Paint and varnish products are produced in a variety of ways, and manufacturers are creating more and more new compositions that differ in their characteristics and scope of application. This variety allows everyone to choose the best option that suits the stated parameters, but sometimes it can confuse buyers. After all, it can be difficult to understand which material is best suited for a particular purpose. To simplify the selection process, you can explore popular options. Among them, Hammerite paint stands out. More details about it and how to dilute Hammerite paint will be discussed below.

What is Hamerite paint?

Primer enamel for rust 3 in 1 Hammerite are produced for household use; they can be applied to metal and wooden surfaces, as well as to some types of plastic products, including plastic pipes.

Many people appreciate the fact that painting does not require a large number of preparatory steps. Before painting the surface, it is cleaned, and then a Hammerite coating is applied, which includes three products at once, including a primer and a rust converter.

Painting does not require a large number of preparatory steps.

Composition and properties of paint

Hamerite has the property of drying quickly; before painting there is no need to mechanically prepare the surface of the product. The material includes:

- Modified alkyd resin;

- Kohler, to obtain the desired color;

- Anti-corrosion elements;

- Thinner and technical wax;

- Fillers and other additives.

The presence of these elements in the composition helps to obtain a number of positive characteristics. These include:

- Creates a reliable protective layer against the effects of rust, capable of protecting treated objects on the street and in the building;

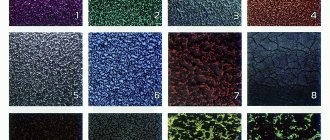

- Hamerait's color range is varied, there are also more non-standard options, such as hammer, cherry, silver, etc.;

- The optimal level of adhesion is suitable for surfaces with rust and metal, which allows you to obtain a durable coating;

- The paint product can withstand various temperatures, both very low and incredibly high; according to the manufacturer’s application, it can withstand even +150 degrees;

- All types of Hammerite can withstand exposure to sunlight for five years. It doesn’t matter whether they were applied to a metal or wooden surface;

- Protects wooden objects located outside from environmental influences; in this case, it is advisable to initially clean the surface and cover it with acrylic primer;

- Plastic pipes can be coated to provide an excellent protective coating.

Creates a reliable protective layer against the effects of rust, capable of protecting treated objects outdoors and in the building.

Main features of Hammerite paint and its varieties

Metal is susceptible to corrosion, everyone knows this. How long the car body can withstand an aggressive environment depends on the quality of the paintwork. None of the compounds provides a 100% guarantee of protection.

Over time, any paintwork fades and burns out, the enamel begins to crack and peel, and pockets of corrosion appear. Therefore, it is especially important to choose a composition that provides long-term, reliable coverage. It is Hammerite paint that can protect metal from many problems, since innovative technologies and components are used in its production.

The main feature of this coating is that there is no need for mechanical preparation of the surface before its application. This significantly reduces processing time. Hammerite paint is applied directly to areas of corrosion thanks to its innovative composition, which includes the following main components:

- modified synthetic alkyd resin;

- anti-corrosion additives;

- technical wax;

- fast evaporating solvent;

- color pigments;

- active additives.

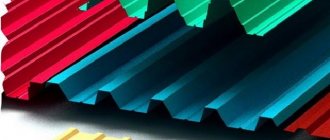

Each component of the paint and varnish mixture has its own purpose, and thanks to their combined action, the painted car body will become immune to rust. Hamerite enamel can create a paint layer with various effects on the metal surface being processed. It happens:

In turn, smooth enamel can have a semi-matte or glossy texture. Hamerite paints can be used both for working on metal and for painting a wide variety of surfaces. The color range of this brand of coatings is very diverse, which allows it to be used in various areas.

This unique composition is great for decorating and protecting plastic, wood, and glass. Can be applied to non-ferrous metals: aluminum, zinc, brass, copper.

Varieties

There are several types of products. The hammer one will be considered first; it is created for painting black parts, resulting in the effect of hammer embossing. For this purpose, aluminum flakes are diluted in the composition. Black paint has good hiding power and covers minor imperfections. Can be applied to the surface without preparation. Wax is used to impart moisture resistance to the protective properties. It is heat resistant.

Black paint has good hiding power and covers minor imperfections.

Smooth paint Hammerite is produced semi-matte, glossy. Of these, a glossy smooth base for coloring stands out, applicable for external and internal work. Additives include wax and silicone, which help further protect the surface from rust. You can choose from a range of colors presented.

Smooth glossy available in 17 colors. Can be used on painted surfaces, and without such a coating in areas with corrosion. Performs well in outdoor conditions.

Smooth semi-matte, gives the coating a matte finish, and is fire-resistant. Suitable for processing heating radiators and hot water pipes. Created in two colors - white and black.

Smooth semi-matte, gives the coating a matte finish, and is fire-resistant.

Hammerite paint for rust, how to dilute it

Hamerite is a durable, one-component, corrosion-resistant finishing coating for external and internal work on ferrous and non-ferrous metals. The surface preparation procedure is kept to a minimum. Short drying time and a special technique for applying a 2-layer topcoat can significantly reduce work time. Silicone additives and the scaly structure of the film provide reliable protection of metal from corrosion for 8 years. The paint can be applied directly to a rusty surface.

- Unique 3 in 1 formula

- Protects metal from corrosion for 8 years.

- Dries quickly on the surface.

- Excellent hiding power and adhesion to rusty surfaces.

*Color on your monitor may differ from actual product color

SUITABLE SURFACES:

Ferrous and non-ferrous metals.

Use Hammerite on ferrous and non-ferrous metals (in combination with Hammerite Special Metal Primer) on interior and exterior applications on fences and garage doors, downpipes and gutters, railings, hardware, weather vanes and flagpoles, garden tools and furniture, bicycles, any other metal elements and structures.

"Pros" and "cons" of using paint

Like any product, this paint is endowed with positive properties, but also has negative aspects. The advantages include the following:

- To paint the surface, you need to make a minimum of preparation;

- For painting you need a minimum of tools, including just one stripper;

- Any beginner can handle the processing process; you don’t have to pay for the services of specialists;

- It takes only three hours for the layers to dry, which will significantly affect the repair work;

- Obtaining a water-repellent and dirt-repellent coating is possible thanks to the silicone included in the composition;

- Prevents the appearance of rusty areas;

- Any surface structure that is selected from the proposed range - matte, semi-matte, glossy - will look attractive on the surface;

- No harmful or unpleasant odor, which is especially important when you have to work inside a building.

The negative side is the inadmissibility of covering a surface that has a layer of bitumen paint.

If it is not possible to determine what material was used previously, then you should paint a small area with paint and wait for the material to react. There should be no swelling or cracks on the surface.

To get all the positive characteristics from the coating, you cannot mix the composition with other paint and varnish products.

It takes only three hours for the layers to dry, which will significantly affect the repair work.

Features of paint application

The first step is to choose the tool that will be used for painting. Traditionally, a brush, roller, spray gun, or spray cans are used. When choosing, you need to focus on the type of surface; if the surface is flat, then a roller and a spray gun will do; if it has a lot of complex transitions, then use a brush. Spray cans are used to paint small objects.

The first step is to choose the tool that will be used for painting.

Brush

A brush should be chosen with natural bristles; application to the surface is carried out in 2-3 layers; especially careful treatment is necessary for curly elements and corners. In this case, the thickness of one layer should not be more than 100 microns.

A brush should be chosen with natural bristles; application to the surface is carried out in 2-3 layers.

Roller

A roller is best suited with short pile made of wool or fur. Working with a roller allows you to quickly paint smooth surfaces; parts with corners and irregularities are best handled with a brush. The first layer should be applied using the same brand of paint solvent.

A roller is best suited with short pile made of wool or fur.

Spray gun

When choosing a spray gun, you need to have the skills to apply coloring compounds using it. The paint is diluted until the desired viscosity is obtained, the surface should be smooth and clean.

Hammerite metal paint in the instructions describes the proportion of adding Brush Cleaner & Thinners solvent, it is equal to 2/1. Dilution will allow you to obtain the required viscosity.

When choosing a spray gun, you need to have the skills to apply coloring compounds using it.

Aerosol

Before spraying, shake the aerosol thoroughly, apply from a distance of 15-20 centimeters, you need to make 3-4 layers, moving from the thinnest to the densest. The 2nd layer can be applied after 2-3 minutes, 3 and 4 after 15-20.

Before spraying, shake the aerosol thoroughly and apply from a distance of 15-20 centimeters.

Tips for using Hammerite paint

In this article you will find answers to the most frequently asked questions about the use of anti-corrosion paint for metal Hammerite

So that the color goes on evenly

To do this, before using Hammerite, thoroughly mix the paint until the color is uniform, as recommended in the instructions on the can. Apply the same number of layers over the entire area of the surface to be painted.

What to do to avoid drips?

Prepare the surface for work in accordance with the instructions. To avoid drips when painting, we recommend applying the paint in a thin layer. A thick layer may leak under its own weight. This is a common occurrence with all topcoats. With Hamerite metal paint, due to its jelly-like consistency, this drawback is not so pronounced. But it’s still better to apply several thin layers than one thick one.

How to paint a surface that has been previously painted?

Select a small area of the surface you are going to paint. Try putting a coat of Hammerite paint on it. Wait for it to dry (takes about an hour). Then check if any defects have arisen during painting. If you are satisfied with the result, feel free to start working. Otherwise, it is recommended to completely remove the old paint layer.

How to paint an unpainted ferrous metal surface?

The Hammerite paint composition is specially designed for applying enamel to metal surfaces. Preparing for painting will take you a little time. You just need to clean the surface with detergent, then rinse it with water and let it dry. After this, you can apply Hammerite metal paint.

What do you need to know when painting a rusty metal surface?

Hammerite is an anti-corrosion paint that can be applied directly to rusty surfaces. Minimal preparation required. Before painting, remove rust using coarse sandpaper or a wire brush. Treat the surface with detergent and rinse off any remaining residue with water. Apply Hamright enamel to a dry surface. It is not necessary to use a primer.

Is it possible to use paint if the surface is very rusty?

In this case, you can use paint. After preliminary preparation (cleaning off rust, washing with detergent and completely drying), apply Hammerite No. 1 Rust Beater topcoat before painting.

Features of using enamel when painting aluminum and galvanized metal

After treating the surface with a wire brush or sandpaper, clean it with detergent, rinse with water, and wait until it dries completely. Apply a coat of Hammerite Special Metals Primer to a dry surface. The paint coating can be applied immediately after the primer layer has dried.

Why did the paint wrinkle after applying the second coat?

To avoid this, follow the technical process. Before applying the next layer, you need to let the previous one dry. If you have already had such a problem, wait until the paint has completely dried, then you need to sand the surface with sandpaper. Wrinkles will be smoothed out. Only then proceed to re-painting. Another reason for paint wrinkling may be the use of different solvents (other manufacturers or brands 646, 647, solvent) on the last and previous layers.

What if the paint starts to flake and peel?

This happens when enamel is applied to a completely smooth surface. To improve adhesion, before starting work, it is recommended to coat a smooth surface (for example, aluminum, galvanized steel) with a special primer, Hammerite Special Metals Primer.

Why did the product rust through after painting?

This can happen in two cases. Firstly, if insufficient paint was applied to the metal surface. According to the instructions, it is recommended to apply at least two layers. In addition, when painting products such as handrails and gates, special attention should be paid to painting recesses and edges. Secondly, the cause of rust could be that the surface was not well prepared for painting. We remind you that it must be cleaned and dried. There may be particles of dirt or water remaining under the enamel layer. This could lead to swelling of the coating, and then to the formation of rust.

Can Hammerite be used for metal products in coastal climates?

Can this enamel cope with salt corrosion?

Considering the characteristics of your climate, before painting you need to carefully prepare the surface for work. First of all, remove the salt from the product. Then, as in other cases, the working area will need to be washed with detergent and allowed to dry completely. To increase the protective properties, it is necessary to apply a layer of Hammerite No. 1 Rust Beater coating to the surface.

Can Hammerite paint be mixed with other paint brands?

No, Hammerite cannot be mixed with other topcoats.

Which is better: aerosol or brush?

If the surface you are going to paint does not have any defects, it is best to use a spray. Spray painting is not suitable if the surface has a small area. The paint will not be used sparingly, being sprayed beyond the boundaries of the product.

How long can I use the enamel after opening the jar?

After you have opened the can, the paint can be reused for another 2 years. In order for unused paint to retain its properties, the jar must be tightly closed with a lid. It is recommended to store in a dry, cool, sufficiently well-ventilated area.

Instructions for use

Before diluting Hamerite 3 in 1 paint, you need to carefully study the instructions provided. It describes in detail how to properly dilute the composition and how much solvent needs to be added. The company advises choosing only the specially created thinner Brush Cleaner & Thinners. It is emphasized that then it will be possible to obtain all the positive properties of the product without spoiling the resulting coating. Dilution rules depend on the type of tool that will be used for coloring.

Dilution rules depend on the type of tool that will be used for coloring.

How Hammerite paint is applied to a metal surface

Before applying it, treating the surface with a primer is not a mandatory requirement. But you can do this if you wish. The effect of paint adhesion to metal will only increase. To do this, use Hammerite No. 1 Anti-Rust.

To achieve the required effect of application, the paint must be applied to metal with a thickness of 100 microns. This must be achieved regardless of the method of applying it to the surface.

If there are areas of well-adhering old paint remaining on the surface, do the following. Apply Hamerite to a test spot. Let dry for 30 minutes and inspect. If the coating is intact and even, then the composition of the previous paint allows you to apply a new one on it.

Hammerite colors

The composition is applied to the surface in the following basic ways:

- brush or roller for painting;

- using aerosol paint in a special can;

- using air spray (compressor with spray gun).

Let's consider the features of using each method.

The first is using a brush, when Hamerite paint is applied to medium-sized surfaces and to objects with complex elements and shapes.

- Assess the viscosity of the paint before use. As a rule, no additional dilution is required. If it thickens, it needs to be diluted. To do this, add 1 part Hammerite Brush Cleaner & Thinners to 9 parts paint and mix thoroughly.

- Use good quality brushes made from natural bristles. This will ensure uniform coating application on the first pass. Do not use brushes whose bristles remain on the surface during the painting process.

- Dip your brush into Hammerite paint no more than half the size of your work surface. This will make it possible to use paint sparingly and without smudges.

Applying Hammerite paint with a brush

- Make movements with the brush preferably in one direction, overlapping each subsequent stroke by half with the previous one. This will ensure uniform paint application.

- Be sure to thoroughly apply Hammerite to areas of the product being painted where access is inconvenient and difficult. This is your area of special attention. It is extremely important that the composition gets there in the required quantity. Otherwise, these untreated parts of the surface will become hotbeds of developing rust. Painting is carried out in no less than 2 and no more than 3 layers. One coat of paint will not provide the desired effect. Applying more than 3 layers will lead to unnecessary consumption of paint material.

- Painting vertical metal surfaces requires special attention. This is due to the fact that, being at such an angle, the applied paint can flow down and form smudges. Constantly monitor the condition of previously applied layers. If necessary, without allowing them to dry, immediately correct this area of the surface with a brush.

- Before applying the next layer, it is necessary to wait at least 3 hours for the previous one to dry. There is no need to rush. This will lead to the destruction of the previously applied coating.

Part painted with Hammerite paint

The second is using a roller. The basic requirements for preparing the paint composition remain the same as when using a paint brush.

This method is used when it is necessary to process metal surfaces of a larger area. It is important to first apply the composition with a brush to the locations of corners, turns, bends and others, to which access with a roller will not be provided.

Features include the method of dipping the roller into a special container for applying paint to its working surface. Do this evenly over its entire fleecy part. Carrying out such an operation will ensure that the Hamerite composition is applied evenly and without gaps.

Painting with a roller

The third is by air spray. The paint composition is applied from an aerosol can or with a compressor and spray gun.

In aerosol packaging it is in a state of complete readiness for use. Used for touch-up painting of small metal surfaces or products.

Large areas are painted using a compressor and a spray gun. In this case, it is mandatory to comply with the paint viscosity requirements. It is necessary to prepare the composition in a ratio of 2 parts paint and 1 part Hammerite Brush Cleaner & Thinners. If this ratio is violated, the spraying process will be difficult or impossible. A thick composition will not spray normally from the spray gun nozzle. Excessively thinned will produce smudges or an unacceptably thin layer of coating.

How to calculate consumption

Hamerite paint consumption per 1 m2 is calculated based on the data indicated on the packaging. To calculate consumption, you must first calculate the area of the product, and then multiply it by consumption.

It is important to consider that consumption is affected by the application method, temperature and humidity, and surface condition. Hammerite paint for metal consumption per m2 is 200 milliliters when painting in 2 layers.

Consumption per m2 is 200 milliliters when painting in 2 layers.

Painting tools must match the surface

At the first stage, before starting work, you should choose the right tool and application method. Roller, brush, spray can, airless spray, air spray or spray gun? The choice depends on the object that is to be “saved” from corrosion. Dimensions, shape, presence of welds, design - everything matters. For painting flat surfaces with a large area, a roller and a spray gun are ideal. These are doors, gates, garages, solid metal fences, iron roofs, etc. The use of an aerosol can is justified if you need to touch up something or update a relatively small flat structure. If you plan to use Hammerite paint on shaped grilles, fences, benches, or any structures that have welded seams, the most suitable tool in this case will be a brush (only with natural bristles!).

Thinning paint

Before work, check the viscosity of the composition. If it is insufficient, then add a solvent. Before diluting Hamerite enamel for rust, mix the paint itself, the air temperature should be from +5 to +30 degrees. Add the required amount of thinner and mix the components thoroughly until a homogeneous mass is obtained.

Before work, check the viscosity of the composition.

Solvent selection

Dilution of the composition must be carried out with a solvent recommended by the manufacturer. Its composition is selected specifically for the components used in the paint.

The use of other solvent analogues can lead to delamination of the coating, a decrease in the declared properties, as a result, the coating will be damaged, and the result will be of poor quality.

Dilution of the composition must be carried out with a solvent recommended by the manufacturer.

Calculation of paint consumption

Hammerite hammer paint consumption per 1 m2 is 100 milliliters; in general, each type of paint has its own consumption. As you can see, the hammer type has low consumption. It is convenient to apply. And the resulting effect will be pleasing to the eye. To buy the required quantity, you need to accurately calculate the area of the surface to be painted.

Hammer is characterized by low consumption.

Hamerite paint differs from many other types; it simplifies the process of processing metal products with rust and saves time. The quality is time-tested, it will reliably protect surfaces from moisture and other factors.

Types of hammerite paints

There are the following types of enamel:

- Hammer. In addition to the main components, this paint contains aluminum shavings, which gives the painted surface the appearance as if it had been beaten with a hammer. This feature helps create the now fashionable “aging effect” on a variety of interior items, and is also used for processing metal products - fences, fences, industrial equipment, etc. Main characteristics:

- high degree of adhesion to rust;

- increased hydrophobicity;

- quick drying;

- variety of shades.

- Smooth, compares favorably with coloring compositions from other manufacturers with the following advantages:

- the composition includes active anti-corrosion components, thanks to which hammerite paint provides long-term protection against rust;

- can be applied to areas affected by corrosion;

- high degree of adhesion and good hiding power;

- has a “3 in 1” effect - can be used as a primer, sublayer and finishing layer;

- easy to apply;

- dries quickly;

- the ability to create a glossy or semi-matte texture.

Regardless of the type, hammerite paints are suitable for protecting, decorating and giving the desired color to both metal surfaces and wood, glass, and plastic.