Door slopes made of MDF give the interior a completely finished look. But their installation requires compliance with certain technological rules that make it possible to achieve the necessary reliability. The fact is that any violations can lead to undesirable consequences. Although all the work can be easily done with your own hands with a minimum set of tools.

Advantages of building materials

Finishing a door opening is a labor-intensive process that requires precision and following advice. Therefore, it is possible to make this kind of cladding yourself. Slopes can be finished with panel materials, the variety of which can satisfy any needs. Often finishing work is carried out with plastic, wooden panels, plasterboard, but MDF panels are considered the most successful.

Advantages of MDF panels

Since this finishing building material has numerous advantages:

- Availability of material.

- Easy to install.

- Aesthetic appearance.

- The density of the material creates additional sound and heat insulation.

- Environmentally friendly. Fiberboard is made by pressing wood chips under the influence of temperature and pressure. The core binders of the fibrous material use carbide resins, which are harmless to humans. Consequently, MDF is an environmentally friendly building material that can be safely used for cladding both exterior and interior structures.

- The color palette allows you to satisfy any request. You can choose the colors of the panels from wenge to bright shades.

Doorway lined with MDF slopes

But like any building material, MDF panels are not without their drawbacks:

- Weak resistance to mechanical damage. If the MDF panel is deformed, the damage cannot be restored.

- Does not withstand significant levels of humidity.

Therefore, finishing door slopes with MDF panels should not be done in conditions of high humidity.

Do-it-yourself MDF front door slope (video)

Advantages of laminate products

Laminate slopes are equally good when finishing the entrance to an apartment or country house, office or any other non-residential premises. This material goes well with various floor coverings.

Laminate has many positive qualities, which makes it popular specifically for arranging slopes:

- Low price and availability. The material is easy to find in the nearest construction supermarket; it is quite inexpensive.

- External attractiveness. Due to the variety of shades and textures, it can be matched to any door. It goes well with designs in which the canvas imitates wood.

- Easy to install. Laminate slopes are very easy to install on your own. It won't take much time and doesn't require any special construction skills. The material cuts well, it is light, bends moderately, so it does not crack.

- Durability and moisture resistance. Laminate can withstand bends well and is shock resistant. Some of its varieties have not only upper, but also lower protective layers that protect the material from moisture penetration.

In addition to these advantages, laminate slopes for interior doors have a significant service life. With proper installation and good quality products, they will last about 15 years, no less than the door itself.

Preparatory moments

All the benefits that come from lining the slopes of external doors with MDF panels can be demonstrated during installation. Therefore, before starting work, you can study a video of exactly how slopes are made at the front door. Wood fiber panels come in 2 options:

- Designed for finishing work (they have an L-shape).

- Wall panels.

Measuring the doorway

Most novice craftsmen have a completely natural question about how to sheathe the slopes of an MDF entrance door correctly. First you need to do some detailing. To make door slopes from MDF, you need to take the dimensions of the opening, which should be drawn on paper. Based on the transferred data, each element should be schematically depicted. It is recommended to take into account the following points:

- Presence of a threshold.

- The order of placement of parts.

- Opening width and angles of inclination.

After installing the door, all gaps between the wall and the frame must be sealed with foam. After the foam has hardened, all excess should be cut off.

How and what is used to finish door slopes after installing the front door

After installing the new entrance door, all that remains is to update them with brand new slopes. They can be integrated into the interior design in different ways; plasterboard, laminate, MDF, PVC sandwich panels, as well as non-standard materials (for example, imitation natural stone) are suitable for design. In order not to spend money on the services of a specialist, you can install the slopes yourself, following the instructions.

Installation of slopes using a frame method

Installation of wooden slats

Slopes made of fiber panels can be made using the frame and glue method. Do-it-yourself installation of slopes from MDF panels using a frame method is carried out using the following technology:

- Along the edges of the slope, both inside and outside, use dowels to secure wooden slats, which must be covered over time with MDF panels. The bars should be level. To avoid distortion of the structure between the skeleton and the opening, wedges must be driven in.

- Cut 3 sheets from MDF (2 for vertical mounting and 1 for horizontal mounting).

- The parts should be attached to the opening and points for cutting should be marked.

- Trimming should be done strictly to the size of the door opening.

Installation of wooden slopes

- Apply liquid nails to the inner edge of the panel and attach to the frame.

- The panels should be aligned so as to achieve a minimum gap between them.

- Fixation can be strengthened using self-tapping screws that are screwed into the upper and lower parts. The screw caps are decorated with special elements.

- The final point is attaching the platbands.

If the depth of the opening does not exceed the width of the MDF, then in this case it is possible to fix it in a seamless manner by installing it vertically.

Various finishes

Today you can use one of the types of finishing of openings or door slopes with MDF panels with your own hands. The easiest way is to glue a pre-made slope to the door frame. You can see what it looks like in the photo. To create it, MDF panels are used. Naturally, this will significantly reduce the time spent on finishing work and will also facilitate the efforts made. You can even do this work yourself.

The advantage of MDF panels, which are made from compressed wood waste, is that they are not afraid of temperature changes and humidity fluctuations.

If you are looking at additional decorative MDF elements, the shade of the color of the door leaf must be taken into account.

Central heating in the house involves predominantly “dry” finishing technology. For optimal thermal insulation and increased sound insulation capabilities, the box must be caulked. The joints that remain between the wall and the frame are traditionally sealed with a special solution. The panels used to cover the slopes are fixed using mastic. It is recommended to then paint the outside of the slopes; preference should be given to oil paint.

In houses where stove heating is installed, wet plaster is predominantly used (photo). The solution that is prepared for finishing work will include different components depending on the building material from which the walls are made, the level of moisture content in the air, etc. The main requirement will be that the plaster adheres tightly and reliably to the wall surface.

Metal doors require their own specific actions when installing slopes and finishing work. For slopes in this case it is better to use a cement-sand composition. If the slopes are wooden, then they are filled with polyurethane foam. The negative aspect of this option is its reduced insulating properties.

Installation of slopes using the adhesive method

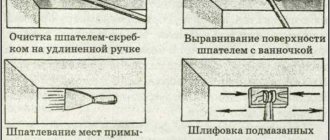

Plastering a door slope

If preference is given to the adhesive method, then in this case you should familiarize yourself with the tips for installing the front door and MDF slopes. Work algorithm:

- First of all, for the glue method, you need to plaster the slopes.

- It is recommended to treat the prepared surface with a primer. After priming, the surface must be waited until completely dry.

- Install beacon profiles according to level. To install profiles on slopes, apply a solution and level the beacons in all directions. Give the solution time to set.

- The solution is applied to the slopes and leveled along the beacons with a spatula. After the manipulations, the slopes should be left for 2 days until the solution completely sets.

- The inside of the part is coated with glue and pressed to the surface.

- When all the elements are installed, the resulting joints are sealed or covered with overlays.

Important! After completing all the manipulations, you can proceed to the exterior decoration of the door structure. For this purpose, it is possible to cover the surface with platbands or level the surface using putty. On the Internet there are photos, videos and reviews that describe in detail the entire step-by-step process of the frame and glue method.

How to bend MDF

Sometimes it becomes necessary to trim elements of a round or semi-oval configuration with wood fiber sheets. Naturally, the question arises of how to bend the material and whether it is possible. It should be noted that it is possible to bend MDF if thin panels are used (the average value should not exceed 3 mm).

How to bend an MDF panel at home

To bend the panel, perform the following steps:

- Manufacturing blanks from fiberboard.

- Make notches in the sheet across the bend.

- Cut pieces of MDF to the required dimensions.

- At the bend points, apply lines at intervals of 5 mm. The undercut should be 1 mm.

- The resulting shavings must be collected and mixed with glue until a paste-like mixture is formed, which fills the holes.

- Place the MDF sheet on the template and fix it with nails. The nails do not need to be driven deep for ease of removal.

- The last stage is removing the workpiece, sanding and painting.

By following the recommendations, you can effortlessly sheathe slopes with MDF panels or other building materials yourself. Anyone can do all the manipulations with their own hands, despite the fact that finishing slopes with a material such as MDF is a painstaking and time-consuming process.