Primer VD AK 133-1: technical characteristics and parameters, features of painting work

Speaking in official language, the acrylic primer VD-AK-133 according to GOST 28196-89 is considered as a water-dispersion paint, although, based on its parameters, such a mixture can be considered one way or another. However, after getting acquainted with its technical characteristics, you will see for yourself, although, by and large, the value of a product is determined not by its name, but by its quality.

We will talk about all this below, and also, as additional material, watch the thematic video in this article.

VD-AK-133-1

Description of material

Primer VD-AK-133 is prepared in accordance with GOST 28196-89 and is a water-dispersion paint that has a variety of useful properties. The product contains the following components:

- water;

- various additives, fillers;

- aqueous acrylic dispersion;

- surfactant;

- biocide

The material is designed to improve the adhesion of various surfaces, as it forms a film and protects subsequent layers of enamel. The soil fits perfectly on wooden, metal, concrete (including cellular concrete), gypsum, fiberboard and chipboard, plasterboard, brick, and natural stone. It is also permissible to apply the product to cement-sand screeds and various plasters. To increase the elasticity of building materials, soil can be added to them before direct use. At home, the material is often used before wallpapering.

A distinctive property of the primer is the ability to protect surfaces from moisture, so it should be used where high requirements for moisture protection are imposed. The material is ideal for interior work - it is environmentally friendly, has no unpleasant odor, and does not produce harmful fumes.

The coating formed by VD-AK-133 soil has the following qualities:

- has no color;

- highly elastic;

- air permeable;

- helps destroy dust;

- reduces paint consumption.

It should be remembered that such a coating does not provide anti-corrosion protection, so it is not capable of protecting metal from rust.

What is it used for?

Many novice builders do not attach much importance to the primer underneath the decorative surface.

As a result of this, after some time the following defects appear on the surface where a layer of plaster or wallpaper was applied:

- wrinkled surface;

- the appearance of cracks on the surface;

- swelling of the coating.

If you use an acrylic primer, then you can appreciate its protection against surface distortion. The composition after application forms a dense film, and there is improved adhesion and protection for the top layer of enamel. This improves the surface gloss.

Another feature that forces the use of such coatings is that the wall after the soil mixture becomes resistant to liquids getting on it.

The important point is that almost all types of soil mixtures can be applied to any surface.

The mixtures vary in composition: they can be produced on a water basis or on organic solvents.

Those mixtures that are made with organic solvents are most suitable for external surfaces, which can sometimes be exposed to precipitation.

For interior work, it is recommended to choose water-based acrylic primers. They lay smoothly and in terms of environmental components are much higher than those soils that are used in external work. In addition, they do not have an unpleasant odor or emit harmful fumes.

Advantages and features of acrylic primer

No preparation of walls, ceilings or floors takes place without first applying a primer. The use of this material is due to the improvement of the adhesive properties of the base and the extension of the service life of the entire finish. Today we will get acquainted with one of the most common types of primer, find out the technical characteristics of the compositions and find out what makes acrylic primer so special.

How do mixtures work?

The principle of operation for all adhesive compositions is the same, the difference lies in the method of application, drying time and the type of surface for which the primers are intended. The current solution performs the following functions:

- Penetrating into the surface, it strengthens it, creating a solid basis for finishing.

- Improves adhesion of surface and cladding

- The vapor permeability of the base is maintained

- It has anti-corrosion and antiseptic properties due to which mold, mildew and rust do not destroy surfaces

- Improves density due to reduced porosity, thereby reducing the consumption of finishing materials

- Priming makes it possible to protect and isolate the finish from the appearance of greasy stains and other contaminants that cannot be washed off

Important! Depending on the material, the primer can have deep penetration, which allows it to be used on loose surfaces. For some manufacturers, stated readings reach 10 cm.

Acrylic primer for walls that do not absorb water well serves as the basis for subsequent treatment with gypsum, plaster, and lime mortars. Among the variety of surfaces, the following are optimal for applying acrylic primer:

- Drywall

- Concrete

- Fiberboard

- Tree

- Plywood

- Monolithic slabs

In addition, it is necessary to prime surfaces under linoleum, laminate and tiles. Universal compositions are made for façade and interior work; their suitability for certain processes is described in the instructions for the primers.

Important! Wood is most susceptible to the negative effects of moisture; antifungal additives make it possible to protect it as much as possible from putrefactive processes. Processing is necessary even in the furniture manufacturing process.

A primer is necessary if:

- Wallpapering - if the soil is used for wallpaper, you can save on the adhesive solution, which is consumed several times less

- Painting - if it is not possible to clean the base from contamination, then the primer will serve as a barrier. Using a tinted primer, which is produced in accordance with all GOST standards, it is allowed to carry out intermediate painting

- When the finishing is plaster, putty, gypsum - the peculiarity is that after drying a rough surface is created, which tends to firmly adhere the finish to the base

- In addition, primers are used for laminate, linoleum and tiles

Advantages and features of choice

The quality of the preparatory work depends on the type of primer, manufacturer, its composition and additional fillers. Acrylic primers are distinguished by their versatility, their ability to strengthen various substrates, and prepare the facade for finishing using paints and putties. Weather-resistant soils are not afraid of mechanical damage and protect the base from wind and moisture for a long time.

Advantages of acrylic primers

An important condition for the use of acrylic primers is their environmental safety. The manufacturer creates a solution that is water-based or contains a small percentage of solvent. Thanks to this, you can prime the rooms inside the house and not worry about the presence of an unpleasant odor. When using solvent-soluble mixtures, you should remember their toxicity, for which it is necessary to use primers for street work. To buy good soil, you need to pay attention to the following nuances:

- Type of surface - if you plan to finish various substrates, then acrylic primers are most suitable for these purposes

- Choice or tinting of color - the peculiarity lies in what type of finishing will be used

- For each material there is a description, thanks to which you can choose a mixture. One type will be suitable for plastic, glass, plaster, varnish, paint, tiled decor, plaster. This is preceded by additional substances that are used in production

- Economical - acrylic mixtures are considered the most economical due to organic resins

- How long will it take for the base to dry - water-based materials tend to dry faster. Water-dispersed primer is optimal for most tasks

- A quality certificate for the material is a mandatory criterion when choosing a primer. Any production of building materials must be accompanied by GOST standards

Important! Poor-quality solutions do not perform their stated functions, and can also be harmful to health, since components of dubious origin may be used in their manufacturing process.

Primers are also distinguished by the form of their release. Stir the prepared solutions well enough before use; they do not need to be diluted. But concentrates need to be diluted until ready before starting repair work. If you are preparing a car or its parts for painting, you can consider the option of using an aerosol primer. The quick-drying solution in the can just needs to be shaken before use.

We recommend: Primer of drywall before puttying - is it necessary to do it?

Proven and sought-after manufacturers

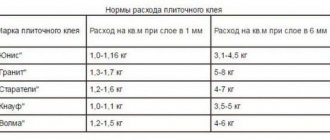

Among the large number of acrylic primers, you should consider the most popular ones and analyze their features. A small table presents the basic data:

| Name | Features, comparison, difference |

| Dufa tiefgrund acryl hydrosol | For treating exterior surfaces and inside the house. Has antiseptic properties. Suitable for rooms with high humidity levels. Area of application: kitchen, bathroom, swimming pool, toilet. It has a neutral smell. Tif soil is an environmentally friendly product and has the ability to bond and strengthen the treatment area. Storage is allowed in a dry and cool place |

| litocol | A water-dispersed solution that is used to prepare internal surfaces, as well as before floor screed. It is distinguished by its ability to lay down in an even layer on cement, aerated concrete, and brick surfaces. |

| Caparol dupa grund, 10l | For subsequent application of acrylic or alkyd enamels. It is allowed to treat surfaces before applying paint to them. The liquid solution has a pleasant smell, which makes it stand out from other primers. The dispersion material is quick-drying |

| braska | The primer, which is a deep-penetrating mixture, strengthens concrete and porous surfaces. The colorless material is used as a coating for painting, finishing with decorative material and plaster. |

Acrylic primer VD AK 133 technical characteristics:

- According to GOST, it is considered as a water-dispersed coating material, which after application must be homogeneous and free from cracks and sagging

- The output building element should be dark green, red, dark red or dark brown.

- Viscosity – 20

- Covering power – 80g/m2

- Adhesion – not less than 1 MPa

- Consumption indicators – 180-210g/m2

- Frost resistance during storage - temperatures below +5 degrees are not allowed for transportation and storage

Advantages of acrylic primers

Acrylic primer Nortex primer its technical characteristics:

- Refers to universal compositions with an acrylic base, which can be used as a primary treatment on various substrates - drywall, stone, wooden surfaces. In the future, they can be painted, glue applied for finishing wallpaper or tiles, as well as putty.

- White color

- Appearance – uniform

- Acidity – 5-6

- Application method: brush, spray gun

- Drying duration – at optimal temperature about 1 hour

- Consumption indicators: for wood from 90 grams per 1 m2, for concrete from 120 grams per sq. m

If you need to prime smooth surfaces - metal, glass, then thick primer can be diluted according to the recipe 1:1 with water. The primer is applied to hygroscopic substrates without prior dilution. If required, you can use dye or pigments for tinting the soil. Acrylic primer Nortex primer price per package 1 kg, 3.3 kg, 10 l:

- Bucket 3.3 kg – 220 rubles

- Bucket 10.5 kg – 615 rubles

- For 1 liter – about 70 rubles

Important! Photo, video lessons and master classes for beginners give you the opportunity to carry out all the repair work in your home yourself.

Primers for paint

If you decide to paint the ceiling or walls, but have not yet selected the necessary primer, then there are several standards for selection. By choosing the right primer, you will be able to quickly and efficiently prepare the base for further cladding. First of all, you should remember that oil paints are applied only to oil paints if it is not possible to clean the surface of the old coating. Primer over old paints is allowed in the following cases:

- If there is no glossy finish

- If the paintwork does not peel off, otherwise it is necessary to remove the falling off coating

Primers for acrylic paint are made with acrylic universal compounds, which have high adhesion and significantly strengthen the walls, extending the service life of the new finish. Any interior requires investment and saving on primer can ruin the entire euro renovation.

Important! Concrete contact primer, which strengthens porous and crumbling surfaces, is even sold on tap. These include premium acrylic primer at a price of 35 rubles per 1 liter.

Among the popular primers, Volm, Knauf and Brozex should also be noted. Anti-corrosion, acrylate, alkyd-acrylic, water-based compositions are used for certain surfaces and require compliance with storage and use conditions. If it says on the package, then the solution is definitely frost-resistant. The degree of frost resistance, viscosity and hiding power is displayed on the packaging.

Important! For primers AK-069 and AK-070, GOST 25718-83 is used.

You should buy primers only in specialized stores, where they will tell you about the differences between the mixtures, help you replace and select a manufacturer, and also provide you with all quality certificates for the product.

Features of using AK 070

Before priming, the base is prepared. It is recommended to remove dust and rust (if necessary), and degrease the working surface.

Sometimes additional use of solvent is required. It is added to no more than 15 percent of the total mass of the primer material.

Then a layer of AK 070 is sequentially applied to the surface. Work with primer in dry weather, without precipitation or fog. If the priming process is carried out in sunny weather, it is worth shading the treated surface for uniform absorption.

Technical standards for drying to a state of readiness for overcoating with the following layers:

- At a temperature of 5 degrees – 3 hours;

- From 5 to 10 degrees – 90 minutes;

- At 20 degrees – no longer than an hour;

- In a temperature range of 30-32 degrees, the primer dries in 10 minutes.

Time indicators are approximate, since the external environment (air humidity, gusts of wind, etc.) significantly affects drying. If painting was done indoors, do not forget about the need for ventilation to evaporate volatile substances. Do not artificially increase the temperature; this will cause an unwanted film to form on the surface, which will prevent the solvent from evaporating.

Different types of containers for primer AK 070

Let us add that after drying the layer acquires one of the shades of yellow, which does not have standard indicators.

Further painting is carried out in one or two layers, which are sufficient to ensure good quality of the coating.

The consumption of the substance per square meter of surface varies, but does not exceed the norm of 136 grams. Under optimal conditions, this figure ranges from 90 to 100 grams per square meter of processed material.

How to apply primer correctly:

Application of the product

Before using the primer mixture, you must make sure that the base is strong and does not crumble or chip. All cracks should be sealed and loose areas should be swept. You must also remove:

- oil stains;

- paint drips;

- lime, glue.

If plaster or putty has just been applied to the wall, you must wait for it to completely set. For many plasters you will have to wait a week, and for sand-cement coatings - up to a month.

All work is performed using rubber gloves. Because there are no toxic substances or solvents in the product, using a respirator is not a necessary condition. At the beginning of work, the primer mixture is thoroughly mixed, if the volume is large, then this should be done using a mixer. Prime at a temperature not lower than –15 degrees; if external surfaces are painted, it is necessary to select dry weather without much wind. Priming is done manually with a roller or brush; large surfaces are treated with a sprayer.

Soil consumption per 1 m2 and how long does it take to dry?

The primer consumption will depend on the temperature its application will be carried out. Another important point will be the application technique.

If you cover the surface with a roller, then the consumption will be significantly reduced, and if you use a brush for painting, then it will increase.

The approximate consumption for acrylic soil mixtures is one liter per area of twelve to fifteen square meters.

After the primer is purchased, it must be inspected, because the instructions indicate the time during which it can dry completely.

It is important to consider the fact that many deep penetration mixtures require some time between subsequent coatings. This period must be at least 24 hours .

Acrylic mixtures can dry completely in half a day. The time it takes for the primer mixture to dry will be influenced by factors such as:

- temperature and humidity level in the room;

- level of porosity on the surface to be coated;

- thickness of the applied layer.

All about the product

Specifications

Note. Below are the technical characteristics of the primer VD-AK-133-1, as a water-dispersion paint with various additives based on acrylic dispersion.

Manufacturer's logo

- When applying the composition to the surface according to TU BY 500021625.090-2007, the color should be green, dark steel, dark blue, dark brown, dark red, old red and red. Deviations are allowed only within the limits established by control color samples.

- The appearance of the coating after its application should be uniform, without corrosion, pores and wrinkles.

- According to the VZ-246 viscometer with a nozzle 4 mm in diameter at a temperature of 20⁰C±0.5⁰C, the conditional viscosity should be equal to 20. In this case, the degree of grinding is at least 20 µm.

- The pH of the paint is from 8 to 10, and the mass of non-volatile substances is about 54%! At temperatures from 40⁰C to 50⁰C, the third degree drying time is no more than 10 minutes.

- Adhesion for VD-AK-133-1 is not less than 1 MPa. The covering power of the composition after drying is no more than 80g/m2. At temperatures from 18⁰C to 22⁰C, the film’s resistance to static water is at least 24 hours. Color fastness no more than 3∆.

We recommend: Features and rules for applying primer GF-0119

Other options

You can apply the primer with a paint roller

To apply this primer paint to the surface, you can use a brush or a paint roller (preferably made of mohair or wool) at the initial viscosity of the composition. But the instructions also allow you to do this with a spray bottle, only in this case it should be diluted with water to a viscosity of 18-20 (data from the VZ-246 viscometer) and use a nozzle diameter on the spray gun of 4 mm.

At temperatures from 18⁰C to 22⁰C, the primer is applied in two layers with an hour break, while the consumption of acrylic paint VD-AK-133-1 ranges from 180 g/m2 to 210 g/m2 (the manufacturer provides a six-month guarantee from the date of manufacture of the product).

In industry, this primer is used for protective and decorative painting of asbestos-cement slate sheets, which are heated to a temperature of 40⁰C to 50⁰C, but if you do it yourself at home, you can paint the slate with a brush, but the temperature should not be lower than 15⁰C.

This paint is also used for exterior finishing (gables, facades) and for interior coatings in rooms with high humidity (kitchen, bathroom). Practice has shown that wallpaper adheres well to walls coated with VD-AK-133-1, as excellent conditions for adhesion are created.

Also, the technical characteristics of the acrylic primer VD-AK-133-1 make the coating neutral to the formation and activity of microorganisms, that is, there is no breeding ground for organic colonies such as moss, mold, algae, lichens and rot.

The weather resistance of the paint is expressed in its resistance to temperature changes, precipitation and ultraviolet radiation (does not fade from sunlight), in addition, the material in any state (liquid or dried) does not pose a fire risk.

Insulated van

Transportation and storage of the VD-AK-133-1 primer is carried out at a temperature of at least 5⁰C, that is, negative temperatures during transportation and storage are absolutely unacceptable, although frost is not particularly important for performance. So in winter, storage is carried out exclusively in heated warehouses, and transportation is carried out in insulated trucks and cars.

Painting works

In the photo - grouting plaster

Before applying a primer to the surface, you should make sure that the rough base is suitable, that is, it must be solid (without loose areas) and there must be no cracks on it. In addition, there should be no grease stains, old paint, lime or wallpaper glue (if it is interior decoration), since all these factors significantly reduce the adhesion properties.

In cases where the plaster or putty is fresh, you should wait until it is completely dry, and if for rotbands and putties this period lasts a maximum of a week, then for cement-sand plasters this period is 28 days.

Mixing paint

Before starting painting work, VD-AK-133-1 must be thoroughly mixed, for which you can use the most ordinary wooden stick or a piece of thick wire, but if the volume is large, then this should be done with a mixer clamped into an electric drill (the mixer is specially for paint).

In addition, you should pay attention to the weather conditions if everything happens outside - the air temperature is allowed to be at least 15⁰C, without any precipitation (rain, hail, fog, strong wind). Before use (after stirring), the composition is filtered through a 0.1-0.2 mesh (GOST 6513).

Recommendation. It is best to use a paint roller for smooth surfaces such as cement-sand plaster, rotband and putty. For decorative plasters, it is much more practical to use any type of sprayer or brush for hard-to-reach places.

Performance characteristics of acrylic-based primer VD-AK-133

If you do not pay enough attention to priming the surface before painting, there is a risk of defects appearing in the future. These are cracks, swellings, wrinkles that shorten the service life of the decorative layer. Acrylic primer VD-AK-133 is widely used in construction and repair and helps create a durable, reliable coating.

Description of material

Primer VD-AK-133 is prepared in accordance with GOST 28196-89 and is a water-dispersion paint that has a variety of useful properties. The product contains the following components:

- water,

- various additives, fillers,

- water acrylic dispersion,

- surfactant,

- biocide

The material is designed to improve the adhesion of various surfaces, as it forms a film and protects subsequent layers of enamel. The soil fits perfectly on wooden, metal, concrete (including cellular concrete), gypsum, fiberboard and chipboard, plasterboard, brick, and natural stone. It is also permissible to apply the product to cement-sand screeds and various plasters. To increase the elasticity of building materials, soil can be added to them before direct use. At home, the material is often used before wallpapering.

A distinctive property of the primer is the ability to protect surfaces from moisture, so it should be used where high requirements for moisture protection are imposed. The material is ideal for interior work - it is environmentally friendly, has no unpleasant odor, and does not produce harmful fumes.

The coating formed by VD-AK-133 soil has the following qualities:

- has no color

- highly elastic,

- permeable to air,

- Helps eliminate dust

- reduces paint consumption.

It should be remembered that such a coating does not provide anti-corrosion protection, so it is not capable of protecting metal from rust.

Primer characteristics

The technical characteristics of the product are established by the above state standard. Each batch has a certificate of conformity, a certificate and a hygiene passport. Here are the main parameters:

- the appearance of the film is smooth, without pits, pores, wrinkles, inclusions,

- conditional viscosity according to the VZ-246 device at a temperature of +20 degrees – 20 s,

- degree of grinding – 20 microns,

- the share of non-volatile substances is 54%!,

- pH of the product – 8-10,

- drying time at temperature +40…+50 degrees – 10 minutes,

- adhesion – up to 1 MPa,

- film coverage – 80 g/sq. m.,

- resistance to water at a temperature of about +22 degrees – 24 hours,

- Primer color – white, upon request – brown, black and others.

We recommend: Primer for plywood - features of choice

The resulting coating perfectly withstands temperature changes from –45 to +60 degrees. It will be resistant to precipitation and ultraviolet radiation (does not fade). A layer of dry soil does not pose a fire risk.

Application of the product

Before using the primer, you need to make sure that the base is strong and does not crumble or chip. All cracks should be repaired and loose areas should be swept. You should also remove:

- oil stains,

- paint drips,

- lime, glue.

If plaster or putty has just been applied to the wall, you need to wait for it to dry completely. For most plasters you will have to wait a week, and for cement-sand coatings - up to a month.

All work is carried out wearing rubber gloves. Since there are no toxic substances or solvents in the product, using a respirator is not a requirement. Before starting work, mix the primer thoroughly; if the volume is large, then this should be done using a mixer. Prime at a temperature not lower than –15 degrees; if external surfaces are painted, you should choose dry weather without strong wind. Priming is done manually with a roller or brush; large surfaces are treated with a sprayer.

Consumption and storage

Consumption per layer is approximately 180–210 g/sq.m. m. Usually the product is applied in two layers. After the first layer has completely dried, apply the second; drying time at normal temperature is 1 hour (if the temperature is below 20 degrees, it is better to wait 2 hours).

The material should be stored for 6 months (recommended shelf life), and the temperature should not be less than +5 degrees. Freezing does not matter for performance properties, but the manufacturer does not recommend keeping the soil in the cold unless absolutely necessary. They transport it in warm trucks and cars.

Main characteristics of VD AK paint of different series

Anastasia Isakova · 10/28/2017

VD AK paint differs from other enamels in its unique composition, which is represented by polyacrylates and their copolymers. The finishing material is used at any stage of repair work and is suitable for painting almost all types of surfaces: wood, plaster, brick, concrete. Let's take a closer look at the properties and characteristics of VD AK paints.

Basic properties

The water-dispersed base is the main advantage of the finishing material.

The optimized composition of the paint and its unique components allow you to process any textured interior item and paint the surface of stone, wood, brick, concrete, as well as plastered walls.

Due to the high-quality dispersion of pigment components, the most significant defects are masked. In addition, the high wear resistance of VD AK paint is higher than that of other enamels.

Important! Some water-based paints require the use of a primer. Such primary treatment is also required when repainting interior items or facades.

Popular products

There are several types of VDAK paints, each of which has its own unique properties and purpose. General description of the most popular products:

- Paint VD AK-1180. Used as a base for initial and secondary coatings. Weather-resistant, moisture-resistant, covers a wide color spectrum. VD AK-1180 paint is popular in the construction of large industrial facilities.

- Paint VD AK-111. Thanks to its unique composition with a latex base, the paint becomes more resistant to mechanical stress and natural factors.

- Paint VD AK-101. The material is suitable for painting surfaces of any type. This paint dries quickly and is completely environmentally friendly, which allows it to be used for interior work.

The most popular paint for exterior work is VGT VD AK-1180 enamel. The material is intended for painting concrete, wooden and plastered walls; it has high water and weather resistance. VGT 1180 facade paint is excellent value for money.

Water-dispersion paints VD AK of other types are used less often or have a narrow profile with limited application properties, for example, painting floors, painting wooden structures, etc. Below we will consider in more detail the technical characteristics of the different options.

On video: features of water-based paints.

Characteristics of different series

Depending on the series, the main scope of application of such paint and varnish products is determined. There is a difference between VD façade paint and universal enamel for interior painting. However, both have acrylate properties, which increases their functionality.

Specifications:

- Paint VD AK-1180. Almost universal in its application, it is used for painting metal, concrete and wooden surfaces. A huge plus is that VD AK-1180 paint does not contain heavy chemical compounds. The enamel is applied at a temperature not lower than +5 and not higher than +35 degrees.

- Paint VD AK-111. Ideal for interior and exterior finishing, it is weatherproof and waterproof, which extends the service life of the coating to five years. However, water-dispersion paint VD AK-111 cannot be used for painting floors, since it quickly wears out under intense loads and friction.

- Paint VD AK-2180. This is an interior finishing material that is suitable for painting walls and ceilings in rooms with moderate humidity. Also, acrylic paint VD AK-2180 is ideal for painting wallpaper.

- Paint VD AK-101. Designed for painting building facades and internal load-bearing structures made of plasterboard, chipboard, fiberboard, non-toxic, forms a special weather-resistant layer that protects the surface from mechanical damage. Another advantage of VD AK-101 paint is that it retains an aesthetically attractive appearance for at least eight years.

- Paint VD AK-449. Used exclusively for painting floors and some other wood surfaces. It has a pleasant color, is fireproof, odorless, and creates a wear-resistant and durable coating. Eliminates rapid wear.

- VD AK-114. This is a matte aqua enamel, which is applicable in atmospheric conditions and for interior decoration. Ideal for wet rooms (bathrooms, kitchens, swimming pools), for walls and ceilings in children's and medical institutions. There is a huge range of colors.

In addition to paints, VD AK-0301 primer is often used. It is ideally combined with any of the enamels of the presented series, and is intended for treating walls indoors and outdoors (before painting, puttying walls, installing ceramic tiles). The primer is stable, lays down in an even layer and completely fills porous, defective areas.

Types of primer

By choosing a universal acrylic primer, you can coat almost any surface. It can be used to process plaster, metal, concrete and brick equally well. But if a targeted effect is needed, for example, reflecting sunlight or enhancing protection against corrosion, then it is preferable to use a specialized mixture.

But a universal primer for wallpaper will work just fine.

The acrylic primer, the characteristics of which are described in this article, may also contain alkyd fillers. Such mixtures are used for treating wooden and metal surfaces. This type of primer is the most suitable option for untreated wood, as it expands its structure.

As a result, ideal conditions are created for applying the finishing coating. If you have to process a metal surface, then a similar composition can be used as a finishing finish. But this type of mixture has one limitation, expressed in the fact that the composition cannot be used to treat surfaces that have been covered with plaster or gypsum, since the alkyd can make the surface fleecy.

When considering acrylic primers, we can also highlight those that are intended for working on metal. Such compositions can protect the material from premature corrosion. Different types of metals must be treated with certain primers, since the characteristics of each of them are different. For example, for aluminum it is preferable to use compositions that contain a high content of phosphates.

This will protect the material.

Acrylic primer, whose characteristics are determined by GOST 17537, can also be intended for use on concrete. As a rule, such mixtures are used under enamel coating. For concrete, polyurethane primers are best suited, which is true for floors, while for walls it is better to use simple mixtures.

Additional Information:

Technical characteristics Color: white, tinting possible with Diva-color paint. The base is acrylic latex. Latex-based acrylic primer technical specifications? Drying time - 1 hour at 20°C and relative humidity 65%. Viscosity - no less than 120 sec.

Adhesion - 1 point. Resistance to water - at least 48 hours. Application temperature from +5°C to +30°C at a relative humidity of no more than 80%.

7.1 In order to protect the atmospheric air from pollution by emissions of harmful substances from enterprises, control over compliance with the standards for emissions of pollutants into the atmospheric air, established in accordance with the requirements in the field of atmospheric air protection, must be organized.

7.3° In order to protect the atmospheric air from pollution by emissions of harmful substances, constant monitoring of compliance with maximum permissible emissions (MPE) is organized using calculation and instrumental methods approved for use by the federal executive body specially authorized in the field of atmospheric air protection.

Many craftsmen know firsthand that concrete cannot be fully bonded to the finish. Therefore, in order to increase the level of adhesion, experts recommend a special primer for concrete surfaces. It is deeply absorbed into the material and provides reliable adhesion.

9.7 Determination of the expected service life of the coating is carried out according to GOST 9.401. A coating based on VDLKM is exposed to artificial climatic factors, after which the safety of the protective and decorative properties of the coating is assessed in accordance with GOST 9.407. Test methods and the number of cycles are selected depending on the operating conditions of coatings in accordance with GOST 9.104, types of atmosphere in accordance with GOST 15150.

9.7 Determination of the expected service life of the coating is carried out according to GOST 9.401. A coating based on VDLKM is exposed to artificial climatic factors, after which the safety of the protective and decorative properties of the coating is assessed in accordance with GOST 9.407. Test methods and the number of cycles are selected depending on the operating conditions of coatings in accordance with GOST 9.104, types of atmosphere in accordance with GOST 15150.

The task of a universal acrylic primer according to any GOST is to create a reliable reinforcement for the base surface.

This is important so that the repair will last not for several months, but for a long time.