Applying hammer paint to metal

The quality of the final result at the preparation stage depends on 2 factors: the cleanliness of the metal surface and the thickness of the coating. We recommend that you do not skimp on cleaning the surface; this will extend the service life of the surface by 15-40%.

Metal cleaning: removing old paint and rust

If there is old paint or a very rusty surface, treat it with a rust converter, which will help soften the rust and clean it off with sandpaper or a wire brush. Then you can sand with fine-grain sandpaper until the surface is clean.

For a clean and dry surface, ready for painting, we recommend using degreaser and solvent R-021, R-646 (R-647). Allow half an hour to dry. This is a small step and is often skipped, thereby reducing the durability and service life of the coating. A clean surface creates good adhesion between the hammer paint and the surface.

Applying 3in1 hammer paint to rust

If the service life is not critical and there is not enough time to remove rust, we recommend using hammer enamel for rust (3in1 paint). They contain a corrosion inhibitor that transforms rust and prevents it from developing, destroying metal, and damaging paintwork.

How to dilute hammer paint

An important feature of hammer paints is their composition, which is not friendly with conventional solvents. He destroys them. The solvent for hammer paint is toluene (or xylene) no more than 5%. Used to bring to working viscosity.

Application of hammer enamel

Typically, hammer enamel is ready for application immediately after purchase; it should be thoroughly mixed. Most often applied in two layers. Coating thickness – 100-150 microns. Allow the surface to dry for two hours between coats (at +20 degrees). In winter conditions, drying time increases approximately 2 times.

What kind of paint is this?

Main components and their functions

The compositions used for painting metal surfaces differ significantly from paints on wood, concrete, plaster, etc. Not only must they have good adhesion (adhesion to the base), but they must also protect the base from corrosion. Otherwise, the metal base will quickly rust and the paint will fall off along with a layer of oxides.

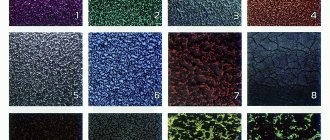

The texture of the protective and decorative coating resembles embossing - hence the name

The choice of compositions for processing metal parts today is huge. But if you want the product to also be beautiful, then I would advise you to stick to the so-called hammer paint.

Hammer enamel is a complex composition that is primarily aimed at finishing metal surfaces. Its name is due to the characteristic texture of the surface - after drying, the product looks as if it was covered with embossing. The main features of such paints are a glossy moisture-resistant surface, high adhesion strength to the base and resistance to external influences, close to absolute.

Diagram showing paint structure

By the way, you can use hammer paint to paint wood, concrete, and other materials. The result will also be quite acceptable, but durability (compared to metal parts) will decrease due to the lower strength of the bases.

These qualities of paint are due to the characteristics of its composition:

- The base is a polymer complex of acrylic, alkyd, epoxy and alkyd-styrene components. In essence, the result is enamel, but with a colossal margin of strength after polymerization.

- Additives : silicone resins and metallic pigments. The former provide the material with elasticity during application, the latter are responsible for the decorative and mechanical properties of the hardened paint. In addition, silicone guarantees moisture resistance and chemical inertness of the material.

Additives and fillers provide the coating with gloss and weather resistance

- Fillers - glass chips, aluminum powder, zinc oxides and other anti-corrosion additives. These materials promote effective adhesion even on smooth metal surfaces, in addition, they provide the hammer effect of the paint.

Almost all hammer paints on the market have this structure. Of course, the composition of additives may differ from one manufacturer to another, and as a result, the difference in operational parameters is quite significant. At the same time, the general qualities - moisture resistance, corrosion resistance and good adhesion - are usually preserved even in inexpensive compounds.

The compositions are quite thick, so when applying them with a spray it is advisable to use a solvent

Material advantages

The popularity of hammer paints both among manufacturers of various metal products and among craftsmen of other specialties is due to their quite obvious advantages.

Advantages of the material:

When painting gates and fences, the weather resistance of the coating comes to the fore.

- Weather resistance. After polymerization, the coating becomes waterproof, reliably protecting the metal base from moisture. In addition, the paint withstands temperature changes and prolonged exposure to ultraviolet radiation.

- Heat resistance. The composition applied to the metal can withstand heating up to 80 ° C without peeling or deformation.

There are fire-retardant modifications of hammer enamels that can withstand higher temperatures. Because of this, in case of fire and other extreme impacts, metal structures retain their strength much longer.

- Mechanical resistance. Polymerized enamel withstands force, friction, etc. Thanks to this, the service life of painted products increases significantly compared to other compositions.

- Corrosion protection. The high tightness of the paint layer reliably isolates the metal from oxygen. As a result, not only is corrosion prevented, but existing rust spots do not increase in size.

The material is indispensable where it is necessary to provide protection against corrosion

- Fast drying. Primary polymerization takes no more than two to three hours - after this time, the applied paint completely stops sticking. This greatly reduces the time spent processing metal structures.

In addition to purely functional advantages, I would also note the external attractiveness of the material:

The combination of relief and gloss is a big plus

- the coating is textured, but at the same time glossy and quite pleasant to the touch;

- The colors of hammer compositions are quite varied. Of course, the palette cannot be compared with the variety of shades of acrylic paints or household enamels, but for the scope of application of hammer paint the choice is quite sufficient.

Both the texture and palette are pleasing to the eye - this is also a plus

Disadvantages of hammer pigments

Here it is worth talking not about the disadvantages, as such, but rather about some operational features. These nuances should be taken into account when choosing a material and working with it - then unpleasant consequences can be avoided.

Flaws:

Cleaning the composition from metal is difficult and time-consuming

- High adhesion strength. It becomes a disadvantage when we have to clean the composition from the metal base. Finding an effective solvent for pigment is almost impossible, and scraping off the material with tools is time-consuming and difficult.

- Corrosion protection only with continuous application. If you leave even a small area unpainted, the rust from it can gradually move under the paint layer. You will only know about this when the enamel around the problem area begins to peel off from the base.

- Difficulty in mechanical application. When working with a spray gun, you need to set the pressure at 4-6 atmospheres - then the composition will lie more or less evenly. If you apply paint at a lower pressure, then “spitting”, omissions and drips are inevitable.

For automated application, it is advisable to use professional equipment - a household spray gun will not cope

- Price. This material is quite expensive. The average price per liter ranges from 400 (Molotex and other domestic analogues) to 800-1200 rubles (Hammerite).

Compounds such as Hammerite are expensive - but also last a very long time

A liter of paint is enough to paint 8-12 square meters when applied in a single layer with a roller or brush.

Tips for application:

For a pronounced hammer effect

To bring to working viscosity, use toluene (or xylene) no more than 5%. Do not dilute with solvent; you may destroy the “hammer pattern” due to the properties of this type of paint.

Hammer Pattern Mesh Size

Depends on the thickness of the applied enamel layer. Smaller layer means smaller cell. And vice versa.

On vertical surfaces

Apply hammer effect paint in a thinner layer. On a vertical surface, a thick layer begins to flow down, forming sagging and disrupting the patterned appearance of the surface.

What are the advantages and disadvantages

The advantages of using this paint are as follows:

- It reliably protects metal products from corrosion.

- Hammer paint does not allow the painted surface to be exposed to too low or high temperatures.

- This product has water-repellent properties.

- The painting procedure is simplified due to the high polymerization speed. This property is especially evident in cases where painting with enamel is carried out using a spray gun.

- When painting, you can apply the product directly to the rust.

Various shades Source gidpokraske.ru

- This enamel forms a durable coating. If you paint a car this way, it will be protected from rust for at least 8 years.

- It contains no substances that can harm people.

- The enamel layer not only has decorative properties, but also protects the surface from moisture, mechanical damage, and temperature influences.

- Using this product ensures cleanliness is maintained.

- Can be used to repair minor surface damage. If there were scratches or small chips, they will not be visible after treatment.

- The paint is highly resistant to vibration. This property is especially important for use in car painting.

- It has no unpleasant odor.

Painting a forged product Source element.ua

However, this product has several disadvantages:

- Hammer paint is expensive.

- High consumption of product during the painting process.

- When using a spray gun, skill is required when working with hammer enamel; you need to know what it is from your own experience.

When painting, you can use different types of tools: brush, roller or spray.