Carrying out work related to painting any surface is a responsible occupation that requires certain knowledge and experience. Primers in a can make the process easier, but the quality of their application also determines how smoothly the paint layer will lie and how effective the surface will be in protecting it from destruction. Several products deserve special attention.

Tips for selecting and using aerosol epoxy primer

Metal coatings are constantly exposed to aggressive influences from atmospheric phenomena: temperature fluctuations, precipitation, ultraviolet rays lead to the destruction of surfaces. These factors accelerate the destructive process; coatings not only lose their attractive appearance, but can also fail, and therefore require repair and restoration of their original appearance.

During repairs, it is necessary to achieve not only an aesthetic effect, but also to protect the surface from subsequent destruction.

The use of primer mixtures is one of the simplest and most affordable ways to finish and protect surfaces. Such primers are produced in a variety of colors, are easy to apply, and have an affordable price.

Purpose and use of soils

A primer is a mixture with which, during repair work, the surface is treated before applying any finishing material. The soil helps to increase tenacity and frost resistance. In addition, the use of soil, leveling the absorbent surface, protects it from corrosion.

Types of compositions and their descriptions

To choose the right primer option, it is enough to take into account the following factors: the type of coating being treated, the operating conditions and the climate of the area. Aerosol primer can be used to treat many types of coatings.

Primer mixtures can be acidic, acrylic, alkyd water-dispersed, latex, based on drying oils or epoxy resins.

Composition and technical characteristics

Acrylic primer. For metal processing, a primer with an acrylic composition based on organic solvents is used. This mixture has proven itself in practice as a reliable and high-quality composition, suitable for processing aluminum and duralumin coatings, helping to obtain a high-strength coating and its excellent protection.

When using such a primer, the properties of the metal do not change even when exposed to high temperatures, since acrylic has a temperature-compensating characteristic.

Acrylic primer is suitable for processing products whose surface is coated with:

- plastic;

- steel;

- aluminum;

- putty;

- metal and so on.

It is resistant to temperature, humidity and adverse weather conditions.

Acrylic aerosol primer is used to treat various types of plastic coatings, small areas such as a rear view mirror or a plastic bumper.

A primer used to prevent corrosion. To ensure good protection of metal parts from corrosion, as well as better adhesion of paint to the surface, an anti-corrosion primer is used.

Strengthening soil. This composition is used to eliminate scratches, dents, small defects, as well as any cracks on car bodies. Several layers of this highly adhesion primer are sufficient to fill mechanical damage.

Corrosive or acidic primer. This composition is designed to work only on metal; it corrodes a thin layer of coating and ensures reliable paint adhesion and fights corrosion. However, an acid primer does not remove rust, but does not allow it to spread.

Alkyd primer is universal, suitable for wood, concrete, and metal.

Epoxy primer

Epoxy primer in an aerosol contains epoxy resin with a hardener, stabilizer, solvent and other additional chemicals, with the help of which the polymer mass remains liquid in a container before it is sprayed under gas pressure onto the coating. The solvent begins to quickly evaporate, and the hardener is activated by air and binds the composition applied to the solid film.

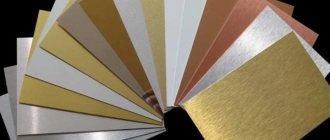

Epoxy primers have enhanced surface insulation properties from moisture, which help protect the coating from aggressive chemical influences. All-season epoxy mixture has high adhesion to galvanized, steel and aluminum surfaces.

Peculiarities

Epoxy composition is used when processing:

- plastic;

- galvanized and chrome-plated parts;

- coatings made of aluminum and ferrous metals;

- light alloys.

Epoxy primer, produced in the form of an aerosol in cans, is used during car repairs to prepare metal surfaces for painting. It was made from a certain resin and chemicals, and is used to create a protective film on the surface of the metal and prevent the process of its destruction.

To restore some equipment parts, using aerosol-type primer is the best option

This mixture has an advantage over acidic ones, since it can be sprayed on all types of metal coatings. According to user reviews, it is considered the best primer for metal, because it not only protects against corrosion, but also insulates from old coatings.

Selecting soil in aerosols

Mixtures of soils are produced in jars and cans in the form of an aerosol. Aerosol cans are one-component formulations; immediately after purchase they are ready for use without additional preparation.

Using an aerosol in cans is most convenient for use.

Aerosol is a product whose identifiable qualities are not much different from primers made from an aluminum container. After applying this component, the surface turns out to be very smooth, where the difference between the painted and untreated part is completely invisible.

We recommend: Drying times for different types of primers

Tips and recommendations for use

Before applying the primer, careful preparation of the surface in stages is required.

- The area to be treated must be washed and dried. To thoroughly clean all exfoliated fragments, you need to use a metal brush. With its help, you can easily remove rust from all unreliable areas, then you need to use sandpaper for metal.

Important. The easiest way to remove old paint is with a special remover - gel for paints.

Instructions for use are on the packaging.

- At the second stage, the area must be degreased using white spirit.

- Then it is carefully cleaned to remove any signs of rust.

- It is carefully sanded to get rid of uneven surfaces.

- The putty mixture is applied, filling scratches and chips with it.

- The coating is sanded.

- seams after welding;

- metal roofs;

- car bodies;

- exhaust systems.

Advice. When you need to leave some places untouched, it is recommended to stick a specialized tape, like masking tape, on the coating, or attach regular paper.

Consumption per 1 m2

Each type of primer has its own consumption for a certain area, so before purchasing it is recommended to carefully read the instructions for use of the drug.

Zinc based sprays

When processing artistic forging products, to give them a beautiful light gray non-glossy look, as well as to protect metal surfaces, for example, in country houses (fences, awnings, etc.), zinc aerosols are used. Zinc spray in aerosol cans is a composition of zinc pigment and a polymer binder with a high zinc content, used to prevent the destruction of metals. It is applied to the surface to be treated by spraying. The result is a wear-resistant coating with increased protective functions and durability.

Treat everything that is subject to destruction with an aerosol spray:

Advantages and disadvantages

The convenience of the aerosol is that it allows you to do the work yourself. Aerosol primer is very easy to use, it dries quickly, adheres well, is quite fluid and can be easily sanded. Features of applying primer in the form of a spray

Before applying the mixture, you need to vigorously shake the aerosol in the can, then apply it to the damaged part, directing the spray at a right angle. In this case, the container must be kept no closer than 30 centimeters from the plane being repaired. Most often, spray with progressive movements to obtain an even and thin coating without smudges, at least 3 layers, waiting at least 30 minutes between procedures.

Spraying should be done over the entire surface to be treated.

It must be remembered that when using an epoxy-based aerosol primer, it is observed that it dries for a long time. If you need quick results, give preference to products with quick drying.

Features of aerosol use and its consumption

During construction and renovation work, it is imperative to prepare the coating before applying finishing materials. There are some peculiarities of using soil in cans. Using primer in the form of an aerosol helps you do without tools: brushes, rollers. There are primers for treating brick, or concrete, plastic and wood. A can can be enough to cover an area of approximately 2 to 6 m2. Primer consumption depends on the type of coating and the degree of destruction. The instructions for use provide detailed information on how to use the aerosol and how much it will be needed for repairs.

When carrying out repair work, sometimes you have to deal with heavily rusted metal parts. It should be noted that it is not entirely necessary to clean them completely; you can simply remove loose fragments of rusty scabs with sandpaper. After this, the primer in the form of an aerosol is applied directly to the rust.

Advantages of aerosol packaging

The use of epoxy primer in the form of an aerosol has certain advantages and benefits over other forms of applying a protective layer.

It doesn’t take much time to prepare the soil for use: you just need to vigorously shake the can several times and warm it up to about 20-25oC. When working with an aerosol, you need to spray with a very thin stream, slowly treating the surfaces of the most complex shapes and even closed profiles.

If not all of the epoxy primer in the can has come out, then the spray head must be tightly closed, and the mixture can be used again.

Review of popular primer manufacturers

The market for paint and varnish products offers a wide selection of primers in aerosol form for treating various surfaces, produced by Russian companies and leading companies in foreign countries.

Krasko LLC is a well-known company that produces anti-corrosion paint and varnish coatings to protect metal structures. The Finnish company Turu valo produces environmentally friendly paints and varnishes, among them there are products that combine the functions of three components: a rust converter, an anti-corrosion primer and decorative enamel. The Kudo automobile series also includes products in aerosol form, which are known to many Russian car enthusiasts and are in demand.

The BOSNY company from Greece is familiar in many countries around the world. Produces aerosols and sprays for various surfaces.

SOLID - the company supplies high-quality products for all types of professional repairs. With SOLID acrylic primer you can level the surface of your car. The Tikkurila brand catalog contains paint and varnish products that are impossible to do without when repairing metal surfaces.

The world-famous HB-BODY corporation produces many of the main types of automotive anti-corrosion chemicals: anti-corrosion agents, automotive paints, which are necessary for processing various car parts.

HB-BODY brand products occupy a leading position in the production of auto chemicals. Aerosols from this company are highly reliable, easy to use and have excellent performance characteristics.

Before purchasing primers, you must carefully study the technical characteristics of the material and its application features. There is no point in saving on the primer mixture; you should choose products from a manufacturer that has proven itself and is in high demand among consumers.

Advantages and disadvantages

The primer is sold in different types of packaging, most often found in cans or cans. Let's consider the main advantages of the latter option:

- The aerosol in the can is a one-component composition, i.e. immediately after purchase it is ready for application and does not require additional preparation.

- Aerosol primer is more convenient to use and at the same time, its characteristics do not differ in any way from the version from a can.

- This primer provides an even and smooth coating, and also allows for smoother transitions between surface areas without extensive processing.

The only drawback and difference of this primer is its density. After all, the composition must be well atomized, so it is forced to have the appropriate fluidity.

Primer in cans is an excellent option for applying to coatings such as:

- plastic;

- black metals;

- light alloys;

- aluminum parts;

- galvanized or chrome plated parts.

Composition and technical characteristics

Acrylic primer. For metal processing, a primer with an acrylic composition based on organic solvents is used. This mixture has proven itself in practice as a reliable and high-quality composition, suitable for processing aluminum and duralumin coatings, helping to obtain a high-strength coating and its excellent protection.

When using such a primer, the properties of the metal do not change even when exposed to high temperatures, since acrylic has a temperature-compensating characteristic.

We recommend: Priming walls before plastering - help in choosing the appropriate composition

Acrylic primer is suitable for processing products whose surface is coated with:

- plastic;

- steel;

- aluminum;

- putty;

- metal and so on.

It is resistant to temperature, humidity and adverse weather conditions.

Acrylic aerosol primer is used to treat various types of plastic coatings, small areas such as a rear view mirror or a plastic bumper.

A primer used to prevent corrosion. To ensure good protection of metal parts from corrosion, as well as better adhesion of paint to the surface, an anti-corrosion primer is used.

Strengthening soil. This composition is used to eliminate scratches, dents, small defects, as well as any cracks on car bodies. Several layers of this highly adhesion primer are sufficient to fill mechanical damage.

Corrosive or acidic primer. This composition is designed to work only on metal; it corrodes a thin layer of coating and ensures reliable paint adhesion and fights corrosion. However, an acid primer does not remove rust, but does not allow it to spread.

Alkyd primer is universal, suitable for wood, concrete, and metal.

Application methods

Acid primer can be applied using several methods and tools:

- Simple brush.

- Spray gun.

- By lowering a metal product into a solution.

- Electrical spraying.

- Using electrodeposition technology.

In everyday life it is customary to use the first 2 tools. Immersion technology is used in factories.

Is it possible to apply paint to acidic soil?

Experts do not recommend applying paint over a layer of one-component acid primer. Otherwise, the components may cause a change in the shade of the paint due to the action of the yellow pigment.

Working with aluminum

Painting parts made of aluminum is associated with certain difficulties, since the paint does not adhere quite well to parts or objects made from this lightweight but durable metal. Like plastic objects, aluminum structural elements or car body parts require preliminary priming, without which after some time the applied paint will simply begin to crack and peel.

Aluminum parts should not be left unpainted, since a feature of this metal is the formation of an oxide film. This has a direct bearing on the chemical activity of a given metal. However, its other qualities satisfy manufacturers so much that it is used in the automotive industry for the manufacture of carburetors, various engine blocks and heads.

Applying primer to vehicle components and parts made of aluminum is mandatory. In this case, the soil performs a protective function.

The paint used to coat certain aluminum elements and structural components has a specially developed composition and is intended not so much to improve the appearance of the product, but to protect it from oxidation and prevent the part from failure.

Rust converters into soil - important features of use

To work on a car body, high-quality and reliable rust removal is often required. The beginnings of corrosion can destroy the body of your car in a matter of months. Using regular primer, you will not be able to protect body parts in any way.

It is simply impossible to produce zinc coating and other effective means at home. Therefore, we have to resort to more effective and easy-to-use means. Specifically, it is a rust-to-primer converter that is used before priming or at the same time as priming.

Your car can get rid of corrosion if you use the product correctly.

Many manufacturers claim that their product contains zinc elements, so a certain amount of galvanizing of the body occurs through a simple application of primer. In this case, the car can be processed independently in the garage or even on the street.

Many brands offer their products and promise amazing results. But in reality, not every material works the way the buyer wants.

The car owner will have to put a lot of effort into choosing a product and learning how to use it correctly to achieve the desired results. Let's look at this technology in more detail.

How does rust converter treatment work?

It turns out that modern anti-corrosion agents can be used simultaneously with surface priming. And if earlier the process of removing corrosion took you a lot of time, now there is no point in spending several hours on this difficult task. You can simply purchase a quality zinc rust converter and enjoy the optimal features of such an amazing material.

The problem is that the range of solutions in this industry is simply huge, and each manufacturer makes its own recommendations. It is worth remembering the following features of the material:

- While there has not been serious testing in all possible situations, the product for cars is quite new;

- you need to understand the instructions; the rust converter is not always applied simultaneously with the primer;

- preference should be given to those solutions that contain zinc, and this increases the cost of the material;

- high-quality products will not be cheap; they are often European compounds with a guarantee of reliable operation;

- There are also domestic offers, which often work well, but they need to be purchased only in the original packaging;

- any fake will do you a disservice; after processing and painting you will have to deal with corrosion again.

We recommend: Fence primer - selection and application rules

It is important to carry out a quality fight against corrosive elements on your car.

Even pure zinc does not always cope with tasks one hundred percent, so primer containing a rust converter will only work if the job is done properly.

It is worth considering which options for such a product can be used as the optimal solution for the car body. There are several worthy brands in this field on the market.

Manufacturers and variants of rust converter when priming

There are many interesting solutions that promise simply amazing results. A good rust converter to primer with zinc will allow you to completely remove the negative effects on the vehicle body. But for this you need to find a good option and a reliable manufacturer.

The market offers imported and Russian products for your car, which are also suitable for any other metal products. Primer containing zinc may not always be suitable for your auto repair solution.

But if you decide to try it, you should give preference to the following rust converters:

- Docker - the manufacturer claims that it contains zinc, and the use of the product is similar to real galvanizing. Corrosion turns into a protective layer that can resist water and condensation.

- Chemist - products under this name can be found in a huge assortment. But only certain solutions can be added to the soil. Read instructions and reviews before purchasing.

- Fenom is another imported option, which is very similar in properties to Khimik, but costs a little more. Quite an interesting way to process a car body without complications.

- Chainmail is a domestic development. The rust converter promises simply amazing results, but reviews do not always confirm its effectiveness. It is often better to choose the more understandable Chemist.

- The shell has a composition almost identical to the previous material. It is interesting that this product with zinc for adding to the soil does not yet have many opinions from experts and buyers.

- Permatex is not yet a very well-known, but quite interesting version of a rust converter. Good car treatment is quite simple and quick.

Amazing results can only be achieved if you use the correct technology for applying material to the body. If there are mistakes, the result is unlikely to please you.

The car body will still be affected by various corrosion processes. The soil will not help stop the rusting process if the zinc does not completely preserve the damaged metal.

It is better to test the rust converter on other metal parts before use.

How to use soil with zinc and various additives?

There are many ways to use such products for cars. Reputable manufacturers such as Chemist provide good instructions and guides for use. However, even following the instructions does not always allow the car to be properly processed. The problem is that you have to know how to apply the product.

In most cases, you will need to apply a rust converter, then take a special acid primer for cars. It will be great if the zinc covers all the corrosion areas. In any case, you should obtain instructions for the purchased material. Otherwise you will not get any results. Take into account the individual requirements of manufacturers.

How does zinc primer work?

A good primer, even with the highest quality characteristics, will not be able to help you obtain the ideal solution for protecting the body. This product only works if there is no longer any corrosion on the body. That's why you need a rust converter. Damaged car parts ideally receive the following results:

- zinc is applied to corrosive areas after their preliminary cleaning and preparation;

- then the active material acts as a preservative for rust;

- after 12-24 hours of operation, zinc elements completely transform rust and make it inactive;

- at the same time, the damaged metal is transformed into a protective layer that can be painted;

- On top of this layer is covered with primer, puttied, then primed again for painting.

The last stage of the renovation work will be painting. It is better to use separate converters that work before priming, rather than together with it. This way you can visually assess the quality of the results and understand how reliably the machine is protected from corrosion in the near future. But, of course, such solutions will not help you completely get rid of the risk of rust on the body.

Let's sum it up

It is difficult to identify truly effective materials and rust converters that work for your car. A good option for protecting the body is galvanizing, but it cannot be done without special costs.

Even at professional stations it is impossible to use high-quality body treatment using zinc. Moreover, they do not protect body parts with soil.

But if you use a combination of a quality converter and a good primer, you can achieve good results.

The cost of high-quality processing at the station will be high, so you can do it yourself. Using modern materials with a quality guarantee, you can carry out repair and protective work on your own.

To do this, it is enough to buy a product with a fairly high price; you should not buy the cheapest solutions. Next, read the instructions and follow everything exactly according to the manufacturer’s requirements.

We recommend: Airbrush primer - types and preparation for application

For priming you will need special equipment.

Primer in cans - application, features and application technique

Thanks to the primer, the paintwork lies smoothly on the surface. The first material ensures tight adhesion of paint to metal or wood. Primer in cans (aerosol primer) is used both for car treatment and in construction. There are several varieties of such aerosols, the composition of which is selected taking into account the characteristics of the material being processed.

Advantages of aerosol primers

Aerosol primers have the following advantages:

- suitable for various materials and surfaces;

- ease of use;

- ensure uniform spraying of the composition over the surface;

- do not require pre-processing of the material.

A spray primer is considered the best choice for those who have not previously painted a car or wood product. Using an aerosol, you can level the paint coating, ensuring uniform application of paint to the surface.

Application of automotive aerosols in construction

Automotive primers differ in composition. This is explained by the fact that in the design of modern cars, in addition to metal, other materials are used, including wood. Primer manufacturers, in an effort to satisfy consumer needs, produce aerosols that can be applied to different surfaces. There are also universal types of sprays suitable for processing wood, plastic and other materials. This means that automotive primers can be used, if necessary, during construction work.

Types of compositions and their descriptions

Aerosol primer is a one-component composition, immediately ready for application to the surface. This circumstance imposes certain restrictions on the scope of application of the material. A number of compounds are used strictly to solve specific problems: increasing anti-corrosion protection, strengthening metal and others.

Primer for wood

For wood, alkyd (adhesive) or acrylate (leveling) primers are used. The first type consists of small molecules that ensure deep penetration of the material into the surface being treated. Due to this, after applying the primer, the wood becomes stronger.

Alkyd aerosols are used in cases where there is a need for high adhesion (strong bond) between the paint and the material being treated. The use of such compositions is advantageous in that the primer provides a prolonged effect. That is, the finishing coat of paint can be applied to the wood within one year after the initial spray treatment. During this time, the substance does not lose its original properties.

Acrylate primer contains latex, vinyl, styrene and other compounds. This material is characterized by increased fluidity. Thanks to this feature, the primer is used when there is a need to level a surface with pronounced defects (large pores, chips, etc.). The use of acrylate impregnation is justified if translucent paint is subsequently applied.

Primer for metal

There are several varieties of metal primers suitable for treating a specific material or used to enhance protection against corrosion, smooth out chips, etch out rust, or other purposes.

Working with aluminum

Aluminum is a difficult metal to process and does not adhere well to paint. To increase the adhesion of materials, it is recommended to pre-treat the car surface with a primer. Otherwise, over time the paint will crack or begin to peel.

The need for primer is explained by the fact that an oxide film is formed on the surface due to the chemical activity of aluminum. The latter prevents the paint from penetrating deep into the material.

Heat-resistant primer

Heat-resistant primer performs the following functions:

- increases paint adhesion;

- prevents metal oxide;

- reduces paint consumption;

- creates a thermal protective layer.

Heat-resistant primers differ in composition, each of which is selected in accordance with the operating conditions of the vehicle. After application with such an aerosol, the metal is able to withstand the following temperatures:

- up to 60 degrees;

- up to 100 degrees;

- up to 300 degrees;

- over 300 degrees.

The automotive industry mainly uses products from the first two groups.

Anti-corrosion primer spray

Anti-corrosion primer is divided into several types depending on the composition and purpose of use. Basically, for cars, an insulating mixture is used, which, by forming a film on the surface, protects the metal from the penetration of moisture and oxygen. The latter trigger oxidative processes that cause corrosion. A mixture of acrylic, red lead, talc and zinc oxide is used as an anti-corrosion material.

Spray primer for plastic

For processing plastic products, acrylic-based spray primers are usually used. This aerosol provides protection against temperature changes and moisture.

Restoration of plastic products

Priming of plastic is carried out to eliminate:

- scratches;

- microcracks;

- small dents and depressions.

We recommend: Is it necessary to prime wallpaper before painting?

This type of primer can be used to restore both automobile parts and other plastic products. The composition in the form of a spray is evenly distributed over the surface being treated, thereby eliminating minor defects. However, such primers do not provide protection from the negative effects of the external environment. The use of an aerosol in relation to plastic is justified by the fact that the applied composition increases the adhesion of the paint.

Epoxy primer in a can

After application, epoxy resins form a reliable insulating layer that prevents metal contact with water and aggressive substances. Moreover, this composition has the same properties that are characteristic of most automotive aerosol primers (increased adhesion and others).

Acrylic primer

Acrylic composition is considered the most common among motorists. This primer is based on organic solvents and is suitable for processing aluminum, duralumin and other non-ferrous metals. In addition to general anti-corrosion protection, acrylic compounds prevent paint from cracking during sudden temperature changes.

Acidic soil

Acid (etching) primer is used for primary processing of the material. This composition corrodes the top layer of metal. After applying the etching composition, it is prohibited to use certain types of materials (in particular, putties). Then another primer must be applied to the acid-treated surface. This combination significantly increases anti-corrosion protection and paint adhesion to metal.

Some special primers

In some cases, when preparing cars for subsequent painting, the following types of primer compositions are used:

- Strengthening. It is used when processing metals or plastics with minor defects. The strengthening compound is applied in several layers until scratches or dents are filled.

- Passivating. Slows down electrochemical processes, thereby reducing the rate of corrosion development. Compositions of this type are expensive, so they are used on those metals that often come into contact with aggressive environments.

- Protective. This primer contains zinc, aluminum or other metals that have the opposite potential to iron. Thanks to this feature, the film formed after applying the aerosol dissolves aggressive substances, protecting the body from negative influences.

- Alkyd-polyurethane. The film formed after applying such a composition is characterized by increased strength to mechanical stress and prevents metal deformation.

- Phosphating. Used for treating surfaces covered with rust. This primer contains two components: a thinner and phosphoric acid. The latter penetrates deeply into the structure of the material, increasing the degree of adhesion of the paint to the surface. This type of soil is used for processing ferrous and non-ferrous metals, galvanized iron.

Using primer in cans

The primer is allowed to be used at temperatures of +10-30 degrees. If during processing more material flies out of the can than is necessary, it is recommended to drain a little liquid into a separate container before processing.

Required Tools

To prime the metal you will need:

- wire brush to remove corrosion;

- sweeping brush for removing dust;

- rag;

- solvent.

If you are priming a painted material, it is recommended to purchase a paint remover. When applying small parts of the car, you should stock up on a brush and roller.

Surface preparation before applying aerosol primer

Surface cleaning is a necessary step in which dirt, dust particles, and vulnerable areas damaged by rust are removed from the material. This procedure ensures uniform application of primer and paint. It will also be necessary to degrease the metal, since the compounds used subsequently do not stick to oily surfaces. Additionally, it is recommended to sand the surface.

Soil selection

The type of soil is selected taking into account the specifics of the work being carried out. In particular, for metals it is not recommended to use deeply penetrating mixtures, except in cases where the material being processed is constantly in contact with aggressive environments.

Treatment

Before applying the aerosol, the can must be vigorously shaken for 20-30 seconds. During this time, the components of the composition will mix with each other. Then you need to install the nozzle at an angle of 90 degrees relative to the surface being treated. It is recommended to keep the can at a distance of 30 centimeters. Next you need to press the nozzle. The can must be constantly moved, without staying in one place for a long time. Repeated priming is carried out half an hour after the first procedure.

How long does it take for aerosol primer to dry?

On average, it takes 30-55 minutes for the aerosol to dry completely. The duration of this time interval directly depends on the type of mixture selected. Epoxy resins cure completely within six hours. And some compositions require 20 hours. If necessary, you can speed up the drying process by pointing the hairdryer at the treated surface.

Aerosol primers are used for processing metals, plastics and wood. These mixtures improve the adhesion of the paintwork to the surface. There are several types of primer material: to increase anti-corrosion protection, remove rust or defects, and others. Such compositions are recommended for use when treating small surfaces.

Primer for car

In car repair, an auto primer is used to prepare metal surfaces for painting. Basically it is epoxy primer. It is created from special resins and chemical reagents to create a protective film on the metal surface and prevent the development of corrosion processes.

Epoxy primer comes in cans and in the form of a primer spray. To repair certain areas of the car, it would be better to use a spray primer.

Surface preparation before priming:

- It is necessary to thoroughly wash and dry the treated area.

- Next, degrease with white spirit.

- Remove any signs of corrosion.

- Sand the surface, but so that there are no irregularities left on it.

- Apply putty and fill scratches, chips, etc. with it.

- Sand.

After preparing the surface, you can apply an aerosol primer to the desired area of the car. It should be applied in two or three layers, while maintaining intervals between applications. Read the instructions carefully; if you follow them, you don’t have to worry about the success of the work being performed.

On video: the advantages of epoxy primer in a can.

How to use an aerosol primer - step by step diagram

Step 1: Surface Cleaning

It would not be superfluous to remind once again that the quality of the primer coating, which can peel off along with foreign particles, depends on how well unreliable areas, dust and dirt are removed from the base. Cleaning also includes degreasing, since if there are oily stains on the base, the compounds we are considering will not stick to the surface. It is advisable to sand down everything, even minor irregularities.

Step 2: Selecting the soil

In principle, even highly specialized mixtures, for example, for metal, can be applied to both concrete and wood. Another thing is that this may not only not improve the adhesion to the surface of the subsequently applied finishing material, but, on the contrary, worsen the contact of the same decorative plaster with the base. For example, metal does not require deep penetration primers, but wood or plasterboard sheets require just such pre-treatment. Therefore, we take exactly the soil that is suitable for the base material.

Step 3: Processing

At this stage everything is simple. We take the can and shake it well until we hear the balls rattling inside. Then we direct the spray nozzle at the wall or ceiling so that the escaping stream hits the surface at an angle of 90 degrees. We hold the can at a distance of 25-30 centimeters from the base being treated and perform back-and-forth movements with the hand from side to side. We smoothly process every centimeter, without lingering in any area longer than necessary. Often 2-3 coats should be applied at 30 minute intervals.

Composition of substances

Zinc-rich primer may contain dust or a mixture of dust and flakes as the main substance. Other components of the composition of metal primers include:

- inhibitors – give the material anti-corrosion properties, increase adhesion (for galvanized iron this is especially important);

- phosphates in aqueous solvents - interact well with any type of finishing coating;

- chromic acid salts - change the properties of the metal, making it passive to rust formation;

- red lead - used as a neutral pigment capable of forming a moisture-resistant insulating film on the surface;

- surfactants – convert rust into poorly soluble or quickly degradable compounds;

- powders of other metals (mono-, bi- and combined mixtures) - the higher the content, the higher the anti-corrosion properties of the primer;

- solvents;

- desiccant;

- resins;

- hardeners, etc.

Based on the composition of the substances, the type, qualities, properties and purpose of primer materials for different types of metal are determined. “Pure zinc” primer mixtures, classified as protective, contain more than 90% zinc. The rest is filled with special resins, liquid glass, and so on.

Primers usually contain less pigment, so they are practically not used as a topcoat.

Zinc primer is not suitable for finishing metal

Peculiarities

Epoxy composition is used when processing:

- plastic;

- galvanized and chrome-plated parts;

- coatings made of aluminum and ferrous metals;

- light alloys.

Epoxy primer, produced in the form of an aerosol in cans, is used during car repairs to prepare metal surfaces for painting. It was made from a certain resin and chemicals, and is used to create a protective film on the surface of the metal and prevent the process of its destruction.

To restore some equipment parts, using aerosol-type primer is the best option

This mixture has an advantage over acidic ones, since it can be sprayed on all types of metal coatings. According to user reviews, it is considered the best primer for metal, because it not only protects against corrosion, but also insulates from old coatings.