Glued veneer boards are very popular and are used for cladding inside and outside the house. But when performing work in areas with high humidity, it is necessary to use special material. Due to the high cost and lack of such products in stores, you can treat plywood for moisture resistance yourself. There are several methods to achieve the desired result.

What is the difference between waterproof plywood and regular plywood?

All types of material are made on the basis of veneer from deciduous and coniferous trees. To connect the layers to each other, special adhesive solutions are used, which are applied in accordance with a certain technology. This is what gives the product water-repellent properties.

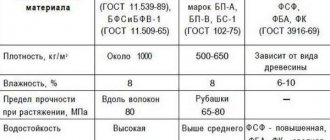

Types of plywood:

- Common options include products labeled “FBA”, produced on the basis of albumin-casein glue. Such panels are extremely environmentally friendly, but are not able to withstand high humidity, which limits the scope of the material.

- A more stable variety is FC, for gluing which urea glue with phenolic additives is used. This variation is characterized by a low level of water resistance, therefore it is suitable for installation indoors and is not recommended for installation in the bathroom, on balconies and open terraces. Even the presence of special additives is not able to prevent warping when exposed to severe humidity and direct contact with water.

- FSF boards have good moisture resistance. This is explained by the use of phenol-formaldehyde glue in production. Although such a material is able to resist harmful effects, it has a low safety record due to toxicity.

- FBS is completely waterproof. This is bakelite plywood that can even withstand exposure to sea water. The manufacturing technology consists of fully or partially immersing the slab in an adhesive and protective composition.

Most often, the relatively inexpensive brands “FK” and “FSF” are chosen as the starting material, but it should be remembered that “FSF” plywood is strictly prohibited for use in residential premises.

FSF is not recommended for installation inside the house and is not found in all hardware stores, but FBS is very expensive, so when using conventional options, you can increase the parameters of resistance to harmful effects yourself.

On a note! Due to the presence of an external cladding, laminated boards have improved properties.

Types of plywood

The moisture resistance of this material depends on the composition and production method. Plywood is a name given to wood boards made using glued veneer (thin layers of wood). Less moisture-resistant birch is used in the production of furniture plywood. Building boards (they are the ones most often used in everyday life) usually consist of 3-5 layers of hardwood, pine and spruce veneer. These types of wood are more resistant to rotting.

But still, the moisture resistance of plywood depends primarily on the type of glue used. Its composition must be indicated in the labeling:

- FBA: casein glues that swell easily in water;

- FC: a mixture of urea and water-resistant formaldehyde resins; materials with such impregnation can only be used indoors;

- FSF: phenol-formaldehydes, adhesives of increased water resistance; the compositions are chemically aggressive and are not recommended for interior decoration of houses and apartments;

- FB, BS and BV: bakelite adhesives and varnishes: additional treatment of plywood from moisture and rotting is not required in this case; wood impregnated with them acquires the highest strength and wear resistance; materials have a special purpose and are used in mechanical engineering, aircraft construction and even the space industry.

Additionally, you can protect FBA, FSF and FC boards from rotting in several ways. Each of them has both advantages and disadvantages.

How to make plywood moisture resistant with your own hands

To impart the desired characteristics, various methods are used, involving the use of special impregnations.

Painting with nitro enamel

This is an effective method that ensures a surface that is resistant even to direct contact with water.

Process diagram:

- All sides of the sheet are sanded using abrasives with a coarse and medium structure.

- The surface is completely covered with drying oil; the ends need to be soaked especially well.

- The paint is diluted to a liquid state and laid evenly on the dry slab. The composition acts as a primer, creating a reliable basis for future work. It is recommended to paint in 2–3 layers. It is taken into account that the last coating should have the smallest thickness.

- As additional protection, fiberglass impregnated with nitro solvents is used. The canvas is glued to the entire area of the panel, but only after the first layer of paint.

Nitroenamel dries completely in a couple of hours, but this paint has a strong and pungent odor of solvent, and it also needs to be applied at least 2-3 times, since the composition is strongly absorbed. The technology

allows the use of similar compositions that are marked as moisture resistant.

Impregnation with drying oil

This solution is one of the most common and most accessible. At home, the oil is used as an antiseptic and increases the durability of the product. Processing is carried out according to the following algorithm:

- Prepare a suitable container, roller and brushes. The drying oil is mixed well and poured into the container. The composition is heated to a temperature of 60 degrees. Caution is required as the material is flammable.

- All plywood sheets must be treated with the prepared solution. It is important to thoroughly saturate each area, paying special attention to the edges.

- The surface is forced to dry. To do this, it is advisable to use a hair dryer with power adjustment.

- The drying oil is heated and the entire processing cycle is repeated. The mixture must be applied until it stops being absorbed.

Natural types of drying oil have a high price, so most often plywood is treated with semi-natural compounds called oxols.

The resulting coating is not only resistant to dampness, but also destroys mold and mildew.

Attention! The base is suitable for varnishing and painting with compositions that contain drying oil used for processing.

Coating with PVA glue

This impregnation for plywood is recommended for use when additional protection against rotting is necessary, which is especially important for floor coverings.

The polyvinyl acetate composition is used to treat the slabs in a similar way: application is carried out sequentially on both sides until the surface stops absorbing the solution, special attention is paid to the ends.

The main difference from the previous method is that forced drying cannot be performed. In addition, the entire complex of work will require at least 7 days, since the film takes quite a long time to form.

To treat plywood to protect it from rotting, it is not necessary to use glue; dispersed compositions based on PVA with the addition of an antiseptic work much better.

What impregnation is better to buy for plywood

Moisture-resistant impregnation for plywood is available in a variety of variations on the market. The composition may contain linseed oil, drying oil and other elements that contribute to obtaining a high-quality result. Mastics are also used, but they differ in the complexity of the work.

It is important to determine whether it is necessary to change the color of the base or whether there is a desire to maintain the original version. Nitro enamels allow you to get any shade from gray to red.

If constant temperature changes are expected, then compositions that can withstand such exposure should be selected. It is better to seek help from a specialist who, taking into account the operating characteristics, will suggest a product that will satisfy all needs.

Nitro enamels allow you to get any shade from gray to red.

Protecting plywood from moisture outdoors

Using glued veneer slabs on the outside requires a more serious approach and different methods.

Fiberglass

The fabric is also used for indoor work; as an alternative, you can choose gauze.

Process technology:

- The surfaces are pre-polished, and the resulting suspension and dust must be removed.

- The prepared substrates must be treated with a certain type of varnish. The solution must not contain polyester or epoxy resins.

- After the mixture has dried for 2 hours, the fiberglass is glued on. The material is distributed over the surface so as to eliminate unevenness.

- Two more layers of varnish are being laid.

The most reliable way to protect ordinary plywood from moisture is considered to be the application of yacht varnish with additional reinforcement of the surface with fiberglass.

Any forced heating of surfaces that helps speed up the drying of the solution is unacceptable.

Epoxy resin

Before you coat plywood with this composition against moisture, you need to choose the right material. For street work, products marked “FK” cannot be used, so FSF is the best option. The mixture is diluted with a substance specified by the manufacturer; the consistency should not be too liquid. The entire surface is covered with the solution, the ends are well coated. The number of layers varies depending on the situation, but it is advisable to apply at least two.

Epoxy resin has a significant drawback - it is expensive, which makes its use inappropriate for household activities.

Two-component epoxy resins are highly resistant to moisture, but after mixing the components, the composition must be applied quickly, as it has a short setting time

Surface preparation

Before impregnating plywood from moisture, its surface must be prepared. This process consists of several stages:

- The slab is drying. It should be such that the plywood is protected efficiently.

- Next comes grinding the surface. Before impregnating the plywood for moisture resistance, it is necessary to clean it well. To do this, use fine-grained sandpaper. For ease of operation, it is attached to a wooden block, and the surface is polished with this device.

- Particular attention is paid to the ends of the sheet. All chips and burrs are removed. If the chips are quite large, you can use wood putty.

Cleaning can be done using a grinding machine. Sanded by hand does not have the same surface quality as using special tools.

It is advisable to acclimatize the plywood; how long this process will take depends on the temperature. If the material is intended to be used indoors, then one day is enough for drying; outdoors at a temperature of 80C and below - 3 days.

Important! The slabs are soaked for some time, and then they must be stacked on a flat surface to dry completely.

Now you understand how to treat plywood to increase its moisture resistance and hydrophobic qualities at home, and you don’t have to buy expensive brands of products. You can use the fairly effective processing methods presented above.

What impregnation is better to buy for plywood (2 videos)

Impregnation for wood (30 photos)

Features of processing slabs before laying on the floor

To obtain a high-quality result when installing sheets on a horizontal base, it is necessary to take into account some nuances of applying a protective coating:

- The panels should not have high residual moisture; acclimatization of the material for at least 24 hours is required. It is necessary to ensure ventilation of the sheets, so they are placed horizontally. To do this, wooden blocks are laid between the panels.

- High-quality grinding reduces composition consumption and promotes the formation of a reliable film. The ends should also not have a burr.

- Impregnation is carried out with the most suitable material according to the instructions. Particular attention is paid to the side that will face the base.

After laying the plywood covering on the floor, the surface must be sanded and primed, then covered with several layers of a protective composition, most often it is wax or varnish.

It is taken into account that the processing is carried out after cutting the product into the required size parts.

Features of the structure

The basis of the plywood production process is gluing thin sheets of wood together so that the natural fibers are directed strictly along or across the long side. The number of layers is most often odd, the minimum is 3 sheets.

Bonding is carried out by various means, of which effective water resistance is provided by certain bakelite compositions: varnishes and alcohol-soluble adhesives. The use of water-soluble modifications of Bakelite and all other types of adhesives leads to the fact that the products cannot withstand the action of water vapor. Low water resistance is especially noticeable when using plywood outdoors. In this regard, it is necessary to treat the material with protective compounds.

How to extend the service life of wooden floors?

Adviсe:

- Organizing a canopy over a plywood sheet mounted on the outside of the house will extend its service life.

- To protect glued veneer installed outdoors from moisture, it should be covered with another material, such as plastic.

- Mounting points are susceptible to moisture first. Therefore, they need to be coated with a reinforced layer of impregnation.

- As soon as small cracks begin to appear on the surface of the plywood, they urgently need to be sanded and covered with a layer of primer.

Thus, by following a number of simple recommendations, you can maximize the life of the plywood covering.

Subsequent treatment of plywood to maintain moisture protection

No matter how reliable protection is used, weather conditions make adjustments to the quality of the material. Over time, the layer may crack; if the veneer layers were glued unreliably, the material may fall apart. It is especially important to protect the ends that are most often exposed to water. Plywood sheets can only be used in areas where there is protection from direct water ingress, for example, the roof. The sheets cannot withstand constant exposure to moisture.

If areas with a damaged coating layer are discovered, the situation must be corrected promptly. You cannot simply apply a new layer of impregnation; you must sand the area so that the rotting process does not take place under the new layer of product. Such correction of lesions will help to significantly extend the life of the plywood.

Plywood sheets can only be used in areas where there is protection from direct water ingress.

Varnishing and painting

You can make plywood moisture resistant and increase its service life by varnishing and staining. To do this you need to prepare the following tools and materials:

- roller, brush or spray;

- putty knife;

- sandpaper;

- primer mixture;

- putty;

- varnish;

- paint.

The paint creates an excellent water-repellent layer on plywood.

If plywood sheets will be used in a residential area, then you should buy water-based paint. They dry quickly enough, have virtually no odor and are perfectly applied to the prepared surface.

To use this material in an open space, ordinary enamel paint for wood is well suited, which is easy to apply and dries quickly at room temperature. Paints can be purchased both in ready-made colors and in basic versions for self-tinting. Before painting, you need to properly prepare the surface so that it is even and smooth. The dyeing technology includes the following work:

- grinding;

- acrylic primer;

- drying;

- treatment with acrylic putty;

- drying;

- grinding;

- padding;

- drying;

- coloring.

Sanding allows you to remove all surface irregularities. This is done with coarse sandpaper. To obtain a perfectly smooth base for further varnishing, you need to sand along the wood structure with fine-grained sandpaper.

Before painting, a coat of primer should be applied to the plywood.

After this, the polished surface is treated with an acrylic primer. Priming and puttying is necessary for:

- leveling the base;

- closing cracks;

- protection of wood from mechanical damage.

The method of painting plywood and the choice of coloring agent largely depends on the operating conditions. If moisture-resistant plywood will be used outdoors or in places with high humidity, the sheet should be painted on both sides, paying special attention to the edges, which are treated with several layers of paint.

If plywood sheets have been stored for a long time in a room with high humidity, then they must be dried before painting.

You can paint lumber with a roller, brush or spray. The latter method allows you to get a better result, since in this case the paint is applied more evenly.

Before applying varnish to an unpainted substrate, it should be sanded with fine-grained sandpaper. After this, remove the dust and cover the surface with diluted varnish. After painting, a layer of varnish can be applied to the plywood to give the surface a shine.

Choosing a installation method

There are 2 main ways to properly lay plywood on a wooden floor:

- Laying on an old wooden base

The method is used if the horizontal difference of the old base is less than 1 cm, and also if it has sufficient strength. This method is simple, but can be used only in limited cases, since the difference in the old floor is often more than 1 cm

If the difference in height of the old base is significant, plywood is laid on logs made of timber. This method is longer and more labor-intensive, but it allows you to deal with significant horizontal differences and damage to the base. Can also be used if the old floor has failed and cannot serve as a solid base for a plywood underlay

Next, we’ll take a closer look at which method to choose in a particular case and how to properly lay plywood on the floor.