For the first time, the method of industrial spraying of polymer powders on metal surfaces was developed in the 50s of the twentieth century in Germany. Powder coating is the process of spraying fine particles of dry, electrically charged paint onto a surface that has an opposite charge. A protective monolithic coating is formed under temperature influence in special polymerization chambers. The powder melts, wetting the surface, polymerizes, and firmly binds to it, forming a durable polymer film. At the moment, various models of equipment are produced on which metal is powder coated. Many types of powder paint have been developed and are successfully used, having special operational and technical characteristics.

Areas to be painted with polymer compounds

Powder paint is actively used in many areas of production where reliable protection of metal parts from corrosion, chemical, biological and mechanical damage is necessary. The list of industries that require polymer painting of products is constantly expanding. This includes agricultural engineering, chemical instrument making, construction and production of building materials, and automotive industry.

Modern compact devices for spraying and polymerizing powder paint have allowed many companies to provide painting services. Nowadays, many service stations and factories producing metal products are equipped with deposition chambers. The price of painting services is quite significant, but the benefits that the client receives are quite significant.

What metal products can be powder coated?

The range of finished products, parts and components that require polymer coating is very wide, and the decorative advantages that painting provides should also be taken into account:

- Metal building structures: profiles, pipes, facade siding, etc.;

- Roofing materials – metal tiles and corrugated sheets;

- Medical equipment and specialized metal furniture for medical institutions;

- Parts and housings of sports equipment in contact with aggressive environments;

- Cases of cars, motorcycles, bicycles, etc.;

- Furniture fittings.

Types and properties of powder paints

Powder paint is a finely dispersed mixture of solids, having the composition:

- Film-forming polymer resin;

- Hardener;

- Pigment fillers;

- Modifiers.

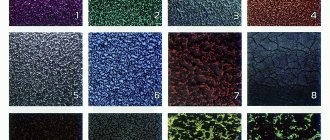

Two types of powder paint are produced, which differ in the way the protective layer is formed: thermosetting and thermoplastic. Painting with a thermosetting composition forms a film protective and decorative coating on a metal surface as a result of a chemical polymerization reaction that occurs during the heating of the product in an oven. This material does not melt or corrode under the influence of basic household and industrial solvents, acids and alkalis. This type includes paints and varnishes based on acrylates, polyurethane, epoxy and polyester resins. The coating is characterized by significant strength and hardness of the outer layer, high resistance to mechanical, chemical and biological influences. Due to the rather high price, it is used in the chemical industry, production of building materials, and mechanical engineering:

- Epoxy paints have significant mechanical and chemical resistance, high adhesion to the surface. When exposed to high temperatures, they turn yellow, and when exposed to intense ultraviolet radiation, the top layer is destroyed.

- Epoxy-polyester mixtures are two-component paints that are more resistant to heat and do not turn yellow over time. Widely used in painting radiator batteries.

- Polyester compositions - used for dyeing products that are constantly outdoors. They have high resistance to UV radiation and do not form a “chalky” coating.

- Polyurethane paints - in addition to anti-corrosion properties, protect the product from abrasive wear in places subject to friction. The treated surface can have both a lasting shine and the texture of crushed silk. They exhibit high resistance to solvents, mineral oils, petroleum products, water and various atmospheric conditions.

- Acrylate compositions - have good resistance to alkalis and thermal effects. Gives coatings a lasting gloss and rich color.

Thermoplastic powder painting of metal forms a film coating due to the melting of the polymer and further cooling of the melt. The price of such compositions is slightly lower. These protective films are thermoplastic and often susceptible to solvent attack. All paints of this type are one-component, these include: polyvinyl butyral; polyvinyl chloride; polyamide; polyethylene.

- Polyvinyl butyral - compositions based on it are used indoors and are able to withstand saline solutions of water at room temperature. They have high wear resistance parameters and are a good dielectric.

- Polyvinyl chloride and polyamide have similar performance characteristics. Painting is possible not only inside, but also outside. They are highly resistant to solvents, atmospheric conditions, abrasion and other physical damage. Give the surface an aesthetic appearance.

- Polyethylene, polypropylene - used to protect cables, pipes, housings of household appliances, etc. They have significant resistance to mechanical stress and are a good dielectric. With prolonged exposure to atmospheric conditions they may crack.

Characteristics and scope

Regardless of the consistency of the mixture, it has several important parameters. Properties of polymer paint for metal:

- Adhesion to the material at the molecular level.

- Shape change when the material is damaged.

- Resistant to water, protects metal from corrosion (even boats can be painted).

- Resistance to open fire (you can paint barbecues or stove boilers), temperature changes.

- Constancy of color (it does not fade or wear off) when in contact with sunlight.

- Tolerance to chemical solvents (alkali, acids).

Please note: Choosing anti-corrosion paint for metal

Polymer painting has everyday advantages: cost-effectiveness (if used correctly), a wide selection of coloring agents. There are also disadvantages: the difficulty of removing and covering it yourself. You need expensive equipment. To apply the liquid product, additional expensive equipment is not needed, but painting skills are required. The master solves the problem with experience. The paint itself is available at a good price, but the equipment requires a large investment, and without it there is no question of any profitability. A person who takes on the finishing of metal products without certain skills will waste the substance. The scope of application of the funds can be external and internal. For outdoor use (for example, for the facade of a house or furniture), polyester or polyurethane products are suitable. For internal use (mainly for household appliances) - epoxy, acrylic or polyester products in dry form. Polyesters are often used to paint car bodies. This is interesting: the choice of anti-corrosion paint.

Wide choice of colors

Characteristics of the composition of powder paints

Regardless of the type of film-forming polymer, all powder paints have the following key characteristics: Solid particle dispersion - there are several methods of painting with a coloring composition, depending on its choice, the maximum particle size varies from 5 to 350 micrometers. In powder paints from leading manufacturers, the particle size is in the range of 20 – 100 micrometers. Hygroscopicity - fine powders have the property of moisture absorption. As a result, the electrostatic properties and flowability of the powder may significantly change, which will negatively affect the quality of the painting service. Flowability is one of the main parameters affecting the quality of painting. The higher the flowability, the easier and more uniform the powder coating is. Flowability is assessed using various methods that operate with such indicators as:

- Speed of mixture pouring out;

- Angle of powder pouring and collapsing.

For good compositions, the flowability parameter of the cone slope is in the range of 36°-45°;

How to wash off polymer paint

This coating can be washed off with a solvent for polymer paint.

Polymer paint is washed off at a temperature from +8 to +25. The liquid is applied in an even layer and kept until cracks appear and the coating swells (from 3 to 15 minutes).

Important! Do not allow the solvent to dry on the surface to be treated.

You can also use the immersion method. To do this, polymer paint remover is poured into a container and the product is immersed in it.

Painting method and stages

The basic technology of painting with powder polymers consists of the following steps:

- Preparation of the working surface;

- Powder spraying;

- Melting and polymerization under the influence of temperature to form a film;

- Cooling the coating.

However, each of the stages can differ significantly depending on what kind of powder is used, or what kind of metal needs to be painted: 1. Preparation is carried out in several stages of cleaning and degreasing. To prevent the ingress of contaminants, a conversion composition is applied. Spraying an auxiliary layer of paint on an inorganic basis to increase adhesion. Some technologies use abrasive cleaning of the surface with metal shot or etching with acids and caustic soda. 2. The primer increases the anti-corrosion resistance of the metal surface. Typically zinc-containing epoxy powder primers are applied; 3. Painting - the powder is applied to a cleaned, dried and cooled surface in a special spraying chamber, manually or automatically. The powder mass in the feeder is suspended (boiling paint) and then fed into the sprayer, which reduces the concentration of the powder and distributes it over the surface to be painted. The electrode in the spraying unit imparts an electrical charge to the particles. All these processes take place in the polymerization chamber. There are many models of such devices, which differ significantly in heating elements, their location, control system, etc.

Technology of application of polymer coatings

The technology of working with polymer powder paint for metal involves the use of a special spray gun. The aerosol serves not only as a spray, but also as a means of charging the powder with electricity.

The spray tank has a positive charge, and the powder elements have a negative charge. This makes it possible to obtain magnetic induction when charges are connected, which provides the most reliable adhesion of the coloring matter to surfaces.

The technology of working with polymer powder paint for metal involves the use of a special spray gun.

Surface preparation

Any metal product must be prepared before painting. The following steps are carried out to obtain the required surface:

- Degreasing the product, any solvent is suitable;

- It is necessary to clean the welded elements from varnish and slag;

- The entire surface is cleaned of corrosive areas, as well as other types of contaminants. The object is coated with phosphates, which provide better hardness and protection against rust. If there was an old coating, it is removed.

It is better to work in a room where good ventilation is provided; the master should wear gloves and a mask.

The entire surface is cleaned of corrosive areas, as well as other types of contaminants.

Applying paint

Polymer painting of metal should be carried out in a special room where dust and dirt do not get into, good lighting is provided to see all unpainted areas. The product must be applied in one layer, for this reason they work slowly, covering the entire surface part by part. The next stage can be carried out immediately.

The product must be applied in one layer.

Polymerization

This process helps to obtain the necessary properties; polymerization involves heating the object in a special chamber. Typically the process lasts 60 minutes, temperatures in the chamber reach up to 200 degrees. The time and temperature indicators are influenced by the thickness of the layer.

In this case, it is necessary to take into account the rate of temperature increase, it affects the resulting effect. Because from this effect the coloring matter begins to be distributed throughout the product, filling its pores, it is better if the speed is low.

Typically the process lasts 60 minutes, temperatures in the chamber reach up to 200 degrees.

Final stage

Then they wait until the chamber naturally cools down to one hundred degrees. Do not open the cell door, otherwise cracks may appear on the object. After the oven has cooled to the required temperature, the item is removed from it and a new layer is applied.

It is permissible to paint up to three layers, the first is a primer, the second is a coloring layer, and the third is a varnish that adds gloss. It is usually applied to cars.

Painting up to three layers is acceptable.

Polymer paints give excellent results and are usually used for metal surfaces, but their scope is wider, because they are also suitable for other materials. The only thing is that such coloring cannot be done independently, due to the need for special equipment. This technology allows you to get a long-lasting result that will have a pleasant appearance.

Advantages of polymer powder coatings

There are several criteria by which the technical, economic and operational performance of polymer powder paints should be assessed: 1. Economic advantages: a. A small amount of waste, surface painting is carried out by 96% of the sprayed substance; b. Possibility of reuse of unreacted paint. Provided that the painting was carried out in a specially designed chamber; c. There is no need to purchase special cleaners and solvents, which significantly reduces the cost of painting services; 2. Impact on the environment: a. The composition does not contain harmful, volatile or carcinogenic substances; b. The storage and painting process has a low risk of fire; c. The release of unpleasant “chemical” odors is significantly reduced. 3. Compared with traditional liquid paint products: a. The performance properties and quality of the applied coating are much higher; b. The lower porosity of the layer significantly reduces hygroscopicity and increases the impact resistance of the product; c. There is no need for additional preparation of the composition for work; d. Irreversible loss of powder is 2-5%; loss of liquid when applied to the same surface of a complex configuration can be up to 45%. e. Curing or chemical polymerization is carried out in 30 minutes;

Paint manufacturers

Among the manufacturers of polymer paints on the market, you should choose proven ones, since the quality of the applied coating, the level of protection and service life depend on this. Consumers identified several companies as reliable brands.

Krasko

The trust of buyers is placed in the Krasko company, which has been operating in the construction market for more than 20 years.

The manufacturer offers a range of products for painting concrete structures, including impregnation, primer and paint.

Streamline Chemical

The manufacturer's line includes a wide selection of products for coloring concrete. Among the company's products are compositions based on polyurethane and epoxy resins, which provide adequate protection and high decorative characteristics of concrete surfaces.

Elakor

The company has been specializing in the production of coloring materials for concrete floors for about 25 years. The products include products for preparing concrete for painting and painting itself.

Sibton

A domestic manufacturer offers products that protect concrete before painting. A large selection of certified products allows you to choose coatings suitable for any occasion.