Characteristics

Adhesive foam for polystyrene foam is a polyurethane-based composition, ideal for attaching slabs for exterior and interior decoration of a house. This adhesive material is characterized by an increased degree of adhesion, water resistance and excellent thermal insulation properties.

In addition, the adhesive foam for polystyrene foam (expanded polystyrene) does not contain freons, which ensures its environmental friendliness and harmlessness to humans.

Advantages:

- one cylinder is enough for 10-12 square meters of area;

- there is no need to stir or dilute the composition with water, it is already ready for use;

- the foam is easy to apply, and excess is removed extremely simply;

- the glue hardly expands;

- the composition hardens in a few hours;

- Provides high-quality, reliable and durable fastening.

A conventional cementitious mixture requires effort when installing polystyrene foam boards and it hardens for at least 24 hours, which significantly slows down the finishing work.

Disadvantages of foam adhesive:

- high price;

- Application must be done using a special gun or tools.

Not all manufacturers make high-quality products, so you should choose adhesive foam from well-known brands with a good reputation.

Advantages of laying blocks on adhesive foam

- Heat loss is reduced.

Adhesive foam has reduced thermal conductivity: when working with it, the thickness of the adhesive seams decreases, due to which cold bridges disappear. - The speed of work increases.

The material reliably fixes blocks faster than conventional mineral glue. Plus, there is no need to waste time on mixing - the foam adhesive is immediately ready for use. - You save a lot.

After all, you don’t need to buy expensive equipment and tools. There is also no need to create storage conditions for the material at the construction site: it is enough to simply leave the box with cylinders in a room at room temperature. - You can work even at low temperatures.

Down to −10 degrees. This is convenient because you do not need to use special winter glue and preheat the water. - The material is easy to transport.

There is no need to order Gazelle, as you would have to do with mineral glue. The cylinders easily fit even in the trunk of a car.

Follow our instructions so that the laying of blocks goes without errors or misunderstandings. You can purchase high-quality adhesive foam at a reasonable price in the TECHNONICOL online store.

Manufacturers of adhesive foam

The best adhesive compositions with exceptional characteristics are produced by manufacturers in France and Germany. In second place in terms of quality are products of Polish, Turkish and Estonian brands.

Domestic glue can be quite good, but sometimes there are downright low-quality products.

Advice! You should not purchase glue made in China, since such compounds are not durable and are often toxic.

The best foam adhesive for attaching polystyrene foam boards:

- TechnoNIKOL;

- Macroflex 65;

- Tytan Styro 753.

TechnoNIKOL

At the moment, two types of adhesive foam are produced under the Technonikol brand:

- 500 PROFESSIONAL universal,

- polyurethane for expanded polystyrene.

500 PROFESSIONAL is universally waterproof and mold resistant. It has excellent adhesion properties to silicates, brick, concrete, all types of plasters, wooden surfaces, ceramic tiles and chipboards.

The adhesive is used for fastening slabs of various insulation materials (mineral wool, polystyrene foam, expanded polystyrene), filling voids and cavities, sealing, gluing false stucco, baseboards and other elements.

The setting time of the composition is 10 minutes, final hardening occurs within 24 hours, the density of the glue after hardening is 25 g per cubic centimeter (the structure does not become heavier), thermal conductivity is 0.035 W/mK.

After interaction with atmospheric oxygen, the composition acquires a soft blue color. It is allowed to work with glue at ambient temperatures from 0 to +35° C.

Polyurethane for expanded polystyrene contains polyurethane, which, after interacting with atmospheric oxygen, increases in volume by a maximum of 10% with the release of isobutane gas.

The adhesive is designed specifically for fastening polystyrene foam boards, but is also suitable for other thermal insulators of synthetic origin, for example, polystyrene foam or extruded polystyrene foam.

The composition is used for fixing finishing elements inside and outside buildings, insulating joints, foundations, basements, floors and walls, gluing polystyrene foam boards, sealing joints and seams.

After setting, the adhesive foam almost does not expand, is resistant to moisture and the appearance of mold, perfectly fills gaps and joints, and has increased adhesion to concrete and other surfaces. Setting time is 10-15 minutes. Cannot be used at temperatures below 0°C.

Both types contain isocyanate oligomers, which release isobutane and propane under the influence of atmospheric oxygen. Available in cylinders of 400, 750, 1000 ml. They are characterized by moisture resistance, good adhesive properties, and are used for exterior and interior decoration.

Macroflex

Makroflex MF 901 adhesive foam is a universal one-component high-quality composition used for quick connection of structures and different materials. Used for external and internal work.

"Macroflex" is an ideal option for gluing metal, ceramic, wood, stone, glass products, as well as MDF, PVC, plasterboard, plexiglass, cork, plaster.

Suitable for fixing polystyrene foam to stone, concrete, wood, brick, ceramic surfaces, even if they are uneven or vertical. The composition is resistant to vibration and low temperatures, adverse environmental factors, and chemical compounds. When hardened, it does not burn, is elastic, and sets quickly.

Areas of application of Macroflex foam

Foam cement "Macroflex" has a wide variety of uses and is suitable for external and internal work. It is ideal for filling small to medium sized cavities, bonding building blocks, restoring block masonry and constructing lightweight lintels. Macroflex can also be used for the following purposes:

- insulation of buildings;

- installation of windows, doors, window sills;

- installation of staircases;

- cladding of various surfaces;

- eliminating gaps;

- filling seams;

- strengthening of insulation;

- arrangement of interior partitions;

- fixation of parts of structures;

- installation of panels on facades, foundations, interior finishing of premises.

Foam cement shows a high level of adhesion with materials such as concrete, glass, ceramics, wood, foam concrete, plaster, cork, and most polymer bases. Foam also adheres well to bitumen and foam coatings, which seriously expands the range of its possible use. The product is only poorly suited for drywall, mineral wool and galvanized substrates, since it does not achieve high adhesion rates with them.

Tytan Styro 753

Tytan Styro 753 is a professional polyurethane composition in 750 ml cylinders.

Used for fastening polystyrene foam boards when installing thermal insulation of roofs, facades, and also indoors. Has excellent adhesion to foam plastic and mineral wool. As well as plaster, wood, cement, concrete, brick, metal surfaces.

One can is enough to cover 10 square meters of surface. The material does not shrink or expand again, it is convenient to use and store.

It has excellent resistance to aging, high humidity and mold. It does not lose its properties at temperatures from –60 to +100° C. Expanded polystyrene slabs can be secured with anchors within two hours after gluing, which significantly speeds up the work.

Adhesive foam for polystyrene foam: brands

Builders consider the best products to be those made in Germany or France. In second place are Polish, Turkish, and Estonian manufacturers.

Experts advise giving up cheap Chinese products. Such products cannot effectively cope with their functions. We recommend choosing trusted brands.

TechnoNIKOL

TechnoNIKOL foam adhesive is a universal polyurethane composition for external and internal insulation of buildings. It is characterized by mold resistance and high adhesion to most materials.

Glue 500 PROFESSIONAL interacts well with PPS. It provides strong adhesion and strength to the seam. According to reviews from craftsmen, it copes with polystyrene foam better than other compounds.

Akfix 960

A one-component composition made in Turkey based on polyurethane, which is often found in building materials stores. Suitable for both expanded polystyrene and foam.

It is used for installation of thermal insulation of building facades. Sold in 900 ml bottles. It is moisture resistant, so it can be used in conditions of high humidity.

The consumption of adhesive foam is economical; one package is enough for several jobs. They can be carried out at air temperatures from -10°C to +30°C and humidity not exceeding 60%.

A professional gun is required for application. Before this, the surfaces must be cleaned of dust, dirt, grease and oil residues. Akfix 960 can be used for external work with materials based on mineral binders:

- brickwork;

- concrete, gypsum panels and slabs.

Makroflex MF 901

Makroflex MF 901 adhesive foam is a means for rapid gluing. Can be used for external and internal work. Macroflex interacts with metal, ceramics, wood, stone, glass, and foam. You can work with it in hot weather.

It is better not to use at sub-zero temperatures. The pre-treated surface must be cleaned, otherwise the gluing will be poor quality.

Ceresit CT 84

Ceresit CT 84 Express adhesive foam for PPS is often found in construction and hardware stores. It is produced in 850 ml cylinders. It is characterized by good adhesion, reasonable price, and ease of application.

Designed for installation on bases made of mineral binders:

- PPS slabs and sealing joints between them;

- Thermal insulation systems on the outside of new buildings and during the reconstruction of existing ones.

It is necessary to work with it at air and base temperatures from -10 to +40 degrees Celsius. Post-processing of the slabs can be carried out within two hours after gluing them. This is possible provided the outside air temperature is from -10°C and its humidity is not lower than 60%.

Tytan Styro 753

This is a mounting foam adhesive from a Polish manufacturer, blue in color, without shrinkage. Titan Stiro 753 is sold in cylinders with a volume of 750 milliliters.

It sets quickly, within an hour. It will take half a day to completely harden. It tolerates humidity, cold and heat well, so the adhesive is used for installing expanded polystyrene and polystyrene boards on building facades. One cylinder is designed to work with 10 square meters of surface.

What is polystyrene foam and polystyrene foam?

Polystyrene foam, which is actively used in construction, is made by treating raw materials placed in a special mold with water vapor. Due to this effect, the molecules increase in volume and sinter with each other. Over time, under the influence of environmental factors, the connection between them becomes weaker, and the material is destroyed. The foam does not differ in strength, since the interaction of the granules is very weak.

Foam plastic used as insulation allows water vapor coming from inside the premises to pass through, they form condensation, which causes an increase in the humidity of the material. As a result, the thermal insulation characteristics of the foam deteriorate, and after some time it collapses.

Expanded polystyrene is a type of polystyrene foam; it consists of closed cells filled with gas molecules, so that no substances from the environment can penetrate into the material. Typically, natural gas, which is highly soluble in styrene, is used to fill the cells. When releasing fire-resistant polystyrene foam, the granules are filled with carbon dioxide.

Useful tips

There are several details to consider when purchasing foam adhesive:

- Good quality glue cannot be liquid. You can check this indicator in large construction stores, as they have special “testers”. Squeeze out a little solution and evaluate the consistency.

- With a cylinder volume of approximately 800 ml, a consumption of approximately 125 ml per 1 square meter is considered normal. The density of the composition causes its increased consumption during work, so this indicator must be taken into account when choosing.

- Resistance to low temperatures allows you to work with foam glue in the cold; the conditions of use must be listed on the label. Such compositions are usually resistant to high temperatures.

- Take a closer look at the components contained in the glue. There should be no impurities of carbon dioxide and freon. It is good if the composition contains isocyanate oligomers.

- The glue setting time should be 10-15 minutes.

- The lowest degree of adhesion relative to a concrete surface should be 0.3 MPa, regarding foam plastic boards - at least 0.8 MPa.

Air circulation between the wall and the thermal insulation is unacceptable, since in this case there will be no effect from the work performed. The foam or polystyrene boards must fit snugly against the wall. The simplest and fastest way to fix the insulation is to use foam adhesive.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

After the plastic windows are installed, it is necessary to carry out finishing work, which involves the installation of external and internal slopes. There are several ways to install them: you can attach them to a pre-installed frame or glue the slopes to the windows using various adhesives.

Types of materials

Work can be performed using the following materials:

- Drywall. For production, GVLV brand slabs are used - this is a moisture-resistant plasterboard. Installation can be carried out in several ways: mounted on glue, putty, polyurethane foam, or mounted on a frame structure;

For the installation of slopes, moisture-resistant plasterboard and plastic panels are used. They have a pleasant glossy surface that harmonizes with the profile of the PVC window. Fastening can also be carried out by fixing it with glue, foam or using modern material - liquid plastic ;

Plastic panels MDF panels. They are not used very often for the manufacture of slopes due to the fact that it is not easy to choose the appropriate appearance of the panels so that they are combined with the profile material;

Advantages and options for such fastening

In addition to the fact that gluing drywall to foam adhesive occurs very quickly, there are other positive aspects of this method of fixation:

- There is no need to assemble the frame - less materials will be needed, costs will be reduced and everything will take a little time.

- The fastening is very strong, since the composition has very good adhesion to almost any material.

- Very serious deficiencies can be corrected - surface bends and holes more than three centimeters deep.

- It will be very easy to work with.

However, installing drywall with foam adhesive also has some disadvantages. First of all, it is worth noting the possible fragility of the fastening. The foam may dry out and everything will fall off. In addition, you will have to constantly monitor the position of the sheet, since the foam will expand and increase in volume, which can cause the appearance of bumps. At the same time, there are two options for gluing drywall to the wall with foam:

- Apply the adhesive composition to the part and press it all at once onto the area to be leveled. Suitable only in cases where drywall is glued with similar glue to a relatively flat wall. If there are protrusions, bumps, level differences and other similar defects, another method is needed.

- Fixation with screws and glue. If you need to make a wall with large defects smoother, then it is better to first attach part of the structure with screws, and only then do the actual gluing.

The second method is a little more complicated and will require additional costs, but they are justified by the possibility of leveling very problematic areas of the plane. In addition, gluing drywall on foam to the wall in this case will not be much more difficult. Both types of installation are worth separate consideration.

Mounting method on polyurethane foam

You can glue the slopes to the windows using polyurethane foam. This is a universal material with a high degree of adhesion. How to glue plasterboard slopes in this way is shown below.

- On the window opening, the width and depth are measured from above. On the sides, the height is measured twice - at the window and at the wall;

At the side openings, the external and internal heights are measured. In accordance with the obtained dimensions, details are drawn on a sheet of drywall;

Marking the part Using a construction knife, cut out the necessary parts;

Cutting parts The polyurethane foam is applied to the slope, the plasterboard part is pressed for a few seconds, then it is separated from the wall and wait until the foam expands again . Then the part is put back and fixed in the required position. In this case, you can use self-tapping screws, which are removed after the polyurethane foam has dried;

The part is glued using polyurethane foam. Metal corners with perforations are installed on the plasterboard corners;

The corners of the slopes are covered with perforated corners. The corners are finished with putty and left until completely dry;

Finishing corners with putty At the final stage, the surface is painted.

Slope painting

Screw method

There is a lot more work to be done here, but the result will be better and it is possible to correct strong bends in the plane or get rid of large bumps. Before gluing drywall to polyurethane foam in this way, it is necessary to carry out some preparatory operations:

- First, several holes are drilled on the part for future fastening and injection of adhesive composition under the surface. A standard sheet requires nine to twelve holes.

- By attaching the part to the base and using it as a template, marks are made on it for drilling.

- Next, following the marks, you need to make holes in the wall and insert plugs or plastic dowels into them.

- Pieces of foam rubber slightly thicker than the space that will remain free between the base and the sheet are glued to the inside of the mounted element. Foam rubber will prevent parts from dangling freely.

- Having attached the finished parts to the base, everything is secured through the holes with screws and wide washers. The washers will prevent damage to the outer side of the parts, and the foam rubber will spring back and they will be slightly fixed.

- Level the vertical and horizontal, using the depth of screwing in the screws, and pump the adhesive into the free holes. In principle, this is where the installation of drywall on polyurethane foam ends.

After the glue has hardened, the screws are removed, and in their place you can screw in ordinary self-tapping screws, recessing the caps into the surface of the sheet. All that remains is to carry out the usual puttying and grinding in such structures at the joints of the parts, and, if necessary, on the entire plane.

Why should you choose plastic products?

Plastic is the most common and versatile material.

Plastic slopes are most often installed

This is due to its performance characteristics and ease of installation. The advantages of plastic slopes include:

- Easy to care for the surface - just wipe the plastic with a cloth and soapy water;

- High-quality plastic does not fade when exposed to sunlight;

- Plastic looks best combined with the profile surface of plastic windows;

- The service life of these products is calculated in decades;

- For plastic slopes, when insulating them, you can use mineral wool. In this case, heat loss through the window structure is reduced and the effect of window fogging is eliminated;

- The moisture resistance of the plastic is obvious, so it does not collapse under the influence of condensation;

- Simple installation - the parts just need to be treated with adhesive and fixed to the surface of the base.

Installation

Plastic slopes can be glued in the traditional way - on polyurethane foam.

This installation has some differences from that used for plasterboard slopes. At the initial stage, a starting profile is installed around the entire perimeter of the window opening . In order for the connection to have sufficient tightness, when attaching the profile, its back side is covered with a thin layer of silicone sealant;

First, the starting profile is fixed. Parts are cut out of sheet plastic 8 mm thick. The window is measured in the same way as when installing plasterboard parts;

A plastic part is cut to size. A frame made of bars is installed around the perimeter of the window;

A wooden block is installed around the perimeter of the window. A starting profile is attached to the wooden frame;

The starting profile is fixed to the wooden frame. The resulting parts are inserted into the U-shaped starting profile. First, a layer of polyurethane foam is applied in a wave-like manner to the entire plane of the base, thus completely filling the space between the block and the frame;

The gap between the block and the frame is foamed. The plastic elements are fixed with masking tape while drying.

After installing the slopes while the foam dries, they are fixed with tape

Attach directly to glue

In this case, gluing drywall onto the foam is very simple, since nothing additional needs to be done except priming. However, the method is only suitable for relatively flat walls that do not have serious differences in level. The advantages of the method include the ability to control the area of glue application and the speed of finishing. It is necessary to apply glue over the entire area of the parts in strips, and then press it firmly in the desired place on the wall. After this, every fifteen minutes for an hour it is necessary to inspect the created plane and press the swollen areas.

Tip: if there is severe swelling, you can use self-tapping screws with washers to temporarily secure the bulging area. Then the screws are unscrewed.

The disadvantage of this method is the impossibility of its use on highly deformed planes. In addition, if you glue drywall to polyurethane foam in this way, it will be more difficult to obtain very even walls than the following method.

What is liquid plastic

Liquid plastic has recently appeared on the construction market. It has found application in many areas, including the installation of plastic slopes.

Liquid plastic is used for gluing plastic slopes

Liquid plastic is a type of modern sealant that can be used as glue when attaching plastic slopes. The content of liquid PVC in its base gives this material many positive qualities.

Mode of application

Using this glue, you can guarantee strong adhesion between the material and the surface.

Using liquid plastic when processing joints and seams, you can be sure that it will never turn yellow, as happens with silicone analogues. This ensures a neat appearance of the window opening.

When temperature changes indoors, plastic panels secured with silicone may lose their joint tightness. And the panels, placed on glue in the form of liquid plastic, will stay in place for many years.

When working with this material, it is important to consider that it hardens in one minute . This is the interval during which it is necessary to apply it and distribute it over the surface. You need to work quickly and efficiently the first time.

Preparing the base

Before gluing polystyrene foam boards, it is necessary to carefully prepare the base.

This is a mandatory condition, since the durability of the thermal insulation largely depends on the accuracy and thoroughness of the preparatory work. This allows you to avoid possible situations in which the slabs could come off, destroying the insulation and the facade itself.

If polystyrene foam boards will be attached to the old base, you need to make sure that it is strong. Also, must be clean, dry, free of moss, lichen, etc. If foam is being bonded to new surfaces, remember that any render or concrete must be completely cured and dry.

Sometimes insulation boards can be very smooth. Therefore, it is best to carry out an adhesion test on a small area first. If it is insufficient, the back surface of the polystyrene foam boards must be sanded where the adhesive is applied. This will improve grip.

Bonding thermal insulation boards

To glue polystyrene foam boards, you will need special glue and a foam gun.

When choosing an adhesive for gluing thermal insulation from polystyrene foam, you should choose a product designed for this type of material. To be sure that the slabs will be securely fastened.

It is also worth paying attention to the fact that the glue has low expandability and good thermal insulation properties.

Immediately before use, the glue should be mixed thoroughly!

Gluing the foam always starts from the very bottom, laying the bottom row on a special plinth.

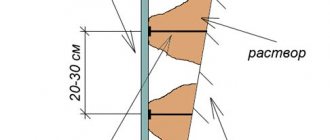

Apply the glue unilaterally, onto the slab, in vertical strips, keeping a distance of 20-30 cm, then apply the slabs (within 10 minutes after applying the glue) and press evenly over the entire plane, for example, using a rule. The gaps and joints between the plates are also filled with glue to avoid any heat leaks that occur at the junction of materials. Excess glue is removed mechanically after it has dried, using a sharp knife.

Instructions: lay aerated concrete blocks on adhesive foam

Adhesive foam is suitable for blocks with minimal geometric deviations - the first row can only be laid with a perfectly flat base. Otherwise, use a traditional solution, which is more suitable for preparing the base.

The blocks are laid at ambient temperatures from -10 to +35 °C. The temperature of the cylinder during use should be from +10 to +30 °C, otherwise it must be kept at room temperature for 10 hours.

Step 1

Let's get started! Sweep away any dust from the surface of the blocks. Shake the can vigorously for 30 seconds. Then remove the protective cap and screw a special mounting gun onto the cross-ring. Unscrew the adjusting screw and dump some glue into the trash container.

Step 2

When applying glue, the container must be held upside down. Material consumption depends on the width of the aerated concrete blocks. If it is less than 150 mm, apply one strip of foam adhesive at a time. From 150 to 300 mm - two stripes. From 300 mm - three stripes. The thickness of the glue should be about 30 mm. Apply the material to both horizontal and vertical faces of the blocks.

Step 3

Make a 50 mm indent from the edge and apply glue. Then, within three minutes of application, lay and adjust the blocks using a mallet and level. Do not tear them off the surface, otherwise you will have to reapply the glue.

Fastening polystyrene foam - mechanical connections

After the glue has hardened, the thermal insulation boards must be additionally secured with mechanical connectors. Their type, length, quantity and location must be included in the insulation design. Typically, plastic dowel umbrellas are used for polystyrene foam, 5 cm longer than the thickness of the foam.

The number and placement of mechanical connectors depends on the specific building (including wind load zone) and height, but as a rule it is recommended that there be at least 4 per m² (the exception is the corners of the building, where the number of dowels should be increased).