Finishing the roof eaves with siding Finishing the roof eaves with siding is an important point in the final completion of the roof work. Finishing the roof eaves with siding emphasizes its edging and serves as the final stage. Here you need to approach the issue correctly and do everything efficiently and competently. First of all, watch the video on our website and after this photo you will be told about the correct manufacturing process. In this article we will look at how to line a roof eaves with siding and will offer instructions on how to complete this work.

Siding for covering the eaves

Vinyl siding is most often used for siding, but wood, galvanized, and galvanized metal eaves siding can also be used. The vinyl version is lighter, more durable, reliable and inexpensive. Standard panels have a length of 3 to 3.6 meters, each of them has profiled strips measuring 10-12 cm and special locks on the edges.

The cornice is sheathed with two types of soffits:

- Solid siding panels with no perforations.

- Soffits with partial perforation.

The use of the second type helps to create more proper ventilation of the space under the eaves.

Vinyl soffits

When hemming the cornice with vinyl soffits, it is important to adhere to the following rules:

- Before direct use, the material is stored in places with limited access to sunlight at a temperature of no more than +60 degrees.

- The installed panels must move freely horizontally.

- When securing the panels, do not apply force to prevent damage.

- It is best to attach soffits using self-tapping screws.

- The fasteners are not screwed in until the cap is completely sunk; it is recommended to leave a gap of at least 1 mm. Pressing too hard may cause the panel to break.

- It is not recommended to use sealant between soffits and corner elements, as well as between panels and profiles.

Installation of a box under eaves

Before directly covering the cornice, the frame is installed. For its manufacture, wooden blocks or aluminum profiles are used. The first option is suitable for clapboard cladding; in other cases, the box is made of aluminum profiles.

For the box you need to take two boards, one of which is mounted on the wall, placing the lower part strictly horizontally. This is necessary for level installation of the siding eaves strip.

Lining the cornice with soffits is not considered a complex process, but requires a responsible approach. In addition to decorative purposes, the panels also have a functional load, since hemmed cornices give the building the appearance of a completed construction and at the same time create protection for the house from moisture and rain.

Among the advantages, it is worth noting easy installation and the ability to implement various architectural ideas thanks to various types of siding and components.

To qualitatively solve the problem of how to sheathe a cornice with soffit, it is enough to follow the steps according to the following scheme:

- Two special strips are installed on the eaves overhang.

- Specially shaped profiles are attached to the board on the wall.

- The soffits are cut into pieces of the required length and aligned in accordance with the width of the overhang.

- One edge of the panel is inserted into the groove, and the other side is fixed to the installed strip.

- A decorative strip is installed along the line connecting the soffits to the external cladding of the house, which makes the overall appearance more attractive.

Types of profiles for filing cornice and gable overhangs

Let's move on to the process of installing spotlights. They do not perform a particularly important constructive function, but you still have to show skill and accuracy here.

The fact is that if you make mistakes when filing the cornice, then it will at least look ridiculous, and in the worst case, birds can easily penetrate into the under-roof space and create problems.

Installation features

You can hem the roof with siding only after installing the rafter system. This will help you correctly solve the problem of how to cover the eaves of a house with siding.

The filing process itself is characterized by several features:

- For high-quality sheathing of the cornice, it is necessary to make vertical cuts of the lower heels of the rafter legs. It is important to ensure that the cuts are parallel to the walls of the house.

- It is best to carry out the cladding using special strips that match the color of the roof or the exterior cladding of the house. Using ordinary wooden boards for this purpose will not add aesthetics to the structure.

- The lower heels of the rafter legs are sawed off vertically, since they must be sewn up together with the entire structure.

- It is recommended to insulate the walls before covering the roof overhang with siding.

Lining roof overhangs with siding is done in two ways:

- In the first case, a horizontal box is made from boards, attaching one of them to the wall and the other to the bottom of the rafters. In the place where the roof slopes meet, place the board with the wide part, making even joints. In this case, it becomes possible to create a structure independent of the walls of the house. The planks are fastened using angles and plates.

- The second option is used for pitched roofs; the eaves are hemmed along the rafter line. In this case, when arranging the frame, it is important to take into account that the angle of inclination of the hem should coincide with the slope of the slope. The rafters in the lower part should be as even as possible so that screwing the boards does not cause difficulties. Using this method for a pitched roof requires the installation of two boards on opposite sides at the junction of the slopes.

Materials

Eaves overhangs are hemmed using various materials: lining, corrugated board, siding, soffits and others, each of which has certain specific properties.

Most often, corrugated sheeting, lining, siding or soffits are used for finishing overhangs.

- Profiled sheeting. It is a corrugated steel sheet with a galvanized coating. To protect the metal from corrosion, the material is coated with a protective polymer coating on top. Corrugated sheeting is lightweight and comes in a variety of colors, which allows it to be used for lining overhangs and contributes to the implementation of original design solutions. Installation of corrugated sheeting on roof overhangs is complicated by the need to cut the sheet to the required size, and also by the fact that the cut points must be additionally protected to prevent metal corrosion.

- Lining. The material is used for finishing the eaves of buildings built of wood, since it is the wooden lining that looks the most organic and gives the structure completeness. Wooden lining should be additionally treated with antiseptic deep penetration primers to protect the material from the negative effects of moisture and biological decomposition. To ensure ventilation of the under-roof space, ventilation gaps should be left between the slats of the material, allowing air to penetrate into the under-roof space over the entire area of its overhangs. Plastic lining is considered the most economical option for finishing roof overhangs. The disadvantages of finishing with plastic lining include the need for additional ventilation holes, which spoil the appearance of the structure.

- Siding. Siding made of polyvinyl chloride is used for filing overhangs. Special U-shaped panels are available for sale, designed for finishing corners, roof overhangs and ventilation grilles. (types and forms of siding are presented here)

- Soffits are special profiled panels made of polyvinyl chloride, designed for lining overhangs. The soffit is lightweight and sufficiently rigid to provide the structure with the necessary wind protection and strength. Ventilation of the under-roof space is ensured by the presence of special ventilation holes on one of the waves of the finishing material.

Regardless of the roof configuration, there are two methods of filing its overhangs: along the rafter line and by installing a horizontal box.

When filing overhangs along the rafter line, it requires that the rafters of the roofing system have a flat surface . The box is created by installing boards to the rafters of the roofing system. The box obtained in this way will serve as a supporting frame for further finishing of the roof overhangs.

The second option involves installing a horizontal box using two boards . The first board is mounted to the bottom of the rafter system, the second - to the wall of the structure, in the place where the roof rafters approach it.

Important! You should start filing the roof overhangs only after completing the thermal insulation of the walls of the structure. If you hem the overhangs and only then begin thermal insulation work, the upper part of the walls of the structure will remain “cold,” which will significantly affect the energy efficiency of the structure.

The rafters of the roofing system also need to be pre-prepared: treated with special protective impregnations, cut so that they run parallel to the wall of the building. The cutting distance of the rafters from the wall should be the same along the entire perimeter of the structure, since otherwise, after filing the overhangs and installing the wind strip, all the irregularities will be noticeable.

Lining roof eaves with siding

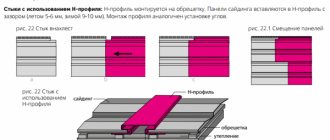

When filing with siding, the sheathing is replaced by a mounted box along the entire rafter line. In addition to U-shaped siding panels, components such as external and internal corners and profiles are used.

Installation profiles are mounted along the edges, into which the siding panels are inserted. Siding is installed sequentially along the entire length of the cornice.

The finishing material is fastened using umbrella nails, the heads of which should not tightly press the finishing material to the sheathing. It is necessary to leave a temperature gap that will compensate for the expansion of the finishing material.

To compensate for the thermal expansion of siding panels, there should be a play of 6-10 mm between the corner profile and the finishing material.

Covering roof overhangs with soffit

After creating the horizontal box, they begin installing the soffits.

Both J- and F-profiles are used for cladding. After measuring the width of the cornice, the finishing material is cut. The length of the soffit should be 6 mm less than the measured width of the cornice. The soffits are inserted into the profile, sequentially adding plates along the entire perimeter of the roof overhang.

As you approach the corner, the length of the spotlights should gradually decrease. To join the two sides in the corner, the edge of the panel must be filed at an angle of 45 degrees.

Lining

The lining is attached to a previously created horizontal box. The technology for fastening wooden lining is quite simple: the material is stuffed between two guides of the created frame. To fasten the lining, you can use umbrella nails or galvanized self-tapping screws. The ends of the wooden lining should be treated with special protective compounds.

When finishing roof overhangs with plastic lining, special ventilation holes should be installed.

To install plastic lining, starting profiles are installed into the grooves of which plates of finishing material are inserted.

The plastic lining is fastened using galvanized screws or nails with an enlarged head.

Regardless of the chosen finishing material, the lining of the roof overhangs should be done with high quality, since the energy efficiency and durability of the structure depend on this. If the technology is not followed, moisture can penetrate into the under-roof space and destroy the thermal insulation layer.

Need to know! If, when filing overhangs, you do not ensure sufficient ventilation of the under-roof space, then water vapor will not be able to escape outside and condensation will accumulate both in the heat-insulating layer itself and on the elements of the roof structure, leading to its destruction.

The process of sheathing a cornice - how to sheathe it correctly

The problem of how to sheathe a roof with siding is solved using the following materials:

- Siding, the color and profile of which are selected in accordance with the type of roofing or material for cladding the facade.

- Profiles of different types, external and internal corners.

- Self-tapping screws. These fasteners do not allow the panels to fit tightly to the sheathing or to the corner profiles.

A frieze strip may also be needed if the installation work requires its use. This element is installed directly above the cornice profile.

Direct installation is not a complicated process, the main thing is that the rafters are properly prepared for installing the box. The parts of the rafter legs protruding beyond the façade line must be strictly parallel and even.

Next, they make a vertical cut of the lower heels of the rafter legs and build up the first sheathing board with a sheet of OSB.

Direct covering of the cornice begins after work on thermal insulation of the walls of the house. Special grilles are made for free air circulation. Carrying out the above actions contributes to high-quality sheathing of the eaves with siding.

Features of copper soffits

Due to its high cost, copper siding is used very rarely, although its quality characteristics are at a high level. Over time, copper becomes covered with an oxide film, due to which it acquires a reddish tint and a beautiful appearance.

Copper soffits are thin sheets characterized by increased thermal conductivity and are highly resistant to corrosion. By lining the cornices with such material, you can solve a large number of problems, including resistance to aggressive environmental influences and moisture. The use of perforated soffits allows you to create conditions for free air circulation.

Connoisseurs of beauty use patinated coatings for covering cornices, which are characterized by the presence of a noble malachite-green hue.

Types of panels

Metal

Since hemming the eaves with wood siding is not very profitable and convenient, let’s try to consider another option. The metal is quite durable and inspires confidence, but due to the same condensation it will begin to rust even though it has a galvanized layer. As a result, rust spots with a characteristic reddish color are visible. Aesthetics will be lost, and along with it, strength will also be lost. Of course, if the option is to purchase a copper profile, as it is resistant to corrosion and has a beautiful, noble shade. But before you line the cornice with this type of siding, think about the cost. The price of copper material is high.

Vinyl

Both previous options are not very suitable, and are also quite expensive. Vinyl siding is relatively inexpensive and more common in construction due to its resistance to moisture.

The polyvinyl chloride from which this type of siding is made has:

- High strength.

- Heat and moisture resistance.

- Wide color palette.

- Nice price.

- Ease of installation

- The fact that installation does not require multi-line instructions.

Please note that siding by itself is not suitable for finishing the cornice, so soffits are used - special products designed specifically for the cornice.

These are panels with or without perforation made of PVC, which are needed to protect the cornice from excess moisture.

There are several types of soffits, which differ in the type of perforation:

- No perforation.

- Partially perforated.

- Fully perforated.

This is necessary for ventilation of the eaves space. In order for the finishing of the cornice siding, the photo of which is attached in the article, to be correctly selected, you first need to familiarize yourself with the project. Based on the engineering solution of the cornice assembly, determine the degree of possible moisture. You can also, by studying the project, immediately select the desired shade of the product that you will use for finishing.

In a warm attic space, it would be more advisable to line the eaves with solid soffits. They are needed to prevent cold air from penetrating inside and protect the roof from moisture that can enter from the outside. Fully perforated panels provide enhanced ventilation. In this case, the panel will contribute to the movement of air masses. This type of panel is used for roofing with non-ventilated continuous decking. For example, if you have a roof made of bitumen tiles or covered with rolled materials.