Painting with three-layer “mother of pearl” “in transition”

In the 80-90s, painting with single-color enamel without smudges and dust was considered the highest aerobatics among painters.

Since the mid-90s - applying “metallic” without stripes and “apples”. Then they began to master the “smooth transition”, learned to adjust the shagreen on parts to the factory one... Technological progress poses new challenges for the modern painter. In particular, skills in working with three-layer coatings - “mother-of-pearl” and “xyrallic”.

Today we’ll talk about repairing three-layer mother-of-pearl using the “smooth transition” method. This type of repair, which is considered the most difficult, will provide a good demonstration of all the intricacies of working with “three-layer.”

Features of three-layer coatings

A three-layer or three-stage coating is a type of “base + varnish” coating.

The first layer of such a coating is a layer of base substrate of one color or another, on top of which a layer of “spectacular” paint is applied and this “sandwich” is completed - a transparent varnish. A three-layer coating most often has a mother-of-pearl effect, the main components of which (mica microparticles) are found in the second layer.

Repairing such a coating has two features.

The first is that the mother-of-pearl layer (the one in the middle) has high transparency - under it we seem to “see a little” of the substrate. This gives a characteristic visual effect to the three-layer coating: the mother-of-pearl particles are “illuminated” from all sides, both from above, through the transparent varnish, and from below, by light reflected from the substrate.

This transparency of the mother-of-pearl layer creates certain difficulties during partial painting. Because if we can see the substrate under the mother-of-pearl, then its border may also be noticeable when touching up the paint. You can try to hide this border with additional layers of mother-of-pearl, but this will greatly change the shade of the coating, which is unacceptable.

Second feature. Since the color properties of the technical layer strongly depend on the thickness of the transparent pearlescent layer, during repairs we can never know in advance how many layers of pearlescent paint will need to be applied.

Moreover, not only the number of layers matters, but also the manner of applying the paint. Each painter has a slightly different layer thickness. That is why pearlescent paint for repairs is usually prepared strictly according to the formula, and is not tinted.

To determine how many layers of mother-of-pearl need to be applied, it is recommended to conduct a special preliminary test before starting painting. After some practice, this test does not require much time or materials, and you can be guaranteed to avoid color mismatches on the new and old surfaces.

Preliminary tests

You can conduct a simplified test, or you can do a more accurate one.

For any of them, you must first prepare three identical test plates.

Simplified test

After drying the test plates, we apply each of them to the car part (tightly, without gaps) and select the application method in which the paint most accurately matches the color of the original coating.

Color comparisons must be made from different viewing angles and lighting.

Let’s say the second plate matches, which means that when painting it is necessary to apply 2 layers of mother-of-pearl under the same painting conditions and gun settings that were used to make the test plate.

Accurate test

If you want to achieve an even more accurate match of the repair coating to the original, it is recommended to conduct a more complex test.

As a result, we have four zones on each test plate:

The first zone is 1, 2 or 3 layers of pearlescent paint, respectively. The second zone is the same plus the last drip layer. The third zone is the same as in the first zone, but covered with transparent varnish. The fourth zone is the same as in the second zone, but covered with transparent varnish.

This test is a double control: the varnished areas of the test plates can be compared with the surface of the part, and the areas without varnish allow you to control the process of applying pearlescent paint before applying the varnish.

Technology and rules for painting with Xerallic

An additive with a pigment composition adds shine and does not affect the color of the car. To give the main color you need to use regular paint, which will break through the pigment. It is recommended to apply Xeralic in 3 layers:

- The base and the color of the substrate are chosen by the colorist. To create the base, use standard paint.

- 1-2 pigments; in the case of several components, it is possible to combine colors in an interesting way.

- Nice varnish.

Acrylic car varnish Novol ULTRA LINE with hardener 2+1

Taking into account the limited choice of glitter colors, you need to carefully approach the selection. It is worth understanding that when large particles are applied, the pigment can cover up to 50–80% of the main color of the car.

When applied directly to acrylic paint, dry pigment may “drown” in it. To prevent such a reaction, it is recommended to use glitter in a binder or clear base mixture.

Craftsmen can offer an unconventional way of using xerallic, in which the pigment is introduced into the primary layer of car varnish. Such a proposal is risky, since a decent result can only be obtained with great experience and a small grain size. If you use a coarse-grained pigment, there is a risk of breaking the top layer of varnish and subsequent cracks. There are special additives for adding to varnish, therefore, using Xeralic in this way is not recommended.

Surface preparation

In one of the previous articles, painting with a metallic transition was discussed in detail and presented schematically. In it we looked at repairing minor damage to the rear fender with a transition over the varnish on the C-pillar.

Let's complicate our task by the fact that the damage on the wing is quite large and located in the central part of the part. And since creating a transition on mother-of-pearl requires a lot of space, we won’t be able to create a transition within the element in this case. You will have to stretch the transition to the adjacent part (door).

When repairing three-layer coatings, the total number of layers is large, and a large area is required to create a transition. Therefore, it is often impossible to perform this repair within one part.

Another complication is color. In our case, under several layers of translucent mother-of-pearl there will be not just a colored substrate, but a base layer with metallic inclusions. According to the developers, such a coating looks even more beautiful (additional shine and depth), but during repair it creates additional difficulties, since in this case the transition must be made not only along the mother-of-pearl, but also along the substrate. For this we will use a colorless base.

As for surface preparation for partial repair of three-layer coatings, its steps are similar to those described in the above-mentioned article.

The priming area is treated with material graded P400-P500 dry or P800-P1000 wet. The remaining area of the part, as well as the adjacent element, is treated with Scotch-Brite gray modification (ultrafine) using matting paste.

Instead of gray Scotch Brite, you can use similar matting felt from other companies, or graded paper P800-P1000 when processed with a dry sander, or graded material P1200-P1500 when sanded by hand in a wet manner.

After matting, the part is thoroughly washed with water to remove paste residues, dried and degreased. Then, having dusted the part with a jet of compressed air and a sticky cloth, you can begin applying the first layers of coating.

Preparation

Three-component paint involves applying three components: a substrate, a base and a varnish. You will first need to obtain this base, although most manufacturers offer a ready-to-use product. If the pigment is mixed with the binder, you can immediately begin painting, otherwise you will need to prepare the base in accordance with the manufacturer's instructions. As a colorless base, only the products specified in the instructions should be used.

You will need a good spray gun and nozzle, since the base needs to be sprayed onto the car, not poured. All components must be prepared in advance - only short time intervals are allowed between levels, you have to work at a pace. When painting in a garage, special attention should be paid to removing dust and maintaining the desired temperature.

The surface is degreased and sanded. Additionally, you can walk over the surface to be painted with a sticky cloth and collect any remaining dust. To reliably remove dust, some craftsmen spray a little paint onto their glove and rub it over the surface. Dust sticks very well to drying enamel, and if you don’t mind wearing gloves or your hands, then this method will undoubtedly give a better result than wiping with wet wipes.

The decision to use a primer is made based on the need to protect the metal from corrosion and the requirements of the enamel. The presence or absence of a primer layer does not in any way affect the final result, but the quality of its application will most likely affect the result. The enamel of the substrate is applied until the metal or primer is completely covered - the number of layers depends on the covering power of the material.

Applying a colorless base

Before applying the substrate (especially if the substrate is not just colored, but with metallic inclusions like ours), it is recommended to apply a layer of transparent base to the part (or most of it), designed to eliminate the visible boundaries of the repaired area.

When repairing three-layer coatings, it is not advisable to apply a colorless base to the primer area. Since there are still many layers ahead of us, the likelihood increases that a large amount of solvent from these layers will affect the soil, sub-dissolving it. This may cause the edges of the primed area to appear.

And since the task of a colorless base is to accept particles of the applied material in the transition zone, we will apply it precisely in this zone, without wasting it on the entire surface.

In our case, the mixture is applied starting from the beginning of the door and somewhere halfway, closer to the handle - it is in this area that the transition will be located.

Application of the substrate

The base substrate is applied in 2-3 layers, each of which should cover a larger area than the previous one. Waiting time between layers is 5-10 minutes at 20°C.

Sometimes it is recommended that after applying two covering layers, add a certain amount of “pure” mother-of-pearl to the base composition and apply another 1-2 layers of this mixture to the surface, gradually expanding the area to be painted. This technology allows you to bring the base shade as close as possible to the mother-of-pearl layer and thus make its border invisible. But remember, in order to “crank out” this action, the base and pearlescent paints must be prepared in the same resin system.

Another important point. Since the thickness of a three-layer coating is greater than that of a conventional two-layer coating, there is a possibility of a decrease in the adhesion and strength characteristics of the coating during further operation. To prevent this, manufacturers often recommend adding a hardener to the substrate - this increases the adhesion between the layers.

What is Xeralic?

Today there is a need to describe what Xeralic is, as there is confusion. In the literal sense of the word, this is an original pigment from Merck KGaA from Japan. Today, this name refers to any product with similar pigment additives, since many companies have a license to produce such paints.

Xeralic is an original pigment from Merck KGaA from Japan.

The substance is sold in the form of a dry pigment with a pearlescent color. During the dyeing process, a special application technology is used, which ensures a smooth and silky surface; it resembles a film with increased shine and shimmer. Initially, the material was developed to replace standard white pearlescent paint. Thanks to the use of a new approach to the composition of pigments, it was possible to create an innovative invention.

Conventional paint uses small muscovites (potassium mica), which provide a silvery tint. Xeralic paint includes aluminum particles, finely ground and with precise edges. Aluminum produces an enhanced shine that is enhanced by other metals in oxide form with enhanced reflective properties.

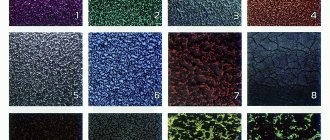

When comparing approaches, Xeralic will have a number of advantages:

- enhanced color saturation;

- does not distort the color of the substrate. Green and blue xerallic are often used, but even the black base will remain unchanged;

- at high and medium lighting levels, a shine effect appears, and in darkened rooms or at night a silky fabric is felt;

- The material’s iridescence exists in 4 planes, in standard mother-of-pearl – in 2, and in metallic – in 1.

Automotive paints Xeralic

The pigment can be added to various modern paints regardless of their form, this helps to paint the car in standard colors. Often a combination of several shades from the 7 main ones is used: yellow, blue, green, white, red, black and gray. Black xeral or just dark colors look most impressive. The impressive look comes in red, purple and silver variants.

When choosing a color, it is better to give preference to colors that are close to the base shade. Today, interesting versions of chameleon-type paints have been developed; they use coating of different faces of aluminum particles with different colors.

Application of “mother of pearl”

We remember how many layers of pearlescent paint we need to apply (this amount was determined by the test) and 15-20 minutes after applying the substrate, we smoothly spray the required number of layers with a wait of 5-10 minutes between them.

You need to apply mother-of-pearl in such a way that the painted area covers the applied substrate, but does not extend too far beyond its border.

Remember that the thickness of the mother-of-pearl layer greatly affects the shade. Therefore, if two or three layers of mother-of-pearl are required to obtain the desired shade, you still need to “enter” the transition zone with only one layer.

To do this, it is recommended to use the narrowing method shown in the diagram below. The first layer is applied to a larger area, and the second to a smaller one, remaining “inside” the first layer. Thus, at the junction of the old and new coatings, we will always have only one layer of mother-of-pearl and the repair boundary will not be noticeable, since the paint is transparent and the color transition will look smooth.

Applying varnish

After 15-20 minutes, the surface is varnished using standard technology (two, one and a half, or one layer, depending on the dry residue). In our case, the transition over the varnish is not performed and both elements are completely covered with varnish.

If you need to do a varnish transition, follow the instructions in the metallic gradation article linked above.

As you can see, despite the more complex technology, surfaces painted with three-layer “pearls” are quite amenable to the same types of repairs as two-layer ones, including painting with a “smooth transition”.

The described technology will allow you to make the repaired coating indistinguishable from the original, even despite the certain technological complexity of “pearl” paints.

Source

Pearlescent varnishes

Any paint requires reliable protection. The pearlescent color of the car is traditionally fixed with a special varnish used at the final stage of painting.

Such varnishes are mainly made on the basis of acrylic and are two-component.

Pearlescent varnish can be completely transparent or contain additional pigment. Today, manufacturers produce varnishes of various shades, with color fractions already added to them.

Based on consistency, varnishes are divided into liquid and thick. To use the former, a professional hardener may be required, and for the latter, a solvent.

In any case, the addition of optimizing compounds is carried out immediately before using the coating, in strict accordance with the instructions. Incorrect mixing can disrupt the structure of the composition, causing mother-of-pearl for cars to lose its unique properties.

The final coating technology depends on some features of the varnish:

- Colorless varnish can be applied to a painted body in one layer as the final painting process

- The use of varnishes that contain pearlescent color pigment will require three layers of coating. In this case, a transparent base is first applied, then a pigmented varnish with the selected color shade is applied to it, and finally another colorless layer is applied.

By color

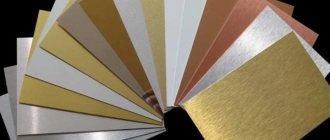

The palette of pearlescent paints is very diverse. However, the most popular are still the classic shades shown in the photo below: black, white, blue and red mother of pearl

Features and technology of painting cars with mother-of-pearl. What do you need to know?

The mother-of-pearl effect on car enamel can look especially chic. Of course, it will only be visible in daylight, and in sunny weather. However, this effect cannot be compared with metallic, although it is very similar. The play of light is very diverse - there are not only unusual reflections when a car is painted with mother-of-pearl, the same reflections also change color, depending on many factors. The main factor is the paint itself, but application technology is no less important.

Painting parts with mother-of-pearl is quite expensive. Moreover, the paint itself is not much more expensive than standard “metallic”. You can save money if you do the work yourself, especially since the work in this case costs the most. Moreover, it is not as difficult as the masters may tell you when they offer to use their services.

Features of white mother of pearl for cars

One of the most popular shades among car owners is white pearl (see photo below). It combines classic and spectacular, but at the same time requires special care when painting the car.

White mother-of-pearl is extremely sensitive to dyeing technology. Even a slight disruption in the dyeing process can ruin the color scheme.

For this reason, some car owners prefer another option - white metallic. But this type of coating cannot compare with pearlescent paint in terms of visual effectiveness. “Metallic” is a simpler and more unpretentious option, which today is even produced on a serial basis.

The best solution: turn to a specialized and reliable car service center for painting services.

If you still decide to carry out the work yourself, you need to carefully prepare and take into account all the nuances. Selecting components for painting is an important step. It is better to purchase the highest quality materials, after consulting with specialists.

The specificity of white color is that it not only does not hide various irregularities and defects of the body, but, on the contrary, emphasizes them.

To avoid such flaws, for painting in white pearlescent color it is recommended to use only the three-layer application method described above.

Mother-of-pearl coating is a worthy option for restyling the appearance of a car. And if you decide to make such an update, we wish you excellent results.

Technology for obtaining mother-of-pearl effect

In general, pearlescent paint is produced using approximately the same technologies as metallic paint. However, it is not the smallest particles of metal that give the unusual shine, but the smallest particles of mica.

The difference is that mica is translucent. If metal simply reflects light, according to optical laws, then mica no longer only reflects it. Or rather, it reflects, but also from the outer edge and from the inner one, where it passed through the thickness of the material. This is what causes the color change, all according to the laws of physics.

After all, light is an electromagnetic wave, and when the reflected rays are added out of phase, a peculiar picture is obtained, with many different wavelengths, and therefore with many color shades. But painting a car with mother-of-pearl is not as simple as it initially seems. Unless, of course, you take into account a number of nuances, and if you take into account...

Composition by layers of paint layer

In general, two main components are used - paint and varnish. Much is similar to working with metallic, but there are a number of differences. So several layers of varnish are needed to get the effect of depth. And the layers of varnish themselves will differ, and in composition.

Light interference as a principle for achieving pearlescent effect

The pearlescent effect is based on the physical concept of light interference.

Interference is an interesting and beautiful phenomenon. Without going into details, its meaning lies in the reflection of light rays from transparent parallel planes, which are located at a microscopic distance from each other, comparable to the wavelength of a particular part of the color spectrum.

The distance between these planes is so small that our eye is not able to see it and perceives two rays reflected from the lower and upper planes as one.

Interference of incident and reflected light rays

The distance between the first and second planes affects which part of the color spectrum will be reflected and what shade of mother-of-pearl our eye will catch. In other words, if the distance between the planes is proportional to the wave from the blue part of the spectrum, then we will perceive blue, and red - red.

As the viewing angle changes, these colors change. So, if you look at the interfering plane at a right angle, then the distance between the reflecting surfaces visually appears smaller, and we see one color corresponding to the wavelength of a given reflected part of the spectrum (with decreasing distance, the hue shifts to the violet region of the spectrum).

At right angles, the distance between the planes seems smaller and we see one color (moving into the violet region of the spectrum)

If we look at the plane from a sharper angle, then the distance between the reflective surfaces visually increases, and we see a different hue (with increasing distance, the hue deviates towards red).

At an acute angle, the distance between the planes seems greater and the color changes, moving towards red

It is this change in the intensity of the rays at the slightest movements of the eye, this color shift that is perceived by the eye as a “pearl” effect.

Life is full of examples of light interference. For example, a puddle into which gasoline has been spilled will shimmer with all the colors of the rainbow until the turbulence of the water calms down and a transparent film of gasoline lies on the water in a layer of the same thickness.

Or a soap bubble. The light is reflected from both walls of the bubble and where the wall is thinner, the colors go purple, where it is thicker we see a reddish spot.

The most obvious example of the phenomenon of light interference is soap bubbles.

The general condition for replicating this effect is two or more reflective planes placed parallel and at a very close distance from each other.

The components of pearlescent paints are made precisely according to this principle.

In fact, each pearl particle is a miniature prism, with the help of which Newton at one time decomposed light into its seven components. Only pearlescent pigment does not completely decompose light into its component colors, but does so selectively.

a) refraction of light rays by a Newtonian prism; b) refraction of light rays in a grain of mother-of-pearl

Thanks to this, we see not just the color of mother-of-pearl pigments, but light of a certain color range, which is refracted in particles of mother-of-pearl and perceived by our eyes.

Painting a car with pearlescent paint - photo, video

Every car owner dreams of his car shining and shimmering in the rays of the sun, and a pearlescent color is chosen specifically for this purpose.

As soon as this color appeared in the painting palette, it began to be used to paint expensive cars, then it was believed that only wealthy owners could take advantage of such luxury.

In addition, achieving a smooth transition of shade is very difficult. The feeling of luxury remains, but everyone can afford such a procedure.

Why is everyone so attracted to this color? The point is its ability to change shade - from golden to one-time, in the shadow it can generally shimmer soft cream.

Pearlescent color - types of paints

The shade of pearlescent paint changes due to its constituent components. When exposed to light, this effect is achieved due to synthetic crystals, which are colored only on one side.

Decorative properties are provided by the process of mixing mother-of-pearl with the base of the coloring paste. The concentration of elements depends on the preferences of the car owner and the result he wants to get.

On average, a normal solution requires 100 grams per 10 liters.

There are several types of paints, and they are classified according to the following criteria:

In the first case, pearlescent pastes can be presented in any shade due to the fact that the paint with shimmering mica pigments is diluted. Drivers often choose the following colors: silver, blue, red, white.

Although the white shade is popular, you need to be prepared for the fact that it requires special care. If a chip or swelling appears on the surface, it will be immediately noticeable with this color.

To avoid streaks and fading, future owners of a white pearlescent shade will have to thoroughly mix the paint with a solvent. The remaining shades are not so whimsical; once a stain appears, it can be retouched, and it will not be so noticeable.

As a rule, when cracks appear, they try to completely repaint the car.

The consistency directly determines how much the surface will shimmer. The mica particles must be larger; this is the only way to achieve a brighter color and refraction.

What is the specificity of the color “mother of pearl”?

This color, in turn, is characterized by a “pearl” effect: the surface layer of paint on the car becomes similar to the inner layer of mother-of-pearl mollusk shells. Depending on the structure of the coloring matter, “mother of pearl” can acquire different shades and pattern structure. The peculiarity of the car paint in question is its ability to shimmer in several shades.

A “pearlescent” effect on the surface of a car can, in principle, be achieved by adding the same metal particles to the coloring matter, but present in significantly greater quantities than in metallic paint, and, as a rule, located in several layers. But in practice, the main component of “pearlescent” paint is most often mica particles, which are coated with a layer of aluminum oxide. They usually have a flat shape and vary in size - the reflection of light from their surfaces creates a shimmering effect, due to which the paint becomes “pearl-like”.

Another important component of “pearl” paint is a special varnish - largely thanks to its presence on the surface of the car, a characteristic effect is formed.

As in the case of metallic, pearl color can be presented in a large number of shades. They can, subject to certain technology, be mixed with each other in various combinations.

How to get pearlescent color

It is very difficult to obtain a white pearlescent shade. To do this, it is necessary to use special pigments that can reflect color.

When a ray of light hits the pigments, a beautiful iridescence is formed, which changes shade depending on the viewing angle. It is worth noting that mother-of-pearl painting is recommended for use in certain weather conditions and for careful drivers, because in the event of serious impacts, it will not protect the body from scratches and chips.

Drivers are presented with a wide range of bright and soft shades. To make the car more noticeable, no additional textures or frills are required.

You can simply mix two or even three unique shades, which will allow you to prepare an exclusive coloring composition.

Follow some recommendations when applying pearlescent paint, and you will certainly get an impeccable result; it’s always nice to show off such a machine to your loved ones:

1. Visual depth can be achieved by double and triple painting. But do not confuse “mother of pearl” with metallic and chameleon shades.

2. When selecting all the components for painting, try to select one specified brand. Simply, formulations of different brands may reject each other, and cracks or swelling may appear on the surface of the car.

Multi-layer painting of the body surface cannot be avoided if you decide to achieve an iridescent effect.

3. The most difficult task when painting is creating uniform highlights on the body. This effect can only be achieved if the paint used is the same temperature as the car body.

If it's colder, the shimmer effect will look completely different. The difference between such transitions will be visible to the naked eye. The same temperature of the paint and the surface guarantees strong adhesion to the metal.

Before application, the surface must be highly polished, because all defects will appear as it dries.

4. The shade of the base should be the same as the base one; the sooner you apply it after cleaning, the better it will affect the body.

5. When making paint, check its fluidity by diluting it with a solvent. Apply the paint in two layers, and be sure to seal the result with varnish. It is applied in several layers.

The first with a minimum amount of solvent. Usually 30-40 minutes are enough for the solvent to evaporate and the layer to dry, then you can carry out the procedure again to fix the varnish layer.

Many people recommend contacting specialists who will advise you on choosing a color. He will also be able to tell you what kind of paint or pigment can achieve the desired effect.

It is worth remembering that this paint is more capricious.

Even after a heavy rainfall, a poor coating can be damaged. Do not skimp on materials and then you will be confident in the result. This is almost the only negative, otherwise you get an original and beautiful appearance.

Be sure to study the recommendations indicated in the paint content; during work, do not forget about protective equipment.