How to cover the outside of a house? Wooden Lining: types and types of installation

The most commonly used types include cedar, pine, spruce and redwood. You can either leave the wood in its natural state or paint it to further tailor its appearance to your desires. In addition to wood types and colors, you can further vary the different types of profiles in which the wood is applied to your home.

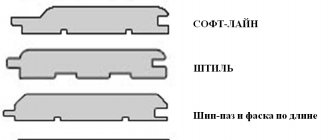

The most common wood siding include:

- One of the classic options is fence, a barn type of wood clapboard , consisting of wide boards joined together and a batten nailed across the joint of the two boards to close the gap, creating a vertical design.

- The tile or lap type are long thin boards or individual slabs installed horizontally with a slight overlap.

- tenon - groove. Like panels, the top of each horizontally installed panel fits into a groove on the bottom edge of the board on top of it.

- Vertical Boards – A series of wide boards are placed vertically with a series of narrow boards in between.

- Wooden sheet siding. Plain sheets of plywood in exterior wall trim, commonly used on inexpensive buildings.

- Block house - imitation of the appearance of a wooden house

Each of these subtypes has its own set of pros and cons. For example, many people prefer the classic look of shingles, but this is the most expensive option. Tenon and groove are the cheapest. The advantages of all types are their impact resistance, natural beauty and almost endless color variations. The tree is also relatively quick and easy to install. This is one of the best options for DIY projects, although professional installation is also a good idea.

Unfortunately, wood is not without its drawbacks. In addition to the regular maintenance it requires, it is also susceptible to damage from termites, woodpeckers and rot. The cost of preserving the appearance of wood siding and protecting it from common threats can quickly offset and reduce installation costs.

Finally, wood is not fire resistant. This can be a major deciding factor if you live in an area with a dry climate where wildfires are common.

Installation stages

- Vapor barrier fasteners;

- Installation of the frame directly;

- Installation of thermal insulation;

- Carrying out waterproofing;

- Construction of the second frame;

- Exterior clapboard finish.

Initially, you should select a material that will act as a vapor barrier; usually roofing felt, aluminum foil or even ordinary plastic film are used for these purposes.

Upholstery with vapor barrier film

A prerequisite is the presence of ventilation of the facade of the house, for which the vapor barrier layer is nailed directly to the slats nailed to the wall. The slats should be attached at a distance of one meter, and their width should be approximately 2.5 centimeters. For additional ventilation, holes (20 mm) are made at the bottom and top between the slats.

Frame installation

The frame can be made with your own hands from boards, securing them to the wall of the building in a vertical position. The thickness of the boards should be in the range of 40-50 mm, and the width should be about 10 centimeters.

The distance between the boards must be left less than the width of the insulation sheets by 1-2 centimeters.

Installation of thermal insulation

Thermal insulation placement is a further stage that requires finishing the house with clapboards on the outside.

It happens through the following steps:

- Installation of mineral wool layers occurs without gaps between them;

- To achieve this, it is necessary to lay two layers of mineral wool at a time, 50 mm thick;

- The main feature of the masonry is that the joint of the lower slabs is covered with the middle of the top layer, and, due to its natural elasticity, no additional fasteners are required, which can be seen in the photo.

Installation of waterproofing

The photo shows the use of waterproofing materials

- To prevent moisture from penetrating into the house, a waterproofing film should be installed, which is mounted on top of the thermal insulation layer;

- The film is fastened using construction staples to the boards;

- Leaving an overlap of about 5-10 cm, you should glue it with tape, which will allow you to get a better effect.

Attention! To get the ideal ratio, you should lay the hydrofilm with the smooth side facing the insulation

Installation of the frame under the finishing cladding

According to the steps described in the instructions above, you should then proceed to install the second frame.

Slats should be nailed to the boards of the first frame on top of the hydrofilm. Their thickness should be 2-3 cm, width 0.5 mm. This makes it possible for additional ventilation and removal of condensation on the hydrofilm;

Timber frame for panels

To prevent rodents and insects from entering the space below, it should be sealed with a metal mesh.

Finishing the outer layer using lining

The final stage is the outer wall cladding with clapboard:

- The process begins with the preparation of boards of the required length, you should start from the bottom, while the starting board is positioned with the grooves upward, a prerequisite is the use of a level to ensure its level position;

- After making sure that the board is secured, you should attach it with nails (clamps). The workpiece must be leveled before fastening;

Installation on clamps - clasps

- Next, the second sheet of lining is installed using a standard tongue-and-groove system. To ensure that the tenon of the upper board fits tightly into the groove of the lower one, you should use a wooden hammer;

- Having secured the second board, you should insert the rest.

Some installation secrets are shown in the photo

After the lining on the outside has undergone complete installation, they begin to vertically fix the boards at the corners of the boards. Here, a mandatory point is the presence of overlap when one overlaps the other.

Window casings are decorated in a similar way; the pediment is sheathed most often by horizontally fastening the boards. Only after completing the entire cladding process should you begin painting.

When starting simple painting, you should observe some nuances:

- The entire surface is pre-treated with a grinding machine. It requires the presence of fixed sandpaper (grain 40-25-80 or 120);

- If using oil paint, it is necessary to apply drying oil in two layers, and apply the paint only after it has completely dried.

Despite the fact that anyone can take advantage of the opportunity to cover the outside of a house with clapboards, this process requires certain physical and time expenditures. An excellent analogue of wooden finishing would be plastic exterior lining.

On our website you can find a large number of videos that allow you to learn some valuable tips and step-by-step instructions.

Finishing the Walls with Lining: Fence, barn type of installation

This type of house siding allows you to be creative because you can use boards of varying lengths. Some of the types of wood used are pine, fir, cedar and redwood. Although wood is the most commonly used material, engineered wood and wood-look vinyl siding can also be used.

Advantages:

- This makes the house appear taller because it is usually installed vertically.

- You can choose between real wood, vinyl, and engineered wood.

- The tree is easy to install and operate.

- You can be creative and use the size of wood you prefer. You can also install panels vertically or horizontally.

Flaws:

- Wood can rot or become infested with pests if it is poorly treated.

Material price:

- $3-5 per sq.m.

Material and tools for work

First of all, you need to buy unedged boards about 3 m long, their width should be about 100 mm, and their thickness should be at least 20 mm. You can choose any type of tree, the main thing is that it does not have mechanical damage, knots or rot. Oak, linden, cherry or pine are suitable for this. Before work, check that the wooden lining is well impregnated with special antiseptic compounds.

Required tool:

Tools for working with lining.

- milling machine or surface planer;

- color pencil;

- ruler;

- set of cutters;

- mounting stapler;

- mineral wool;

- wood screws;

- perforator;

- nails;

- plumb and level;

- waterproofing film;

- hammer;

- polyurethane foam (slightly expanding);

- wooden planks with a section of 4x5 cm.

Block House – Excellent Material for House Cladding

A block house allows you to make a house that looks like a real wooden or country house. This is done using cypress, redwood, pine or cedar logs. Block house planks must be dried and treated to give them a longer service life. They can be colored, although leaving them in their natural state is preferable by simply adding a clear coat.

Advantages:

- This gives the house a natural, rustic look.

- The appearance of a block house is durable if it is made using high quality wood and with proper maintenance.

Flaws:

- The initial costs are high because the material is more expensive than regular wood paneling, as well as the cost of maintenance.

- Block house finishing requires regular maintenance to prevent insect infestation. Cracks in the planks must be sealed to prevent disintegration.

Material price:

- $5-10 per sq.m.

Material Specifications

Before finishing the exterior with clapboard, you should familiarize yourself with the basic characteristics of the cladding. It can be represented by standard or eurolining. The first has a humidity of 25% and narrow joints. If this is not top-class material, its surface may be poorly planed and have a fleecy base.

If you want to get better quality, you should pay attention to eurolining. Its humidity does not exceed 15%, the products have ventilation grooves, and the error is quite impressive in width. The product is classified into four grades and has no lint on its surface. If you want the cladding to last as long as possible, you should choose a lining with less humidity so that it does not warp over time and when drying.

Tile type - rare Installation of Wooden Lining

Wood cladding panels are made using single blocks of wood that can be cut into different shapes. The machine cuts to ensure uniformity and smoothness. They are installed on top of each other - overlapping. Some of the types of wood used are redwood and red cedar. This type of cladding material is environmentally friendly and gives the house the appearance of an old country house.

Advantages:

- The cladding material gives the home a natural look that blends well with its surroundings, such as waterways and forests.

- finishing the facade with such siding is cheaper compared to brick and stone with the same rich appearance

Flaws:

- Cladding materials require regular maintenance, including sealing and painting, to ensure they are not damaged by the weather.

- susceptible to moisture and may develop mold and moss if not maintained properly. Insects and wind can also damage wood; it can become deformed, curled and cracked.

Horizontal façade cladding with wooden clapboard - modern style

The exterior is made using thin strips of wood arranged horizontally, in some cases using a tenon and mortise design. Wood helps create a rustic feel for the home. Some of the types of wood used include cypress, pine, fir and spruce.

Advantages:

- This gives the home a classic, rustic look and improves curb appeal.

- The wood is environmentally friendly.

- Wood can come in a variety of textures and colors.

Flaws:

- Exteriors require regular maintenance to keep the wood from cracking, rotting, warping or deteriorating. The facade should be repainted or repainted every three to six years.

- Initial costs are high, especially if you use woods such as redwood and cedar, which are considered rot-resistant.

- Wood is susceptible to water and insect damage if not treated properly.

Vertical lining of the facade with clapboard - classic style

In this case, the wooden strips are placed vertically, which can help emphasize the height of the house. Like the horizontal strips, they are joined together using a tenon groove. The forests used are pine, spruce and cypress.

Advantages:

- This gives the home a classic, rustic look and improves curb appeal.

- The wood is environmentally friendly.

- Wood can be customized using stains and paints.

Flaws:

- Exteriors require regular maintenance to keep the wood from cracking, rotting, warping or deteriorating. The facade should be repainted or repainted every three to six years.

- Initial costs are high, especially when using woods such as redwood and cedar, which are considered rot-resistant. Wood is susceptible to water and insect damage if not treated properly.

How to paint facade lining

Once it has been decided how to treat the lining outside the house, you can proceed to preparing the surface. Cladding is usually accompanied by the formation of dust, especially if the frame was made of wood. The facade is cleaned of fine dust and dirt, after which you can begin processing. If the material was installed a long time ago, then the façade already has platbands and shutters. Before painting the walls, they are removed. Joints and irregularities are sealed, and then the wood is left to dry completely.

If there is an old layer of paint, it must be removed from the surface of the lining outside the house. Craftsmen paint the material only after the outer cladding has been prepared. Sometimes, after prolonged use, the walls of the house turn black. In this case, the layer that has changed color must be removed. For this, a special solution is used, which is left for a certain time. Old paint can be removed using a sander or sandpaper.

Often, novice home craftsmen think about the question of how to cover the outside of the lining. When solving this problem, you should remember the need to impregnate the outer surface with an antiseptic. Soil and drying oil will level the base and protect the material from fungus and insect attacks. The walls are sanded and treated with alcohol. An alternative solution may be a weak solvent. The surface should be left until dry, only then can you begin to apply paint. The outside of the block house is processed using the same technology. This will extend the life of the building and the materials of the walls of the house.

Artificial wood paneling

Faux wood siding (clap) looks almost exactly like real wood, but it is made from composite materials. Unlike vinyl or fiber cement with wood grains, faux wood siding is based on real wood. Various fibers and parts are combined to create an authentic finished product.

The main advantage of faux wood lining is the presence of real wood. It costs much less than natural wood. Engineered wood can also be manufactured to suit your personal preferences. It is available in a variety of styles that imitate different types of wood and colors. Not only does it look like real wood, it also has a distinct texture. Another advantage of this material is its durability. Expect your engineered wood to last at least 20-30 years. Engineered wood can withstand extreme temperatures, humidity, fire, and insects well. It needs little maintenance.

The only real downside to note, other than the fact that engineered wood isn't exactly real, is that you can't repaint or refinish it. The color you initially choose is a color that will stay forever, you cannot repaint it.

MODERN DESIGN OF LINKING IN THE HOUSE COVER

The design of this house's cladding with wooden clapboards uses modern façade paneling - the result is stunning. This couple has created the perfect property for their family located on Hwasser Island. Due to the island's spectacular weather and the home's exposed seaside location, a low-maintenance wood that could withstand all weather conditions was required.

This striking home was designed to stand out from the more traditional cottages in the area. However, the owners also believed it was important to look to the future and build a home suitable for today, with the ability to meet the needs of their dynamic family. During the summer, the family can enjoy the outdoor space from the roof terrace, which offers breathtaking views of the natural environment.

The terrace is built with finely adjusted railings that act as walls to create a sheltered lounge suitable for casual entertaining. When the weather worsens, the sliding doors leading to the terrace are closed and the family can enjoy the magnificent view regardless of the weather.

After prolonged exposure to weather conditions, the wood paneling on the facade took on a silver-gray hue, which allowed the exterior walls of the house to replicate the colors of the natural stone next to it. The finishing of the façade, decking and terrace flows smoothly into the landscape. The weathered patina improves the appearance of untreated wood without affecting the durability and dimensional stability of the cladding material used.

As an environmentally friendly product, modern wood panels were selected for the facade primarily due to their durability and naturalness. In addition, it was especially useful that such cladding material for the facade of the house does not require significant maintenance other than routine cleaning, with a 30-year guarantee even in northern climates.

Developed in Norway, the patented timber facade panel uses an environmentally friendly process that continuously improves the properties of softwood using biological fluid obtained from agricultural crops. By polymerizing the wood's walls, durability and dimensional stability were greatly improved, giving it characteristics similar to those of tropical hardwoods.

When choosing the material for the façade of the house, it was especially important that the wood should not require maintenance, which allowed the owners of the house to make the most of their free time for walking with the children. This home is a perfect example of how wood takes on a silvery gray patina over time, adding beauty and natural identity to the project.

Basics of choosing eurolining

Before choosing a material for cladding, you should study several rules:

- To avoid further deformation of the material, which occurs as a result of shrinkage and leads to the formation of cracks, you should choose a type of lining whose humidity will be in the range from 10 to 15%;

Checking humidity with a moisture meter

Advice: Ask the seller to confirm the declared humidity - if he refuses, there is reason to think about the advisability of the purchase.

- Be sure to inspect the material for wormholes and foreign stains;

- The number of knots in the selected material should be minimal.

Note! The exterior cladding of a house should be made from material made from coniferous trees, since hardwood (not counting aspen) is not suitable for external cladding.

Coniferous species are more preferable

COVERING SIDING PANELS FOR EXTERNAL WALLS OF A HOUSE ON THE LAKE SHORE

If you want a warm feeling from your exterior, cladding the facade with clapboard will give you this! Look at these photos of houses covered with wooden clapboards and you will see this. Fortunately, modern protective materials allow you not to think for a long time about restoring the facade of a wooden house.

Don’t be afraid to apply new technologies to old, proven materials and you will get ultra-modern wooden house facades that will delight you every day!

The one-story wooden house is located on Orcas Island, one of the archipelagos of San Juan Island off the coast of Washington, USA. The house is equipped with retractable panels that protect it from very windy storms, the prevailing ocean currents that come ashore in winter. Situated on the coast of an island, the house uses both retractable wood panels and the surrounding forest for winter protection. is widely used on the facade and interior of the house as a finishing material . But look how ultra-modern the cladding looks!

On the south side of the house there is a rocky shore overlooking the Pacific Ocean. The architects, answering the question of how to cover the facade of the house, used natural colors of cedar cladding on the facade to harmoniously combine this wooden house with the surrounding landscape. The lining material for the exterior cladding of the house is local.

The surrounding forest helps protect the house from weather conditions, which are severe quite often.

Stone collected from the site was used to level the area for the house. The space occupied by the house was compensated by the green roof on it.

The site is on an island with pristine shorelines and marine life, so carefully engineered stormwater flows were designed to replicate pre-construction conditions.

Wooden wall panels are installed on tracks, which allows them to close tightly or open widely depending on weather conditions.

When the weather is good and the panels are open - behind them is a wall of large panoramic windows, which can also be closed or opened wide for easy access to the outdoors.

This double sliding panel system is used on both the front and rear façade of this modern timber home.

When both sets of slides are open, you can easily walk through the house from the front yard to the back deck without opening the door.

The home's wide open spaces are ideal for allowing ocean views to travel unimpeded throughout the home and yard.

When the glass panels are closed and the wall panels remain open, cold parties remain comfortable.

The home's outdoor deck also boasts a large size, allowing you to enjoy outdoor dining.

This stunning outdoor dining table was crafted from two planks of naturally weathered building material.

The roof overhang and deck siding is Western Red Cedar.

Around the back of the house, the alcove is also lined with red cedar clapboard, and the open deck is left uncovered to weather conditions.

The back deck slopes down to the portion of the landscaping that was leveled for the home's foundation.

Inside the home, wood floors, clapboard ceilings and walls act as a frame for impressive views.

Even the view from the front of the house is magnificent and constantly showcases the local animal life.

When the wall panels are closed, the view to both sides of the house is still not completely blocked, and natural daylight can illuminate the interior areas.

On cold days, when the house is closed, a wood fireplace is used for heating. The design with open square shelving on both sides is the main focus when covering the wall panels. Even the wooden paneling of the ceiling of this wonderful interior does not create the impression of a grandmother’s dacha. As a nod to the color of the ocean and sky, several parts of the interior feature rich blue hues.

The indoor dining table is made from a slab of Fir wood, but unlike the outdoor dining table, it has not been treated for outdoor use. The kitchen overlooks the side façade and deck. It has four small storage rooms on the side walls. The overhangs on the other side of the house are longer and contain a master bedroom overlooking the side garden and ocean, as well as a guest suite overlooking the side garden and a master bathroom overlooking the front yard. Unlike the social area, there is no clapboard paneling in the bedrooms, bathroom and toilets.

MODERN COVERING A HOUSE WITH SIDING – A STYLISH OPTION FOR A FAÇADE

This modern home, with wood siding on the exterior, is located less than an hour from Oakland in a new neighborhood filled with family homes and trees. The stylish modern home hides its occupants from prying eyes while its mid-height fence surrounds the property on all sides. Gray wood siding contrasts with darker roof cladding and black steel window frames. Huge windows are an indispensable attribute of a modern home nowadays.

The façade of the house appears to consist of several supporting walls that protrude and partially mask the numerous windows. All the lines of this modern house tell us about its modern design both outside and inside.

The back has a glass entrance and just a couple of windows. Additional light in the room is provided by skylights in the roof. The facade siding with which the house is sheathed is even suitable for the shower area.

The main entrance and garage create the impression of an impregnable fortress due to the absence of windows. The garage door features the same wood siding found on the exterior of this modern home.

Gravel, slightly mixed with greenery, surrounds this one-story house. Mostly weeds grow on wooden flowerbeds, but how do they match the wooden cladding of the house facade! The color combination of light and dark facade cladding with wooden siding visually lengthens the walls of the house. The slope of the roof further enhances this effect.

The interior of the house also has a large amount of wood. White plaster walls balance it out, creating a more modern look. Tiles in the bathroom and kitchen add another interesting element to the interior. Numerous seating areas make full use of the huge square windows. Although the overall decor seems quite minimal, the wood grain and natural lighting do a great job of giving it plenty of detail.

The process of fastening the lining

Before sheathing the walls, the material is brought into the room and left for two days. This manipulation is essential for the tree to fully acclimatize.

Important! If you rush and skip this stage, there is a high probability that the structure will warp.

All work must be carried out at positive air temperatures, and the optimal humidity is at least 60%.

The essence of the technique:

- Most often, installation is carried out in a horizontal position, so install the first plank at the bottom so that its tongue (groove) faces upward.

- As in wallpapering, fixing should begin from a corner that is located away from the entrance to the room.

- Check the board thoroughly with a level, taking into account the horizontal and vertical surface.

- The first board is fastened, and the rest are then grooved and then fixed with clamps. be careful with the first and last elements, it is better to secure them with screws.

- After finishing, you need to decorate the walls with baseboards and corners, or you can paint the lining walls with stain or varnish the surface.

Experience guarantees completion of finishing work within a day, even including installation of the frame. Natural materials will give the room comfort and warmth, will last a long time, and will preserve its beauty.

HOUSE DECORATION WITH SIDING – MODERN VILLA IN VILNIUS

Mountains envelop a cool modern villa in the forest of the Lithuanian capital Vilnius. The ultra-modern building boasts a sophisticated design and a spacious, well-kept fenced lawn.

A one-storey villa built entirely of wood and clad with wood panels (siding) in a modern style. It is located at the foot of the hill and one of its floors occupies its upper part.

Its side of the public area sections on the base structure gives the villa a distinct rock silhouette that also frames the interior architecture. Many floor-to-ceiling windows and sliding doors provide easy access to the grass carpets outside while also opening up to the surrounding forest views. Each level has its own outdoor lounge where its occupants can enjoy nature to its fullest.

Inside, a modernist aesthetic takes over every room, using nothing more than light wood and black steel. When fog sets in, the villa takes on more mysticism. Raises his head and shows his wooden teeth from the fog. It seems that no one else can see it, the structure is so artfully integrated into the environment.

FINISHING WITH WOODEN SIDING – TILE TYPE OF WALL COVERING

Decorating a house with wooden siding is solid, simple and reliable! The traditional approach to registration of private property is found everywhere in urban and rural areas. In this article we have collected information about what siding is and how it affects the appearance of the house.

The use of decorative cladding for the design of buildings dates back to the 60s, when residential areas with cozy one-story houses began to be actively developed in the United States. Finishing a wooden house with siding is a popular technology in our country, which attracts attention with its simplicity and style. The great success of siding is explained by its moderate cost, wide selection of materials, as well as design solutions.

Insulation of a wooden house is a pressing issue for our climate zone. Finishing with siding is the best alternative to polystyrene foam, which will give a solid appearance to the building and make it more advantageous against the background of adjacent objects.

The photo below shows wood siding finishing using the example of a one-story house surrounded by natural landscapes. In this case, a classic project in eco design is depicted.

Such houses are common in Scandinavian countries, as well as suburban areas throughout Europe. The main emphasis is on the monochrome exterior, due to the combination of natural pastel shades to match the roof.

Exterior finishing of a wooden house with siding can be done in various ways. Manufacturers produce cladding panels with individual structure and color scheme. Decorating the outside of a wooden house with wood siding is considered the most affordable and diverse in terms of design. For the manufacture of sheets, pine, beech, birch, and maple are used - environmentally friendly material that gives a “breathable” structure to the wall.

The panels prevent the accumulation of condensation in the intermediate layer and create high-quality ventilation. In addition, the material is durable and resists sudden temperature changes. Due to its noble appearance, impact resistance, and durability, finishing the facade of a wooden house with wooden siding is widely used among property owners.

Wood siding is available in several types:

- Block house. The panels have a convex shape that imitates a log frame of a tree. The material is available in several grades. Class A - the most reliable, without cracks, irregularities, or rough structure. Class B is the optimal solution in terms of price = quality ratio. Class C is the least quality type of block house.

- False timber. The cladding board has a perfectly even shape.

What are the advantages of siding for decorating the walls of a house:

- Wood siding is perhaps the most popular, original, but expensive construction method. Thanks to the high quality of the material, the appearance of the house becomes incredibly thoughtful and harmonious with the surrounding landscape.

- Wood siding is ideal for exterior use. Wood is an environmentally friendly material with excellent sound-proofing and heat-insulating properties. For cladding, transverse sections of the trunk with rounded sides are used, which creates the impression of a wooden house.

- The panels do not require a special approach to installation and are easy to install. Long service life, ease of maintenance - these advantages will be appreciated by anyone who strives to decorate their home with style and taste.

- It is customary to decorate a wooden house with wood siding together with insulation. In summer, the wall can become very hot under the influence of the sun, and in winter, on the contrary, it can cool down. This negatively affects the thermal insulation of the interior, which requires the installation of an intermediate layer.

How to choose lining for outdoor work

Before you start purchasing finishes, you need to figure out what selection factors to use. On sale you can find simple and eurolining. The first one is often produced by Russian manufacturers and has an affordable price, but also less good quality. The foreign analogue has an attractive appearance, lower levels of humidity, resistance to deformation and is offered for sale in several forms. Among others, it is worth highlighting:

- standard;

- block house;

- landhouse;

- American.

The most common type is the block house; this material is universal and has an affordable price, and is suitable not only for external but also internal work.

In order to decorate the facade with wooden lining, you need to choose the right material. It can belong to different varieties. The highest, for example, has no cracks, knots or defects on the surface. It should be borne in mind that lower quality material without additional processing may have traces of insect activity. You should not purchase those products that already have putrefactive formations on the surface.

Quite often, cladding is sold without additional protection. Therefore, you need to think about the question of how to cover the lining outside the house. For this you can use:

- facade paints;

- varnishes;

- stains;

- waxes;

- glazing antiseptics;

- matte antiseptics;

- impregnation.

After installing the lining, the outside of the house can be treated with regular façade paint. It is better to prefer the water-based acrylic variety. You can also cover the lining with varnish or stain. These funds are used both together and separately.