Why do you need to paint slate at all?

The fact that the use of paints allows slate to achieve the desired color is understandable. But besides the decorative function, coloring compositions also have more important properties. Let us remember that slate is a porous material, prone to the formation of microcracks. Water easily gets into them, which with the onset of winter cold turns into ice and begins to “tear” the fibers of the material. The same deforming processes occur when mosses and lichens grow in the pores. The problem of premature destruction of slate is solved by painting. Coloring compounds form a durable film on its surface, blocking access to asbestos cement to water and microorganisms. As a result, deforming processes are suspended and the slate gains additional years to its service life.

Painted slate, thanks to the paint film, becomes smooth. It does not retain atmospheric moisture and snow melts off easily. And if dirt accumulates on the roof, you can simply wash it off with water from a hose or car wash.

Another problem that can be solved by painting is the theoretical harmfulness of slate. The version that asbestos-cement sheets are not environmentally friendly came to us from the West and is successfully cultivated by many manufacturers of more expensive and modern roofing materials. Its essence is that slate during operation emits asbestos dust, which is harmful to the environment and human health. There is much evidence that this opinion is unfair, however, if this aspect bothers you, paint applied to the slate will completely block the possible release of asbestos dust and will 100% preserve your health.

Thus, staining slate allows you to:

- increase the decorative effect of the roof;

- give asbestos-cement sheets a color with the desired degree of matte (matte, semi-gloss, glossy);

- smooth the surface of the slate;

- protect the slate from moisture and the growth of mosses and lichens on it;

- prevent cracks from appearing;

- block the slate dusting process;

- increase the durability of slate by 1.5 times (subject to periodic renewal of the paint layer).

Why paint slate?

Before you start choosing paint, you need to understand why slate is painted in the first place. As we said above, this material has an unattractive gray color that can be successfully hidden during the painting process. Moreover, both aesthetic and practical nuances are hidden. Despite the fact that in many respects slate roofing is superior to metal and corrugated roofing options, weather and time can ruin even it.

This is because atmospheric influences such as changes in temperature and moisture over time lead to the formation of asbestos chips on slate, which is one of the reasons for the formation of microcracks and moss. And this reduces its reliability and attractiveness. That is why it is recommended to paint slate, because in addition to additional protection from the troubles listed above, paint will give it more attractiveness and durability. Also, many modern types of paint for slate have high antiseptic properties, which will also protect this material from the formation of mold and mildew.

How to paint slate?

There are many modern roofing materials on the construction market. However, good old slate is still popular due to its durability, cheapness and ease of installation. Asbestos-cement slate is available in the form of profiled sheets, flat slabs and roofing panels. Corrugated asbestos-cement sheets are used for roofing, balcony fencing, and as a load-bearing floor covering. Wall panels, sandwich panels, partitions, etc. are mounted from flat sheets.

- However, this roofing material also has disadvantages:

- inexpressive appearance;

- asbestos dust released into the air is harmful to humans;

- It quickly becomes overgrown with lichen and moss.

But all these weaknesses of the material are easily eliminated. It will be enough to paint it with special paint for slate.

Disadvantages and advantages of slate

You already understand that painting slate has a positive effect on its characteristics. But since we said that such roofing material has many advantages over some analogues:

- does not conduct electricity, does not rust;

- high strength due to the reliable connection of asbestos with cement;

- will last much longer;

- has excellent resistance to moisture and does not get so hot in the sun;

- lower cost compared to analogues.

Of course, it has many other positive features, such as the absence of toxic emissions during combustion or good sound insulation, but this is no longer so important for consumers.

Slate also has some disadvantages, but fortunately there are not many of them. They are expressed in large weight (one sheet of slate can weigh about 18 kg). In addition, despite its high strength, this material is quite fragile. It can be damaged during careless transportation.

Advantages and disadvantages of colored slate

It is important to take into account the fact that the popularity of flat colored slate for facades is due to a large number of advantages that cannot be ignored. When making a purchase, it is recommended to take into account the following positive aspects that are inherent in colored roofing material:

- Affordable price. As practice shows, the cost of colored slate is low, although such roofing material is much larger in size than standard sheets. That is why this type of building material for arranging the roof of a living space can be afforded by every person, regardless of income level.

- It is quite easy and quick to carry out installation work. Due to the large size of colored slate, the process of laying roofing material does not take much time. If necessary, you can carry out all the work yourself, without the involvement of specialists. In this case, it will be enough to be able to work with a construction hammer and do the work with someone else.

- Specifications. During operation, the roofing material is not subject to heating when exposed to direct sunlight. In addition, many experts recommend taking into account the fact that colored slate has a high level of thermal insulation and sound insulation properties, as a result of which the material can, according to these characteristics, compete with metal tiles. Due to the slight susceptibility of the finished product to temperature changes, slate, if necessary, can be used in regions with any climatic conditions, including in the far north. Since slate is not subject to fire, this helps to ensure a fairly high level of fire safety.

- Long service life. The service life of a roof covered with colored asbestos-cement sheets can reach a maximum of 60-70 years; in this case, not only the presence of a protective layer of acrylic paint composition, but also the correctness of the installation work will play a special role.

- Ease of use of roofing material. During the installation process, if such a need arises, the slate can be quite easily processed and cut into pieces of the required size. In this case, the peculiarity is the fact that the technical characteristics will not be lost after processing the roofing material. It is for this reason that finished products can be used for arranging roofs of any level of complexity and configuration.

Since each product has not only advantages, but also disadvantages, in this case they must also be considered and taken into account before making a purchase. Thus, many experts and consumers highlight among the weak points the fact that the material is quite fragile, as a result of which it is easy to damage during installation work. In addition, the material has a fairly high weight, as a result of which several people are required to install the roof. In some cases, moss may appear on the surface of the finished product during operation.

Slate paint - how to choose the best paint for the sheet?

Asbestos fibers are not compatible with all types of paints. Oil and enamel products are least suitable for arranging a slate roof . Simple enamel begins to flake off and hang down within a few months after application, but specialized enamels are actively used for arranging slate roofs.

How to paint slate? In addition to specialized enamels, the following types of products are used for coloring slate:

- Acrylic . Belongs to the group of water-dispersed products, which are characterized by a high degree of waterproofing. Acrylic fills even the smallest holes in slate and prevents the growth of fungi and plants in them. The paint is represented by such brands as Akrilakma, Triora, Novbytkhim.

- Modified acrylate.

- Silicone paints . Extend the service life of slate by an average of 5 years. They have good adhesion (adhesion to the roof surface). The main disadvantages are that they have a high price and completely burn out in 10-15 years on the sunny side of the roof

- Acrylic silicone products . They combine the best qualities of both types of paints. , "Sofexil".

- Polyurethane products.

- Liquid plastic. High-tech material, characterized by low price and high resistance to mechanical and atmospheric influences. But liquid plastic is toxic, which increases the requirement for caution when installing it.

One of the best materials in terms of price, quality, ease of painting and safety of painting is acrylic.

Types of paints for slate

There are a lot of requirements for slate paint. Its resistance to fading, exposure to high and low temperatures, and precipitation is valued; degree of adhesion to asbestos cement.

In any case, you cannot paint slate with anything, the first paintwork material you come across. The following options for suitable paints are available:

- acrylic paints;

- organosilicon (silicone);

- alkyd;

- enamel "Liquid plastic".

Let's consider the properties of each type of coatings separately.

The most extensive group consisting of acrylic-based paints. Their color is intense, with varying degrees of matte (both matte and glossy effects are possible). There are two types of such compositions: water-soluble (water-dispersed) and organic solvents.

Type #1 - water-based acrylic paints

They contain aqueous dispersions of acrylic copolymers (latexes), coloring pigments and various additives (biocides, antifreeze, etc.) in an aqueous environment. Water is used as a diluent for this composition - no more than 5-15% of the total volume.

Water-based acrylic paints:

- non-toxic, no pungent odor, explosion- and fireproof (due to water base);

- easy to apply, does not form streaks;

- do not require a special solvent;

- it is possible to use diluted paint as a primer;

- dry quickly (one layer in 1-2 hours);

- increase the frost resistance of slate;

- form a waterproof film;

- prevent the migration of asbestos dust from slate;

- The service life of the coating is 5 years.

Among the most famous and reliable water-based acrylic paints are:

- Alpina Dachfarbe from Caparol (Germany) is a silky matte acrylic paint that gives slate a deep red, brown or green color. Resistant to atmospheric influences, frost-resistant.

- Kilpi from Tikkurila (Finland) is an elastic matte paint with a wide range of colors (tinting according to Tikkurila’s own catalogs). It is easy to apply, does not fade in the sun for a long time and retains color intensity until the end of its service life.

- “Roofing paint on slate” from “Novbytkhim” (Russia) is a matte paint that is resistant to atmospheric influences. Forms lasting protection against the appearance of mosses, lichens, and algae on slate. Available in 5 colors, tinting is possible using existing systems.

- “Aquagel AK-1Sh” from TM Sticolor of the Stirol concern (Ukraine) is a dispersion paint with a matte structure. Forms a smooth film with a flat surface, from which water easily drains and does not retain dirt. Available in red and green.

A special type of water-based acrylic coatings is rubber (latex) paint. It contains the same acrylic latex, pigments and additives as conventional water-dispersed materials. But, unlike them, latex paint resembles a thick mastic, which, after drying, forms an elastic film, flexible like rubber. It absolutely does not allow water to pass through, does not crack, and has high adhesion to porous materials, including slate. The latex film of paint tightens cracks up to 1 mm wide and prevents the appearance of new ones. A prominent representative of this LMK group is “Rubber Paint” from Novbytkhim (Russia).

The properties of acrylic paints for slate using the example of a specific Eurostil Nova coating from Supraten (Moldova) are discussed in the following video:

Type #2 - acrylic paints with organic solvents

These paints are not diluted with water, but with organic solvents. Contains: acrylic resin (synthetic latex), color pigments, additives, organic solvent (most often white spirit). The degree of matte finish of such paints depends on the resin content. The more it is, the more pronounced the gloss of the dried film of the composition.

Organic solvent paints are different:

- a more durable film than water-dispersed compositions;

- high water-repellent properties;

- elasticity;

- light fastness and long-lasting color intensity;

- pungent odor.

Solvent-based acrylic paints are presented in a small range on the market. Thanks to its excellent quality, matte paint “Eternit” from Polifarb (Ukraine), produced in red, brown and green, has proven itself among craftsmen. Due to its wear resistance, the color of this paint practically does not change even at the end of its service life. Another popular option is Shikril paint from KrasKo (Russia). It is easy to use and has a high degree of coverage.

Type #3 - organosilicon (silicone) paints

Organosilicon paints are rightfully considered the most reliable and durable for slate. They are suspensions of pigments and fillers in an organosilicon (silicone) binder. Due to the presence of silicone, this type of paint is characterized by increased elasticity, so some of them are able to bridge cracks up to 2 mm thick!

Properties of silicone paints:

- high strength;

- maximum elasticity, the ability to carry out repair work and seal fairly wide cracks in slate using a silicone composition;

- fungicidal and algicidal properties that prevent the proliferation of microorganisms (in the pores and on the surface of slate);

- high water- and dirt-repellent properties;

- the possibility of excluding the priming stage from the painting process;

- Silicones are non-toxic, do not have an aggressive odor, and are fireproof;

- service life is 10-15 years.

Repeatedly tested for painting slate enamel “KO-slate”, produced (Ukraine). It impregnates the top layer of slate, providing deep, long-lasting color. The company produces “KO-slate” in two colors – red-brown and green, but there is the possibility of custom tinting.

The same company produces enamel OS-5103K (color green), intended for protective and decorative painting of many materials, including asbestos cement. The material has increased heat resistance, acid and alkali resistance, and resistance to chemical gases. Thanks to this, painting slate with OS-5103K enamel can be done at industrial enterprises.

Type #4 - alkyd slate paints

The composition of alkyd slate paints consists of alkyd resins, pigments, fillers in an organic solvent. Alkyd enamels, as a rule, dry quickly and form an elastic film that is not prone to cracking.

Properties of alkyd slate enamels:

- high moisture resistance;

- increased adhesion to slate;

- weather resistance;

- does not require the mandatory use of a primer before painting;

- durability – 5 years.

An example of high-quality alkyd enamel is “Quick-drying enamel for slate” from (Ukraine). It is characterized by very fast drying (at 20˚C the layer dries in 1 hour) and has no pungent odor. Available in the most suitable colors for the roof: red, brown, blue and green. Another alkyd-based product is “Roof Enamel” produced by Empils (Russia). In addition to high protective qualities, the paint has a wide tinting base consisting of 10 colors.

Type #5 - polymer paints “Liquid plastic”

They are a suspension of polymers (polyurethane, vinyl or polystyrene), pigments and additives in a solvent. After the composition dries and the solvents evaporate, the paint forms a thin plastic (polymer) layer with a glossy or matte surface on the slate.

Characteristics of “liquid plastic”:

- absolute moisture resistance (completely blocks the access of water to the slate);

- chemical inertness

- high drying speed;

- environmental friendliness;

- fire safety (does not burn after drying);

- resistance to fading;

- application without prior priming;

- high frost resistance, as well as the possibility of application at low negative temperatures (down to -10˚C);

- coating durability is 10-15 years.

Reliable polymer paint Liquid Plastic is produced by Denalt (Canada). This paint is produced on an alkyd-polyurethane base, which gives the composition special strength.

Polymer paint PPG-1 produced by Komoil (Belarus) is another reliable choice. Its composition contains polystyrene, which, after drying, forms a protective and decorative coating of various colors. Ps-160 paint (Ukraine) also has a polystyrene base. It is a weather-resistant enamel that forms an elastic surface with a glossy effect.

Other paints for slate ↑

1. “KILPI” is a Finnish acrylic coating for roofs, which is produced by the well-known company Tikkurila. Used for painting tiles, slate, roofing felt, bitumen fiber boards and other materials. Valued for its special elasticity at very low temperatures. One liter of coloring solution is enough to paint no more than two square meters of surface.

2. “DACHBESCHICHTUNG” is a German roof covering produced by. This semi-gloss paint is suitable for complete painting and partial repair of painted surfaces made of clay, concrete or slate roofing tiles. The paint coating freely allows water vapor to pass through, while protecting the roofing material from the effects of precipitation. Features a high degree of adhesion. If the base is professionally prepared, the paint layer can last for many years. One liter of coloring mixture is enough for 7 square meters of roofing.

3. POLIFARB – AKROFARB is produced by the Polish manufacturer of paint and varnish coatings “Debiza”. The paint is made on the basis of acrylic dispersion. It is used for painting not only roofs, but also facades finished with clay-cement slabs or slate. The applied coating dries in three hours. A liter of paint is enough to paint 5-7 square meters of roof surface.

4. “AKRILAKMA-SLIFE” is a Ukrainian water-dispersed acrylic paint intended for work on slate. Available in two color options: red-brown and brown. After painting, you get a smooth, uniform matte film that dries in just one hour. One liter is enough to paint 6 square meters of slate surface.

5. “UNISAL” is a Slovak water-dispersion paint for slate roofs, which is manufactured in Russia, located in the city of Belgorod. During production, technology used in Slovenia is followed.

It is valued for its high degree of hiding power, weather resistance and light resistance. Used for household and industrial painting of slate, as well as other asbestos-cement products. Can be applied by hand or machine. The paint color range includes the following shades:

- white;

- brown;

- grey;

- oxide red;

- black;

- green.

The time required for the coating to dry is no more than one hour.

One liter of paint is enough for five square meters.

6. “POLIFAN” is produced in the city of Kolomna. A universal paint that is used not only for painting slate, but also for painting reinforced concrete, plastered surfaces, brick, chipboard, fiberboard, curb stone and other materials intended for exterior finishing. Paint consumption is one liter per three square meters of surface.

In addition to the listed paint and varnish products for slate, there are other brands on the market, which allows the buyer to choose the best option taking into account price and quality. Now there should be no questions about how to paint flat or wavy slate, because they are based on the same asbestos-cement base. Now you know that you can make an old slate roof look stylish. At the same time, the entire appearance of the house will change for the better.

What paint is not suitable for finishing slate?

The most unpleasant result that is possible after choosing the wrong paint for slate finishing is a peeling roof within a year. For slate, you cannot use regular façade paint or for exterior use.

This is due to the fact that:

- Asbestos fibers have a special structure, and the coating not intended for them can slide off in layers after a year.

- The roof of the house is the most exposed element, which is exposed to scorching sun rays, hail and wind with small debris; it can heat up the most. Facade paint is not designed for such specific conditions.

- Plain enamel is absolutely not suitable for painting slate. Over time, it will not only begin to peel off, but will also hang down in rags, which will give the roof a rather pitiful appearance.

- The quality of the paint is influenced by its coloring. This happens due to the purchase of paint from one manufacturer, made on the same base, and the solution used for coloring has different properties, and also due to incorrect mixing of the compositions. On slate, such a coating will not last long.

Advice: You should not experiment with compositions that do not combine with each other.

- The reason for the paint peeling off on slate may be snow on the roof: after it thaws during the day and with frost at night, an ice crust will appear, which will peel off the color, which requires a smooth and even slippery coating on the slate.

Tip: This point is very important for the rafter system: the less snow is retained on the roof, the lower the variable load on the rafters, which will increase the service life of the roof.

- It is recommended to let new slate sit for at least a year before painting.

Do-it-yourself painting of flat slate - preparing the surface

As we have already said, before applying paint, the slate surface should be prepared for painting. In this case, the preparation is divided into several stages, each of which should be carried out as efficiently as possible. Otherwise, it is not a fact that the paint will last for several years.

Roof preparation stages:

- First of all, you need to carefully inspect the entire roof and remove the moss that grows on the north side. To do this, you can use a drill with a brush or a regular metal brush, although it will be much heavier, but a power tool will make the work much easier. Only in this case should you act very carefully so as not to damage the slate in any way.

- Also check the integrity of the roof. If there are breaks or cracks, be sure to seal them using a special mixture, which is prepared from materials such as cement, PVA glue diluted with water, or fluffed asbestos.

- The next step is removing debris and carrying out a procedure such as dust removal from the roof. These works can be carried out using water and brushes. After completing the procedures, allow the roof surface to dry. If you have any car washer available, you can use it - this will reduce the cleaning time. The surface should also be treated with a special antifungal agent, which will increase the service life of the slate.

- An important stage in the preparation of slate is its coating with primers. It is this stage that will increase the level of adhesion of the material, ensuring good adhesion of the paint compositions to the coating. If the treatment is carried out poorly, it threatens to quickly peel off the paint.. In addition, purchasing a primer will allow you to reduce the amount of paint you use, which is especially important if you are going to use expensive options.

Variety of colors and tinting options

The most popular paint colors for slate are red, brown, and green. They appear in the range of most paints. At the same time, the color base of a particular material can include either 5 or 100 different colors and shades. But what to do if you want to paint the slate, say, light yellow, but the selected paint does not have such a shade in the range? Tinting will come to the rescue. Most paint manufacturers provide the ability to paint their paints in any tone corresponding to color catalogs - RAL, NSC, Symphony. Tinting at the enterprise is carried out using special equipment, using tinting pastes and paints.

You can also do the tinting yourself by adding tinting paste to the purchased paint and stirring the mixture with a mixer.

Generalization by type

As you can see, there is a considerable assortment. There is plenty to choose from. But it is necessary to point out that each variety has its own price, which plays an important role when choosing. This is especially important when you need to paint slate on a large roof area. An expensive option will lead to an increase in the budget allocated for painting.

But, as practice shows, such a choice is a coin with two different sides. Expensive paints such as silicone or polymer make it possible not to repair the coating for 15 years. In this case, the applied paint layer burns out slowly, practically without changing the original color. But the cost of the material is two to three times higher than the same alkyd ones. Therefore, the consumer, when purchasing slate paint, must take this point into account. That is, buy a cheap option, but repaint it after 5 years. Or give preference to an expensive coating.

Varieties

Today, colored slate is popular. The peculiarity in this case is not only the variety of colors, but also the existing varieties. Thus, slate can be:

- wave;

- flat.

Each type has its own characteristics, which must be taken into account before making a purchase.

Important! If necessary, you can find colored wave plastic slate for sale on the goods and services market.

Colored wave slate

A feature of wave colored slate is its increased level of rigidity, which is a rather important point. Finished products are marketed for sale in a wide assortment of shades; the sheets have standard sizes; the number of waves can vary.

Thus, today the most popular is colored roofing material with 8 waves. As practice shows, this type of material is actively used for arranging the roof of residential premises, but wave slate can often be found as a fence. You can choose the color yourself if necessary.

Attention! If necessary, you can see exactly what colored slate looks like in the photo.

Colored flat slate

In this case, the name speaks for itself. If we consider colored flat slate, then it is worth taking into account the fact that it completely lacks waves. Due to the fact that the manufacturer uses chrysotile fibers as the basis of the material, this allows it to play the role of a kind of reinforcing mesh, as a result of which the finished product acquires a fairly high level of strength. This type of material is actively used for arranging fencing; in some cases, flat colored slate is suitable for the construction of temporary structures.

What paints are best for slate? Manufacturer and price

Do not forget that the quality of paint often depends on the manufacturer. The more reliable and popular the latter, the less likely you are to end up with bad products. But there is a downside to this, as their offerings often have a higher cost compared to lower quality alternatives. And here you have a choice, since on the one hand, slate painting is carried out in order to save money and not replace the coating with a more expensive one. On the other hand, you will not get the desired effect from a cheap product. Therefore, we recommend getting to know the market leaders in this category.

On the domestic market you will find a huge number of options, both from manufacturing companies in the CIS countries and from foreign ones. Among the first, paints from Butanit, Polifan and Unisal deserve special attention. All of them are distinguished by good resistance to weathering, ultraviolet rays and will retain their original appearance for a long time. Among foreign manufacturers, Germany is in first place with the Dachbesischichtung brand, which offers excellent paint for creating durable coatings. In addition, you should not pass by the Finnish Kilpi and the Polish Polifarb. They are excellent acrylic paints with a short drying time.

Advantages and disadvantages

There are no noticeable differences between colored and gray slate. Except in cases where the surface is coated with acrylic paint. In all other cases, the pros and cons depend on the slate material. Thus, among the main advantages of asbestos slate, affordable cost, simple processing and installation are noted.

And also - low thermal conductivity, which allows you to save on heating the house, resistance to rotting and burning. Among the disadvantages of the material are its fragility and the content of a component harmful to human health - asbestos.

To avoid effects on the body, you should choose a relatively safe option - colored chrysotile cement slate . Non-asbestos soft coverings are relatively lightweight and can be produced in rolls and sheets.

They provide a high level of waterproofing without the use of additional materials, and the amount of waste during installation is less than that of other types of slate - up to 5%. Installing a covering reduces noise levels during precipitation.

The roughness of the surface allows you to avoid snow falling dangerously for people even without installing snow guards. Among the disadvantages, one can note less durability compared to asbestos-cement slate. In addition, despite the affordable price of the material itself, its sheathing is relatively expensive.

Flat slate

Another option is colored plastic slate , which can be standard or transparent. Among the advantages of the material are low weight, low thermal conductivity and a high level of moisture resistance.

Polymer slate is easy to process and has good sound insulation properties. The disadvantages include the possibility of expansion under the influence of high temperatures, a short service life (up to 15 years) and vulnerability to pinpoint impacts.

Slate coloring technology

The choice of paint and its color is a responsible process. But, unfortunately, even the most expensive and high-quality enamel cannot guarantee a reliable decorative and protective coating on slate. If you do not follow the painting technology, then the pigmented film will almost certainly behave unpredictably. For example, it will begin to crack, swell or crumble much earlier than the end of its service life (possibly even a few days after painting). Therefore, you also need to know how to paint slate correctly!

The process of painting slate is carried out in several stages:

Stage #1 - preparing the slate surface

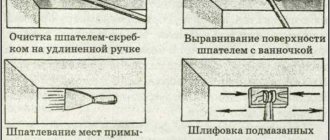

The slate surface to be painted must be cleaned of dust, dirt, fungal and plant deposits, and unstable (or incompatible with the chosen paint) coatings.

Cleaning can be done in two ways: dry mechanical (manual or mechanized) and using pressurized water jets. Sometimes these methods are combined and performed alternately.

For manual mechanical cleaning, wire brushes are used to scrape off efflorescence, dirt, moss and lichens. The work requires considerable effort and accuracy, and the cleaning speed is very low. You can clean slate faster and better with the help of tools. To do this, put an attachment on a grinder or drill, which is essentially the same brush for metal. When the tool is turned on, it begins to rotate, cleaning off surface defects of the slate.

The second cleaning method is to wash the slate with high-pressure water jets, which are created by car mini-washes (Wagner, Karcher, etc.). In this case, the created pressure should be within 100-250 atmospheres. Mini washers that release water at a lower pressure will not be able to remove contaminants, while higher pressure mechanisms will destroy not only the defects, but also the slate itself.

Stage #2 - priming

To impregnate the top layer of slate, special compounds are used - primers. They are selected in accordance with the instructions for using the specific coloring composition. For example, organosilicon paint Ko-slate is combined with silicone primer KO-011S. However, organosilicon paints, as well as “Liquid Plastic” compositions and alkyd enamels can be applied without prior priming. Acrylic paints, on the contrary, require the use of a primer. These can be either special compositions (for example, Dupa-grund for Alpina DACHFARBE) or paint diluted according to the instructions. To obtain an impregnating primer for Alpina DACHFARBE acrylic paint, it is enough to dilute it with water to 10% of the volume.

The primer is applied to the slate in 1-2 layers using a brush, roller or spray gun.

Stage #3 - painting itself

Direct painting is done over the dried primer. As a rule, it is enough to apply 2 layers of paint, the first of which will be the base, and the second – the finishing. The base layer is the main one; it must carefully cover the entire surface of the asbestos cement, including the ends, corners, joints, ridge and corner parts. After the first layer has dried, paint it again. The task of the second (finishing) layer is to ensure that the painted slate receives a bright, uniform color, without streaks.

Treatment is carried out with a brush, roller or spray.

This simple technology will give slate color and high decorativeness, comparable to the beauty of tiles, bitumen or metal roofing. In addition, painting (with periodic renewal of paint) will provide reliable protection for the roof from environmental influences and will increase its service life for decades.

Finishing a slate roof with your own hands according to the advice of craftsmen

When finishing a slate roof with your own hands, you should listen to the advice of craftsmen. To feel safe when working at height, you should use a safety belt. Cleaning, priming and painting the surface must be carried out in a protective suit, goggles and a respirator.

If you don't have a spray bottle, painting slate with a flat surface should be done with a paint roller rather than a wide brush. For the first layer to dry, you need to leave more time than indicated in the instructions; most often, they consider ideal conditions that differ from reality.

You can paint slate before installation or directly on the roof using a brush or spray gun.

Before carrying out work, you need to familiarize yourself with the weather forecast for several days in advance: the coating will last longer if it does not rain after the final stage. On a steep gable roof, it is better to work with an assistant. A high-quality painted roof surface will delight owners with its appearance for many years; the coating will not peel off or crack over time.

Dear reader! Your comments, suggestions or feedback will serve as a reward to the author of the material. Thank you for your attention!

The following video has been carefully selected and will certainly help you understand what is presented.

Flat slate paint - choice

First of all, it should be said about what compositions should not be used for coloring. It would be a mistake to buy the first paint you come across in a store that is suitable for outdoor use. As a result, you may end up with a peeling roof soon after painting.

When choosing paint for slate roofing, there are two things to consider:

- The special structure of asbestos fibers

- Features of roof operation. This is the most unprotected part of the entire house. It is the roof that is most affected by adverse weather conditions - precipitation in the form of rain and snow, scorching rays of the sun, wind.

If you use regular façade paint, it will soon peel off and hang in tatters, so choose one of the following options.

Polyurethane paint

Budget and practical option. The paint coating, which forms after complete drying, withstands temperature changes well and perfectly protects the slate. It is best to purchase solvent-based paint, as it penetrates better into the slate structure and has a service life of about twenty years. Water-based compounds do not have this ability.

To save money, you can take concentrated paint, which must be diluted with a solvent before use. In this case, take a little less solvent than indicated in the dilution instructions.

Acrylic paint

A great way to choose exactly the color for your roof that you had in mind when planning your design. This means that snow and water slide off very quickly and do not linger on the roof. This virtually eliminates leaks and moisture contact with the slate.

When painting the roof with acrylic paint, the temperature should be above +5 degrees, and at the same time there should be no scorching sun. After about a day, the paint should be allowed to dry.

Silicone paint

One of the main advantages of silicone is its water-repellent properties. Before applying silicone paint, you need to treat the slate with a silicone primer. The paint is applied in two layers, which affects the cost. Silicone paint is non-toxic, has fire-fighting properties, is resistant to chemical influences and mechanical damage.

The disadvantage of silicone paint is its fading. On a sunny side, after ten years the paint may turn gray.

Liquid rubber

Rubber paint hardens on the roof in a thick, uniform layer. It does not delaminate even when used in extreme conditions. The thick film perfectly protects the slate from atmospheric influences and the paint does not fade.

The disadvantage of liquid rubber is toxicity. It is necessary to work with this composition outdoors, with respiratory and body protection.

Paint life and reviews

Although slate paint manufacturers predict an approximate service life, the fate of such a coating on a particular roof or wall will depend on many factors. This is evidenced by reviews of people who have “modernized” slate roofing using paint.

- Pigment. If it is of poor quality and has little resistance to sunlight, such a paint coating will cease to be saturated quite quickly.

- Binder (that is, the film-forming substance in the paint). If it is weak, it will not be able to retain the pigment on the surface of the slate roof. As a result, the paint will come off unevenly.

- Primer. Without such a layer on the loose and porous surface of painted slate, most paints adhere less well and their service life is noticeably reduced.

- Quality of preparatory work. If dust and dirt are not removed well, the paint will not adhere well to the surface it is applied to.

- Coloring quality. A thin layer of paint sticks to slate worse than a thick one. At the same time, excessively thick layers create a film that can crack under the influence of humidity and sudden temperature changes.

- Exploitation. If water often stagnates on the roof, ice forms in the off-season, and snow and ice often slide down in winter, this affects the quality of the paint coating.

As practice shows, the outcome of the plan to paint a slate roof largely depends on the conscientiousness of those who undertake this task. There are times when, as the snow melts after the first winter, traces of paint deterioration become visible. But if you approach the work thoroughly, then slate can look elegant, high-quality and stylish for ten to twelve years.

See video instructions for painting slate below.

Installation features

During installation work, it is recommended to take into account some nuances and take into account the recommendations of some experienced roofers. Thus, it is best to use colored slate for roofing, the slope of which varies from 25 to 45 degrees. In the case where the slope is quite steep, installation will be much more difficult; in addition, the consumption of roofing products increases significantly.

When arranging the grating, you should pay special attention to the size of the asbestos-cement sheets. Thus, in order for the finished structure to have a high level of strength, it is necessary to ensure that each sheet of slate is supported by 3 sheathing bars. For example, if you plan to use sheets having a standard size of 1.75 * 1.13 m, then when arranging the sheathing you should take a step of about 65-75 cm. In this case, many experts recommend using sparse sheathing, as a result of which you can use rafter system.

As practice shows, often the base surface is not always smooth, there may be differences. In such situations, it is recommended to use special gaskets during installation work, thanks to which you can compensate for all existing differences and irregularities.

Installation can be carried out with horizontal overlap in several ways:

- in one wave - used when the slope is quite steep;

- in two waves - excellent for flat slopes, in this case the roof will be much more reliable, in addition, the service life will be significantly increased.

To fasten asbestos-cement sheets, nails are mainly used, which are equipped with special sealing elements, staples and tightening tapes.

In order for the installation to be carried out correctly and the efforts made are not in vain, it is recommended, among other things, to know how to move on colored slate. In this case, many experts advise using walking ladders for movement; for extreme cases, the softest shoes are perfect. It is necessary to move on the roof very carefully. This is due to the fact that the roofing material is quite fragile and can be damaged very easily.

Attention! Asbestos-cement sheets must fit tightly not only to each other, but also to the roof sheathing.

Painting slate - what, how and why?

Let’s take as a starting point that you will have to personally tidy up the roof of the house, which means that you will have to become thoroughly familiar with such a rather important process as painting slate with your own hands – from “a” to “z”. If the slate on the roof of your house is in good condition, without cracks or damage, durable and does not allow water to pass through even in heavy rain, then you can begin work. But in order to put your roof in order for the next ten years and be confident in the final result of your work, you will still have to make considerable efforts. To do this, you will need to at least check, and if necessary, update the entire roof or part of it.

If your coating is completely leaky, then no amount of painting will help such a roof covered with cracks. Here you need to safely buy new slate, which will be the color you want. We will talk about work that concerns such a process as painting slate on a roof, but for the material that has been in use for more than one year. So, after one decade, or maybe more, your roof doesn’t look very good, and let’s say it’s completely unpresentable. Which means you need to get to work. As experts say, painting old slate is a completely doable job, but it is labor-intensive and not as easy as it seems at first glance. So, you will need, firstly, to find out about the real condition of the roof, and secondly, to decide on paint and varnish materials.

In order to avoid problems in the future, you need to choose the right material. And don’t listen to those who confidently say that after painting such a product, the paint layer will crack and crumble literally after the first cold weather. There are many examples when, after painting (with the right materials), painted slate pleased its owners with its appearance for many years. So we make it a rule to choose paint accurately and comply with technological requirements when working. In addition, you should consider what kind of slate you have - wavy or flat. It depends on what is better to paint - with a paint roller or a brush. If you already use the material (installed on the roof), then you will have to stock up not only with patience, but also with a ladder (preferably very stable, since the work will not take an hour or two). If you are going to paint the product on land, then prepare a special elevation for convenience (so that the product does not crack or get dirty).

Painting flat slate: is it possible to paint, how and with what?

Flat slate can not only be painted, but even necessary. The fact is that painting significantly extends the service life of slate and reduces emissions of harmful asbestos into the atmosphere (after all, slate is a rather fragile material, under the influence of certain forces it can begin to crumble, and paint protects it to some extent). The service life of painted slate increases by one and a half to two times. The paint prevents moss from growing. In addition, painted slate looks much more attractive and fun than classic gray.

The first step is to purchase everything you need. Let's start with paint. To paint slate you can use:

- acrylic paints. One of the best options. Acrylic paint is non-toxic, dries quickly, and creates a smooth, wear-resistant surface. A roof covered with acrylic paint better repels moisture, due to which water and snow melt off much faster;

- silicone based paints. They are also non-toxic and protect the roof from precipitation. They have such disadvantages as high cost and high consumption when painting, which further affects its cost in the direction of increase in price;

- liquid plastic. This polymer enamel is a practical and durable coating. This coating dries quickly, forming a smooth film on the roof. It is quite inexpensive, but is inferior to acrylic paints in frost resistance, so it’s worth thinking about;

- oil enamels (for slate). The enamels are also durable and come in a wide range, so there is room to go wild. However, this option has many disadvantages - the service life is about three years and the enamels take a very long time to dry (because of this, you need to carefully select the day when painting will take place, you need an accurate weather forecast);

- silicone paint (for slate). It is a set of several silicone-based dyes and fillers. The material turns out to be durable, but you need to apply it in two layers (at least). Among the disadvantages, it can be noted that before application it is necessary to carefully prepare the surface;

- bitumen-based compositions. Cheap and extremely moisture- and frost-resistant paint. I don’t even want to comment on the disadvantages: the composition is toxic, takes a long time to dry, and wears off quickly;

You will also need brushes, and since our surface is flat, a roller would also be an excellent option. Convenient container for paint. A brush with stiff bristles + a brush with metal bristles for particularly neglected areas. Drill with a brush attachment. Primer (special, for slate). Ideally, you could get a washing machine (Kärcher or similar).

If everything is ready, you can begin work on site. The first step is to inspect the surface of the roof.

If damaged slate segments are found in some places, they must be repaired. To do this, use the following mixture = cement + PVA glue + fluffed asbestos + water. Using the resulting mixture, we restore chips and other damage, of course, after cleaning them first.

Now we begin to clean the entire surface from moss and any dirt. This is an important stage, since the quality of the painting and the service life of such a coating will depend on the quality of the work performed. Wash the roof very thoroughly, and when it is dry, you can proceed to the next stage - primer.

Priming the slate is an equally important step; it is the primer that ensures good adhesion of the paint and slate, and therefore directly affects the durability of the coating. In addition, priming will reduce paint consumption.

And finally, after priming, you can proceed to the final stage - painting. It is more expedient to perform this work from top to bottom. You can work with brushes or a roller, but the best option, of course, is a spray gun. Whatever type of paint you use, it is advisable to apply at least two layers. Before applying the second and each subsequent layer, of course, you must wait until the previous layer has completely dried.

As you can see, if you are not afraid of heights, then the procedure for painting slate is not that complicated, the main thing is to wait for good weather and do everything consistently.

By the way, now it’s not such a problem to find already painted slate.