Items that are used outdoors require additional protection. After all, they are exposed to negative environmental influences, leading to rapid destruction. To increase their service life you cannot do without the use of protective equipment. One of the popular types of paints and varnishes for processing various products is red lead paint. It is most often used to process metal products, although it can also be used for other surfaces. Minium paint, what it is will be described below.

Red lead paint - what is it?

Minium is an inorganic pigment of natural origin. It is obtained naturally by transforming the metal by oxidizing it to produce a component in the form of salts. Minium formula - Fe2O3, is mined in nature, usually in places where volcanoes are active. It is easy to see, because the color of red lead is bright red or brown.

Two types of ore can be used in red lead: iron and lead. The first type has a brownish tint; limonite ore is used for production. Minium lead stands out for its rich red color and also has an orange undertone. The ore is processed using dry methods. Thus, after obtaining powder from minerals, it is mixed with drying oil and paint is obtained, which creates a reliable protective layer.

Lead paint has a number of positive properties, these include the following:

- Resistance to temperature influence, holding temperature varies from -50 to +60 degrees.

- Creates a hard and durable coating.

- Creates a protective coating that can withstand moisture, as well as chemical exposure, creates a film on the surface.

- Protective layer against corrosive formations.

- Long service life.

- Economical consumption.

- Can be used outside and inside the building.

- High density.

- Reasonable price.

- Ease of use.

Minium is an inorganic pigment of natural origin.

What is the purpose of red lead?

Minium is applicable for different areas; it is distinguished by the creation of a stable “barrier” on the surface that can withstand various external influences. The scope of application includes the following options:

- The most popular is painting surfaces with red lead to create an anti-corrosion layer;

- It can also be used as a primer for wood, while the top can be painted with another material, but it is also possible to limit yourself to using only this pigment. Protection is created from the rotting process, drying out, from exposure to sunlight and water;

- For buildings made of ceramic bricks, the paint gives an additional moisture-repellent effect and returns the natural shade to the material;

- The paint is also applicable to concrete products; it gives a beautiful external coating, protecting against the harmful effects of natural factors, increasing the durability of concrete.

Minium is applicable for different areas; it is distinguished by the creation of a stable “barrier” on the surface that can withstand various external influences.

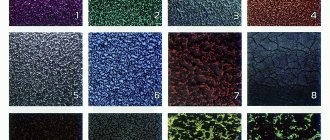

Synthetic and natural colors

Dry color is a powder that does not dissolve in chemicals, a fine dispersion, and exists in different tones.

The shade of the substance is obtained by mixing inorganic powder into the composition.

The presence of tinting powder in paintwork materials greatly increases the resistance of the metal to rust; in addition, the level of resistance to mechanical loads becomes better.

In reality, two types of colors are used: natural and synthetic. Artificial ones have a large selection of shades.

Natural pigments are made on the basis of natural additives that are taken from the depths of the Earth.

Natural additives are maximally environmentally friendly, safe and perfectly protect against various environmental influences.

Iron minium is considered a natural remedy.

In addition to red lead, natural colors include the following materials, whether iron or not: chalk, ocher, graphite, umber, and the like.

Features of the pigmented composition

The basis of the substance is the formula Fe2O3, the main component is iron oxide, which contains 65-95% of the total mass. When answering the question: what color is red lead? They come from the ore that is used in production. The most popular is the creation of red lead, it is distinguished by its red color; lead made with lead is less bright, its color is brown.

To bring materials to the required state, dry processing methods are used, they are brought to a powdery form. Then the powder is calcined under the influence of high temperatures in an oxygen or air environment. Temperatures reach up to 400-600 degrees. The separation process is carried out. Then comes the selection of powder having a given dispersion.

The finished paint is obtained by mixing powder with a liquid substance. Thus, two types of red lead are distinguished - lead and iron. They differ in their properties and scope of use, so we will review them separately in more detail.

The finished paint is obtained by mixing powder with a liquid substance.

Lead based material

Red lead is a solid substance that is characterized by high resistance to aggressive external influences. To obtain red lead in factories, two methods are used:

- Lead is completely melted and placed in an oxygen environment, subjected to high temperatures;

- Lead metal is heated and then sprayed into the atmosphere and cooled.

Afterwards the powder is packaged; storage containers can be wooden or plastic, paper bags can also be used. Minium lead is rarely used in everyday life due to its toxicity. Painting of this type of structure located on the inside and outside of premises is not used.

However, it is often chosen for painting pipes and underground communications, because its application creates an effective barrier against the formation of rust on products.

Its use in shipbuilding is popular; it is even sometimes called ship paint. In the military sphere, it can be used in the production of explosives; powder is used as their element. It can also be used by gardeners; agronomists use the powder as a primer for planting a number of plants. The drying period takes longer compared to the iron type, but a protective film against moisture is formed immediately, which lasts a long time even with constant contact with water.

Red lead is a solid substance that is characterized by high resistance to aggressive external influences.

Iron based material

Iron minium, what is it? It is also solid in structure and is used as a coloring agent. It turns out, according to production technologies from iron. During production, the substance is calcined in air, where limonite iron is concentrated in large volumes. As a result, iron oxide is obtained, which then goes through the grinding stage and becomes bright red.

Packing is done in wooden and plastic containers. At the same time, several types of red minium are distinguished according to their intended purpose:

- K – used in the production of putty mixtures and paints with a thick consistency;

- D – when creating enamels with the effect of protection against rust, coloring products, putty mixtures. Its use is popular in the shipbuilding field;

- E - intended for the creation of enamels and facade paint and varnish products;

- AK – enamels and paints that are distinguished by their anti-corrosion properties for general use.

Iron minium has a low toxicity rate, so it is permissible to use it both inside and outside the building. At room temperature, if the composition has been properly prepared, the drying process will take about 2 days. Features low consumption. Under these conditions it will be 150 grams per square meter.

Iron minium has a low toxicity rate, so it is permissible to use it both inside and outside the building.

It can be used to create glass, thermite, catalysts; the saturation of its color depends on the viscosity of the product. Can also be used in enamels and paints to create a vibrant shade and for fire retardants.

The use of powder in the production of oil paints is in great demand. They can be used for interior work, as well as for covering facades and other street structures. Thanks to its properties, the coating can withstand all natural negative factors to which a product used outdoors is exposed. The protective coating can last 18-24 months if applied in two layers.

Adding a natural element to paint and varnish products helps to obtain color stability; even exposure to ultraviolet rays does not affect its brightness. It also exhibits excellent resistance to high temperatures.

When painting, it is necessary to adhere to fire safety, the substance is flammable.

The use of powder in the production of oil paints is in great demand.

Areas of use

The main use of natural pigment is to treat surfaces that are most susceptible to negative atmospheric influences and aggressive environments from salt water. High adhesion properties ensure strong adhesion of the material to the surface. Due to its properties, the material is used for painting marine vessels, cars and other structures susceptible to corrosion are treated with it.

This material is used:

- in the manufacture of glass (optical, crystal, radiation-resistant glass);

- as a catalyst in building materials;

- in order to protect embedded elements in reinforced concrete structures from corrosion;

- for the production of explosives;

- for the manufacture of batteries;

- for painting cars;

- in putties.

Ship or sea red lead is in demand among consumers. The fact is that during the operation of a marine vehicle, the underwater part of the vessel becomes heavily overgrown with algae, which interferes with normal movement, and since red lead is poisonous, this does not happen.

On video: treating rust with red lead.

Comparative characteristics of compositions based on iron and lead

Thus, studying the two species separately makes it possible to draw up a comparative analysis of them. In terms of their protective qualities, both substances, obtained from different ores, have equally high performance; they are resistant to various types of influences and have a long service life.

In terms of decorative properties, their similarity should also be noted. They give rich and stable color to products. At the same time, they retain their brightness for a long time. They have slightly different shades, but this depends on the amount of pigment, and some adjustment can be made to the resulting shade. The consumption of both types is small, but when calculating it is necessary to take into account the thickness of the layer, as well as the type of surface on which the paint will be applied.

The lead type is somewhat ahead of the iron type in terms of its technical characteristics, but at the same time it is highly toxic. And its domestic use is limited. The iron type is more versatile and can be used in more areas.

The lead type is somewhat ahead of the iron type in terms of its technical characteristics, but at the same time it is highly toxic.

Application principles

Before working with red lead, you need to study the instructions for its application. The packaging may indicate unique application features that are important to consider to obtain the desired result. If the paint is too thick, it is diluted with turpentine, solvent or solvent.

Surface preparation

How to prepare metal for painting:

- Clean surfaces with a metal brush to remove plaque.

- Remove rust using specialized chemicals or abrasives.

- Degrease surfaces with kerosene or solvent.

How to properly use red lead paint on wood and metal

To get the desired result after painting an object, you first need to carry out preparatory work. The item must be cleaned of all types of contaminants and completely dried. When working with metal objects, they are first cleaned of rust elements, solvents are used, and then priming is carried out.

If there are any uneven spots, they should be filled with putty. If the object is made of wood, then sanding is carried out; sanding can also be used. Next, apply drying oil.

It is necessary to choose moisture-resistant sandpaper for sanding a wooden surface.

If there is old paint on the product, remove it and carefully sand the surface. If there are greasy stains on the product, it is necessary to degrease it. For this purpose, it is cleaned with washing powder, soap or soda solution; the product in chalk is also cleaned of it.

If there is old paint on the product, remove it and carefully sand the surface.

How to breed red lead

To use red lead as a coloring agent, it is mixed with a liquid agent; the best option would be to use drying oil. The ratio is made as follows: 20% drying oil to 80% red lead powder.

Mixing a large volume of components together at once is difficult; it is difficult to obtain a uniform consistency without lumps. The instructions recommend rubbing the powder with drying oil in a paint grinder until a thick oily liquid is obtained. Before direct use, dilute the paint with drying oil, or you can use white spirit.

To use red lead as a coloring agent, it is mixed with a liquid agent; the best option would be to use drying oil.

You can also use a more accessible and easier method, which has been known to shipbuilders for a long time. You need to do the following:

- The red lead is filled with water and left for 24 hours.

- After this time, the water is poured out.

- Mixes the powder, while gradually adding 100% drying oil.

- Gradually, the drying oil will begin to displace the remaining water; it will need to be drained.

In order to make the mixing process easier, you can use a construction mixer, but it should work at low speeds; you can use a screwdriver.

To make the mixing process easier, you can use a construction mixer.

When working, you must follow safety rules. The substance is flammable and toxic. Therefore, there should be no open sources of fire near it, and the room should be well ventilated. The master must protect himself with rubber gloves. Storage is also carried out in a place where children will not find it, far from sources of fire and heating devices, moisture and ultraviolet radiation.

Storage is carried out in a place where children will not find it, far from sources of fire and heating devices, moisture and ultraviolet radiation.

The article described in detail what red lead is. This is an excellent substance that is of natural origin and can create a bright and resistant coloring layer on various surfaces. It is important to select the right type for the work; it is undesirable to use red lead in everyday life, as it is toxic. It would be more appropriate to use the iron type.

Alternative solutions

If lead paint is not the best solution for some reason, you can think about an alternative. Finding a replacement for red lead is not so easy, especially one that is price competitive. However, the following options can be recommended:

- Electrically conductive paint "Zinga". This paint and varnish material contains zinc. Paint is widely used to protect cast iron and steel from rusting. The substance can be applied to metal over a very wide temperature range.

- Another replacement option is fire-retardant paint “Polistil”. This paint and varnish composition corresponds to the fourth fire safety group. Coatings treated with Polistil last for at least ten years.

In conclusion, it is necessary that “Polistil” will not become a full-fledged replacement for red lead. Therefore, if environmental considerations are not decisive, it is still better to give preference to red lead-based paint.