- Luda, look, am I like the Terminator?

- Yeah..., only liquid. (excerpt from Comedy Club).

I am glad to welcome the honorable reader!

Liquid nails are a type of construction and installation adhesive used for fastening various materials. It is based on polymers and synthetic rubbers, the proportions and quality of which determine adhesion (degree of adhesion).

For your information: the name comes from the name of the product, Liquid Nails (from English - liquid nails) invented by an American manufacturing company in 1968. They appeared on our Russian market in the 90s and “stuck” well in professional and amateur environments.

The specifics of the product require certain understanding and skills. Otherwise, there is a risk of damaging the bonded surface. In this regard, our topic of this article is liquid nails instructions for use. In addition, it will be useful to know how and with what to clean the surface if something goes wrong. Go!

Purpose

Construction adhesive “Moment Installation” is used for the following purposes:

- for installing mirror bases on different planes;

- for attaching PVC panels;

- to attach shelves and decorative structures to any base;

- for fastening tiles.

The glue is waterproof, which allows it to be used in conditions of excessive dampness. They can be used to glue tiles or mirrors in bathrooms, showers, swimming pools, kitchens, etc.

Drying speed of the composition

Another very important characteristic that you should pay attention to when choosing a composition is the speed at which it will dry. This is important because if the finished part is needed in the near future, then it is better to use stronger and quick-drying compounds. Liquid glue sets differently, it all depends on the composition. Therefore, you must read the instructions on the package very carefully. It specifies the drying speed during setting and the time after which the finished part can be used.

Using liquid nails without a gun Source irecommend.ru

In order for the composition to set correctly, after applying the glue and installing liquid nails, you need to squeeze the elements together and hold for several minutes. The composition finally sets at least a day after gluing, but some models of liquid nails can handle it in 18 hours. The longest period of gluing is 7 days.

Therefore, you need to calculate in advance how many days it will take for the glue to completely dry and immediately make the part. A large amount of composition will not help the finished work dry faster, so you should not add more glue than necessary.

Using liquid nails at home Source proraboff.rf

Types and composition

Based on synthetic polymers

Additional components are solvents of organic origin, which explains the pungent aroma. Liquid nails react with plastic and PVC, so it is not recommended to connect surfaces made of these materials.

The marking on the products of this group is “MR”, it is placed on the packaging. Synthetic compounds are highly durable and resistant to moisture. Due to easy flammability, use of the product near open flame is prohibited.

Acrylic based

The marking indicated on the container is “MB”. They are neutral in composition, so they are suitable for work inside the house. Usually they install baseboards, fillets or PVC tiles.

Manufacturers of products display all information about the composition, main qualities and types of materials that can be glued together on the packaging and official website.

Types of glue liquid nails

There are two of them - organic-soluble and water-soluble.

Organosoluble - created on the basis of artificial rubber.

They have better adhesion than the latter, set faster and remain durable, even down to -40°. Good when working with ceramics, glass, plastic.

They have a pronounced “chemical” smell. Therefore, you need to work with them in ventilated areas, wearing rubber gloves and goggles. Flammable when applied and dried. Conclusion: all processes must be removed from heating devices.

Water-soluble - most often produced on an acrylic base.

Good for gluing porous surfaces, and are better (than organic) environmentally friendly;

They do not tolerate the freeze/thaw cycle and are destroyed by constant exposure to water.

Stamps

Glue Moment “Liquid Nails” is produced in 16 variations. Each has its own adhesive strength, differs in composition and is designed for a specific material.

Express MV 50

Universal assembly adhesive, does not contain solvents, used for joining wood, PVC, insulating boards. You can plant baguettes, door jambs, and decorative elements.

“One for everything. Super strong"

Manufactured using Flexec technology. Plastic, monocomponent, has a high adhesive force, so it can be used to glue heavy and large elements. They can work on any surface with any porosity, seal cracks, and seal.

Moisture accelerates the hardening of the joint, so it can be used in rooms with high dampness. They can be used to connect natural stone, concrete, brick. The product is not used for working with glass, copper, brass and PVC.

“One for everything. Transparent"

It has the advantages of the previous brand, it helps to seal seams in water, but not in conditions of constant immersion. Shelf life: no more than 15 months.

Glue Express Decor

White acrylic composition. Quickly glues any materials, but maximum adhesive ability is achieved with hygroscopic surfaces. Suitable for fixing decor.

“Moment Montage. Waterproof"

It belongs to moisture-resistant products of class D. This is a universal composition marked MB-40. They can firmly glue any materials.

"Super strong MVP 70. Transparent"

Due to the gripping force of 70 kg/m. sq. quickly glues any materials. Typically, wall panels and interior design elements are mounted on it. There is also a white composition.

"Superstrong Lux MV-100"

It has the qualities of the previous brand, but its adhesion force is 100 kg/m. sq. To glue heavy elements to them, there is no need to use supports or clamps.

"Extra-strong MP-55"

It is made on the basis of rubber. They can be used to glue heavy objects of any texture. After application, it forms a thin film that is dry to the touch, protecting the bonded surface from contamination.

The strongest adhesion occurs at the first contact of the surfaces during the destruction of the protective shell, so it is not recommended to move the working elements after bonding.

Specifications

Rubber based

| Compound: | Contains toxic volatile substances that give the glue a pungent odor, so when working with it you need to carefully ventilate the room. |

| Special Features: | Moisture resistance, frost resistance (operating temperature can reach -40 °C) |

| Color: | Flesh color, there are white and colorless models. |

| Application: | Installation, but can be used as a sealant. |

| Type of glued material: | Almost anyone. |

| Type of bonded surfaces: | Better glues smooth surfaces that do not absorb moisture. |

| Drying time: | Some varieties can dry instantly. The average working time, depending on the brand, can be 10-30 minutes. It sets within a day, and liquid nails dry completely in a maximum of 7 days. |

| Operating temperature: | -12… +35 °C |

| storage t°C: | From -20 to +30 °C, fully restored after defrosting. |

| Solvent: | White Spirit. |

| Expiration date: | 1.5-2 g. |

| Consumption per 1m2: | Depends on the brand. |

| Release form: | Cartridges, tubes. Weight 0.125-0.4 kg. |

Water based

| Compound: | Does not contain toxic substances, no pungent odor. Has great gripping force. |

| Special Features: | Water resistance, frost resistance (up to -20 °C) |

| Color: | White, colorless after drying. |

| Application: | For installation indoors and outdoors. |

| Type of glued material: | Various materials. |

| Type of bonded surfaces: | The surface must absorb moisture. |

| Drying time: | The working time of the train is 5-15 minutes. When completely dry, you can paint with acrylic paints. |

| Operating temperature: | +5… +30 °C |

| storage t°C: | From +5 to +30 °C |

| Solvent: | Excess glue can be easily removed with a damp sponge. |

| Expiration date: | 18 months |

| Consumption per 1m2: | Depends on the brand. |

| Release form: | Cartridges, tubes. Weight 0.125-0.4 kg. |

How to work with the composition - the correct algorithm

Before using Moment Installation liquid nails, be sure to read the instructions for use. This will save time and perform the job with maximum accuracy. Before you begin applying the adhesive, the working surfaces must be cleaned and thoroughly degreased. As a result, the coating should be completely free of dust, grease or dirt. Surfaces must be dry. Use a special gun to apply glue. The work will go faster with it.

Method of applying liquid nails

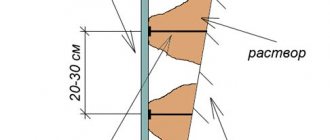

Depending on the texture of the coating, the composition must be applied in dots or thin strips located separately from each other. Immediately after this, place the surfaces to be glued together and press firmly. If you are working with massive products, you can use a wooden or rubber mallet to fix them. However, if you use liquid nails to glue wood, it is better to do without impact tools so as not to damage the wood structure.

After gluing you will need to wait. If you are gluing wooden or plastic surfaces, they will set within 10 minutes after applying the composition. In the case of aluminum surfaces, you will have to wait more than 20 minutes. At the end, you need to remove the remaining drying glue. Acetone or any other solvent can easily cope with this.

Instructions for use

During work, you must follow safety rules.

Before starting gluing work, you need to clean the surfaces from dirt and foreign objects, sand them, then degrease them. The materials to be bonded must be at room temperature.

The optimal air temperature for work is +10 °C and above. Some types of polymer adhesives can be used at subzero temperatures.

If the glue is in the form of a cartridge, then before use you need to cut off the protective seal and put on the cap. The end of the cap is cut at an angle of 45° to the desired diameter.

Next, the cartridge is installed in the construction gun: press the locking tab, pull the rod towards you, insert the cartridge into the gun body, push the rod back until the disk stops at the bottom of the cylinder.

Make several idle trigger presses until the glue starts to come out. To stop feeding, press the locking tab. This movement reduces the pressure of the compound inside the cartridge.

Adviсe

- It is better to use a construction gun to apply the product. It can later be used to work with sealant.

- If work is carried out on newly constructed concrete walls , then it is better to postpone this for at least a month to allow the surface to dry and the concrete to set.

- If you plan to glue PVC panels to painted walls , they must first be sanded. If the surface does not absorb moisture well, then it is better not to use acrylic nails or to prime the surface first.

- To increase the adhesive properties of expanded polystyrene , it is first coated with wood glue, which is diluted with water 1 to 1. After drying, you can begin to apply the glue.

Complete curing of the composition requires from 12 to 24 hours; during this time it is not recommended to load the glued surfaces, so as not to reduce the quality of the gluing.

Where can liquid nails be used?

To find out where to glue with liquid nails, you need to decide on the composition of the liquid glue itself. For gluing large elements, it is better to use liquid nails rather than ordinary glue. The scope itself differs slightly depending on the classification of the material. This universal material is mainly used to connect the following parts:

- drywall;

- brick;

- glass;

- plastic;

- tree;

- chipboard;

- cork panels and surfaces;

- ceramics and tiles;

- non-ferrous and ferrous metals, as well as their alloys.

Using liquid nails Source st-middelkoop.nl

People often wonder whether it is possible to glue ceramic tiles to liquid nails. In this case, it is very important to use very resistant compounds, since ordinary acrylic liquid nails will not be able to withstand such material. Liquid nails for tiles work very well, but paying attention to the composition parameters is very important.

Is it possible to make liquid nails with your own hands?

On the Internet you can find descriptions of many ways to make glue with your own hands, using only available objects and products. Will such a composition perform its functions? It is unlikely that it will compare in characteristics with “liquid nails Moment Installation”, manufactured industrially.

When creating “liquid nails”, components are used that cannot be purchased, and it is impossible to reproduce the manufacturing technology at home. You can try to glue small objects together with homemade glue, for example, a broken toy, but you should not use them for household repairs and construction.

It is closest to “liquid nails” in terms of the method of applying hot-melt adhesive in the form of solid rods, which are inserted into a hot-melt gun and melt under high temperature. If “liquid nails” are not available, then hot melt glue can replace them in some cases.

Liquid nails - areas of application of the material

The composition is a special installation adhesive material that is used by professionals in construction and other fields. It differs from its closest analogue (Moment glue) in its composition. Liquid nail adhesive consists of a large number of fine fillers, which together guarantee reliable adhesion of two or more surfaces. After gluing with liquid nails, the product can withstand quite heavy loads.

If the initial plasticity of the composition is very low, then to increase this indicator you can add a certain amount of white clay to it. True, after this the fixation force of the material will decrease slightly.

Liquid nails

The composition was first used in 1968 for gluing two wooden partitions. After this, the material was improved, as a result of which the glue began to better hold massive products. Nowadays, a composition such as Moment Montazh liquid nails is used in the construction industry to work with a wide variety of objects. Because of this, this material and its analogues are often called universal glue. In most cases, glue is used to work with the following materials:

- wood;

- drywall;

- plastic;

- glass and plexiglass;

- aluminum;

- natural cork.

In certain cases, adhesive compounds even play the role of sealants. Using them, you can efficiently seal bathrooms, windows, door frames and some other products widely used in the construction industry. In addition to the construction industry, liquid nails are widely used in repair work. They are often used for gluing wallpaper made of bamboo or other heavy woods. To paste, you need to apply glue to the back side of the trim, attach the wallpaper to the wall and lightly tap it with your hand.

After this, it is very important to remember to remove the trim and wait for the glue to dry. After 5–7 minutes, the wallpaper can be put back. Of course, part of the composition will crawl out from under the slats. However, there is no need to remove the glue immediately; it will be much easier to do after it has dried. You can also install ceramic tiles using liquid nails. In this case, the reliability of fixation will be even higher than when using traditional tile compounds. At the same time, not everyone can afford to use glue instead of tile sealant, as it is quite expensive.