CMC adhesive has been one of the most popular solutions used for wallpapering for quite a long time. Providing strong and reliable gluing of sheets to the wall surface, it has another, very important advantage.

There are many types of CMC

So, unlike some analogues, this adhesive composition can be diluted, in fact, at any water temperature. And at the same time, no clots, lumps or various forms of sediment will form in the adhesive solution. All this is due to its operational and technical characteristics, as well as the chemical properties of the raw materials.

Composition of the solution

The composition of CMC glue consists of shavings formed as a result of processing wood material at the factory.

The prepared solution has high adhesion to many surfaces (concrete, stone, wood, plaster, etc.), except metal. Wallpaper is of varying quality and weight. Before purchasing, the outgoing material is evaluated, since for heavy wallpaper it is better to take a more concentrated product.

Composition of the solution: adhesive powder – 55 percent, sodium chloride – 20 percent; moisture – less than 12 percent. The finished solution will be obtained after 2 hours. To prevent the mixture from spoiling, it is worth adding potassium-aluminum sulfate.

Interesting video about the topic:

Types, composition and technical characteristics of wallpaper adhesives

Chemical enterprises produce their own type of CMC for different types of wallpaper. The features of each are indicated on the label or packaging. In any composition, the base substance must be at least 50 percent, and the proportion of sodium chloride must be 21 percent. The humidity of the mixture is up to 12 percent. The solubility of the powder is 96 percent.

CMCs differ in composition and percentage of carboxymethylcellulose. Almost all manufacturers produce universal adhesive that can be used for gluing all types of wallpaper. For each finishing material, its own solution is prepared, in which water is taken in larger or smaller quantities.

For light thin wallpaper

For the thinnest paper wallpapers, it is recommended to use KMC Burny, KMC-N, KMC-1 (Shavings). The form of glue is a white or pink powdery substance, without any odor. Before use, the powder is diluted in water according to the instructions for use. The adhesive solution applied to the surface takes a long time to dry. During the renovation period, make sure that there are no drafts in the room.

Medium weight

Non-woven wallpaper is considered slightly heavier than paper wallpaper. For their gluing, CMC-N or CMC-N Super-Max, Mini-Max, Extra Fast are used. This product is a powder of small granules. The packaging must indicate the type of wallpaper for which the adhesive is used. Any glue is diluted with water according to the instructions.

Thick heavy wallpaper

Inyl wallpaper is considered the heaviest. To cover surfaces with thick wallpaper, use CMC Super Strong. In sTo cover the surface with thick wallpaper, use CMC Super strong. PVA glue is sometimes added to the remainder of the adhesive composition. Externally, glue for heavy wallpaper looks like a white fibrous mass. Before use, the product is diluted with water in the dosage specified in the instructions.

Main characteristics

CMC wallpaper glue is protected from the formation of mold and mildew, which will not appear on the wallpaper. If the composition includes sodium tetraborate, then there is no need to worry about the appearance of insects. Due to these characteristics, the powder is often added to putty mixtures and concrete solutions.

This product is produced at Russian and foreign enterprises.

Main technical characteristics:

- composition humidity up to 12%;

- 96-100% soluble in water;

- infusion, swelling of components, activation of properties - 2-3 hours;

- When ready, it can be used within a week.

The amount of water added depends on the density of the wallpaper: for thin material - 8 liters of water per half a kilo of powder; for thick fabrics - 7 liters of water per half kilo of powder.

In order for the glue to fully activate its properties, the water for dilution is taken warm, and the swelling mass is left overnight.

How to use?

To lay linoleum or carpet, the adhesive solution is applied to the floor using a spatula.

Immediately after this, finishing material is laid on the base.

The cladding must be pressed firmly to the base. Upon completion, it is necessary to leave the finish for three days until the glue has completely dried. The optimal composition consumption in this case is from 0.5 to 0.7 kilograms per m2.

Advice from an expert: You can add cement mortar to the glue. This will help speed up the hardening process of the layer if it is necessary to carry out the work in the shortest possible time. Proportions – 1: 1. To prepare the mixture, you need to mix one part cement and three parts sand.

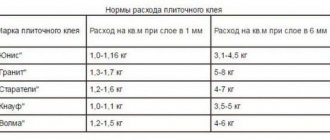

When using an adhesive composition for laying ceramic tiles, the composition must be carefully applied to the back side of the finishing material. The optimal layer size is about 203 millimeters. Afterwards, the tile must be firmly pressed against the wall and fixed in this position until the glue sets. Complete hardening of the glue occurs after three days. At this time, under no circumstances should you influence the finish. From 0.4 to one kilogram of glue is consumed per square meter.

Bustilat is actively used for installing wallpaper from various materials.

If the glue thickens over time, it should be diluted a little. Add one-seventh of pure water to the mixture; this is the maximum allowable volume. If the product is fresh, there is no need to dilute it.

It is worth noting that the frozen layer of Bustilat cannot be removed with hot water, so washing off old wallpaper and treating the base in this way does not make sense.

The most popular, affordable and effective method is mechanical cleaning, which is carried out using a metal spatula or a sharp scraper. You can also use a grinder that has a special attachment in the form of a metal brush. This method will help get rid of glue residues, but during operation there is a lot of dust and noise. Protect your respiratory tract with a respirator while working.

The second method is to wet a cloth with water and heat the cloth with a hair dryer or iron. Under the influence of temperature, the crust of the layer will become elastic. This is an efficient and silent, but time-consuming process.

- Before starting work, thoroughly ventilate the room.

- The working surface should also be prepared by cleaning it from dirt, traces of grease and various compounds. If necessary, a priming procedure is carried out (if the base has a porous structure).

- Be sure to read the instructions for use of the product. All necessary information is indicated on the packaging.

- The price of glue depends on many factors: manufacturer's markup, store percentage, type of composition. The minimum price per kilogram is about 100 rubles.

Bustilat is used for gluing the following materials and products:

- wallpaper;

- linoleum;

- carpet;

- parquet;

- asbestos-cement products;

- wooden elements;

- tile.

Glue is produced with the addition of chalk, water, carboxymethylcellulose additives and additional components that improve performance.

The glue has the following characteristics:

- Initially it has a white or light gray color, and after drying it becomes transparent.

- 100-200 grams of composition are consumed per square meter.

- Completely hardens in 24 hours.

- There are no alcohols in the composition, so the substance is non-flammable.

- Suitable for indoor and outdoor work in warm weather, as it is water-based and can freeze in the cold.

Bustilat is especially often used for wallpapering, but many other problems can also be solved with its help.

Sold ready-made in bottles and cans of various sizes.

Advantages and disadvantages

Positive features of CMC:

- Reliable adhesion of canvases to any type of surface, except metal.

- Does not contain toxic compounds, is safe for the body and the environment.

- There is no identified, characteristic odor.

- Easy to prepare solution.

- Easy to apply to work surface.

- Contains components that protect the surface from the formation of fungus and mold.

- Combination with other substances - soap composition, starch, gelatin.

- Contains insect repellent components (sodium tetraborate).

- Economical use.

- Doesn't show up through wallpaper.

- The finished solution can be used within a week, unlike other formulations that are suitable only a few hours after preparation.

The disadvantage of using it is that the solution is ready for use no earlier than after two hours. Although foreign brands have been improved, the mass is prepared within 15 minutes, and the price is correspondingly higher.

Advantages and main manufacturers of CMC

In addition to the already mentioned advantages (versatility, extreme simplicity in diluting the powder, reliability, protection against microbes and mold), CMC wallpaper adhesive has the following advantages:

- the appearance of stains and stains on the surface of the wallpaper is excluded;

- the repulsive odor is completely absent;

- the glue is very easy to prepare and use;

- the product is successfully combined with other chemical compounds.

Products of this kind, both domestic and foreign, are widely represented on the building materials market. Russian CMC glue has distinctive features, such as an affordable price and satisfactory characteristics. At the same time, it usually swells in 2 hours, which is acceptable from the point of view of the GOST standard.

The cost of foreign-made products is much higher. At the same time, the solution is prepared faster; after 15 minutes after dilution, it can already be used for wallpapering.

Undoubtedly, one of the most popular manufacturers of KMC wallpaper adhesive in Russia is Vympel Trade Center LLC, operating in the Moscow region. All its products are provided with the necessary certificates.

Types of CMC glue

There are several types of CMC, each of which is for a specific application:

- “1-Shavings” – glues light washable wallpaper with a paper base.

- “1” – released for light paper-based wallpaper.

- “N” is an economical option for paper and textile materials.

- “Extra fast” – for gluing canvases to concrete, plastered bases, used as a primer.

- “Super-Max” – glues all types of paper webs to concrete surfaces.

- “Mini-Max” – used for gluing light, washable wallpaper with a paper base.

- with PVA – glues all textile and paper materials to concrete, wood, plastered surfaces; not suitable for painted walls due to low adhesion; It has a color indicator, which is very convenient when applied to the canvas.

Other applications of glue

In addition to being used as wallpaper, the composition can be used in other areas of industry. For example, it is indispensable when drilling wells in oil and gas fields in order to become a regulator of drilling fluids. It is also added to clay during the production of ceramic tableware to improve the quality of the material. Special processing of paper makes it more durable and creates an adhesive layer on the surface if necessary.

CMC is added to paints and varnishes as a thickener. It serves as the basis for water-dispersion paints and compositions intended for coating facades. Builders add CMC to putty and painting mixtures, again for improvement.

In addition to all of the above, CMC glue is actively used in the production of matches, faux fur, and detergents. It has also found its application in the mining industry and foundry production. In biological experiments, such a composition acts as an ion exchanger for sorbitol.

Manufacturers of CMC glue

In construction stores and markets there are Russian and imported TMs for sale. The price of the former is much lower, but the technical characteristics are not inferior.

Well-known manufacturers:

- Vympel 75V is produced in Russia. The finished solution has high viscosity and water-retaining properties. Suitable for all types of wallpaper on all surfaces, including metal. Without toxic substances, safe. Packing in bags.

- Karbocel produces a universal CMC product for all types of fabrics. This is an environmentally friendly product with high solubility. Highly effective product without fillers. Available in packages of 0.3 kg, 0.5 kg, 15 kg.

- Omega produces a carboxymethylcellulose-based adhesive with the addition of antifungal components. Suitable for various wallpapers in structure and width. The solution is prepared within three hours, resulting in a homogeneous mass without lumps. Shelf-life Unlimited.

- Polycell CMC-7 is a white fine-grained powder, highly soluble in water at any temperature. It is used in construction as a thickener for putties, increases the plasticization of solutions and the adhesion strength.

- Malva produces an adhesive designed for attaching multi-layer wallpaper (foam film), paper-based and fabric-based canvases. Fastening is carried out on painted, concrete, plastered, wooden surfaces.

What types of wallpaper glue are there?

Modern wallpaper adhesives are convenient when preparing for work. It is enough to pour the glue into water at room temperature with quick stirring, and after 3, maximum 15 minutes, the glue is ready for use. Gone are the days when you had to soak the glue, bring the mixture to a boil, and then wait for it to cool.

In terms of composition, the glue is available in two types: CMC glue, based on cellulose, and glue based on modified starch.

CMC glue

CMC glue has good adhesive properties. The glue is ready for use no less than three hours after mixing it with water. It has relatively low consumption and low price. A package of CMC glue weighing 500 grams is enough to cover 50 m². The price of a pack is 50-60 rubles.

KMC glue is suitable for gluing any types of wallpaper. For light wallpaper, take 8 liters of water per 500 grams of glue, for heavy and dense wallpaper, prepare thicker glue - 500 grams per 7 liters of water. CMC glue is diluted in warm water and left to swell for 3-8 hours. The swelling time is indicated on the packaging. With such a long time to prepare the glue, it is better to soak it overnight. You soak it in the evening and in the morning the glue is ready for use. Wallpaper glued with CMC glue is difficult to remove during subsequent repairs.

Starch-based adhesive for various types of wallpaper

Based on modified starch, glue is produced for each type of wallpaper. The composition of the glue differs in additives, but the adhesive base is starch, which is an environmentally friendly product. When wallpapering in damp rooms, choose an adhesive that contains antifungal additives.

According to their intended purpose, starch-based wallpaper glue is produced in the following categories:

- Adhesive for paper wallpaper - suitable for all types of paper wallpaper and light vinyl.

- Vinyl wallpaper adhesive - used for thick vinyl wallpaper. Many manufacturers add methylcellulose to the composition of such glue.

- Universal glue - used for all types of wallpaper.

The packaging of universal glue indicates in what proportions the glue should be diluted. For paper wallpaper, the glue is diluted to a liquid consistency. This is necessary to quickly soak the paper base of the wallpaper. Thick glue is difficult to apply evenly on thin wallpaper; after drying, unevenness may form on the wallpaper.

For heavy wallpaper, the glue should be thicker and more viscous than for light paper wallpaper.

4. Glue for non-woven wallpaper. Contains antifungal additives. Glue is applied to the wall.

5. Glue for glass wallpaper. Also suitable for gluing non-woven wallpaper. In addition to modified starch, the composition includes methylcellulose.

Features of use

CMC has many positive aspects that expand its scope from domestic use to industrial use:

- Light textile industry.

- Regulates the properties of drilling glue during oil production.

- An additive to mortars that increases the elasticity and adhesion of surfaces.

- As a thickener in the production of varnishes and paints.

- As an ion exchanger for sorbitol in BIO studies.

- Production of matches.

- Production of ceramic products (binder mixture).

- When producing paper, it gives it strength, etc.

Alternative uses

CMC glue is used not only for wallpapering walls. Due to its high adhesive characteristics, this product is used in various sectors of the national economy.

Construction

CMC is added to tile mortar, gypsum or cement putty. This glue is mixed into the solution used for laying foam blocks or aerated concrete.

Production of finishing and construction materials

Glue is mixed into clay or cement or gypsum mixture in the manufacture of finishing building materials. CMC increases the strength of the finished product and improves its performance characteristics.

Chemical industry

In the paint and varnish industry, CMC is used as a thickener. Carboxymethylcellulose is the basis for the production of facade and various water-dispersion paints. This substance is used in the production of various synthetic detergents.

Mining of oil and gas

Carboxymethylcellulose is used as a stabilizer for highly mineralized clay suspensions. This substance is used as a regulator of the properties of drilling fluids when drilling oil and gas wells.

How to properly prepare glue: procedure

The packaging contains information detailing the method of diluting the powder:

- Prepare a container of the required volume (a plastic bucket is often used).

- The water is measured and checked for temperature (optimally 25 degrees).

It is necessary to pay attention to the issue of water temperature; in very hot water the glue will cook; in cold water clumping may occur.

- Glue is poured into the water with constant stirring.

- After thorough stirring, leave it alone for two hours.

- After mixing, the mass is ready for use.

How to cook

To prepare the mixture you will need:

- Adhesive composition.

- Capacity. This could be a bucket or basin. The main thing is that there is enough volume.

- Water. To prevent lumps from forming in the resulting mixture, the water must be clean and its temperature must be 25 degrees.

- Stirring tool. To do this, they often use a stick or a construction mixer.

How to dilute glue:

First of all, you need to read the instructions on the packaging of the adhesive composition and find out the proportions in order to mix the mixture correctly. After this, you must first fill the container with water. It is necessary to stir the water until a funnel is formed, and pour the contents of the package into this funnel in a thin stream, without ceasing to stir. When the powder and water are combined in the required ratio, you need to leave the mixture to swell. This takes from 15 minutes to an hour, depending on the type of glue.

Standards for production

As mentioned earlier, CMC is produced in strict compliance with the requirements specified in GOST. However, it is not subject to the standard that regulates the production of polymer-based adhesives and starch compositions. In the first case, the rules for the manufacture of adhesives based on synthetic resins, vinyl and polyvinyl acetate are prescribed. The second GOST regulates the production of starch both for food purposes and for the chemical industry.

The production of KMC glue is carried out according to the technical conditions TU 2231-034-07507908-2001 and TU 6-55-40-90. These documents indicate all the characteristics that this adhesive composition should have.

Carboxymethylcellulose: properties and description

Carboxymethylcellulose is a cellulose derivative, which is a weak acid in the form of a light beige, odorless, tasteless, finely crystalline powder. The name is often replaced by the abbreviation KMC. It is an ether of cellulose and glycolic acid.

Preparation and chemical properties

The material is synthesized from non-edible natural raw materials, filled with a concentrated alkaline solution and treated with chloroacetic acid. The resulting impurities of glycolate and sodium chloride are washed off.

CMC is highly soluble in alkalis and water, but insoluble in mineral oils and organic solvents. Dissolving in water, it forms transparent viscous solutions that are plastic and sometimes thixotropic.

Such solutions react well with synthetic and natural polymers, other water-soluble cellulose ethers, salts of alkaline earth and alkali metals, and ammonium.

The sodium salt of carboxymethylcellulose (Na-CMC), an anionic polyelectrolyte, which is a colorless amorphous substance, has received the greatest practical application. It dissolves well in water and binds it, and such solutions are resistant to monovalent salts.

Since one of the main properties of the material is the ability to form a stable and viscous colloidal solution with long-term action, Na-CMC is widely used in various fields of industry. In particular, it is used as a thickener, plasticizer and resorbent:

- To regulate the characteristics of drilling fluids located in aggressive environments in the oil and gas industries and geology;

- For flotation enrichment of sylvinite ores in the mining and chemical industry;

- As a plasticizer for coating mixtures of welding electrodes, an additive to concrete in construction;

- Finishing, sizing and thickening agent in the textile industry and in the manufacture of detergents;

- Thickener for putty mixtures and paints in the paint and varnish industry.

But the most popular use of this material is its use as an adhesive for wallpaper, linoleum and ceramic tiles.