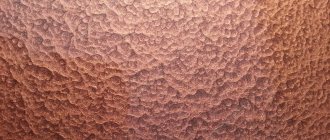

Hammer paint is intended for painting metal surfaces. A complex composition requires compliance with certain rules when working. The texture of the coloring composition after application and drying masks unevenness. Visually similar to rough work with a hammer on the surface, it creates the effect of chasing. Hammer paint has a wide range of applications and a long service life.

What it is

This paint is mainly used for painting metal products. It has a high adhesion rate and protects the painted surface well. In appearance, it resembles metal processed using hammer blows. This was the reason for the origin of the name.

Hammer paint is produced in gray color. If a different shade is needed, the required amount of colored enamel is added to it. Often when using it you need to bring it to the desired degree of thickness. For this purpose, it is diluted with a solvent.

The paint reliably protects the surface not only from temperature fluctuations or moisture, but also from mechanical influences. If you hit it with a hammer, it (provided it is completely dry) will remain intact.

Epoxy, alkyd-styrene and acrylic bases are used in production.

Hammerite paint Source remoo.ru

The addition of aluminum powder, glass powder and silicone oils gives the painted surface the appearance typical of hammer enamel and increases its durability. Some brands use technical wax to help create a protective film.

It is sold in liquid form in jars or cans.

Kinds. Color spectrum

These formulations are available in three varieties:

- NTs-221: relatively cheap compounds intended for indoor work; their protective properties are slightly lower; This hammer paint for metal has a lot of colors - there are about 2 dozen of them;

- ML-165: they can only be used to paint degreased surfaces; durable, heat-resistant, can easily withstand elevated temperatures, but when heated they can release a small amount of toxins; There are only three colors: golden, gray and black;

- Hammerite: the highest quality and most expensive; reliably protect the metal from oxidation, does not require priming, has the widest palette of shades, from khaki, copper, silver, gold to dark chocolate; but the most popular is black hammer paint.

A significant disadvantage of such compositions is the price. For one kilogram you will have to pay a couple of thousand, or even more, rubles. Therefore, it is unprofitable to use them as facades. The disadvantages include the difficulty of removal. The paint adheres so firmly to the surface that it can only be removed with special strong solvents or a grinder.

In Russia, this type of coating has not yet found widespread use for one simple reason - unfortunately, about 3/4 of this type of paint is fake.

What are the advantages and disadvantages

The advantages of using this paint are as follows:

- It reliably protects metal products from corrosion.

- Hammer paint does not allow the painted surface to be exposed to too low or high temperatures.

- This product has water-repellent properties.

- The painting procedure is simplified due to the high polymerization speed. This property is especially evident in cases where painting with enamel is carried out using a spray gun.

- When painting, you can apply the product directly to the rust.

Various shades Source gidpokraske.ru

- This enamel forms a durable coating. If you paint a car this way, it will be protected from rust for at least 8 years.

- It contains no substances that can harm people.

- The enamel layer not only has decorative properties, but also protects the surface from moisture, mechanical damage, and temperature influences.

- Using this product ensures cleanliness is maintained.

- Can be used to repair minor surface damage. If there were scratches or small chips, they will not be visible after treatment.

- The paint is highly resistant to vibration. This property is especially important for use in car painting.

- It has no unpleasant odor.

Painting a forged product Source element.ua

However, this product has several disadvantages:

- Hammer paint is expensive.

- High consumption of product during the painting process.

- When using a spray gun, skill is required when working with hammer enamel; you need to know what it is from your own experience.

When painting, you can use different types of tools: brush, roller or spray.

Advantages and disadvantages

The undoubted advantages of blacksmith paint include:

- Efficient leveling . Enamel smoothes out minor defects.

- Corrosion protection . Protects metal from the formation of iron oxides for 8 years.

- High temperature resistance . Most compositions can withstand heating up to + 80 °C.

- Quick drying . The polymerization period for the aerosol application method is no more than 2 hours.

- Decent durability . Not afraid of vibration, moderate mechanical impacts and precipitation.

- Work without long preparation . There is no need to putty or prime the surface. It is enough to remove loose rust.

There were some downsides :

- Low elasticity . In places where bends and dents form, microcracks form where moisture can penetrate.

- Poor compatibility . They can be applied without any complaints unless on coatings with a similar base of binding components.

Where is it used?

This paint can be used for the following purposes:

- It can be used for painting various metals: copper, aluminum, steel and others.

- Widely used in construction for painting structures made of metal.

- It can be used for doors, safes, and industrial furniture.

- Hammer paint is used for painting automobile bodies.

- Forged products are painted with this product.

- When used in the interior, the use of such a product creates the effect of antiquity.

Painting procedure Source remoo.ru

Can be used for painting glass and plastic. In this case, you must first thoroughly clean the surface. Painting of wooden parts is allowed, but this can only be done if a primer is applied.

Application area

Traditionally, hammer painting was used in the manufacture of forged and cast iron products. Nowadays, blacksmith paint is used to cover a wide variety of metal objects and surfaces:

- interior and garden furniture (office cabinets, safes, indoor chairs, park benches);

- parts of machines and mechanisms (casings of machines, housings of electrical panels, elements of vehicles);

- doors, gates, fences;

- steel structures for construction purposes (supports, beams, fastenings, drainpipes, weather vanes);

- small functional and decorative items (frames, shelves, forged jewelry, garden tools, technical tools, metal fittings).

Hammer enamels are widely used for painting forged products and furniture.

Hammer enamel can be applied not only to metal, but also to surfaces made of wood, hard plastic, glass, and ceramic tiles.

When deciding on the use of blacksmith paint, you must remember that it is best applied to horizontal surfaces. The emulsion will drain from vertical planes, and the characteristic shagreen effect will not form. It is good if it is possible to turn the object into a horizontal position. If you need to paint a vertical surface, you will need quick-drying hammer paint, which does not have time to spread.

Types of paint

There are various varieties on sale, each with its own characteristics that must be taken into account when choosing. When hammer paint is used, what it is depends on the brand used:

- The cheapest brand is nitro enamel NTs-221. It has decorative properties, but cannot protect the metal from corrosion, humidity and other types of influence.

- If you use ML-165, it will withstand high temperatures. Even at a temperature of 130 degrees, it will fully retain its protective properties. This product has increased adhesion. It is allowed to apply this composition to rust.

Examples of using ML-165 paint Source i.ytimg.com

- The basis used in the manufacture of EP-1323 enamel is epoxy resin. It can be used both as a paint and as a primer. Metal painted with this enamel will be completely protected from corrosion and high temperatures. This brand is used mainly for painting metal doors, forged products or cars.

- British-made Hammerite is considered one of the highest quality types of hammer paint. It has a relatively high price. This composition not only acts as paint, but can also serve as a primer. After complete drying, a film is formed that protects the surface from oxidation. It is prepared on the basis of alkyd and silicone resins.

It is not recommended to use a spray gun when painting with this paint. The product has wide application. The manufacturer allows it to be applied without first removing rust.

Can of Hammerite paint Source metal-constructor.ru

When choosing, it is important to consider that hammer enamel for metal is relatively expensive. Therefore, you need to purchase a variety that will be of sufficient quality to solve the problems facing the buyer.

Compound. Main characteristics

To understand what hammer paint for metal is, let’s figure out what it consists of. Although the secret of its manufacture remains a secret, it is known for certain that the binder in it is alkyd-styrene resin and fatty acids. It also contains silicone and aluminum powder. An uneven film, similar to chasing, is formed due to the introduction of crushed glass. The addition of fine-grained oils, capable of covering even the smallest irregularities, significantly increases the protective properties.

Let us list the main characteristics of such compositions:

- do not have a pungent odor;

- absolutely safe and free of toxins;

- extremely durable, an impact may leave a dent on the metal, but not even a crack will appear on the paint; it even withstands vibration perfectly;

- are not afraid of temperature changes (withstands up to 80°C), sunlight, and do not fade;

- do not lose their protective properties for 8-10 years: you no longer have to paint the metal often;

- form a film that cannot become electrified, that is, dust and dirt do not stick to it; as a result, even white hammer paint remains clean during use;

- hide irregularities and flaws;

- can even be applied to a layer of rust;

- dry very quickly, within 2 hours (application of a second layer is recommended a little later, after 5 hours, when the film not only dries, but also gets stronger).

The disadvantages include considerable consumption of material (up to a liter per 9-10 sq. m). When painting, a little less hammer paint for metal in spray cans is used.

How to paint

When you need to use hammer paint on metal, how to paint it will be discussed below.

Before starting work, the surface must be cleaned. At the same time, dirt, rust stains, and remnants of old paint are removed. It is usually acceptable to paint over rust, but removing it will increase adhesion to the metal.

After this, remove dust and degrease with white spirit or a similar product.

Shake the composition before use. This is necessary to ensure that the particles are distributed evenly. The liquid will thicken quickly. Therefore, painting must be done as quickly as possible. If it is necessary to add hammer enamel, this is done in advance.

When working, you need to use personal protective equipment Source hausnet.ru

It is recommended that the surface on which work is carried out be in a horizontal position. At the same time, no drips will form during the painting process.

It is recommended to use a primer. This is not necessary, but it will increase the adhesion force to the metal.

In order for the coating to be of high quality, it is necessary to have two or three layers of paint. After applying the first layer, you need to wait at least two hours until it begins to dry. Then you will need to paint again.

Complete drying time depends on the brand of enamel used. In most cases, its layer will be completely ready in three days.

When using a roller, you should avoid those made of foam rubber. Enamel can easily corrode this material. For hammer paint, you need to choose one that is made of fur.

It is necessary to choose the right brush Source pechiexpert.ru

Painting with hammer paint using a roller

There are several ways to apply hammer shade. The most common:

- With a brush. It is better to paint small areas. The hammer dissolves the brush bristles if they are not natural. You need to apply 2-3 layers.

- With a spray can or spray gun. Great for large areas. The most expensive way to paint an object. Apply in 3-4 layers.

- With a roller. You can paint smooth and fairly large surfaces. The length of the pile is 4-11 centimeters. The enamel itself spreads over the plane if the roller is chosen correctly.

Of the methods listed, the best one is a roller. It will save money when applied to the surface, and also has a fairly large area to work with. So, how to paint with a roller and hammer paint? Painting with a roller is not difficult, but there are some subtleties:

- The first layer of hammer substance is diluted 9 to 1 with solvent. Subsequent layers do not need to be thinned;

- a medium-sized roller is needed;

- the substance is applied to the corners, then the rest of the surface is painted;

- must be applied in several parts. If the layer is thin, bubbles may appear, and the protective properties become worse;

- the second comes after passing for at least half an hour;

- a third layer is applied if needed. The substance is applied in a thick coating to avoid sagging.

It is advisable to apply hammer paint with a roller to a horizontal surface. This will make it easier to apply a layer of paint, and the absence of streaks will be good news.

Features of car painting

When using paint with a hammer effect for this purpose, you will need to prepare:

- Short-pile fur paint roller.

- A brush for applying paint.

- Solvent for diluting the composition. Typically Nos. 646-648 are used for this purpose.

- Abrasive for surface cleaning.

- Primer for paint.

In addition, you need to prepare the paint, diluted to the desired degree of thickness. It will thicken quickly. Therefore, it is necessary to complete the work as quickly as possible.

Application of hammer effect paint

Application of hammer paint

Considering that, along with decorative properties, modern manufacturers of hammer paint are significantly improving protective functions, the scope of application of hammer effect coatings extends to:

- Industrial equipment (external protective elements of machine tools, housings of electrical appliances and other metal products).

- Metal constructions.

- Furniture production, safe production (hammer coating gives a more elegant look, and color shades make it possible to use in various styles of decoration of residential and office premises).

- Automotive and mechanical engineering.

- Household and household needs (for painting metal doors, fences and gates, forged interior elements, garden and park equipment, containers, etc.).

- Non-metallic surfaces (used on wood and plastic, tiles and glass).

Video description

This video shows how to paint a garage door with Hammerite paint.

Although priming is not necessary, it is recommended. This will improve the quality of painting.

The operating procedure is as follows:

- While painting, some parts of the machine may get in the way. They must be dismantled before painting begins.

- The surface must be cleaned of dirt and treated with a solvent to degrease.

Painting a boat Source otdelka-expert.ru

- If there are rust stains, they must be removed using sandpaper. Although the paint can be applied without removing them, nevertheless, with such preparation the degree of adhesion will be higher.

- If there is too much rust, it is recommended to treat the stains with a rust converter. Hammerite paint can be used for this purpose. It is applied only to stains and wait until completely dry.

- The surface to be painted must be coated with a primer.

- The roller needs to be dipped into the paint and then rolled over the ribbed surface to collect excess paint.

- After applying the first coat, you need to wait two hours and do the second painting. It takes at least seven hours to dry. After three days, the surface to be painted will harden completely.

If there is a need to paint areas with a complex surface configuration, then in this case it will be more convenient to use a brush.

When painting a radiator it is convenient to use such a brush Source hausnet.ru

If there was previously a layer of gloss on the paint, it must be removed. Otherwise, the adhesion of the hammer paint to the surface will be too weak.

Application methods

Let us tell you in detail how to paint with hammer effect paint:

- Despite the fact that it can be applied even to a small layer of rust, grease, dust and dirt, it does not tolerate. Therefore, it is necessary to first thoroughly degrease the surface with acetone or white spirit.

- There is a simple way to check for fat. You should attach a piece of napkin or thin paper to the metal. If oily stains appear, the degreasing process should be repeated.

- Although the paint adheres perfectly to the surface, it is advisable to treat metal that is too smooth and shiny with sandpaper or a grinder. This will help increase adhesion.

- Old layers of other types of paint are removed. If they peel off over time, the painting process will be pointless. A small layer of rust can be left. You only need to get rid of large pieces and sagging.

- The surface must be perfectly dried.

- Only non-ferrous metals require priming. Ordinary steel does not need to be primed.

- This paint is applied as usual, with a brush or short-haired roller. When using a spray gun, the composition must be diluted a little thinner. Hammer paints are diluted with white spirit or special solvents.

- Work begins with corners and edges. They are processed most carefully. After all, rusting begins precisely from these places. Then the rest of the surface is painted.

- According to the instructions, hammer paints should be applied in several layers. There may be at least two or three, or even four.

- When using cans, shake them well to lift the sediment from the bottom. This dyeing method is considered the most effective. Using an aerosol, you can thoroughly treat even hard-to-reach places.

- Wooden surfaces can also be painted with such solutions. In this case, the composition must be diluted with thinner acrylic primer.

Thus, today hammer paint is one of the most effective methods of corrosion protection. It can even be applied to products that have previously been subject to corrosion, without removing the rust layer.

Some tips

When using hammer paint, it is recommended to take the following into account:

- When painting vertical parts, it is recommended to use a spray gun. In this case, it will be easier to avoid the formation of paint runs.

- Painting should not be carried out where there is high humidity or temperature. The applied coating will have poor adhesion. If painting is done indoors, it is important to provide ventilation during work.

- When painting new products, it is important to completely remove traces of factory grease and contamination before starting work.

A metal fence coated with hammer paint will be more durable Source remoo.ru

Carefully applied paint will serve the owner for many years.

Hammer paint for metal how to paint

How to paint a metal door with hammer paint

Hammer paint works well for painting metal doors and gates. This paint has a special texture when it dries - the result is a surface with an interesting visual effect, as if it had been beaten with a hammer. Hammer paint has stable anti-corrosion properties; it contains special silicone resins and metal pigments, which increase its density and increase resistance to external influences.

Benefits of hammer paint

- No preliminary preparation of the surface to be painted is required. The paint already contains primers, which facilitates and improves the painting process when there is no time or opportunity to thoroughly clean the surface of the doors from old rust.

- Hammer paint is corrosion resistant and dries quickly.

- The color of the products does not change and does not lose its saturation for quite a long time.

- The dyeing technology is simple and convenient.

- Beautiful aesthetic appearance. Hammer effect paint comes in a variety of shades that will help improve the appearance of metal doors. Forged gates look very impressive and textured when hammer paint is used to paint artistic forging elements.

- Hammer paint has the useful property of repelling dirt and dust - painted products always look neat and do not require special care.

How to paint metal gates with hammer paint

It is very important for car owners that the garage provides reliable shelter and protection for the car. In addition to the strength and reliability of fastening the locks, it is also necessary that the garage doors are not afraid of rain, snow, dampness, frost, and temperature changes. To prevent garage doors from rusting, their surface must be painted with corrosion-resistant paint. The optimal solution for protecting metal surfaces from rust is painting with hammer paint.

The technology for painting metal doors with hammer effect paint is not at all complicated.

- Remains of old paint are removed from the canvas using a metal brush or an electric drill with a special attachment.

- The surface of the metal door is thoroughly cleaned with acetone.

- Hammer paint contains primers, but for a better painting effect, the surface of garage doors is primed.

- Paint the gate using a roller or spray. A paint brush is not suitable for painting a wide surface - with its help it is very difficult to achieve a uniform layer of paint and the absence of streaks or smudges.

How to properly paint a metal door with a roller

Roller painting is effective for large, smooth, flat surfaces.

- Before starting to paint a metal surface, to apply the first layer, hammer paint is diluted in a ratio of ten parts paint to one part solvent. The next layer does not need to be thinned.

- For work it is better to use a medium-sized roller.

- First, paint is applied to the corners and edges of the doors using a small brush, and then the remaining surface area is painted with a roller.

- One layer will not be enough - the protective properties of a single-layer coating are not as effective as when painting in several layers. The decorative effect also deteriorates - if the paint layer is too thin, then bubbles may form on the dried painted surface. To avoid this, apply an additional layer of paint.

- The next layer must be applied at least half an hour later, waiting for the first layer to set a little on the surface.

- If necessary, apply another layer of hammer paint. It is important to remember that the last layer of paint is thicker than the previous ones, so that there are no smudges or sagging.

- Resistance to temperature changes.

- Enamel can be applied directly to rust, without the prior use of primers and converters.

- Hammer paint dries quickly.

- Resistant to moisture. Good hammer paints protect metal from corrosion in the open air for up to 8 years.

- Mechanical strength.

- No toxic fumes after drying (you can paint interior items).

- Excellent decorative properties. These coloring compositions have not only a wide palette of colors, but also high resistance to fading.

Technology of painting hammer paint using a paint brush

A brush for painting the surface with hammer paint is used on complex shaped configurations where detailed and fine painting is required. It is recommended to use brushes with natural bristles. It is not necessary to dilute hammer paint when painting with a brush.

Two layers of paint are applied to the horizontal surface. When painting a vertical surface, it is optimal to apply three layers to the surface in order to avoid smudges. In this case, hammer paint can be diluted at the rate of nine parts paint to one part solvent. The temperature at which hammer paint manufacturers recommend painting a product should not be too low or too high. Optimal range: from +5 C to +30 C.

Tip 1: How to paint with hammer paint Tip 2: How to paint with a roller

Repair is a thankless task. However, if you do it wisely, you can save a lot of time and effort. If you paint the ceiling while standing on a chair and moving the brush back and forth, you can quickly get tired. After all, you have to constantly get down to move the table, and you can’t constantly wave your arms. Rollers were invented for these purposes. You don’t need to stand on the table with it, because thanks to the long handle, the roller easily “reaches” the ceiling. However, if you do not know how to work with a roller . he won't help you much.

It is advisable to use a roller for painting large surfaces. Therefore, it is just suitable for the ceiling. For convenience during the painting process, you can use a special mini-bath for the roller. which is a flat container with two steps and low sides. The paint roller rolls along the first step and leaves excess paint on the second. You can, of course, make a small plastic or tin tray into which the paint from the roller will drip, but you can get by with just one tray.

Experienced painters know some tricks that they are willing to share with you. It is best to paint the ceiling twice in perpendicular directions. This is necessary so that the paint blends properly. Then there will be no “bald patches” on your ceiling. Some professionals advise painting the ceiling three times, although this should be done depending on the situation. If the paint is of high quality, then two times will be enough. If you can save paint, then don't waste it. Do not forget to also wait a certain time, which should be indicated in the instructions for use of this type of paint.

Some people are interested in whether it is better to paint the ceiling with a wide roller or a narrow one, what kind of pile the roller should have, and so on. There is no clear answer. In some cases, the choice of roller depends on the material from which the ceiling is made. Some people choose a roller based on personal preference. But one thing is for sure: a wide roller will help you get the job done faster and save paint, and a fine-nap roller will apply paint more evenly than a medium- to long-nap roller.

It is also worth paying attention to the materials from which the rollers are made. These can be synthetic fibers and pile or natural. But that is another story .

Tip 3: How to paint with enamel Features of hammer paint and technology for its application

Hammer paint is an extremely durable coating. Initially, it was used for painting factory and laboratory equipment, machinery and various structural elements that were operated in unfavorable conditions. Gradually, the scope of application of the material expanded, and over time, designers noticed the unusual “shagreen” texture of hammer enamels. And now this specific coating can be found in a variety of places, including residential interiors.

Features of hammer paint

Hammer enamel is easy to recognize by sight. It has a specific texture, similar to the surface of metal that has been hand-chased with a hammer. Hence the name of the paint - hammer or forge.

Hammer effect paint

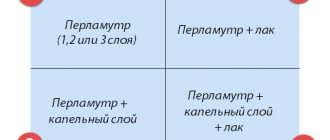

Such paints and varnishes are made on acrylic, alkyd-styrene, and epoxy bases. They add silicone oil and fillers - aluminum powder and fine glass. The finished mixture in a liquid state has the highest adhesion to the surface being painted, and after drying it forms a particularly durable coating.

Due to the presence of metal powder, hammer paints have a high density. This increases the durability of the coatings, but makes them more difficult to apply using a spray gun.

Designed for protection rather than decoration, hammer paints were initially only available in gray. When they began to be used as a decorative material, manufacturers included colored pigments in the composition. Nowadays, hammer paint is produced in a variety of colors, but it always has a special texture and metallic sheen.

Color palette of hammer paints

Advantages and disadvantages of blacksmith paints

The main advantages of hammer coatings:

On a note! Dried hammer enamel has water-, dust- and dirt-repellent properties. Thanks to this, painted objects always look clean and tidy.

Hammer enamel is very popular due to its unusual appearance and many advantages.

Forge paint also has disadvantages:

- It is very difficult to remove from the surface with solvents and abrasive tools.

- If you leave unpainted areas, then corrosion from them will eventually spread to the coating itself.

- Thick enamel is difficult to apply with a spray gun.

- The paint is not cheap, and it costs quite a lot.

Application area

Traditionally, hammer painting was used in the manufacture of forged and cast iron products. Nowadays, blacksmith paint is used to cover a wide variety of metal objects and surfaces:

- interior and garden furniture (office cabinets, safes, indoor chairs, park benches);

- parts of machines and mechanisms (casings of machines, housings of electrical panels, elements of vehicles);

- doors, gates, fences;

- steel structures for construction purposes (supports, beams, fastenings, drainpipes, weather vanes);

- small functional and decorative items (frames, shelves, forged jewelry, garden tools, technical tools, metal fittings).

Hammer enamels are widely used for painting forged products and furniture.

Hammer enamel can be applied not only to metal, but also to surfaces made of wood, hard plastic, glass, and ceramic tiles.

When deciding on the use of blacksmith paint, you must remember that it is best applied to horizontal surfaces. The emulsion will drain from vertical planes, and the characteristic shagreen effect will not form. It is good if it is possible to turn the object into a horizontal position. If you need to paint a vertical surface, you will need quick-drying hammer paint, which does not have time to spread.

Types of hammer paints

The most popular brands of blacksmith paints:

Hammer paint from the English manufacturer - Hammerite

On a note! Regardless of the brand and manufacturer, hammer paint can be sold in cans and spray cans.

Preparing the surface for applying hammer enamel

Painting with hammer paint can be done directly over rust or an old layer of any other coating (except oil-based, bitumen-containing and powder paints). But the surface still needs to be prepared before applying it:

- New metal products are washed from factory lubricant (2-3 washes with white spirit or solvent and one wipe with acetone). When there are no traces of lubricant left on the metal, it is treated with sandpaper or a wire brush to increase adhesion.

Wire brushing

Then wash with water and washing powder, rinse and dry thoroughly. Attention! Heavily rusted metal is cleaned of loose and flaking rust. Forge paint will only adhere securely to firmly held rust.

Primer treatment

Hammer paint application technology

- Interior decoration Ceiling

- Walls

- Doors, arches

- Window

- Stove, fireplace

- Kitchen decoration

- Bathroom, toilet

- Corridor, hallway

- Balcony, loggia

- Other rooms

- Finishing of buildings Country and private houses

- Wooden houses

- Baths, saunas

- Finishing materials Drywall

- Cladding panels

- Wallpaper, cork

- Tile

- Laminate, linoleum

- Decorative plaster

- Finishing work Plaster

- Primer

- putty

- Painting, whitewashing

Painting doors is a procedure that is performed due to various circumstances. But it needs to be taken into account.

The question of how to glue the ceiling plinth to the wallpaper arises when all the finishing work is completed.

A wooden arch is an extremely popular type of decoration. It is used to decorate openings, as decoration.

- Rubber paint for metal Rubber paint Rubber paint has appeared on the domestic construction goods market relatively recently. This building material...

- Epoxy paint for concrete floors Acrylic, rubber, epoxy and polyurethane paint for concrete floors - which is better? Polyurethane enamel Elakor…

- How to paint wood with acrylic paint. Made by myself, homemade items, things made by hand. The Made by myself website contains a huge archive...

- Paint for non-woven wallpaper for painting Selection, consumption and features of applying paint on wallpaper Pasting wallpaper for painting is deservedly popular...

Briefly about the main thing

Metal products painted with hammer paint are not only reliably protected, but also look stylish and beautiful.

It is important to choose the right brand, paint carefully and let the product dry completely. This paint is relatively expensive, but it has good adhesion and will serve well for many years.

High-quality hammer paint will reliably protect the metal from moisture, temperature changes and mechanical damage.

Ratings 0

TOP most popular brands of coatings for metal

Nowadays, enamels for painting metal are produced by a huge number of manufacturers, but not all of them have gained popularity among consumers. However, there are certain brands that are in particular demand and popularity among developers. These are manufacturers of high-quality paint and varnish products such as Hammerite, Ace Rust Stop Enamel, Sniezka, CERTA and others. The TOP most popular anti-vandal and protective compounds include the following brands:

Enamels from the English world brand Hammerite have long established themselves as high-quality compositions for coating metal surfaces of all types. They have excellent anti-corrosion properties and significantly increase the service life of external metal structures.

The main advantages of the brand are:

- very fast drying speed;

- no drips or splashes during application;

- the ability to apply the composition directly to rust;

- long service life (up to 8 years or more).

This American brand produces weather-resistant enamels for exterior and interior use. Glazing wood preservatives for exterior use comparison? The paint of this brand can improve the wear resistance of a metal surface for many years.

The compositions have a huge range of colors and are perfect for painting iron doors and other surfaces.

The advantages of products from Ace are:

- high anti-corrosion performance;

- resistance to mechanical action;

- long service life.

Sherwin Williams is one of the largest manufacturers of paint and varnish products in the United States. The characteristic features of the enamels of this brand are the magnificent glossy appearance of painted surfaces and a wide range of color compositions.

The main advantages of Sherwin William paint:

- increased corrosion protection;

- resistance to mechanical damage;

- weather resistance;

- low toxicity;

Protective enamels from the domestic manufacturer CERTA have been successfully used in our country for fifteen years. The brand produces quick-drying paint with anti-corrosion properties.

The advantages of the Certa Plast brand are:

- resistance to ultraviolet radiation;

- immunity to temperature changes;

- weather resistance;

- long service life;

- economical price.

Additional Information:

This is a special type of solution for metal, which allows you to get an interesting external effect. The basis of such compositions can be different, but the decorative result is achieved through aluminum powder and fine glass fraction. A special additive is silicone oil.

Today, the construction market is replete with a huge number of paints for exterior metal work. In any construction supermarket you can easily find enamels of various types and types, differing from each other in their composition, technological characteristics and price.

We present a catalog of paints for special purpose metal: primer-enamels, enamels, “3 in 1” paints. The main advantage of our product range is the ability to choose paint for specific operating conditions, application and for a specific type of metal. Optimally selected protective material is the key to effective operation of metal structures.

You can purchase enamels for metal wholesale and retail at. Paint for galvanized metal against rust? For more than ten years, we have been producing high-quality paint and varnish products, which are presented in a wide range under the trademarks “Unikom”, “Dacryl”, “Polyureton” in the website catalog.

Similar compositions are applied to various surfaces made of metal. They are actively used against rust for outdoor work. There is no need to use primers before applying enamel to the surface. This is due to the fact that primer with enamel is a combination of the advantages of a primer mixture, anti-corrosion paint and enamel for metal surfaces.

As a result, the sequence of work with primer-enamel is greatly simplified, and all you have to do is follow simple recommendations.

All of them are used in most cases in everyday life. In addition to them, there are two-component epoxy paints, silicone-based coatings, polyurethane paints and other types, but these are already industrial lines. Such paints provide greater resistance to corrosion, can withstand high temperatures and withstand aggressive environments. However, the cost of such enamels is quite high, so for household needs a simpler metal paint is usually used, the price of which is in the range of 200-300 rubles per liter.

This material is quite consistent with the quality and does not cost too much.

How to do it yourself?

Having determined the type of coloring composition, we begin work, which conventionally consists of three stages:

- Selection of all necessary materials.

- Basic surface preparation.

- Coloring.

Let's talk about each of them in more detail.

Materials and tools

To work you will need:

To save time, use an aerosol, then brushes and rollers may not be needed. Do not forget about means of protection against paint getting on your skin and mucous membranes - rubber gloves, a respirator.

What is needed to prepare a metal (iron) or wooden surface?

The essence of the preparation is to achieve good adhesion of the metal to the paint and give the coating durability.

- First, remove all decorative elements, removable fittings - handles, number, peephole. Seal parts that cannot be removed with masking tape. It is better to remove the canvas itself from its hinges and paint it in a horizontal position.

- To remove the old layer of paint, use a special remover or remove the remains with sandpaper, a sanding machine or a wire brush. The surface is degreased and covered with a primer.

Instructions on how to paint inside and outside

After completing the preparatory work, we move on to painting. Instructions:

- We cover the surface around the door leaf with a protective film, and also make a flooring on the floor.

- First, paint hard-to-reach areas with a thin brush.

- To paint a large area, use a roller. Apply layers of paint from top to bottom.

- We apply the selected composition in two layers, with the second layer applied after the previous one has completely dried.

- At the end of the work, after the surface has dried, remove the protective film.

Using these tips, the door leaf will get a decent appearance.

Do not forget to also paint over the hinges, which have previously been sanded with sandpaper. If smudges have formed, then also rub them with sandpaper, and then re-coat the surface.

Do not paint exterior doors when temperatures are below freezing or when it is damp outside.

Painting your front door is easy. The main thing is to carefully select materials and tools, and carry out preliminary surface preparation. If you strictly follow the dyeing technique, you can get a result that is no different from the industrial one.

Source: okcomfort.com

What is hammer enamel

Hammer enamel (sometimes called "blacksmith's paint") is a decorative coating for metal. The name “hammer” was assigned to this paint, because after processing it the surface looks like embossing with potholes and irregularities, made with a hammer. Or it could be stains with a voluminous effect. Think of antique handmade metal jugs – that’s exactly what this metallic effect looks like. If you look at orange peel, you'll see that hammer paint forms similar bumps.

This enamel appeared as a necessary material for painting equipment in factories and laboratories. And later it began to be used for other purposes due to its resistance to external influences. The high density of hammer enamel is ensured by metal powder. Also, modern hammer dyes add colored pigments of various shades, fine glass and aluminum flakes, which improve the texture of the enamel.