Steel siding is a narrow decorative panel, which is obtained by profiling thin sheet galvanized steel with a polymer coating. They are used for cladding facades, fences, and also for decorating roof overhangs. The panels are covered with a polymer layer of various colors, including metallic shades or wood and stone colors. At the same time, the practicality of steel siding is many times higher than, for example, wood. Metal resists environmental influences much more effectively and does not require special treatment, regular painting or any additional investments.

The line includes four types of siding rental.

Lbrus®

Siding that follows the shape of laminated veneer lumber. The letter L in the name stands for Light, emphasizing the light weight and mounting of the metal material. Lbeam is suitable for walls and fences, for lining cornice and gable overhangs, as well as suspended ceilings. It can be mounted both vertically and horizontally.

A modified version of this siding is available for clients of Metal Profile Vostok Company LLC - Lbrus®XL . It features increased panel width (335 mm instead of 240 mm) and an improved lock shape. This profile looks especially advantageous on large planes of facades.

Famous manufacturers

The production of metal facade siding is widely developed today. There are a large number of manufacturers, both domestic and foreign, represented on the construction market. Product lines differ in their appearance, size and technical parameters. It is worth researching all manufacturers before making your final choice.

Grand Line

Metal siding for finishing Grand Line facades is presented in a large assortment. Grand Line produces products in standard sizes, but it is possible to manufacture according to customer specifications. All metal siding of the manufacturer complies with state standards, which is confirmed by relevant documents.

The company provides a long-term warranty for the entire range of products. The most popular metal facade sidings are “Vertical”, “Block-House”, “Ekobrus”, “Shipboard”.

Metal kit

One of the largest domestic ones. Production is carried out with the involvement of the best specialists and the introduction of modern technologies.

The quality of metal siding from this manufacturer is confirmed by certificates. All products comply with SNiP standards and GOST requirements.

Insi

The INSI company manufactures products from polymer-coated steel. It has an affordable price and high quality characteristics. The manufacturer offers both material for horizontal and vertical installation.

The company's products have an attractive appearance; a wide color palette allows you to create a unique exterior using metal siding.

Crown

The products are popular because they are durable, reliable, durable and original in appearance. The presence of ventilation gaps makes it possible to minimize the harmful effects of moisture.

The use of high-quality materials guarantees reliable protection from negative external influences. The company offers customers more than 3,000 types of metal siding, and the range is constantly expanding.

Tekhpromstroy

The company has wide production capacity and produces not only roofing and facade cladding products, but also additional materials, additional ventilation systems, drainage, etc. The thickness of metal siding is 0.45-0.55 mm.

Reliability and durability of façade materials is enhanced by the application of high-tech polymer compounds.

What is the siding attached to?

Siding panels are installed on wood or steel sheathing that is pre-attached to the wall of your home. A metal substructure is many times more reliable than wood, since it does not rot, does not dry out, and is not of interest to insects, so we will consider the option of installing siding on a steel frame.

It consists of mounting brackets (KK) and L-shaped guide profiles. As a rule, the arrangement of a ventilated façade also involves the use of insulation and the presence of a waterproofing membrane.

Installation of steel sheathing (subsystem)

Installation of metal structures for siding begins with preparing the walls of the house. If you are covering a new building with siding, you must first free the walls from peeling paint, cracked plaster and other unstable elements. You will also have to temporarily dismantle parts of the drain, antennas, signs, etc.

Then make markings on the wall along which the brackets will be installed. You need to step back at least 100 mm from the edge of the wall, then a step of 600 mm is recommended. Brackets with a washer are mounted on the wall using facade anchors through an isolon (paronite) gasket to eliminate cold bridges. Choose the length of the brackets taking into account the thickness of the heat-insulating layer and the mandatory ventilation gap to remove condensation between the façade cladding and the waterproofing membrane. The ventilation gap must be at least 40 mm (40-60 mm recommended). If the distance from the wall, taking into account the insulation and ventilation gap, is more than 230 mm, you will need reinforced brackets (RKU) and their extensions (UK), which allow you to indent the substructure from the wall up to 350 mm.

Laying thermal and waterproofing

Not every building needs additional insulation, but most often there is still a need for external thermal insulation. Insulation, as a rule, requires wooden, frame houses, buildings made of foam blocks and other materials.

The thickness of thermal insulation boards is calculated using special formulas - many manufacturers have programs for calculating the thickness of insulation. It is not advisable to select this parameter “by eye”, since it is easy to make a mistake in this matter and then you will either spend money on additional heating, or the cost of the insulating layer will be so high that it will not pay off even after a few years.

Installation of insulation should begin from the base upward so that the slabs have support underneath. Basalt or glass wool slabs are placed directly on the brackets. If two layers of insulation are needed, the top layer must be laid with a shift relative to the bottom one so that the joints of the plates do not coincide. Thermal insulation is fastened with “fungi” - plastic disc-type dowels. Usually 5-7 pieces are required per slab.

A hydro-windproof membrane with an overlap of 150 mm is installed on the insulation. It is very important to choose a material that will allow steam from the insulation to escape outside, but will not let moisture in.

Installation of the guide profile

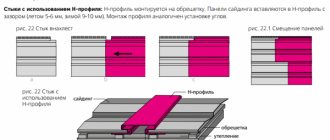

The next step is to install the frame directly under the metal siding. The L-shaped profile (or the main parts of the sheathing) is mounted across the siding. That is, if you plan to mount the siding horizontally, then install the guides vertically. They are fastened with stainless steel rivets 4.8x10 - two per connection. At the junction of two profiles it is also necessary to leave a compensation gap of 6-15 mm. The guides must not be fastened close to each other.

Since walls are rarely perfectly level, the brackets are designed in such a way that they allow the plane of the sheathing to be leveled with an error of up to 30 mm. In difficult cases, you will have to install longer brackets or extensions.

Installation of additional and shaped elements

Some of the additional elements are installed before the siding itself is installed. This:

- base ebb;

- starting strip (for Shipboard, Lbeam XL and Woodstock siding);

- complex finishing strip (for L-beam siding);

- complex and lower prefabricated corner and joining strips (simple and upper prefabricated ones are installed after the siding);

- 3D strips of window and door slopes.

The base molding, starting or finishing strip are secured with self-tapping screws to the guide profiles. Use a level for proper installation.

Complex additional elements are distinguished by the fact that they not only cover joints and corner joints, but also hide their own fastening, which gives the facade a more aesthetic and neat appearance.

In the case of simple planks , they are mounted to the siding itself with self-tapping screws, so the joints are exposed by the hardware.

Prefabricated corner and butt strips are used for Woodstock siding. They consist of two parts - upper and lower. The lower part is mounted before installing the siding panels, using self-tapping screws to the sheathing. After finishing the façade with siding, the upper parts of the planks are inserted into the lower parts until they click, without additional fasteners.

To install the docking strip , it is important to calculate in advance all the dimensions you need and decide where it will go. Siding is manufactured in lengths from 0.5 to 6 meters in centimeter increments. When ordering panels, keep in mind that it will look better aesthetically if the connecting strip runs 4 and 4 meters between the panels rather than 6 and 2.

To design window and door openings, 3D slope strips, small aquilon strips and ebb strips are used. Along with 3D slopes, a simplified version can also be used - a eaves overhang plank or a complex eaves overhang plank.

FORBIDDEN!

Do not use an angle grinder to trim siding. During its operation, damage occurs to the polymer and zinc coating of the panels. In the future, this will lead to very rapid corrosion.

Installation of siding panels

After installing all the necessary elements, you can begin installing the siding panels themselves. Please note that the installation of metal siding Shipboard and Lbeam XL is carried out from the bottom up, and the installation of metal siding Lbeam and Woodstock is carried out from top to bottom. The first row of siding clings to the starting strip. The free edge is attached with self-tapping screws with a 4.2x16 press washer to the sheathing profiles.

In this case, it is important to screw in the self-tapping screw exactly in the middle of the mounting hole and leave it a little, literally 1 mm, undertightened. This is necessary to compensate for thermal expansion. If you overtighten the hardware, the siding panels may become deformed or ripple. In the case when the fastening hole hits the sheathing with only one edge, we recommend increasing the length of the hole in order to still screw in the self-tapping screw in the middle.

Each subsequent row of siding clings to the previous one and is attached in the same way. Don't forget to check the level of the panels. If you have installed complex additional elements: the siding panel is inserted with one end all the way into the corner strip, and insert the other end behind the joining profile. Then move the plank slightly so that on both sides there is a gap of 6-10 mm between the siding and the edges of the planks. If you plan to install simple extensions, also leave a distance of 6-10 mm at the corners and in the place of the joining strip. Under no circumstances should you install metal siding end-to-end or overlapping.

IMPORTANT

To avoid the effect of repeating the pattern of siding with ECOSTEEL® coating, we recommend alternating panels during installation, mixing them in random order from different packs of the same length. It is optimal to mount the planks alternately from five or more packs, if they are available. This is especially true for siding in the colors Golden Oak, Cedar and Pine.

The last panel of siding may not fit completely into the remaining space. In this case, regardless of whether the last panel is attached to the top or bottom, you will have to cut it to size, install a Z-shaped strip and secure the remaining siding strip with rivets.

Design of window and door openings

If you have indicated in advance the most accurate dimensions of all openings and parts of the house, then you will practically not have to cut the siding yourself. It will already be equipped with panels of the required length. But horizontal cuts, where they are necessary, will need to be made directly during installation. To do this, you first need to secure a small piece of siding near the opening and make a mark on it, moving another 6 mm along the wall from the edge of the window. Then transfer this dimension to the panel and cut. The same tolerance of 6-10 mm must be made when cutting vertically.

To create a neat and complete appearance of a house covered with siding, use special shaped elements. For windows and doors, 3D slope strips in combination with small aquilon strips are suitable. This solution will favorably emphasize the relief of the facade. The small aquilon strip is attached to the window with self-tapping screws, then the 3D slope strip is inserted into it. If necessary, it can be trimmed to fit the depth of the opening. Then a possible uneven cut will be hidden inside the small aquilon strip, preserving the beauty of the facade. Instead of a 3D plank, a eaves overhang strip can be used - simple or complex.

Instructions for finishing a house with metal siding

There are two methods of attaching metal siding: hidden and external:

- When finishing the façade with metal siding, the fastening elements are located on the inside of the panels and are not visible from the façade. Panels for hidden fastening methods are made to exact geometric dimensions and require cutting and fitting, so this type of metal siding is unique and individual. This increases the cost of work and practically reduces to zero the possibility of self-installation of metal panels due to the need for highly qualified workers performing the installation.

- The external method of attaching siding does not require high qualifications and skills; it is enough to strictly adhere to the manufacturer’s recommendations for installing the finishing material.

Metal soffit

The metal soffit is made using planks:

- with smooth,

- perforated,

- partially perforated surface.

Perforation of the surface allows the finishing material to breathe without accumulating moisture vapor from precipitation.

This type of siding is used mainly for finishing eaves and slopes on the under-roof side of the roof, as well as gables.

Soffit panels have special locking elements, which allows them to be accurately fixed to each other. The structure of metal soffits is attached to the surface frame using self-tapping screws. Metal soffit panels have a single color.

Tips and tricks

Experts with extensive experience in finishing facades using metal siding recommend:

- Give preference to material that imitates a log if you want a discreet and practical option. This material is resistant to temperature changes and is also less susceptible to fading under the influence of ultraviolet radiation, therefore maintaining its attractiveness longer.

- When performing the finishing procedure yourself, it is better not to combine cladding options, but to use exclusively the horizontal or vertical method.

- Require documentation confirming the quality of metal siding before purchasing, as well as a warranty.

- Carefully calculate the amount of material needed. If you have doubts about the correctness of the calculations, it is better to contact specialists.

- When using vertical siding, install from top to bottom.

- When installing, use a metal sheathing that can withstand the load and eliminate deflections and deformations.

By strictly following the installation instructions and taking into account the recommendations of professionals, it is possible to independently make a luxurious home cladding with metal siding.

The appearance of buildings finished with metal siding is striking in its originality and style. At the same time, the houses have an expensive, presentable appearance. By choosing the right shade of material and combining the colors of façade and additional elements, you can achieve a stunning visual effect.

Installation features

Installation of metal siding requires the use of a large number of different additional elements:

- slats;

- platbands;

- corners;

- rack

If the building has prepared, even walls and there is no need for insulation, the material is attached directly to the wall. In other cases, a supporting frame made of wood, metal profile or galvanized metal is required.

Polymer in the world of design

High performance in the decorative design of external facades is given to the siding by a special polymer coating, which can be of several types:

♦ For a high gloss finish. One of the most popular types of siding treatment is applying a layer of polyester (PE) to its surface. Panels with this coating are distinguished by their long service life, practicality and functionality.

Polyester is an elastic material. When used, it seems as if the siding gently envelops the building, creating a durable, airtight shell.

Such panels are so affordable and versatile that they are suitable for cladding any buildings: both huge country cottages and small dachas.

Cute little house with metallosidin with polyester

This metal siding can be of absolutely any color.

♦ Tree. Metal siding is treated with matte polyester (Matt-PE) to create an unusual velvety coating that imitates various natural materials. It contains Teflon, which increases the protective properties of the sheet.

Particularly popular in our country is metal siding made from logs or wooden beams (block house). It is almost impossible to distinguish it from real wood.

But, unlike capricious wood, such panels require minimal and simple care (they need to be watered with a hose from time to time), and their service life is much longer.

Metal can successfully imitate wood siding

♦ Stone. The original type of polymer coating made from a synthetic polymer with the addition of mineral granules is known as polyurethane (PUR). It is famous for its high resistance to ultraviolet radiation and mechanical stress.

A colored layer of marble chips, porcelain stoneware, glazed ceramics or clinker is applied to the surface of the panels. It resembles stonework. Imitation of marble, granite or brick is especially good.

Metal siding with a polyurethane coating has low thermal conductivity and is not afraid of cold, heat and moisture. It is resistant to rotting. Such panels are successfully used when finishing curved walls.

♦ Leather. To form an unusual metal siding coating with imitation leather, plastisol is used. The effect of embossed leather gives a rich and presentable look to the home. Plastisol is highly resistant to impacts and damage. It is recommended to use it in conditions of high humidity (for example, on the sea coast).