Primer is a special composition that is applied to the surface of the car before applying the paintwork. The soil has a high content of pigments. The main function of the primer is to improve adhesion (adhesion) with the subsequent layer of paintwork.

p, blockquote 1,0,0,0,0 —>

When repairing a car body, they usually prime the putty repair area, which also has fragments of the old paintwork. Pure metal also needs to be primed. Thus, auto enamel is applied to the primer or to the old paintwork (provided that the old coating is compatible with the applied enamel).

p, blockquote 2,0,0,0,0 —>

Soils have different compositions and, depending on this, have different properties.

p, blockquote 3,0,0,0,0 —>

Anti-corrosion (“acid”) primer:

p, blockquote 4,0,0,0,0 —>

It is applied to clean metal and protects it from corrosion. This is a primary primer and must be coated with a secondary primer, that is, putty or paint cannot be applied to it immediately. It is always recommended to cover the “bare” metal with an anti-corrosion “acid” primer. If the metal of the new body panel is coated with high-quality factory primer, then “acidic” primer is not used.

p, blockquote 5,0,0,0,0 —>

Epoxy primer Epoxy primer is intended for anti-corrosion protection of metal surfaces. Just like acidic soil, it is primary. For further painting of the surface, it must be covered with secondary primer. It is worth mentioning here that epoxy primer sprayed onto a flat (without minor defects) surface can be painted even without sanding paper. But this can be done before it has completely hardened, several hours after priming. If the primer has hardened, it must be treated with sanding paper and primed with acrylic primer. Then dry the acrylic primer, sand it for painting and then you can paint.

p, blockquote 6,0,0,0,0 —>

Epoxy primer contains special resins and special active additives that prevent the development of corrosion processes on the metal surface. It dries quickly and after curing becomes resistant to mechanical and temperature influences. The surface covered with this primer, even without applying paint and varnish materials, is well protected from corrosion.

p, blockquote 7,0,0,0,0 —>

Epoxy primer after application forms a dense film that does not have pores.

p, blockquote 8,0,1,0,0 —>

The disadvantage is the long drying time. At a temperature of +20 °C it averages 12 hours. An increase in drying temperature leads to uneven polymerization of soil layers and leads to the appearance of defects.

p, blockquote 9,0,0,0,0 —>

Which primary primer is best to use and whether they are compatible, you can read in the article about primary acid and epoxy primers.

p, blockquote 10,0,0,0,0 —>

Two-component pore-filling primer:

p, blockquote 11,0,0,0,0 —>

This primer is most often used before painting a car. Porosity-filling primer can be applied in a thick layer. It fills the pores that remain on the putty, as well as the marks left by sanding paper.

p, blockquote 12,0,0,0,0 —>

However, you need to remember that the putty surface must be prepared for priming according to all the rules and the risks from sanding should not be too large. If you fill too deep scratches with this soil, then after some time, after drying, the soil will sag and all defects will be visible.

p, blockquote 13,0,0,0,0 —>

One-component nitro primer:

p, blockquote 14,0,0,0,0 —>

Apply before painting with alkyd or nitro enamels. This primer is not compatible with acrylic car enamels or metallic paints. The main advantage is that it dries very quickly.

p, blockquote 15,0,0,0,0 —>

One-component acrylic primer:

p, blockquote 16,1,0,0,0 —>

It is convenient to use as it comes in an aerosol package. But it is also sold in regular containers.

p, blockquote 17,0,0,0,0 —>

Sufficiently high quality soil. Dries quickly and is easy to use. Compatible with almost all types of paints.

p, blockquote 18,0,0,0,0 —>

Primers for plastic:

p, blockquote 19,0,0,0,0 —>

When repairing plastic, special primers are used to increase adhesion. If you are painting new plastic, then after priming with a special primer you can immediately apply paint.

p, blockquote 20,0,0,0,0 —>

Application of primer:

p, blockquote 21,0,0,0,0 —>

Before spraying, the primer must be thoroughly mixed, and in some cases, if necessary, diluted with a thinner to a working viscosity. When diluting different soils, you need to check the instructions for each specific product.

p, blockquote 22,0,0,0,0 —>

It is forbidden to dilute with solvents to the working viscosity; only thinners must be used.

p, blockquote 23,0,0,0,0 —>

Next, it is important to filter the soil.

p, blockquote 24,0,0,1,0 —>

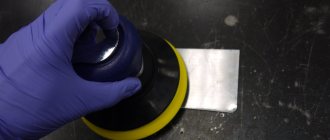

For application, primer spray guns with a nozzle of 1.5 - 2.0 mm are usually used. Apply 1 – 2 layers. If desired, you can apply more layers, taking into account the fact that in preparation for painting, part of the primer will be sanded off. But you need to remember that it is not recommended to apply a layer that is too thick, especially since it will not dry well. Each layer must be applied after the previous one has dried. Interlayer drying time is approximately 10 – 15 minutes.

p, blockquote 25,0,0,0,0 —>

Preparing the surface for applying primer: - clean from dust; — before priming, plastic parts must be wiped with an antistatic agent; - degrease the surface.

p, blockquote 26,0,0,0,0 —>

Ground grinding:

p, blockquote 27,0,0,0,0 —>

When sanding dry before painting, use P400. When preparing with water, P800 is used. In areas of panels that have a complex shape, as well as in hard-to-reach places, you can use Brite tape.

What is automotive primer

Automotive primer is a whole segment of products used for application to the cleaned surface of a vehicle body.

Primer for painting a car is applied as a base, which can be sanded, and only then a ball of sealant is used.

Automotive primer for metal, or rather a high-quality product, does not belong to the budget segment, but savings may be the reason to repeat the painting. Therefore, it is better to immediately settle on the most suitable high-quality product.

Automotive putty is distinguished by its dense structure and its water resistance. It is applied as a protective ball against oxidation. Before use, combine with hardener and apply several balls to the body. To work, you need to purchase a spray gun. The epoxy primer coat is applied first. This guarantees optimal adhesion to metal elements. It will be an excellent base for applying subsequent layers.

How to apply primer before painting a car

Alkyd primer and everything you need to know about it.

Any surface must be primed before applying finishing paints and varnishes. This method of painting ensures the durability of the paint. Alkyd primer has a high degree of resistance to aggressive environments. This primer is used to cover surfaces that need protection from moisture. After complete drying, the protective primer layer is coated with alkyd paints. It is not recommended to use paints that are not compatible with the primer for this purpose.

Main properties and scope

Alkyd primer composition is almost universal. It is used to improve the quality of surfaces of wood, metal, glass, galvanized steel, and concrete. Alkyd primer applied to external metal structures and technical parts of buildings and industrial structures will reliably protect them from corrosion. Later, the primed metal surface is painted with alkyd paint (enamel). This combination of coatings gives the metal anti-corrosion resistance. Primed metal will use much less paint.

The polymers that make up the soil fill all the small cracks and pores on the metal surface. Thus, additional mechanical protection of the surface is created. Alkyd primer can be used on wooden surfaces before applying decorative and finishing materials (paint, putty, glue). If the surface of a tree is primed, then to create an external protective layer, in addition to alkyd paints, you can use liquid wallpaper. This combination of finishing materials with the base gives an excellent result, providing the wood with durability. Thanks to the high adhesion ability of soil and liquid wallpaper, a coating is created that is inseparable from the wooden surface.

Wood can also be painted using one or two layers of alkyd impregnation. Concrete, just like metal and wood, after applying protective primers, should be painted with alkyd paints. Completely dried alkyd primer creates, thanks to the polymers contained in its composition, a protective film. Therefore, primers, alkyd paints and impregnations are suitable for use in exterior work and interior decoration. Alkyd primer is compatible with alkyd impregnation, alkyd and acrylic paints, nitro paint, PVA glue and acrylic putty. It is not recommended to use this type of soil for finishing work on gypsum, plaster and any other crumbling building materials. This does not apply only to concrete.

Alkyd primer: technical characteristics

The properties of alkyd compositions intended for preparing surfaces for finishing are very wide. In addition to improving the adhesion of the base material, they increase its water resistance. No less important are the antiseptic properties of alkyd polymers, which prevent the formation of mold and mildew. The main technical characteristics of alkyd compositions also include:

- Resistance to temperature changes from -40 °C to +60 °C.

- Reduced consumption of subsequent finishing compounds.

- Increasing the resistance of substrates to abrasion and chemicals.

- Reducing shrinkage and swelling of wood under the influence of moisture.

- Protecting the surface of painted wood from bleed-through of resinous areas.

Application technology

Alkyd primer is produced completely ready for use. Before starting work, it is necessary to prepare the surface well by cleaning it from dirt and drying it. The wooden base is cleaned of burrs, and the cracks are filled with putty. The metal surface must be cleaned of rust and degreased.

You need to work with this composition wearing gloves. Before application, the alkyd primer must be well mixed and, if necessary, diluted with white spirit, solvent or xylene to a viscosity of 21-24.

The polymer alkyd primer is applied using a brush, roller or spray in one or two layers. The time for complete drying of each layer at a temperature of 20 ° C and air humidity of 70% is 24 hours. This primer is frost-resistant, so it can be stored at subzero temperatures.

Disadvantages of alkyd primer.

- long drying period;

— if the alkyd primer has not dried completely, some paints may curl upon contact with it;

- only the upper part of the surface is processed. That is, the alkyd primer does not penetrate deep into the material and cannot be used as a fixative for crumbling and loose materials. For them it is necessary to use acrylic primers;

— a construction bandage made of synthetic material that is not completely glued to the surface cannot be wetted with an alkyd primer. Because the bandage will bubble and stretch;

— despite the fact that white spirit is not a highly toxic substance, it is still quite harmful. Therefore, until the alkyd primer dries completely, the room must be well ventilated;

— the tools used for priming (brush or roller) must be stored wrapped in a rag moistened with white spirit. To prevent air from entering, they are additionally wrapped in polyethylene. This way the tools can be stored for a week. Then they can only be cleaned with special means.

Advantages of alkyd primer.

— high soil strength;

- resistant to abrasion after drying;

— reliably covers resinous knots. They are not visible even after several years;

— any paints (acrylic, alkyd, enamel, latex and nitro paint), glue (wallpaper, universal, PVA) and putties (acrylate and acrylic) lie smoothly on it;

— in addition to metal surfaces, alkyd primer is suitable for priming wood, plastic, plaster, laminated surfaces, chipboard, fiberboard, concrete, as well as surfaces previously painted with any paint;

- Can be used at sub-zero temperatures;

- low-toxic chemical composition. You can work without using special protective equipment; it is enough that the room is simply well ventilated;

— you can dilute the alkyd primer or clean the surface from it using white spirit. Inexpensive and accessible chemical.

WHAT IS ALKYD PRIMER MADE OF?

Alkyd primers use a component similar to the varnish base for glypthal or pentaphthalic coatings. Synthetic primer resin, unlike paint, does not contain film-forming additives, substances that increase density and squeeze air out of the decorative layer.

An alkyd resin primer is not as thoroughly cleaned of residues of the original components as a varnish product for glyphthalic or pentaphthalic paint. In its “raw” form, such a primer has a dirty tint. Therefore, in some cases, such a primer is not cleaned, but is artificially saturated with dark brown, black or gray pigment and reagents are added that reduce the surface tension forces of the liquid primer film. The solvent for the synthetic alkyd primer base uses more volatile substances than the paint.

This allows the primer mass, which is more liquid than paint, to easily penetrate into the smallest pores of the walls. Thanks to the modification of the resin with vegetable drying oils, the primer easily adheres even to wall surfaces contaminated with micron cement dust. The latter factor is usually an insurmountable obstacle for most viscous epoxy and polyurethane primers.

WHICH WALL PRIMER IS BEST SUITABLE

Finishing of internal and facade walls with alkyd primers differs in operating conditions and safety requirements. First of all, it should be understood that alkyd primers are not enamels; they have a similar composition, but a completely different structure on the wall surface. If we draw an analogy, glypthal enamel can be compared to a high-quality aluminum pan, while alkyd primer, at best, looks like a colander.

Some of the most commonly used ones include:

- GF 021, GF 032 - general purpose primer for preparing wooden and metal surfaces and walls for painting. Option GFP 021 contains substances that convert rust residues into a stable insoluble compound with a dense structure. Good primer for wood;

- Soil GF 0119 GOST 23343-78. The composition for treating wooden, metal, concrete walls of internal non-residential premises is diluted with xylene, solvent, and white spirit. Touch-drying time is 90-120 minutes, complete drying at room temperature is 10 hours. The dried surface is absolutely safe, but application requires the use of good supply and exhaust ventilation. Typically comes in red-brown color;

- Alkyd primer "Tikkurila" with the effect of anti-corrosion protection of ferrous metals. Available in five colors: green, gray, red-brown, black, silver. Apply to completely dry surfaces. Drying time – 5 hours. Used to coat metal and concrete walls.

Important!

For interior work, it is recommended to use alkyd primer No. 021 and No. 0119. All primers containing rust modifiers or for which toluene-based solvents are used are strictly not recommended for treating interior walls. Often, glypthal varnishes can be used as an alkyd primer for gluing wallpaper on walls to strengthen the wooden surface. They do not contain red lead or lead pigments, so they will always be safer and easier to use.

Types of soils

Alkyd primers come in several types. The attitude towards one or another group is determined by their composition. Glypthal. Their main difference is that they consist of a coloring pigment and filler. They, like alkyd primers, find their use in finishing work outside the building and inside the premises. Used to create a protective film on the surface of concrete, wood, metal, glass.

Enamels and paints are laid on top of these primers. Glypthal primers, which have a wide range of applications, are called universal or general purpose primers. There are certain types of this material that can only be used for metal surfaces. They are distinguished by their ability to create a water-repellent film with anti-corrosion properties. Perchlorovinyl primer is intended for application to metal, plaster, and concrete. Not used for indoor work. Dries within an hour.

Polyvinyl acetate primer. Dries in half an hour. Use only in combination with alkyd paints. Polystyrene primer. Can only be used for external street work due to its high toxicity. It is suitable for use on wooden substrates. Alkyd-urethane primer enamel. Designed for coating metal surfaces of vehicles and external metal structures. It is characterized by increased moisture resistance.

The density of the metal is so high that special tools and mechanisms must be used to process it. To make a hole in the ...Tag "Next" When hanging art, shelves, TVs or other heavier objects on hollow walls, you can greatly increase their safety with ...Tag "Next" Screws are one of the easiest and most useful tools when -or created. It is an integral part of any construction project. Regardless of ...Tag "Next" Self-tapping screws are different from traditional screws because they make their own threads when screwed into plastic, wood or metal. Self-tapping screws ...Tag "Next" Paint and varnish materials (LCM) - a multi-component system that is applied in liquid or powder form to a previously prepared surface and after drying ...Tag "Next" This article highlights the importance of close coordination between transactions in a typical bathroom installation project . Introduction When installing a new ... Tag “Next” As you know, there are many ways to improve the ceiling. However, not all of them are characterized by low cost and ease of implementation. An excellent option, ...Tag “Next” Comfort in the home is the dream of every owner. However, anyone, even repairing the highest quality, can ruin the shape - an unpleasant phenomenon that ...Tag "Next"

Properties of primer for cars

The characteristics of all types of primers must be taken into account by craftsmen at the initial stage of application. It is important for the master to master all painting skills to prevent delamination of the product.

There are primers on the market that combine the characteristics of a primer and filler. Naturally, it is more rational to use different materials for applying to metal and plastic.

Guaranteeing perfect adhesion is only 50 percent of the success, which is decided by the soil. It is important to take into account anti-corrosion features. An attempt to apply an anti-corrosion primer for a car with a massive ball will cause a decrease in its strength and lead to cracks. This is exactly the case when a lot does not mean good. The autoprimer is applied with a thin ball, which must be dry before applying subsequent ones.

Peculiarities

Since alkyd primers are universal, they have gained great popularity in our country. These primers can be used on metal, wood, concrete, plastic, and even glass. Depending on what material the primer is applied to, it performs the following functions:

- protects against corrosion and rusting;

- increases the adhesion rate (adhesion of the finish to the base);

- reduces the consumption of paint and varnish products by filling all pores and cracks;

- makes the surface of the material more durable, so the finishing paint or putty applied over the alkyd primer will not flake off, peel or fall off;

- increases the water resistance of wood materials; after applying the primer, the wood practically does not swell or shrink;

- provides antiseptic protection, so that fungi and mold do not settle on the surface;

- increases resistance to the negative influence of the environment and various aggressive chemical compounds;

- increases the resistance of the material to abrasion;

- protects the paintwork from the appearance of resinous substances.

Types of automotive primers

Types of car primers vary depending on the manufacturer and price.

There are three classes:

- Epoxy.

- Primer/car putty with a leveling structure.

- Sealant.

Types of soil according to protection mechanism:

Types of car primers vary depending on the manufacturer and price.

Passivating - metal chromates are added to their composition, which gives the car material passive characteristics:

- if droplets of water subsequently fall on the body, the oxidation process will not occur;

- This class includes goods marked GF-031 and other types that comply with GOST;

- the fender and bottom of the car are additionally protected with a lead-based compound.

Tread protection - protects the body. This layer takes on any negative impact of the environment.

Features of tread protection:

- the manufacturer supplemented the composition with metal dust with the most insignificant potential, in comparison with the body, based on lead, zinc, aluminum;

- This class of goods includes epoxy primers of the EP-057 type. This is an ideal suspension of powder with metal particles in resin. The composition must be stabilized before application; bentonite and polyamide hardeners are most often used;

- primer, which is dominated by inert microparticles, is intended for minor repair work on vehicle bodies. It does not react with impurities and elements of other products used. Mechanical features protect the metal from water droplets;

- in this class, FL-OZK and GF-21 are in demand;

- phosphating primer for cars. Acids are considered their main component, they work firmly with the metal of the vehicle and create a tread ball with their hardly soluble layer. Maximum adhesion rates allow these mixtures to be applied with a minimal ball, compared to others;

- aggressive acids uniquely penetrate the metal ball, adhesion increases to the maximum level;

- This series is distinguished by the brand - VL.

Epoxy primer

The material is applied as the first layer. The active substances form an indelible film on the body, which helps protect the metal from deformation and rust. Apply with a special sprayer.

There are also a number of companies that produce this primer in a can. The primer in car spray cans will ideally apply to subsequent materials, which will prepare the vehicle body for painting.

Their main advantage:

- ideal adhesion to metal;

- the soil does not require additional sanding.

Only visual defects caused by the master are leveled (there may be drips that have frozen).

Often craftsmen apply primers by hand: the metal body is covered with a filler composition (a material used with one active substance, with a minimum percentage of toxicity and an accelerated absorption mode, optimal protective characteristics). After a set time, several balls of primer are applied to the filler, which are then sanded. The final stage is a ball of sealant and paint.

Realizing that the primer is a ball that no one sees, many owners decide to save on it and invest more money in paint. This is fundamentally the wrong approach. Such savings often become the reason for re-painting the vehicle. The materials of the budget line create a shrinkage ball, so all the errors that were made during painting become as noticeable as possible.

Professional craftsmen always refuse to work with budget soils, thereby saving their time and nerves.

Alkyd or acrylic primer for cars

At the request of the workers, a short post to bring some beauty. Grounds from left to right.

The first two are acidic primers for aluminum, non-ferrous metals and steel-cast iron. Excellent adhesion, etch the surface, and hold just a shine.

Body 960 gives yellow color, OTRIX 960 gives white. They smell terribly because they are highly toxic. Each cylinder is covered with inscriptions about this. I work with them only in a respirator with carbon cartridges. The third is regular acrylic primer. The most inexpensive and widespread. The fourth is alkyd primer.

The first is acrylic regular enamel. The second is alkyd enamel. The third is heat-resistant paint. Organosilicon. Apply to bare metal, without primer. It is fragile and breaks easily, but people love it because it is “heat-resistant” and is ready to tolerate all its shortcomings. The fourth - as for me, is the most normal black matte acrylic aerosol. There are cheaper cylinders, but they have stable quality and excellent coverage.

Important point. Acrylic paint is used with acrylic primer, alkyd paint is used with alkyd primer. Acrylic paint on alkyd primer (and vice versa) will give shagreen.

Just a few words about solvents. Or rather degreasers. If you need to remove old grease, oil, traces of paint, etc., I use nuclear 647 solvent. To the point where I pour it into a bowl and bathe the parts there. All fats and oils dissolve perfectly in it. If you just need to controlly wipe the surface from dust and fingers, then I use a degreaser. It doesn't smell and doesn't corrode your hands. Well, when there are doubts that I have completely removed silicone-containing lubricants, I use anti-silicone. I don’t really understand how it radically differs from a degreaser, but it really copes with silicones.

When I work with aerosols, I always use a respirator so as not to pick kilograms of paint out of my nose, not to mention the harm to the lungs. On the head there is a beret, on the face - a shield or, in extreme cases, glasses, because... paint particles hang like a cloud throughout the workshop. After finishing painting, after 15 minutes I turn it on full industrial exhaust.

Which car enamel should I buy – alkyd or acrylic? This is a question asked by many motorists who have decided to update the appearance of their car. Here it should be said that there is no definite answer - it is worth taking into account the purpose of painting and the allocated budget for car repairs. Let us next consider the strengths and weaknesses of the two types of car paint to make it easier to make the right choice.

Alkyd paint for cars: pros and cons of coatings

Alkyd paint for cars has been used for painting for decades and has managed to prove its positive qualities. It is used to give an updated look to the body due to the ease of application to the surface and the wide variety of color shades in the palette. It quickly polymerizes and does not require the application of several layers, however, it requires careful surface treatment before painting and mandatory varnishing - this can significantly improve the performance characteristics of auto enamel.

Do not forget that rapid setting leads to the formation of a thin film, which, under all environmental conditions, does not allow the entire applied layer to dry quickly and evenly in depth, so special hardeners are now added to the car paint composition. Alkyd paint for metal protects the surface from aggressive external influences and, as a result, from corrosive processes, but it is short-lived. After a short time, most likely, the surface will have to be renewed due to peeling, faded color and loss of attractive shine. The big advantage of this type of coating is its low cost.

Acrylic primer for cars

As the name suggests, the material is based on acrylic particles. Thanks to such active substances, it can be used not only on metal surfaces, but also on plastic. And this is especially important when you need to process the bumper.

In addition to filling various irregularities, the soil simultaneously solves the following problems:

- The surface of the body becomes perfectly smooth, which is especially important before applying a layer of paint.

- Improved adhesion characteristics.

- Protection of metal from the appearance of rusty specks and drips.

The material is applied to the treated area immediately before painting. After such careful preparation, the paint goes on as smoothly as possible and works well with the metal body. This allows you to achieve reliable and long-lasting results.

The soil is distinguished by the following features:

- Strength. The primer for cars should be as durable as possible.

- Resistance to environmental factors (rain, high humidity, UV light).

- Resistant to temperature changes.

Due to its numerous characteristics and advantages, the material is universal, therefore it is often used by craftsmen.

Acidic soil is used less often.

Acrylic primer for cars

Automotive primers and their applications

Epoxy primer Epoxy primer is intended for anti-corrosion protection of metal surfaces. Just like acidic soil, it is primary. For further painting of the surface, it must be covered with secondary primer. It is worth mentioning here that epoxy primer sprayed onto a flat (without minor defects) surface can be painted even without sanding paper. But this can be done before it has completely hardened, several hours after priming. If the primer has hardened, it must be treated with sanding paper and primed with acrylic primer. Then dry the acrylic primer, sand it for painting and then you can paint.

Epoxy primer contains special resins and special active additives that prevent the development of corrosion processes on the metal surface. It dries quickly and after curing becomes resistant to mechanical and temperature influences. The surface covered with this primer, even without applying paint and varnish materials, is well protected from corrosion.

Epoxy primer after application forms a dense film that does not have pores.

The disadvantage is the long drying time. At a temperature of +20 °C it averages 12 hours. An increase in drying temperature leads to uneven polymerization of soil layers and leads to the appearance of defects.

Which primary primer is best to use and whether they are compatible, you can read in the article about primary acid and epoxy primers.

Two-component pore-filling primer:

This primer is most often used before painting a car. Porosity-filling primer can be applied in a thick layer. It fills the pores that remain on the putty, as well as the marks left by sanding paper.

However, you need to remember that the putty surface must be prepared for priming according to all the rules and the risks from sanding should not be too large. If you fill too deep scratches with this soil, then after some time, after drying, the soil will sag and all defects will be visible.

One-component nitro primer:

Apply before painting with alkyd or nitro enamels. This primer is not compatible with acrylic car enamels or metallic paints. The main advantage is that it dries very quickly.

One-component acrylic primer:

It is convenient to use as it comes in an aerosol package. But it is also sold in regular containers.

Sufficiently high quality soil. Dries quickly and is easy to use. Compatible with almost all types of paints.

Primers for plastic:

When repairing plastic, special primers are used to increase adhesion. If you are painting new plastic, then after priming with a special primer you can immediately apply paint.

Application of primer:

Before spraying, the primer must be thoroughly mixed, and in some cases, if necessary, diluted with a thinner to a working viscosity. When diluting different soils, you need to check the instructions for each specific product.

It is forbidden to dilute with solvents to the working viscosity; only thinners must be used.

Next, it is important to filter the soil.

For application, primer spray guns with a nozzle of 1.5 - 2.0 mm are usually used. Apply 1 – 2 layers. If desired, you can apply more layers, taking into account the fact that in preparation for painting, part of the primer will be sanded off. But you need to remember that it is not recommended to apply a layer that is too thick, especially since it will not dry well. Each layer must be applied after the previous one has dried. Interlayer drying time is approximately 10 – 15 minutes.

Preparing the surface for applying primer: - clean from dust; — before priming, plastic parts must be wiped with an antistatic agent; - degrease the surface.

Ground grinding:

When sanding dry before painting, use P400. When preparing with water, P800 is used. In areas of panels that have a complex shape, as well as in hard-to-reach places, you can use Brite tape.

Should I work dry or with water? Water is a source of corrosion, and some primers are designed for dry sanding only. The advantage of working with water is the absence of dust. Also convenient to use sanding paper. It clogs less and if it does clog, just rinse it with water.

When working dry, you can use a sander to speed up the work. And, most importantly, the risk of corrosion is reduced.

A reasonable solution can be considered dry sanding using water in inconvenient places. Bumpers can be easily sanded with water, making sure to dry thoroughly before painting.

It is better to use a primer color similar to the color of the applied paint. This will make it easier to cover the repair area. You can also tint the primer to match the color of the paint.

A light gray color can be considered universal; it will match any paint color.

Print article

Nuances of choosing a primer

When choosing a material, it is initially important to check the production date. Craftsmen try to use materials from the same company in their work, since otherwise the active substances may contradict each other and ruin the work done.

The main thing: it is better to buy only proven companies. How much does a car primer cost? There is only one answer - not cheap.

Which soil is best for cars? Let the master make this choice. Each product is accompanied by an application leaflet, which contains information about how long it takes for the material to dry. The first and subsequent balls are applied observing all deadlines; in addition, it is important to optimally prepare the surface.

Features of use

Good craftsmen who work in professional car services work according to the following scheme:

- Before applying the first layer of paint material, several types and types of primer are applied to the treated area. Initially, acid-based primers or any other phosphating base can be used, which guarantees maximum adhesion.

- The primary ball is applied to the cleaned area, which is also degreased. The main thing is to optimally distribute the material. Using sanding paper is not advisable. Caution: you need to be extremely careful when applying phosphating and acid compounds! It is important to ventilate the room to avoid poisoning from chemical gases.

- Then the secondary ball of car primer is laid in several layers. It is more rational to use materials based on two components (soft in texture). They optimally mask minor deformations on the surface.

- Each ball is applied after a set period of time. In the workshop, where high-class specialists work, they use materials that cannot be further polished.

- If it is possible to achieve a perfectly smooth metal surface, compositions that give a glossy surface can be used as a secondary primer. Grinding in this case will be unjustified.

In order for the primer for the car to dry, just wait up to half an hour and you can begin the final painting.

There are several types of primers 1- Primary primers 2- Secondary primers (filling, sanding) 3- Primers for plastic (adhesive) 4- Primers insulating incompatible coatings

1. Primary soils

As a rule, they are applied to bare metal and serve for anti-corrosion protection.

are divided into acid and epoxy primers. Acid primers

(reactive, etching) - Its main properties are high adhesion and anti-corrosion effect. Therefore, the purpose of acid soil is to protect the metal of the car body from rust. Why is the soil called acidic? This is explained by the fact that it is cured with acid. The main component of the reactive primer is phosphoric acid, which forms a poorly soluble film on the surface that is firmly bonded to the metal of the car. The acidic aggressive composition is able to penetrate the metal and thus increase adhesion. Must be covered with agrilic primer Apply in a thin, uniform layer of approximately 10 microns Examples of acidic primers

Novol- PROTECT 340 technical for primer professional.novol.pl/kar…_LT-02-08_PROTECT_340.pdf BODY-960 technical - www.hbbody.com.gr/product…index.php?p >Reoflex Phosphating primer CF 1+1 technical - reoflex.ru/ru/3/10/58/ Brulex – 2k primer Contact – technical manual – www.brulex.com/files/2K-%…y%D0%BD%D1%82-Contact.pdf Epoxy primer

– Unlike acidic soil, the protection of epoxy primer is based mainly on its physical properties of forming a dense and hard film that prevents the penetration of moisture and oxygen. It is epoxies, but applied by cataphoresis in special galvanic baths, that are used in almost all automobile factories. The advantages of epoxy primers include a denser and harder (due to the absence of pores in it) coating, which is much harder than that of any polyester putty. Such primers create an excellent anti-corrosion effect and have good adhesion to almost any material. Due to its chemical neutrality to any surface, this material can also be used as an insulator for problematic surfaces.

Examples of epoxy primers - NOVOL- PROTECT 360 - professional.novol.pl/kar..._LT-02-09_PROTECT_360.pdf BODY- www.hbbody.com.gr/product/?p >Reoflex - reoflex.ru/ru/3 /10/56/ PPG-DP40 - technical manual - ru.ppgrefinish.com/media/…ng-system-ppg-deltron.pdf I would like to note that non-acid and non-epoxy primers are not a PANACEA OR A MIRACLE RESULT AGAINST corrosion. If you do not remove the rust mechanically, it will still not appear so quickly, but it will appear.

2.

Secondary acrylic primers

- The main purpose of acrylic primer is to fill pores, small scratches, defects on the body panel after sanding. Also, its task is to create a substrate for applying paint and varnish, since the paint must be applied to a primed surface or to an old paint layer. Acrylic primer comes in different colors. Black, white, gray, red. There are also different proportions of mixing with the hardener 3+1.5+1.4+1 (they differ in viscosity and layer thickness). Some acrylic primers can be used using the “wet on wet” method

3.Primers for plastic

– designed to improve the adhesion of paints and plastics. It kind of liquefies the top layers of plastic, thereby allowing paint and varnish materials to firmly adhere to the surface. Basically, these are transparent 1-component primers; a little silver can be added to them so that you can better see where you are priming. Apply in 1 thin, even layers.

Padding

Home / Articles about materials / PrimingPriming a car is one of the important processes of body repair. If when puttingty we directly achieve a certain shape of the part, then priming serves for anti-corrosion treatment and as a connecting link between the putty and paint. Because under no circumstances should you paint directly onto putty or metal. Priming is a mandatory process for body repair, and in this article we will try to tell you what primers exist and their use in car body repair.

Let's consider the main types of soils:

- Acrylic primer 1K - This is a one-component acrylic primer, mainly wet primers, which are applied in a thin layer, playing the main role: adhesion, corrosion protection, also used on new parts.

- Acrylic primer 2K – This is a two-component acrylic primer. It is a universal product for various types of repairs. It is used for final leveling of the surface, for filling small pores and sanding marks. Good filling ability: easy to process, short drying time.

- Anti-corrosion primer - Used for application to bare metal. Protects against corrosion. It is necessary to cover the top with 2K primer, since paint cannot be laid on top of anti-corrosion primer. It is applied in a thin layer, unlike pore-filling primers.

- Primer for plastic - A separate group of primers that are intended specifically for application to plastic. Provide excellent adhesion during further application of acrylic primers, fillers and paints and varnishes. They have high elasticity.

Priming bare metal

When painting, it is necessary to strive, taking into account the available technical capabilities, to create anti-corrosion protection similar in quality to the factory coating. If during the pre-treatment process it turns out that bare metal is visible, it is necessary to carry out one of the following treatments before painting:

- Acid (phosphating) protective priming

- Protective primer based on epoxy resins

- Application of 1K anti-corrosion primers

Acid priming

With acid protective priming, we are talking about a two-component product. Its pot life after mixing is about 24 hours at 20°C. The interval between applying individual layers should be about 5 minutes. You can apply two to three layers. Drying time before applying filler is from 30 to 90 minutes at 20°C.

Polyester putty should not be applied to acidic soil, since it will dissolve the soil in its uncured state. Only 2K filler primers can be used. But applying an acidic protective primer to hardened putty is possible without problems, since the putty in this case is chemically inactive.

The drying time of the primer is divided into 3 phases

- Dust drying - dust no longer sticks to the paint layer. When pressing on the paint layer, fingerprints may appear on the layer

- Assembly drying - the painted part can be installed. The appearance of fingerprints on the paint layer is possible only with strong pressure. The layer has not yet completely hardened

- Final drying - the paint layer can be further processed or sanded.

Technology of using and processing acrylic primer

The filler layer forms the substrate for applying the paintwork. Paint should only be applied to the primer layer or to the old paint layer. Let's consider the purpose of the soil filler.

The filler has the following functions:

- Leveling uneven surfaces to be repaired

- Overlapping layers of putty and primer

- Substrate for the paint layer in order to achieve optimal surface condition for paint

Paint should not be applied directly to putty or acidic primer. Otherwise, the consequence will be poor quality of the painted surface and defects in the paintwork.

Acrylic 2K primer filler is a two-component acrylic-based composition and has qualities similar to two-component enamels. Various pigments can be used for such soils.

The filling capacity of filler, otherwise called primer filler, is determined by the content of the solid component in it. Filling capacity is classified as follows:

- Standard: standard solid content

- MS: average solid content

- HS: high solid content

The process of applying acrylic primer “Filler”

One of the methods of applying filler is the “wet on wet” . The filler is applied as an intermediate or insulating layer. Typically two or three coats are applied, depending on the repair, allowing 5-10 minutes between coats. After the soil has completely hardened, it can be sanded.

Colored primers - fillers are used when you want to apply as little paint as possible in order to avoid differences in the shades of the coating. When mixing paint, the substrate matches the color of the final paint coating.

The type of filler used is determined by the nature of the repair and the surface to be painted. By using the appropriate proportional ratio of hardener and thinner, it is possible to purposefully impart certain qualities to the filler. It is important to choose a hardener and thinner depending on the ambient temperature:

- “Quick” filler for temperatures below 18°C;

- “Standard” filler for temperatures from 18 to 25°C;

- “Slow” filler for temperatures above 25°C.

The viability of acrylic-based fillers ranges from 30 to 60 minutes. Do not apply more filler than necessary! For large surfaces to be repaired, acrylic primer filler is applied to the entire part; if puttying has not been done (new part), then there is no point in using filler, but 1K - anti-corrosion primer (wet on wet) is applied. For small surfaces, the filler should cover the entire layer of putty. The application of acrylic primer is carried out using a spray gun with a spray gun suitable for the given primer, which is best done in a spray booth. Using a spray gun (high output at low pressure) a good coverage of the filler can be achieved. Spray gun for applying filler primer with a nozzle size of 1.6-1.8mm.

When applying filler intended for subsequent sanding, several layers are necessary to remove irregularities. For example, for small areas to be repaired, the layer of filler on the putty in these areas should be thicker than in the boundary areas. With several passes with a spray gun, each time you should cover a smaller area than the previous time, i.e. we apply priming from larger to smaller.

Sanding and processing of acrylic primer

The primer should begin to be sanded after it has completely dried. In this case, special attention should be paid to layers of increased thickness. Sanding a filler that has not completely dried leads to the formation of scratches and clogging of the abrasive. The drying time depends on the type and thickness of the filler layer. It ranges from 3 to 12 hours at 20°C. Instructions must be found on the product can.

The grinding process has two stages:

- Coarse grinding

- Final sanding

Proper sanding of primer, as well as other paint and varnish material, is step sanding. In step grinding, you start with a coarse abrasive and end with a fine-grained abrasive. When sanding in steps, do not use too coarse an abrasive, as otherwise the scratches on the filler layer will be too deep.

Final sanding

The final sanding process depends on whether painting will be done or not. The film thickness for single-layer painting (acrylic paints) is greater than for two-layer painting (metallic + varnish).