Types of gypsum putty

As the name suggests, this putty is made on a gypsum base. European manufacturers usually use white gypsum, and their product comes in a snow-white version, while domestic manufacturers sometimes produce putty from gypsum mined in Russia, but it has a yellowish tint, and accordingly, the finished mixture will turn yellow. In addition to the main component, the putty contains modifiers, polymer and mineral additives.

In the form of mineral fillers, quartz sand or finely ground marble flour are usually used - depending on the size of the fraction of these additives, putties are divided according to their purpose:

Starting. It has a coarser grind, compared to others - it looks looser and grainier. Starting putty is used to level the plastered layer and fill unevenness or roughness. Provided the surfaces are fairly smooth, it can be applied without prior plastering. If the finishing is carried out by gluing wallpaper or applying decorative plaster, then only the starting putty will be quite enough, and the minor defects left after it will be hidden by the subsequent layer of finishing.

Finish. It is very finely ground, there are no noticeable grains in it, in appearance it is a plastic, homogeneous mass of snow-white color. It is intended for final finishing of surfaces to an ideal state. It is not leveled, but rather “smoothed” walls, ceilings, arches - any parts of the interior, to an absolutely even and smooth state. After finishing, you can apply paint - no irregularities or imperfections should be visible.

Universal. Combines the properties of starting and finishing putties. Roughly speaking, it’s something between the first two types. The universal putty has an average filler fraction and can be applied in a medium to thin layer. Still, it should not be applied thickly - there is a possibility of cracks. This putty is well suited in cases where the surfaces are more or less smooth and require only surface treatment for a fine finish. Or, there is no need for a too perfect finish due to subsequent layers.

Naturally, gypsum putties containing sand will be applied in a thicker layer, since the fraction of quartz additives cannot be very fine. And those that contain marble flour can be very finely ground, its grains can be tenths of a millimeter, respectively, this putty will work as a finishing putty, and it is applied in a very thin layer.

Recommendations for selection

The first thing you need to pay attention to is the moisture content of the dry mixture. The optimal value is considered to be a number not exceeding 0.30% by weight. Also, the products should not contain particles with a diameter greater than 5 mm. Compliance with GOST 31377-2008 is important.

It is worth emphasizing the requirements for the hardened layer: tensile, compressive and adhesion strengths must be greater than or equal to 1.0, 2.0 and 0.3 MPa.

The buyer can find out all these characteristics from the seller or by examining the packaging of the composition.

You need to know exactly for what purpose gypsum-based putty is purchased. If this is leveling out significant surface flaws, then it is better to buy a starting mixture. When it comes to eliminating micro-defects in the base or giving it an exceptionally smooth texture, finishing compounds are relevant.

To stock up on the required number of bags, it is necessary, again, to start from the surface that needs treatment.

The consumption of the starting mixture, the application thickness of which can be equivalent to 6 cm, is 0.8-2 kg.

The universal one may require from 0.7 to 1.2 kg, and the finishing one – about 0.5 kg. The calculation is carried out per square meter of surface.

Pros and cons of gypsum putties

Modern construction stores are replete with an abundance of offers for putties - the choice is simply huge, there are a lot of options for putty mixtures. Gypsum putty has been a known material for quite some time, and of course, today there are a lot of other, more modern analogues for it. What makes experts still prefer the good old gypsum putty?

Pros:

- Safe for health. Gypsum is an environmentally friendly natural material, it is completely safe for human health and does not pollute the environment. In general, the entire composition of gypsum putties is safe.

- Excellent vapor permeability. Gypsum allows surfaces to “breathe” as it conducts air and moisture well. Such putties have excellent vapor permeability, which allows you to create the right microclimate indoors.

- Ease of operation. Gypsum putties have a plastic structure, which makes them easy to apply. These materials will be ideal even for a beginner who is picking up a spatula for the first time, and will make it easier for real specialists to carry out work and significantly speed up the puttying process.

- Easy to sand. Their subsequent processing is also convenient - after applying the finish, it can be easily sanded to a mirror shine. Once dry, gypsum is very easy to work with and sanding does not require much effort.

- High level of adhesion. Gypsum putty is quite unpretentious and can be successfully used on various surfaces: drywall, cement, brick. It has a high level of adhesion, and in principle, it does not matter what material will be the base.

- There is no shrinkage. Since gypsum putty always contains plasticizers and modifiers, after it has completely dried, shrinkage will not occur, which means cracks will not form.

- Economical consumption. The consumption of gypsum putty is much less than that of some other types, say, cement putty, which means it is more profitable to use them.

- Price. The cost of gypsum putties is very affordable; these finishing materials are available to everyone. Since their main component, gypsum itself, is not expensive, putties also have a budget price.

As you can see, gypsum putties have many advantages and all of them are significant, so despite the constant emergence of newer materials, gypsum putties continue to occupy a leading position in overall sales volumes for finishing materials.

Minuses:

They are not moisture resistant. Gypsum putties are not moisture resistant, which means they cannot be used in rooms with high humidity, such as a bathroom or kitchen. Typically, gypsum putties are used for the initial and final finishing of residential premises.

Advantages and disadvantages

Starting soil, or base soil as it is called, has positive and negative characteristics. Basic because it is required for almost all finishing works. After the base primer, the finishing primer is applied.

Advantages:

- easy to apply;

- handles irregularities and crevices;

- hardens quickly;

- used to cover various surfaces.

There are practically no disadvantages to starting soil. The relatively high price of popular manufacturers is one of the main problems. Consumers often save money by not purchasing a quality product, after which problems associated with destruction begin.

In what form can you buy gypsum putty?

Gypsum putty is usually presented in construction stores in two forms:

- Dry putty mixture

This product is sold in bags of various packaging: 5, 10, 25 and 50 kilograms. Depending on the size of the area to be treated, it is necessary to give preference to one or another volume of putty. Dry putty is convenient if you need to putty a large area - it is convenient to dilute it in portions, completely using up what has already been mixed.

Diluting the dry mixture is quite simple; to do this, you must strictly follow the proportions of water and dry powder indicated on the package. For better mixing and making the finished mixture plastic, it would be correct to use a construction mixer - a special attachment for a hammer drill.

- Ready-to-use putty

This gypsum putty is sold in buckets and is completely ready for use. The only point is that it also needs thorough mixing.

Important point:

gypsum putties have a rather short shelf life. Usually the packages indicate from 6 to 12 months. Therefore, before you take your purchase out of the store, be sure to check how long the putty is still usable.

Features of ceiling putty

Plastering the ceiling

Unlike vertical planes, finishing the ceiling is associated with certain difficulties. You have to work standing on a stepladder or sawhorse. To do this, you need to stand with your arms stretched up. All this causes a lot of inconvenience to the employee.

The support platform should be selected so that its height provides the most comfortable working conditions.

2 people must participate in finishing the ceiling. One worker directly works with a spatula. An assistant scoops the solution onto a spatula and gives it to the plasterer. This will significantly speed up the process of puttingtying the ceiling.

Brief overview of gypsum putty manufacturers

Since gypsum putties are very popular, almost every manufacturer of building mixtures also has gypsum materials in its assortment. Let's look at the most famous manufacturers of gypsum putties.

Knauf

This brand is actually a forward in gypsum mixtures. In particular, there is a line of new generation gypsum putties: Knauf Fugen. This series of gypsum products has specially developed formulations using the highest quality raw materials.

Knauf Fugen is available for sale in three variations:

- Standard - ordinary gypsum putty,

- Fugen GF is a special putty for plasterboard surfaces,

- Fugen Hydro is a composition for moisture-resistant drywall.

All three products are sold dry, that is, they require preliminary preparation for use. In addition to gypsum, the powder contains plasticizing and modifying additives. Knauf Fugen gypsum putties are also specially designed to prevent premature drying of the mixed ready-made putty, maintaining its plasticity and ideal working consistency.

Advantages of gypsum putties from this series:

- Eco-friendly composition, completely safe, even when used in bedrooms and children's rooms.

- Durable coating of walls and ceilings. Gypsum putty, when dried, forms a hard, durable layer, which can also be used to cover reinforcing mesh, corners and similar elements.

- Economical consumption. If we talk about smooth surfaces, then it’s completely minimal.

- Smooth top layer. The surfaces are finished with gypsum putties for finishing - you can not only glue wallpaper, even thin ones, but also simply paint it in the desired color.

- Knauf Fugen, despite its European origin, has a very reasonable price, and convenient packaging allows you to purchase exactly the amount of product needed for finishing.

Of the minuses , experts who constantly work with this product highlight the following facts:

- The putty dries quickly. On the one hand, this is good, on the other hand, it is not entirely convenient, especially if the work is not performed by a specialist, and therefore not too quickly.

- Due to the high strength of the finished layer, it may be difficult to sand the surface after drying. You need a large abrasive and quite a decent amount of force.

- These putties cannot be applied in a thick layer. Maximum coverage is no more than three centimeters.

In principle, the disadvantages are not so significant and are a consequence of the positive qualities.

Timmax EXTRA S45

Russian-made putty, however, is distinguished by the highest quality of the finished coating. Ideal for both outdoor and indoor use, as well as for rooms with high humidity. It is also important that this type of putty is not afraid of low temperatures, which is why it can be used outdoors or indoors where there is no heating. It has excellent adhesion and is easy to work with, thanks to the high elasticity of the finished mixture.

Sold only in dry form, packed in paper bags.

Ceresit CT 225

Gypsum-based finishing putty. It is applied in a thin layer and serves as the final finishing touch for surfaces to perfect condition. After this product has dried, the surfaces can be painted, decorated with artistic painting, and other types of fine finishing are also possible.

Disadvantages:

- It is produced only in dry form and only in bags packaged in 25 kilograms - this is not always a convenient purchase option.

- Hardens very quickly in open air. The ready-to-use mixture should be used literally within half an hour, maximum forty minutes! You should be careful when working, as frozen putty is difficult to fix.

Kreisel 662

This is a universal gypsum putty that is ideal for finishing brick or concrete surfaces. It is popular due to its amazing adhesive ability, as it can be used on both pre-plastered and even untreated surfaces. It is also suitable for rooms with high humidity levels - which is also a significant plus. And if we add to the advantages of this product its quite reasonable cost, then the high demand for this putty becomes completely understandable.

In addition to these brands, there are a huge number of other well-known and not so well-known manufacturers whose gypsum putties are also of good quality and affordable. The range of these products is so large that it is impossible to cover all the good mixtures in one article. When choosing putty, first of all you need to pay attention to the manufacturer, the consumption indicated on the packaging and the expiration date - these data will be the key to purchasing a quality product.

Details

Varieties, characteristics and composition

According to accepted standards, all putties are divided into finishing, starting and universal. They differ in properties and characteristics and properties, size and fillers. But any product contains gypsum and polymer-type additives, due to which the putty dries quickly, and the treated surface is smooth and durable. Often these substances can be called gypsum polymers, and they will give the coating:

- Elasticity.

- Plastic.

- Flexural strength.

- Resistant to cracking.

Usually the products are produced in packages of 5 or 50 kg, and buckets and jars with the finished mass (diluted with water) of 5-10-20 liters are less common. Many putties are white, but there are grayish ones, and the most expensive ones are snow-white. The characteristics of the products vary depending on their type and manufacturer.

The average indicators of materials are as follows:

- Operating temperature range – from +6 to +31 degrees.

- The main thickness of the layer without the use of reinforcing mesh or tape is 1 cm.

- Correct dilution: 1 measure of water is used for 2 measures of dry powder.

- Setting time is 1 hour.

- Complete drying time is 5 hours or more.

- The duration of final strength development is 1 week.

- Consumption ranges from 1 to 1.4 kg per square meter.

How long the solution takes to dry, its consumption and other technical characteristics should be specified on the packaging.

Overview of species

Starting putty

If we talk about gypsum starting putty, then such material is classified as plaster mixtures. Its main purpose will be to level the ceiling and walls, seal large defects, eliminate large level differences, and also fix devices for socket boxes. As a rule, this composition can be used to level and smooth plaster, and in new houses it is used as the first layer or after priming. To save money, you can buy the base mixture in gray, because it is cheaper. The product should not be applied in a thick layer, but in case of significant differences, reinforcing coatings should be used. Without the latter, the layer of dried material will simply fall off. It is better to completely seal the largest holes and defects with cement plaster.

Finishing putty

This composition helps to form a smooth surface for finishing types. As a rule, such compositions are applied in 1 layer, forming a white, smooth coating. It can be covered with wallpaper, painted, even in light colors. In appearance, the finishing coating differs from the starting product in its excellent smoothness (due to the fact that there are no large particles) and whiteness.

Universal composition

There are also universal products (start-finish) that have unique properties. They can be applied in a thick layer with a minimum particle size. The scope of application is wide - sealing joints on drywall sheets, eliminating cracks and deformations, and also leveling bases. Such products have a white tint and do not require the application of finishing putty.

Process

Preparatory stage and application

Before using gypsum material, it is important to familiarize yourself with the sequence of actions and carefully follow the rules for preparing the solution and base.

Preliminary work

All surfaces to which putty will be applied must be clean. Dust, dirt and stains should be removed. To clean cracks and recesses, you should use a vacuum cleaner, which will make it possible to quickly remove even the smallest particles. Then use a deep penetration primer - it improves the adhesion of the putty to the base.

Preparation of the composition

The instructions always describe the process of making the building mixture if it is sold in dry form. Tools, as well as the mixing container, must be clean. The algorithm is as follows:

Pour the required amount of water into the bowl.- Add the powder in small portions (it’s best to sprinkle it by hand, because it will be evenly distributed throughout the water).

- As the powder exceeds the water level, wait 2 minutes for the mixture to soak.

- Mix the mass manually, but better using a construction mixer or drills with attachments (at low speed).

- If the mass has a liquid consistency, there is no need to rush to add a new portion of powder - after a couple of minutes the mass will begin to thicken.

It is not worth preparing a lot of solution at once, and its shelf life is limited, because the mass will begin to harden and deteriorate.

Application

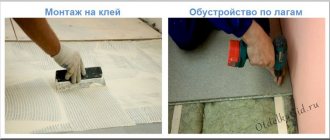

So, to apply gypsum putty to the walls, you need several spatulas of different sizes. Using a small one, take the mass and place it on a large spatula. Next, use smooth and even movements to make strokes on the wall or ceilings. In this case, the tool should be held at an angle of 55-60 degrees to the surface, and press evenly on the base.

Please note that the thickness of each layer should not be 0.5-0.8 cm for the starting layer. The directions of movement on the surface of the walls are from bottom to top, on the ceiling towards you. If necessary, use reinforcing mesh. If the layer is more than 1.5 cm, it is better to use galvanized tape, which is important to screw with dowels. The applied strokes are leveled with further movements of the spatula.

After the first layer has hardened, make a second one, and so on until a smooth surface is obtained. The final layer is created last. After final hardening, the putty should be sanded using sandpaper, which is attached to the block. Afterwards, the ceiling or walls can be primed and final finishing can begin.

Instructions for puttying

First, mix the solution according to the instructions given above. It should be noted that all manufacturers offer their own recommendations for creating a working mixture. Such instructions are placed on the packaging.

Using gypsum putties for various surfaces

To apply the first layer of putty, use a metal spatula. At the same time, we hold the tool at a certain angle to the surface. We press the spatula to the surface, spreading the putty evenly over the material being processed.

To prepare a wall for wallpaper, a couple of layers of leveling mixture will be enough. If we are talking about preparing the surface for painting, you will need three or even four layers of putty.

After applying the starting composition, we rub the surface and apply the finishing putty. After the final puttying, we carry out another grouting, with the help of which we remove the remaining minor defects of the coating.