

If the primer is made from good raw materials and in accordance with technology, it takes on the appearance of a homogeneous mass without foreign inclusions. The composition is ideal for priming rough materials before installing waterproofing. It provides strong adhesion of insulation to concrete, reinforced concrete and cement-sand structures.

50-liter package "TechnoNikol 01"

Among the advantages of TechnoNikol 01 are the following:

- simple application technology;

- good adhesion of materials;

- quick drying (from 1 to 5 hours);

- high hydrophobicity;

- anti-corrosion properties;

- no sticking effect;

- temperature stability;

- Possibility of use in cool weather.

Waterproofing materials "TechnoNikol"

Release forms - standard and concentrate ↑

The manufacturer packages the products in sealed buckets of 20 and 50 liters. The approximate consumption of bitumen primer "TechnoNikol 01" per 1 m2 is 250-350 ml. The volume depends on the type of surface to which the composition is applied. The more pores and microcracks there are, the better the primer material is absorbed.

In addition to the standard form, TechnoNikol 01 is produced in the form of a concentrate. It must be diluted with white spirit, gasoline or other suitable solvent. The consumption of bitumen primer per 1 m2 should be calculated using the same standards: 1 liter is enough to treat 3.33 m2 of surface.

Norms

To prevent the dried primer from chipping off the coated surface, the concrete, cement or wood coating should not release moisture. Bitumen mastic is applied under the primer. If the surface is initially dry and does not cause problems, then you can immediately apply a layer of primer. The supplier company indicates the recommended range of values for consumption per square meter - the user can quickly navigate the specific situation. The fact is that the bitumen primer, without which a high-quality coating is impossible, contains up to 7/10 volatile solvents and has some so-called. drying percentage. The bitumen primer consumption is calculated independently.

If you apply too thin a layer, it will not last long. It may crack, fade, or peel even without the surface releasing moisture. If you go overboard with the quantity, the surface can also crack: everything that turns out to be superfluous will simply fall off over time.

Any primer provides an average consumption rate of approximately 300 g/m2 on a cold surface. Some manufacturers that supply bitumen primer in 50-liter tanks provide, for example, coverage of up to 100 m2 of surfaces in a house or non-residential building with the contents of one such tank. For a 20-liter tank this is up to 40 m2 of surface. It is easy to calculate that 1 dm3 (1 l) of primer is enough to cover 2 m2 of surfaces - the increased rate provides for rough concrete, cement, unsanded wood or chipboard, where this value can double.

When treating the foundation (without screed), approximately 3 kg of thick substance per square meter may be required. For roofing and coverings, this value can increase to 6 kg/m2. If you need to produce, for example, a substitute for roofing felt (cardboard and bitumen, without mineral bedding), then the consumption rate will drop to 2 kg/m2. At the same time, the concrete support or ceiling will be more durable - thanks to high-quality waterproofing. Planed, sanded wood may require only 300 ml per 1 square meter. m. surface; the second (and third) layers of the primer composition, applied to almost any surface, require the same amount.

Porous surfaces, for example, foam blocks without external finishing (plaster, wooden flooring) will require up to 6 kg/m2. The fact is that any fluid composition similar to a liquid easily seeps through the upper layers of air bubbles, the shell of which is the building mixture used in the manufacture of foam blocks. Uneven and porous surfaces are covered with a wide brush (which can be found in the nearest construction supermarkets). For smooth surfaces - sanded wood, steel floors - a roller is suitable. Due to their smoothness, metal surfaces will require only 200 g (or 200 ml) of primer composition. A flat concrete roof with powder (including roofing felt) may require 900 g or 1 kg per 1 m2.

TechnoNIKOL mastic consumption

Very often TechnoNIKOL mastic is confused with a primer. For the convenience of visitors, it was decided to post a table of mastic consumption here.

Consumption in liters (kilograms) per square meter

Waterproofing (1 layer on concrete)

Waterproofing (2 layers)

TechnoNIKOL mastics and sealants are used mainly for insulating seams, but with their help you can even create a roof if you use fiberglass. You can reduce mastic consumption if you treat the concrete surface with a primer, for example, No. 01, before application. The mastic surface is protected with primer 57, which protects the layer from sunlight.

You can also glue rolled soft roofing onto the mastic without using a gas burner.

The company also produces a range of sealants, for example, TechnoNIKOL 70, which are used to protect pipes, cables, and metal structures from moisture.

Primer Density

The density of any substance is the amount of its mass in kilograms that can fit in a cubic meter. The result itself can be very ambiguous, as it depends on many factors. The main one of these factors is temperature. The higher it is, the higher the density will be.

Therefore, this building material is used cold.

Bitumen primer TECHNONICOL No. 01 is intended for preparing various types of surfaces for laying materials during waterproofing and roofing work. It provides high-quality and reliable adhesion to cement-sand screeds, concrete slabs and any other rough and porous surfaces.

Primer TechnoNIKOL No. 01 is made from bitumen and organic solvents. In this case, to obtain the solution, only those bitumen are used whose softening temperature is at least 80°C.

Also, the primer is completely free of inhomogeneities and any foreign inclusions. The mass fraction of non-volatile substances is at least 35-40%.

Made from the highest quality bitumens and carefully selected solvents, this primer has excellent performance properties:

- deep penetrating action;

- high drying speed - no more than 12 hours at a temperature of 20°C;

- heat resistance;

- no stickiness.

Table of Material Characteristics

| Parameter name | Bitumen primer TechnoNIKOL No. 01 | Bitumen primer TechnoNIKOL No. 01 (concentrate) |

| Presence of inhomogeneities and foreign inclusions | No | |

| Drying time of the applied layer at 20 °C, hour, no more | 12 | |

| Mass fraction of non-volatile substances, %, not less | 30-40 | |

| Softening temperature °C, not lower | 80 |

Features of use

Concentrate. Before starting work, a solvent must be added to the primer. The use of kerosene, gasoline, and white spirit is allowed. Dilution of the bitumen primer is carried out in a range of proportions from 1 to 1.5 to 1 to 2.

Ready solution. The bitumen primer, completely ready for use, just needs to be mixed thoroughly.

To apply the layer, it is recommended to use brushes or nylon brushes. With this approach, the bitumen primer is quickly absorbed into the treated surface and thereby provides good adhesion to waterproofing and roofing materials.

Consumption

The consumption of ready-to-use primer is 250-350 ml/m².

Precautionary measures

- Do not allow primer to come into contact with eyes or skin.

- It is recommended to carry out work in well-ventilated areas.

- Do not use primer in close proximity to fire sources.

The shelf life is 1 year. There are no special requirements for the primer regarding storage conditions. The solution can be kept at temperatures from -20 to +30 degrees Celsius. Preferably in a dry place, protected from light.

Bitumen primer

- PPU shell

- Geotextiles

- Fiberglass

- Rolled fiberglass PCT

- K-FLEX

- Septic tanks

- Thermal insulation of pipelines

- Protective coatings for pipe insulation

- Anti-corrosion materials for pipes

- Geomaterials

- Non-woven fabric for light industry

- Composite materials

- Pipe expansion joints

- Fencing means

- Fire retardant materials

You can buy bitumen primer in our sales departments in Yekaterinburg, Chelyabinsk and Perm. We will quickly and cheaply send the material to other regions of the Russian Federation. We have very favorable conditions! Any volume to order on time! A qualified specialist will tell you the consumption and help with calculations!

DESCRIPTION

Does not require temperature control.

Easy to use.

Easily penetrates the surface.

Bitumen primer is a primer, which is a solution of bitumen in a quick-drying organic solvent, used mainly for waterproofing work. If working with traditional bitumen is difficult and fire hazardous, then bitumen primer is an excellent alternative that allows even an untrained employee to perform the necessary insulation work efficiently and safely.

The primer is packaged in sealed metal buckets or plastic canisters, which also facilitates its transportation, storage and use.

USING A BITUMEN PRIMER

Bitumen primer is an inexpensive material for waterproofing brick, concrete and metal surfaces, cement-sand screeds, and road crushed stone. Apply the pre-mixed primer using a roller or brush; when thickening, it is advisable to dilute it with a solvent, white spirit or gasoline. If necessary, apply in several layers, with a short break for drying. Concrete and brick are porous, absorbent materials, so only repeated application of waterproofing can saturate their surfaces.

To prime the surface with one layer of bitumen primer, you need to spend from 0.25 to 0.35 kilograms per square meter. Its consumption depends on the surface roughness and adhesion ability. For monolithic, durable and smooth surfaces, less material is spent, whereas if we are talking about rough, porous and loose bases, the consumption will be greater.

Work with bitumen primer should not be carried out near an open fire, because the solvents and bitumen contained in it are flammable and fire hazardous materials.

All work on applying bitumen primer must be carried out outdoors or in rooms with sufficient ventilation!

We offer licensed products. Materials for protection against corrosion and rust will last a long time. The following advantages can be highlighted:

simple and easy application;

processing large areas of metal structures that have a complex configuration;

high level of efficiency;

excellent protective properties;

durability of the coating during operation;

after application, a protective film is formed that does not allow moisture to pass through;

BUY BITUMEN PRIMER

You can buy bitumen primer from our company at retail, as well as wholesale, for cash and non-cash payments, discounts are provided for volumes. We have been supplying insulating materials throughout Russia for many years, we guarantee you the quality of the goods supplied, and will promptly ship them using a transport company convenient for you.

Standards for using bitumen primer

Basement waterproofing diagram.

The amount of special primer per 1 m2 of surface depends on its composition. There are masses that are applied hot or cold, made on the basis of solvent and water. For example, hot mastics are considered a material that does not shrink after hardening, the thickness of the layer and its area do not decrease. Calculating the quantity is not that difficult. Bitumen mastic is consumed in the amount of 0.8-1 kg per 1 m² when gluing roll materials. If waterproofing work is carried out using only a primer, then the consumption will be from 2 kg to 3 kg per 1 m² for 1 layer with a thickness of 2 mm.

The dry residue for 1 layer with a thickness of 2 mm requires 3.5-3.8 kg. What is dry residue? This is the value that remains after the drying process. This is usually expressed as a percentage of mass to volume used. The dry residue value is the volume of initial material required to form a film of the required thickness. Bitumen consumption for waterproofing is usually 20-70%. It should be taken into account that with the same thickness of the layer of material with a residue of 20%, the amount will be approximately 3 times greater than with a residue of 70%. This proves that bitumen consumption per 1 m² with a larger percentage of the remainder will be much more economical than with a smaller percentage. This means that the labor intensity and cost of waterproofing work will be less. The result will be significant savings.

The bitumen consumption per 1 m2 is low due to the fact that it is a highly effective waterproofing material that reduces moisture absorption.

Water protection will be economical, durable and reliable.

Today, 3 types of primers are used:

- Bitumen primer. Required for priming the surfaces of high-quality fused roofs.

- Bitumen-polymer, which can be used for metal, cement-sand, concrete bases. Such primers are used for built-up, self-adhesive roofs, if it is necessary to treat spans of bridge structures.

- Bitumen emulsions. Used as primers, they are excellent for protecting any base, structure, or surfaces. The need for them is minimal, but the quality is ensured at a fairly high level.

Bitumen primers TechnoNIKOL, Aquamast, Bitumast - characteristics and application

Handle (1) - a welded curved piece of metal pipe or rod. Side axles (4) in the amount of 2 pcs. - pieces of water pipe with a diameter of 25 cm, a length of 3-5 cm. They are welded oppositely, just above the center of the tank and serve as its support on the legs. We drill holes at their ends to fix the legs. Patch (5) is a welded piece of metal plate to prevent burning of the bottom of the tank - the thicker it is, the longer the service life of the product. The legs (6) have a cross-shaped base made of metal pipe scraps (strips, angles, rods, etc.) and a stand (height and diameter as desired) made of a metal pipe. At its upper end we weld a ring with a diameter of 32 mm (sawed off from a water pipe).

The drain pipe (3) at the end must have a thread with a diameter of 32 mm. It is screwed in instead of a heating element. You can make it yourself by welding a thread at an angle to a piece of pipe with a diameter of 32 mm or 40 mm (sold in plumbing stores). The legs on the tank bushings can be secured with a regular nail or a suitable piece of wire. This collapsible design increases the mobility of the product when moving and transporting.

The drain pipe (3) is unscrewed, through this hole the tank is filled with small pieces (melting time is reduced) of bitumen, which, by the way, is easily crushed. It is good to use for this purpose a funnel made of thick paper, or the top of a plastic container with a suitable neck diameter.

Waterproofing with bitumen

Scheme for applying bitumen mastic.

Before applying mastic, it is necessary to carefully prepare the surface to be treated, that is, clean it of dust and debris, and also dry it well. This mixture can be laid on old bitumen coating, if it adheres well to the finishing surface, and on metal structures with traces of rust. The integrity of the waterproofing layer can be damaged by various sharp edges, so before carrying out the main work, such protruding elements should be removed.

External waterproofing of the foundation is carried out by applying bitumen in 3-4 layers using a regular brush or roller. In this case, the total thickness of the coating should be about 4 cm.

The thickness of the layers and their number depend on the depth of the base.

The deeper the foundation is placed, the more layers of waterproofing need to be used. For walls, 2 layers are quite enough. The next layer of bitumen is applied only after the previous one has completely dried.

The correctly selected type of bitumen mastic and compliance with all the rules for its application will allow you to create a high-quality waterproofing layer that will serve you for at least 30 years.

Bitumen mastic can be used for waterproofing various surfaces: roofs, foundations, fence posts, etc.

d. The material is relatively inexpensive and can be bought at any hardware store. Service life more than 5 years, diluted with gasoline or white alcohol.

But before purchasing, it is important to correctly calculate the consumption of bitumen mastic. For well-known companies, consumption information is indicated on the label

But for the convenience of our readers, we will tell you in detail what consumption of bitumen mastic per 1 m2 of waterproofing is optimal.

How to save money?

In terms of saving primer, there are little tricks. For example, for a primer, the composition can be slightly diluted with gasoline or white spirit. In this case, it turns out to be more liquid, but it can really be used as a preparatory impregnation and it practically does not lose its properties. Of course, this does not contribute to the quality of waterproofing, but if the customer does not want to meet halfway, then there is nowhere to go.

The consumption of TechnoNIKOL bitumen primer per 1 m2 can also be reduced by purchasing concentrate, modification No. 02. The density is quite high, so you can dilute the solution with a ratio of 1:2 or even 1:3.

Another option to save money is to abandon the primer altogether, buy bitumen mastic and dilute it thinner

. The effect is almost the same, it just takes a little longer to dry.

Although for those who have a private house, you can spend money on a primer once in your life, do not regret it, and lay a good roof. And then for many decades you can forget about the roof altogether. Nothing will leak.

Surface treatment volume

The consumption of bitumen per 1 m2 or other composition depends on many factors. Today you can use various types of protection, including:

Wall waterproofing scheme.

- Penetrating, i.e. impregnating waterproofing. It is used for finishing porous surfaces; it contains small particles of cement and sand, and chemically active particles. This composition is used for basements, for foundations, and when it is necessary to repair concrete structures. It will take 800 g with a layer thickness of 1-3 mm. If there are cracks, then the amount increases to 1.1 kg per square m.

- Calmatron is a special type of waterproofing that is used for brick and concrete surfaces. The volume is 1.6-3.2 kg per 1 m², if 2 layers are applied.

- The adhesive protection is applied to vertical and horizontal surfaces and has a high level of protection. The quantity depends on how many layers will be applied and how wide the material is. We must not forget about the overlap, which is 10-15 cm.

- Paint protection is a material that is applied in liquid form to the surface of the structure. After drying, a strong film is formed that prevents moisture from penetrating inside. The quantity depends on what type of material is used. Most often these are bituminous compounds that provide the maximum level of protection. When bitumen is consumed per 1 m2 of waterproofing, it takes approximately 0.8-2.2 kg.

- Coating waterproofing is a mixture based on polymer, bitumen mastics, resins, mineral-cement, polymer-cement plasters. Can only be used for external work. The costs in this case are as follows: 2-3 kg will be required for every 1 m² of area.

- Pure bitumen is not used so often in construction; mixtures based on it remain popular. But it is still used for waterproofing foundations, if necessary, to carry out repair work on roofs. Consumption depends on the thickness of application and whether any additives were used, on average it is 2 kg per 1 m². It also takes into account under what conditions and for what surface it will be applied. For example, for roofs and foundations this indicator will be completely different. We must also remember about the number of dry residues, i.e. the amount of material remaining after drying.

Application area

Primers are divided into several types, which determines the scope of their use. Conventionally, the compositions can be divided into the following groups:

Roofing - used for preparing surfaces, acting as a connecting link between the base and roll or sheet waterproofing.

Road - an adhesive substance for binding crushed stone and gravel.

Pipeline - prevent corrosive changes and increases the adhesion of dissimilar materials.

Universal - multifunctional compositions that are equally suitable for any surface.

Bitumen-based mastics can also be considered multi-purpose compositions. They are used for waterproofing:

Roofs on structures for various purposes.

Underground structures and communications.

This shows that primers and mastics are used in identical areas of construction, but the difference between the materials is significant.