What is hammer paint?

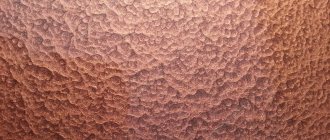

Hammer paint is a type of painting material that has ultra-durable characteristics and ease of application. It got its name because of the pattern, which is reminiscent of hand hammer chasing, thanks to which it is possible to hide defects in the painted surface.

Types of hammer paint

Initially, the material was used in factories and laboratories, where products were affected by chemical or mechanical factors, and was also used for external metal structures for durable protection against corrosion. The material contains resins, which provide these characteristics.

On average, about 100 g of enamel is used per 1 m2, depending on the method of application. The price of hammer paint for metal is high, which means that with high consumption, using the material is not a cheap pleasure.

You can apply paint using brushes, a roller, a spray gun, or ready-made from a spray can. Paint is sold in stores in finished form. Initially, the paint was made in the most common colors, but as it gained widespread popularity for decorative purposes, a wide palette of colors appeared.

The enamel is highly resistant to temperature and weather changes, rust, mechanical damage, and paint is difficult to remove from surfaces, even with the help of a solvent.

The paint is produced in several forms: aerosol - in cans; liquid - tin cans and plastic buckets. Enamel is produced only in finished form; powder form is not used due to its complex composition, and it is impossible to prepare it at home. The paint can be purchased with a glossy or matte finish. Description and instructions for use are described on the packaging. You need to buy a specific shape depending on the surface to be painted.

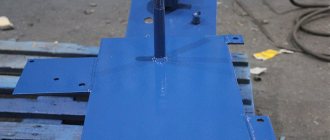

Hammer paint in aerosol form

Features of painting with blacksmith enamel

A few tips that will be useful to those who use this coating to paint metal or other materials with their own hands for the first time:

- Avoid working at aggressive temperatures. General recommendations: the temperature should not be below +10 degrees and above +30. It is better to stick to the golden mean - +20-25 degrees.

- To achieve a beautiful textured pattern, apply several layers. But remember that you need to strictly monitor the overall thickness. If the layers are excessively thick, the enamel will take too long to dry.

- Hammer enamel does not require the preliminary application of putty and primer. The fact is that it is made in such a way that it can even be applied to rust. And the primer is already included.

- Irregularities, small cracks and scratches do not need to be covered up. The enamel itself will hide this.

- It is advisable to paint metal structures using a roller. The fact is that spray guns do not provide the desired texture, so they are better used for surfaces that do not require the creation of a relief pattern.

- The application technique is not always the same. This is due to the coloring of different materials and the degree of their damage.

- It is prohibited to use blacksmith enamel on surfaces containing bitumen. Glossy materials must be roughened before painting.

- When painting wood materials, treat the surface with water-based acrylic primer. This will prevent the enamel from penetrating into the wood pores.

- If you decide to treat a new metal surface, be sure to wash off the factory grease using greasy solvents and acetone. You can check for the presence of grease residues using filter paper that is applied to the metal.

- If grease stains appear, it means that the surface is not completely cleaned.

- If the metal is smooth, use a wire brush for sanding. This is necessary for better adhesion.

Painting gates without removal. Video

Compound

The composition of paints may differ in additional components that manufacturers add for marketing purposes. But the basic composition of the paints is the same.

| Component | Properties |

| Aluminum flakes | Create a hammer pattern |

| Metal powder | Creates a shiny surface |

| Glass chips | Adds texture and increases service life |

| Silicone and acrylic resins | Bonds the paint and the surface being painted. |

| Technical wax | Creates a protective layer |

The characteristics of the paint depend on the ratio of the components. And to create resistance to high temperatures, a special component is added to the enamel.

Is it possible to make blacksmith enamel at home?

Since this enamel has a high cost, enterprising owners figured out how to make paint at home. If you want to benefit from their expertise, you need to prepare the following tools and components in percentage:

- UVL-1 varnish: 96.8%;

- metal shavings from aluminum – up to 6% maximum; 0.5% soot;

- silicone oil;

- capacity;

- construction mixer or electric drill with an attachment for stirring solutions;

- latex gloves.

Soot contributes to the formation of shade and relief, but the hammer effect is achieved through aluminum shavings. Silicone oil is necessary to form the hard particles that make up the texture of the enamel.

Manufacturing Features

Oil enamels are mixed in a warm room. It is advisable to do this in a specialized painting chamber. Combine all ingredients except silicone oil, it is added at the end of mixing.

First, stir the mixture with a wooden stick, spatula or other tool. Now mix with a mixer until the chips become a homogeneous mass. That is, it should not float to the surface of the solution.

To change the shade, you can add enamel of any color, but remember, it should not exceed 30% of the total mass. Dilute the resulting mixture with silicone oil in the amount of 5-8 drops.

Whatever method you choose: ready-made paint or homemade paint, you will get an interesting textured surface in an industrial style.

How a metal entrance door can be painted can be done in a special article. We also recommend looking at special compounds, such as anti-vandal coating for walls.

Scope of application

The scope of application of the material is quite wide. This is due to durability, corrosion protection and interesting patterns. After complete drying, the enamel is safe for humans, which means it can be used for interior decoration.

You can apply paint to almost any type of surface - metal, concrete, drywall, wood, corrugated board, plastic, MDF and others.

The most popular brand of the manufacturer is Hammerite. Hammerite paint ML-165 is distinguished by its quality, long service life and dries quickly. Other well-known brands include Hamerton, Parade Z1, Molotex and Mister Hammer.

Initially, hammer enamel was used in factories and enterprises for painting metal structures, as it is resistant to temperature and weather changes, and also provides excellent protection against rust.

Heat-resistant enamel can withstand temperatures up to 300 degrees Celsius, thanks to a special component in the composition. The price of such hammer paint is slightly more expensive.

Hamerton hammer paint

Areas of paint application:

- Painting of metal structures, products and tools in production, construction, wooden objects;

- As a coloring material for metal doors, safes and furniture;

- For painting cars and their metal parts (wheels, tires, etc.);

- Used in the blacksmith industry, when painting forged objects. For painting purposes, patina with gold, copper or silver plating is used;

- For decorative and advertising solutions.

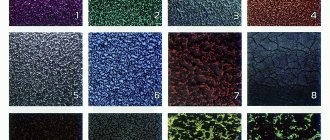

Due to the popularity of use, a wider selection of colors has appeared. Previously, there were only black, white, and gray colors. Now they produce the following colors:

- Antique Copper

- Antique Bronze

- Antique Oak

- Antique Green

- Antique Blue

- Antique Golden

- Antique Purple

- Blue-gray hammer

- Blue hammer

- Khaki hammer

- Green hammer

- Gray hammer

- Brown hammer

- Red hammer

- Silver gray hammer

- Silver black hammer

- Dark gray hammer

- Chocolate hammer

Secrets and tips

Despite the simplicity of the application technology, there are small tricks when working with hammer compounds. Those that I am confident in (tested in practice!) I will share with you:

- We paint in dry weather. When applied, hammer compounds do not like moisture very much, so you can only work indoors on a rainy or foggy day. If you neglect this rule, then bubbles will form in the thickness of the material, which will burst when dry.

- No primers. The use of priming compounds greatly impairs the adhesion of enamel to the metal base. Cleaning off rust and degreasing is quite enough.

When applying, it is advisable not to take long pauses - this way the coating will be uniform.

- We work quickly. When applied, the composition sets almost immediately, so there is no need to pause during processing. If you interrupt for a long time, a clear boundary will form in the paint layer between the old and new layers, along which delamination will begin over time.

- The thicker the paint, the more pronounced the relief. The hammer effect can be adjusted by adding a solvent to the material (646, xylene, solvent and special compounds). On the other hand, this reduces the effectiveness of corrosion protection, so you should not abuse solvents.

An example of the difference in texture: on the left in the photo is a composition using a solvent, on the right - without it

Advantages and disadvantages

Hammer effect paint has the most important advantages - durability and impressive appearance. Other advantages of enamel include:

- Resistant to a wide range of temperatures;

- Quick-drying;

- You can paint objects without preliminary surface preparation - primer, etc.; can also be applied directly to rust;

- Resistant to water and moisture;

- Protects metal surfaces from rust for 8 years;

- Resistant to mechanical damage;

- Safe for health after complete drying;

- Resistant to direct sunlight, does not fade;

- Wide palette of colors;

- Easy to use - you can paint it yourself;

- Resistant to dry and wet cleaning, and also has the ability to repel dirt;

- Hides unevenness.

Hammer paint palette

Disadvantages of enamel:

- Paint is difficult to remove, even with a solvent;

- From unpainted old areas, rust can transfer to the paint layer;

- Difficulty in applying thick paint with a spray gun;

- High price;

- High consumption per 1m2.

Application of hammer effect paint

Application of hammer paint

Considering that, along with decorative properties, modern manufacturers of hammer paint are significantly improving protective functions, the scope of application of hammer effect coatings extends to:

- Industrial equipment (external protective elements of machine tools, housings of electrical appliances and other metal products).

- Metal constructions.

- Furniture production, safe production (hammer coating gives a more elegant look, and color shades make it possible to use in various styles of decoration of residential and office premises).

- Automotive and mechanical engineering.

- Household and household needs (for painting metal doors, fences and gates, forged interior elements, garden and park equipment, containers, etc.).

- Non-metallic surfaces (used on wood and plastic, tiles and glass).

Application methods

Paint can be applied to many surfaces and in several ways - with a roller, brush or spray.

Before painting you need to treat the surface:

- Degrease metal products using white spirit and acetone;

- Then we check the quality using paper - apply it to the metal, for oil stains to appear, repeat the cleaning procedure;

- A smooth and shiny surface should be rubbed with a grinding machine, sandpaper or a wire brush. This is necessary to increase the adhesion of the paint to the surface of the object being painted.

If the enamel is applied to an already painted coating, then you just need to remove dust, dirt and other contaminants, wash with water and dry. And then repaint it.

Tip: If you apply paint to non-ferrous metals, the surface is first primed with a special primer before coating.

Tips and recommendations for use

The dye can be used to work on different surfaces. Hammer enamel can be applied in several ways.

Before using the composition, the base must be thoroughly treated:

- Remove grease stains with a solvent.

- Check the quality of cleaning using paper.

- Then sand the base with a grinding machine and a metal brush.

- If the dye is used on a painted surface, it should be cleaned of dirt and washed well.

Experts also recommend carefully checking the expiration date of the composition and using gloves and goggles when using aerosols. Although the dye does not contain toxic substances, you must be careful with it and avoid getting the composition on the mucous membranes and eyes.

Enamel application technology

Painting with a brush is the most popular method for painting complex surfaces. It is convenient to use a brush for painting iron stairs, winding gates, and automotive products. They paint in several layers, it is extremely important to thoroughly treat all the corners and curls so that rust does not transfer from them to the newly painted surface. It is better to turn vertical surfaces into a horizontal position. Use undiluted enamel. Paint in one or two layers.

Roller painting – used for wide surfaces or walls. It is better to paint with paint diluted in advance with a solvent. In this case, the enamel is first applied in corners and hard-to-reach places, and then on a flat surface.

Application of hammer paint

Aerosol in cans is a convenient, fast and effective method of application. Allows you to create a seamless pattern. Before painting, shake the can for about 2-3 minutes, and then apply a thin layer at a distance of 20-25 cm. Each layer must be allowed to dry. They paint while holding the can vertically in their hand.

Pneumatic method - using a spray gun. This is the fastest way to paint a large, wide surface. Apply in several layers, with the first layer being the thinnest. After it has completely dried, cover with the next, thicker one. You can only paint with liquid enamel, so you need to dilute it correctly. You can dilute the enamel with special solvents. To achieve the correct consistency, use a viscometer. If it is not there, then you can dilute it “by eye”.

Thus, the application method is chosen depending on the desired surface and material capabilities. The most popular way to decorate the interior is with a spray can and brushes. But for outdoor use, on the contrary, it is better to leave the choice to the pneumatic method or the roller application method. Varnish is absolutely not needed, since the enamel itself has a protective layer.

What is hammer paint? This is a durable paint and varnish material that, if applied correctly, will not allow the surface to rust. It is also resistant to water, dirt and mechanical damage, easy to apply and excellent for decoration.

How to use?

When painting a car, buy ready-made enamel with a thick consistency, which, if necessary, is diluted with solvents No. 646-648. Additionally, xylene and solvent can be used, and sometimes gasoline is used. It is better to use a solvent and primer from the same manufacturer; the instructions contain recommendations for dilution.

The technology requires preliminary removal of oil paint from the target area. When painting new metal, be sure to remove the oil coating with a degreaser.

The thicker the applied layer of enamel, the more prominent and larger the design pattern will be.

To avoid an unsightly wave-like pattern on vertical surfaces, it is advisable to apply the paint in a thin layer.

Painting with brush and roller

Before proceeding to staining, it is important to thoroughly mix the enamel so that all heavy particles rise from the bottom and are evenly mixed throughout the liquid. Hammer paint does not necessarily require priming the surface, but with a primer the effect will improve.

The substance hardens quickly, so it should be applied just as quickly in 2-3 layers. There is a pause of about 2 hours between layers, this time will be required for hardening. At first, it is recommended not to drive in rain or fog.

Painting a car using hammer paint

When applying the composition with a roller, follow the same rules as when applying it with a brush. An important condition for a high-quality coating is that a foam roller will not work, as the paint will corrode this material. The best option is to use a fur coat.

Using a spray can and spray gun

When using a spray gun, it is important to know that the process of applying a thick composition of hammer paint requires high pressure - about 6 bar. Before application, you should check the thickness of the enamel; too thick a consistency will lead to clogging of the gun. To properly dilute the substance, it is recommended to use the manufacturer’s instructions located on the paint.

The standard dilution proportion is: 2 parts of the main composition and 1 part of the solvent. Next, cover the surface with enamel in 3 or 4 layers. If processing is carried out in a box, the technology will be slightly different, as will the proportion.

When using an aerosol, paint the surface in 2-3 layers. Before the procedure, shake the can quickly for 10-15 minutes. A distance of 25-30 cm should be maintained from the car to the aerosol.

Photo gallery of finished works:

What it is

This paint is mainly used for painting metal products. It has a high adhesion rate and protects the painted surface well. In appearance, it resembles metal processed using hammer blows. This was the reason for the origin of the name.

Hammer paint is produced in gray color. If a different shade is needed, the required amount of colored enamel is added to it. Often when using it you need to bring it to the desired degree of thickness. For this purpose, it is diluted with a solvent.

The paint reliably protects the surface not only from temperature fluctuations or moisture, but also from mechanical influences. If you hit it with a hammer, it (provided it is completely dry) will remain intact.

Epoxy, alkyd-styrene and acrylic bases are used in production.

Hammerite paint Source remoo.ru

The addition of aluminum powder, glass powder and silicone oils gives the painted surface the appearance typical of hammer enamel and increases its durability. Some brands use technical wax to help create a protective film.

It is sold in liquid form in jars or cans.

What is good about “chasing paint”?

This type of paint is characterized by low consumption and good hiding power. For 10 sq.m. you will need 1l. hammer paint. This is a very good indicator, especially when compared with not very high-quality old-style paints.

It should be noted that hammer paint lasts a long time, which makes this type of paint even more profitable. A high-quality coating can serve without repair for more than 8 years.

The hammer paint layer dries within 6 hours.

The permissible temperature range of use is from +5 to +30 degrees. Celsius. Hammer paint cannot be used at sub-zero temperatures.

Hammer paint is sold in cans of various capacities from 250 ml to 5 liters. It is very comfortable. Taking into account the consumption of hammer paint and the surface area that needs painting, you can calculate the material very accurately and thereby avoid purchasing excess paint that will have to be thrown away. For professionals, there is the opportunity to purchase hammer paint in so-called buckets with a capacity of up to 20 kg.

The shelf life of hammer paint from the date of manufacture is 24 months.

How to paint

When you need to use hammer paint on metal, how to paint it will be discussed below.

Before starting work, the surface must be cleaned. At the same time, dirt, rust stains, and remnants of old paint are removed. It is usually acceptable to paint over rust, but removing it will increase adhesion to the metal.

After this, remove dust and degrease with white spirit or a similar product.

Shake the composition before use. This is necessary to ensure that the particles are distributed evenly. The liquid will thicken quickly. Therefore, painting must be done as quickly as possible. If it is necessary to add hammer enamel, this is done in advance.

When working, you need to use personal protective equipment Source hausnet.ru

It is recommended that the surface on which work is carried out be in a horizontal position. At the same time, no drips will form during the painting process.

It is recommended to use a primer. This is not necessary, but it will increase the adhesion force to the metal.

In order for the coating to be of high quality, it is necessary to have two or three layers of paint. After applying the first layer, you need to wait at least two hours until it begins to dry. Then you will need to paint again.

Complete drying time depends on the brand of enamel used. In most cases, its layer will be completely ready in three days.

When using a roller, you should avoid those made of foam rubber. Enamel can easily corrode this material. For hammer paint, you need to choose one that is made of fur.

It is necessary to choose the right brush Source pechiexpert.ru

Video description

This video shows how to paint a garage door with Hammerite paint.

Although priming is not necessary, it is recommended. This will improve the quality of painting.

The operating procedure is as follows:

- While painting, some parts of the machine may get in the way. They must be dismantled before painting begins.

- The surface must be cleaned of dirt and treated with a solvent to degrease.

Painting a boat Source otdelka-expert.ru

- If there are rust stains, they must be removed using sandpaper. Although the paint can be applied without removing them, nevertheless, with such preparation the degree of adhesion will be higher.

- If there is too much rust, it is recommended to treat the stains with a rust converter. Hammerite paint can be used for this purpose. It is applied only to stains and wait until completely dry.

- The surface to be painted must be coated with a primer.

- The roller needs to be dipped into the paint and then rolled over the ribbed surface to collect excess paint.

- After applying the first coat, you need to wait two hours and do the second painting. It takes at least seven hours to dry. After three days, the surface to be painted will harden completely.

If there is a need to paint areas with a complex surface configuration, then in this case it will be more convenient to use a brush.

When painting a radiator it is convenient to use such a brush Source hausnet.ru

If there was previously a layer of gloss on the paint, it must be removed. Otherwise, the adhesion of the hammer paint to the surface will be too weak.

Features and composition of hammer enamel

When producing hammer enamel, special acrylic, alkyd, and epoxy components are used, thanks to which the hammer paint for metal receives specific properties.

The presence of silicone resins and metal pigmenting compounds in the composition makes it possible to achieve a visible metallization effect. After the paint dries, the coating becomes resistant to external aggressive factors.

Thanks to additional fillers: fine glass, aluminum powder, and other components that provide high anti-corrosion protection, the painted surface receives additional strength.

The paint also contains “aluminum flakes”, which create the effect of texturing the painted surface, and silicones give the painted surface a water-repellent property.

Benefits and Losses of Using Hammer Paint

Hammer paint is resistant to almost all adverse factors that can affect it, including ultraviolet radiation, moisture and water, temperature changes, salts and other chemicals, and so on. This makes hammer paint durable.

The film that is obtained after the hammer paint dries is highly elastic. Thanks to this, the paint does not crack, even when it is subjected to severe stress.

Hammer paint adheres very well to all known materials, despite the fact that its main purpose is to paint metal surfaces and parts.

Due to the fact that hammer paint creates a hammered pattern, it is able to hide even serious flaws and imperfections on the surface on which it was applied.

Hammer paint is suitable for painting rusty surfaces and parts.

Hammer paint dries quickly, does not leave streaks and lies evenly on the surface.

As for the shortcomings, there are none as such. Is it possible to mention here the main limitations. This paint should not be used at low temperatures, and it is also not suitable for application to varnished surfaces.

Types of paint

There are various varieties on sale, each with its own characteristics that must be taken into account when choosing. When hammer paint is used, what it is depends on the brand used:

- The cheapest brand is nitro enamel NTs-221. It has decorative properties, but cannot protect the metal from corrosion, humidity and other types of influence.

- If you use ML-165, it will withstand high temperatures. Even at a temperature of 130 degrees, it will fully retain its protective properties. This product has increased adhesion. It is allowed to apply this composition to rust.

Examples of using ML-165 paint Source i.ytimg.com

- The basis used in the manufacture of EP-1323 enamel is epoxy resin. It can be used both as a paint and as a primer. Metal painted with this enamel will be completely protected from corrosion and high temperatures. This brand is used mainly for painting metal doors, forged products or cars.

- British-made Hammerite is considered one of the highest quality types of hammer paint. It has a relatively high price. This composition not only acts as paint, but can also serve as a primer. After complete drying, a film is formed that protects the surface from oxidation. It is prepared on the basis of alkyd and silicone resins.

It is not recommended to use a spray gun when painting with this paint. The product has wide application. The manufacturer allows it to be applied without first removing rust.

Can of Hammerite paint Source metal-constructor.ru

When choosing, it is important to consider that hammer enamel for metal is relatively expensive. Therefore, you need to purchase a variety that will be of sufficient quality to solve the problems facing the buyer.

Composition and technical characteristics

The paint received its positive qualities thanks to its constituent elements. The product consists of:

- Alkyd resins;

- Epoxy;

- Aluminum powder or flakes;

- Silicone resin and oils;

- Fine glass.

The following characteristics are distinguished, which may vary slightly among manufacturers:

- Density 1 kg. per liter;

- The time required for drying is 120 minutes;

- The binding element is alkyd resin;

- Gloss – 66;

- Resistant to high temperatures - +80 degrees;

- Shelf life after opening the container is 2 years.

The time required for drying is 120 minutes.