An aerosol mixture is an excellent alternative for this. Spray paint is easy to apply, as it applies in an even, thin layer. But it should be noted that not all alkyd compositions can be produced in the form of aerosols.

To change the physical properties of paints, many manufacturers add certain substances to the composition.

Depending on this, products can be divided into several types:

- alkyd-urethane;

- styrene;

- other.

Alkyd paint: characteristics, advantages and disadvantages

Painting with alkyd paints

Alkyd paints have the following characteristics:

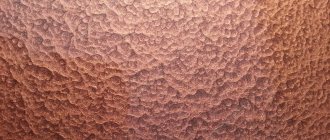

- Characterized by high adhesion of the film coating. Good compatibility with various types of surfaces simplifies painting and reduces the cost of preparatory work.

- Good protective properties. Durable and elastic high-density film has increased elasticity and hardness. Weather resistance allows for outdoor use.

- Increased practical covering power. The hiding power of the film depends on the quantity, type and quality of pigments and fillers used. The surface activity of alkyd oligomers allows the use of paint with a significant dry residue content, which increases covering power and reduces consumption.

- Alkyd paint has good technological properties. Increased spreadability ensures ease of application and allows the use of a roller, spray or brush.

- Average drying time. In conveyor production, products are painted followed by temperature drying.

- Hydrophobicity provides resistance to water and satisfactory resistance to detergents.

- Good decorative properties. Possibility of adjusting the degree of gloss. Minimum likelihood of delamination, smudges, pockmarks, wrinkles and other types of defects.

- Insufficient environmental friendliness. The harmlessness of use depends on the type of solvents and diluents used. For example, xylene and solvent are many times more harmful than white spirit or turpentine.

- Huge variety of possible compositions. Ease of obtaining optimal coatings for various conditions, including anti-corrosion, electrical insulation and others.

Alkyd enamel PF-115

White enamel PF-115, intended for outdoor use, is popular. Requires at least two layers of coating. In addition to good performance characteristics, it has a beautiful surface. In total, PF-115 enamel is produced in up to 24 color shades. The varnishes and enamels used for cars are made on the basis of high-quality alkyd resin of high transparency with special additives. Acrylic paint has higher parameters, but its cost is also higher.

Advantages of alkyd paints:

- resistance to moisture and other atmospheric phenomena;

- durability, light fastness;

- low price;

- excellent adhesion even for smooth metal surfaces, do not require significant preparation costs for painting;

- increased elasticity, resistance to cracking;

- high strength and wear resistance, used for flooring;

- the possibility of obtaining both glossy and matte and semi-matte surfaces;

- universality, used for metal, wood and concrete;

- ease of use, minimal shrinkage, supplied ready to use;

- good fluidity, thixotropy and hiding power;

- slight tendency to yellowing;

- quite a large color palette;

- easy to clean, resistant to detergents.

Flaws:

- contains components harmful to health, when drying they give off a pungent odor;

- low vapor permeability limits the use of façade paints;

- fire hazard.

Film formers

The key component of enamel is the film former. The following types of additives are found in alkyd mixtures:

- Pentaphthalic.

- Glypthal.

- Ethrifthalic.

- Xyphthalic.

Releases with pentaphthalic elements create a thick film with good resistance to mechanical stress. Hypthal foams dry quickly, but do not provide protection from precipitation and other influences. Therefore, their main area of application is interior work.

Pigments

To ensure that the finishing layer has a characteristic shade and opacity, special pigments are added to the paintwork composition. They are insoluble fine powders. Depending on the source material, pigments can be natural or inorganic.

They affect the color saturation and durability of the paintwork. In addition to decorative qualities, the components also determine the performance characteristics of the alkyd composition.

Some additives create a protective film, preventing moisture penetration and rust.

Fillers

Needed to improve the technological properties of paints and varnishes. They affect hiding power, opacity, viscosity and wear resistance.

Carbonates, barites and silicates are used as fillers. Granite and quartz make the mixture resistant to wear, and mica protects the surface from high temperature and electrification.

To increase the degree of particle dispersion, manufacturers add analogues of organic fillers to the composition.

Carbonates are used as paint fillers to improve viscosity and wear resistance.

Supplements

Some components are needed to speed up the drying process, others - to increase the resistance of the coating to negative factors and maintain the plasticity of the paint. Anticoagulants and stabilizers promote uniform distribution of the composition over the surface without separation.

Solvents and thinners

Solvents are selected taking into account the fat content of alkyds. When the indicator is high, aliphatic components are used, when the indicator is medium, a mixture of solvents is used, and when the indicator is low, aromatic high-boiling additives are used. Thinners are needed to change the flow properties of paints and varnishes.

Consumption

There are certain standards for the consumption of alkyd enamel per square meter of painted surface.

In the process of calculating the norm per 1 m2, the following factors should be taken into account:

- viscosity of the substance - the thicker the substance, the more liquid it can be diluted;

- surface quality and number of layers;

- what kind of work is being performed: internal or external.

On average, the consumption of alkyd enamel per 1 m2 is about 110-130 g. In this case, it is imperative to take into account some important points. For example, if a metal surface is painted, the amount of material consumed can increase significantly.

The use of enamel indoors will be greater than for painting metal outside.

Painting exterior surfaces during bad weather conditions can also cause a significant increase in paint consumption. In order to ensure greater efficiency of enamel, it can be diluted using white spirit, solvent and other solvents.

Before applying each subsequent layer, the previous one must be given 24 hours to dry completely.

Areas of application

Alkyd enamels not only prevent the negative effects of external factors on the treated surface, but also protect the product from corrosion. The range of applications for such mixtures is quite extensive. Today they are used for:

- Treatment of metal roofing, drainage communications, fencing, heating radiators and benches.

- Painting wooden structures: log walls, facade parts of frame structures, etc.

- Decoration of concrete slabs, asbestos-cement screed and brickwork.

To form a protective film on a concrete or wooden surface, it is recommended to purchase an alkyd composition with urethane fillers.

Popular types of alkyd enamels

Among the huge number of different types of alkyd paints, there are several compositions that are most popular among professionals.

PF-115

This pentaphthalic-based composition is intended for painting metal and wood surfaces. Requires two layers of application. The palette has 24 shades, including bright glossy colors. The coating can be applied either by spraying or using a brush. Dries in a day. The most popular brands are “Tex” and “Leningrad Paints”.

GF-230

Enamel paint for finishing work related to painting ceilings or walls. Experts are skeptical about whether it can be used for floors or outdoor work, since the composition is less resistant to mechanical stress than pentaphthalic analogues. When applied it has a characteristic varnish smell. The best and "Teknos". “Yaroslavl paints” are also popular.

Matt alkyd paint

This category is characterized by a high degree of polymerization and increased resistance to moisture. If necessary, the coating can be washed and treated with cleaning agents. Matte alkyd compositions can withstand temperatures up to 60 degrees and are more economical, providing a consumption of 130 g/m2.

Aerosol enamels

One form of release of alkyd-based paints is aerosol cans. This is convenient: brushes and rollers are not required for painting work. Using a spray, you can paint any hard-to-reach places with high quality - the enamel lays down in an even layer and does not leave smudges. Aerosol application eliminates the problem of time constraints - the question “how to dry quickly” is not relevant, since polymerization lasts only five hours. Compared to how long it takes for alkyd enamel to dry during traditional painting, this is extremely fast.

There are also specialized types of alkyd-based paints, the composition of which is designed specifically for a specific type of surface.

Types of alkyd enamels by chemical composition

The short abbreviation on the can's label helps identify the base used to create the paint. There are several types of markings:

- GF – paint based on glyphthalic varnish;

- PF – enamel on a pentaphthalic varnish base;

- CS - a mixture of increased chemical resistance used for metal;

- KO – coating containing silicon components of organic origin;

- ML – melamine-alkyd enamels;

- MS – alkyd-styrene mixtures.

There are two most popular types of alkyd enamels, differing in the type of varnish included in their base - pentaphthalic and glypthal.

- Mixtures marked PF can be found much more often - they are distinguished by high strength and water resistance.

- Glypthal-based paints dry much faster, but are less resistant to mechanical stress.

Features of practical application

Alkyd paints are effective to use and do not require special painting skills. Before application, it is necessary to clean the surface from the previous coating, wash it of dirt and treat it with a degreasing compound. For painting you will need:

- brush, roller or spray gun;

- solvent;

- masking tape;

- respiratory mask and gloves.

The composition is diluted to reduce the viscosity of the composition. White spirit is optimal as a solvent. It is used in the mixing process, which guarantees the absence of negative chemical reactions. Using aerosol cans greatly simplifies the process - the paint in them is already in the optimal consistency and is ready for application.

In order to obtain a durable and strong coating, alkyd enamel is applied in several layers.

If painting work takes place indoors, it will be necessary to provide high-quality exhaust and ventilation - this is due to the toxicity of the components contained in the composition. Also, it is necessary to work with gloves and a respirator mask.

Enamel consumption

The average coating rate for alkyd enamels is 150 g/m2. As a rule, one liter should be enough to treat ten square meters of surface. It all depends on the consistency of the enamel, as well as the solvent used for dilution and the characteristics of the surface. Painting metal structures will be more economical than treating similar surfaces made of wood or concrete.

Before painting, it is strongly recommended to calculate the amount of work to be done in advance in order to purchase the optimal amount of enamel.

Types of alkyd enamels by area of application

Paints based on alkyd varnishes are suitable for various types of painting work. To understand which paint to paint a particular surface, digital marking is used. It consists of three digits: the first indicates the purpose, and the last two indicate the serial number in the product catalog.

According to their intended purpose, alkyd enamels are marked as follows:

- 0 – enamel for ground work;

- 1 – for external painting;

- 2 – for indoor use;

- 3 – preservative composition;

- 4 – enamel of increased water resistance;

- 5 – composition containing special components;

- 6 – paint that is resistant to interaction with oil- and gasoline-based mixtures;

- 7 – coating with increased chemical resistance;

- 8 – special heat-resistant enamel;

- 9 – a composition that provides electrical insulation and conductive properties.

Glypthal-based paints, due to their lower strength, are recommended for interior decoration. Pentaphthalic enamels are better suited for treating external surfaces, as well as elements subject to regular mechanical stress.

Most modern compositions do not require the use of a paint hardener - polymerization in air ensures the strength of the coating.

Tips and tricks

In order to get the maximum benefit from a finishing material, you need to clearly understand its purpose and use it where it is intended.

Alkyd paint is applied with a brush, roller or sprayed onto the surface. Before painting, the base must be prepared in advance, cleaned of dust, dirt, roughness and previous finishing or facing materials must be removed. On average, painting 1 m² requires from 30 to 150 grams of material .

Before use, the paint must be thoroughly mixed to a uniform consistency. Regular shaking of the can is not enough; it is better to stir the material with a regular wooden stick when opening the container.

Brushes for alkyd materials should be purchased from natural fibers; synthetic ones are not suitable, as they will retain the paint, reducing the degree of gloss.

For painting wooden surfaces, for example, floors, it is better to use a material with an increased degree of abrasion resistance PF-253. Almost all types of alkyd paints are suitable for painting metal products, but the environment of use should be taken into account . For example, to paint heating radiators, it would be correct to choose PF -223. It is suitable for interior use only and is resistant to high temperatures. Before use, it must be diluted with gasoline.

Non-standard room decoration is not complete without the use of spray enamel. It is easy for her to paint small details and paint over hard-to-reach areas. It is odorless and dries very quickly.

For painting doors and furniture, it is better to use thixotropic alkyd paints . They are easy to apply with a brush and have an attractive semi-matte finish, but to avoid smudges, it is better to use a roller. This coating is not afraid of frequent washing and the use of detergents.

Regular alkyd enamel is suitable for painting almost all substrates; it is a universal coating . It is used both indoors and outdoors. It is moisture resistant, durable and not afraid of temperature changes. Most often it is used for painting facades.

Very often, to improve the adhesion of surfaces, the base is primed before painting with alkyd paint. This also allows you to reduce the consumption of paint and varnish material.

Marking

In order to correctly select the required alkyd enamel, you should familiarize yourself with the markings, which indicate the scope of its application:

- Alkyd primer – 0;

- Suitable for exterior decoration – 1;

- Alkyd paint for interior work – 2;

- Used for conservation work – 3;

- Alkyd waterproof enamel – 4;

- Special purpose – 5;

- Increased resistance to petroleum products – 6;

- Suitable for providing protection against aggressive environments – 7;

- Resistance to temperature changes – 8;

- Used for painting electrical wiring – 9.

Manufacturers

There are many manufacturers of alkyd paints and varnishes, but the most popular and well-proven brands are Kudo and Olimp.

Kudo are alkyd paints and varnishes widely used for painting vehicle parts, tiles, metal and wood surfaces. They are used for both interior and exterior work. Available in aerosol cans, they belong to the group of universal coatings. They have high adhesion, are durable and weather-resistant, have an attractive gloss, and are resistant to mechanical damage.

Olimp offers a wide selection of alkyd and alkyd-urethane coatings.

Their line includes materials for painting windows, doors, concrete floors, heating radiators, and building facades. They have anti-corrosion and antiseptic properties and are intended for use both indoors and outdoors. To expand the color range of paints, manufacturers have developed a computer tinting system.

Alkyd or acrylic paint. Which paint should I choose?

When choosing paint, the consumer is faced with the question of which paint to choose - alkyd or acrylic. Let's take a closer look at the properties and distinctive features of each category.

Alkyd paints are paints and varnishes that contain alkyd varnish and a solvent. There are 2 types of paints in this category, the markings of which are easy to distinguish by their abbreviations: pentaphthalic (PF) and glypthalic (GF).

Alkyd paints

Alkyd enamels have found a wide range of applications not only for interior finishing work, but also for exterior work. The widespread use of paints in this category is achieved due to a number of advantages.

- good performance characteristics: dense film, good covering ability.

- resistance to mechanical stress;

- weather resistance and water resistance of paint

- fairly quick drying of the coating

- low price and large selection of enamels

- a wide range of applications, both for external and internal work on wooden and metal surfaces.

Despite the wide range of possibilities, these paints also have disadvantages:

- pungent, unpleasant and persistent odor. When using these paints, it is always necessary to use a respirator and, if possible, be sure to ventilate the room;

- fire hazard;

- instability to ultraviolet radiation;

- not long service life of the coating

The use of alkyd enamels will not cause you much difficulty. Even without instructions, you can do all the work yourself, using a brush or roller. Drying time is fast, but you must wait a day before the film is completely cured.

The range of alkyd paints includes glossy and matte film options. For metal surfaces, it is most convenient to use glossy paint, as it is less dirty. Matte paint is more susceptible to household chemicals.

Acrylic paints

The basis of acrylic paints is polyacrylic polymers, which in turn improve properties such as elasticity, degree of drying, and resistance to various environmental factors.

An important advantage of acrylic paints is their high adhesion and long service life of the coating. The paint is able to adhere to foreign surfaces and at the same time retain its properties for a long time. On plastered surfaces the service life reaches up to 20 years.

Acrylic paints are resistant to ultraviolet radiation. This property of the paint makes it possible to use it for facade work, maintaining its appearance for a long time.

Another important advantage of acrylic paints and varnishes is the absence of a sharp and unpleasant odor, they are non-toxic and suitable for interior work. Since the paint contains no solvents, when working with it, you do not need special protection in clothing or a respirator.

The drying time of acrylic paints is an important point in choosing a particular type of paint. Depending on the conditions and composition of the paint, it will take you from 30 minutes to a couple of hours until the film dries completely.

The undeniable advantage of acrylic coatings, in contrast to alkyd ones, is their ease of use and the ability to correct shortcomings when applying paint at any time. It is easily removed from the surface, without any traces or stains.

How to choose?

Alkyd paints are produced by many companies today, but not all of them are of high quality.

When purchasing such a product, you should pay attention to several characteristics:

- Price. Cheap enamels are not capable of long-term and high-quality protection of the surface from corrosion. Preference should be given only to foreign brands that have proven themselves well in the market.

- Purpose. All types of alkyd paints are used with specific materials. In theory, wood mortar can be applied to concrete or metal, but it will not stay on that surface for long. Therefore, it is better to use only specialized solutions.

- Compound. Only high-quality materials should be used to make paint. All this must be confirmed by relevant documents. It is important to pay attention to the level of safety, since some modifications can release very toxic components. Therefore, it is not recommended to work with them at home.

Alkyd paints are universal protective solutions that can extend the service life of almost any material. They should be used sparingly in everyday life, since there are safer analogues of similar products on the market.

Main advantages

Alkyd enamel has two important qualities:

- high durability;

- elasticity.

Surfaces painted with these paints dry much faster than any other non-alkyd paint. This is important for interior work - you don’t need to worry that you will have to leave the premises for a long time or that the drying process will stop the construction or repair process. The main properties also include color - it will not fade in the sun or turn yellow over time. Enamel does not shrink, which often happens with other types of paints and varnishes.

Alkyd-type enamels are also well suited for outdoor outdoor work - the paint can easily withstand sudden temperature changes.

It does not lose its qualities at temperatures from -50° to +60°. The material also withstands other atmospheric influences well - snowfall, rain, frost.

In the video: experiment - painting with enamel with the addition of varnish.

Differences between paint and enamel

A composition based on filler, color pigment, solvent and binding additives is called paint. The desired shades are obtained by mixing the pigmenting components. The protective film is created by polymer particles. Other inclusions are necessary to create haze, fire and moisture resistance and other technological properties.

The pigment, which consists of resin or varnish, is called enamel. Such paints and varnishes contain organic solvents, fillers and additives of natural origin. The required shade is created using red lead, soot, titanium dioxide and ocher. The thickness of the consistency is regulated using construction solvents, such as turpentines, solvents and white spirits.