How to decorate doors with MDF panels yourself

Published by: Arthur Kanapatsky 0

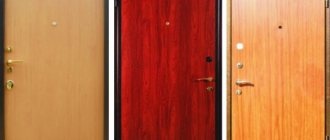

Today, iron and metal entrance doors in houses have practically become a necessary element - they help a person to feel safe. However, despite the rather menacing appearance, the externally metal door does not look very attractive. In order to correct the situation, the door is finished with MDF panels. At first glance, cladding MDF doors seems difficult. After reading the article, you are convinced that decorating doors with MDF panels with your own hands is not a difficult process at all.

Advantages of MDF entrance doors

Among the main advantages of entrance doors finished with MDF panels are:

- wide range of colors and stylistic solutions;

- the ability to choose a door in any price category;

- long service life;

- good sound insulation;

- unpretentiousness and easy care.

Entrance doors can be selected for a city apartment, a respectable cottage and a small country house, an office space and a grocery store. This versatility significantly distinguishes metal doors finished with MDF panels from other types of entrance doors.

Advantages of MDF finishing

MDF is a medium-density wood-fiber board used for finishing the front door outside and inside. Suitable for cladding doors made of iron, metal and steel - even steel doors with MDF finishing look amazing, impressing the most demanding aesthetes.

Why should you give preference to this particular material?

- Wide choose. Modern manufacturers willingly please the consumer by providing us with numerous options with a variety of colors and textures. It is possible to finish with materials that imitate natural ones - thus, entrance doors with MDF finishing acquire an elegant appearance. Design options are widely presented in the photographs provided by the manufacturer - choose your unique option, completely transforming the appearance of the hallway.

- Durability. Wood-fiber materials will retain their presentable appearance and useful qualities for many years. They perfectly tolerate various mechanical loads and are not afraid of temperature changes and sunlight. Compared to upholstery made from leatherette (easily torn and fading before our eyes), MDF boasts a combination of beauty and practicality.

- Safety. The panels contain absolutely no substances that can harm human health, unlike some other facing materials.

- Easy care. No difficulties are expected - forget about expensive detergents, delicate procedures - you just need to periodically wipe the panels with a damp cloth. In addition, MDF does not absorb unpleasant household odors at all - no additional care is required.

- Ease of installation. It is possible to finish with MDF panels without involving specialists. All you need is the necessary tools and extreme accuracy, then finishing the MDF door will be quick and successful.

- Sound insulation and thermal insulation. The materials will provide you with a cozy, warm hallway - it is possible to add a layer of insulation on the outside.

- Acceptable price. Depends on the specific type of panels, however, in general, they belong to the average price category.

- Possibility to install slopes made of similar material.

Design features of MDF entrance doors

What is MDF? This is an environmentally friendly material created by pressing a fine fraction of lumber production waste. Unlike fibreboards, MDF has minimal water absorption, is characterized by high strength and good sound insulation properties. Manufacturers of these products produce slabs of different thicknesses; panels for finishing entrance doors have a thickness from 4 to 24 mm. What are the differences between these panels?

Slabs of 4-7 mm cannot be milled due to their small thickness; they are used in the production of smooth doors. The surface of the panel is laminated with films based on multilayer paper impregnated with melamine or PVC. Such MDF entrance doors have an affordable price, but have a low level of sound insulation. Despite the simplicity of design, they are in high demand, as they are available in a wide variety of colors and are able to satisfy the aesthetic needs of customers.

10-16 mm slabs are used for the production of panels with embossing or milling, which significantly expands the capabilities of designers. Such MDF metal entrance doors have a balanced price and have good soundproofing characteristics. They are widely used and are produced by all major manufacturers of entrance doors.

18-24 mm slabs are not so widely used, despite the fact that they provide more opportunities for original milling. Due to their high price, they are used in the production of premium entrance doors. MDF panels 18-24 mm provide a high level of sound and thermal insulation and further strengthen the door structure.

On the inside, metal entrance doors with MFD finishing can have any design. They use thin MDF panels, laminate, leather, and photo printing - this allows you to choose a model that fully matches the interior of the hallway. The inside of the doors is finished with practical materials, which ensures easy maintenance. The internal filling of the doors is similar to models of other types of entrance doors. To improve thermal insulation and sound insulation characteristics, mineral wool insulation is used.

Panel installation

Before you begin the finishing work, you should prepare the tools and the doors themselves in order to avoid additional problems after installation.

First, let's get rid of the cracks around the doorway - polyurethane foam is perfect. Carefully fill in all the holes and cracks, and after drying, cut off the excess elements with a knife. Next, the surface is well treated with a primer.

The doors themselves should be freed from any additional elements: we remove the locks, handles and peephole. In addition, if there was casing that you now want to replace, it must also be completely removed using a spatula or knife. If you plan to use glue or liquid nails when installing the panels, pre-prime the surface for better adhesion. If the door is metal, treat it with an anti-corrosion agent. Also, in the MDF panel itself, you should carefully select and cut a hole where we will install the lock later.

Let's move on to installation. First, the doors should be removed from their hinges - in principle, it is possible to carry out installation work while hanging, but this increases the risk of distortions (getting rid of them is quite labor-intensive work). They are laid on a flat surface, providing the most comfortable working conditions. All areas are sanded, all unnecessary elements are removed - old paint, traces of corrosion, remnants of previous upholstery. The panel should also be prepared - wipe it thoroughly from the wrong side to avoid peeling.

Special mounting adhesive is applied to the door base - it should lie in waves, and the edges must be coated very well - this way the panel will be securely fastened. The adhesive itself is chosen based on the type of materials used. It is better to mark in advance the location of all possible connectors. The panel is laid on the surface and begins to be pressed, having first leveled it as much as possible - everything must be in its place, otherwise you will have to do the work twice. If you want to play it safe and additionally fix the MDF with self-tapping screws, drill holes around the perimeter of the surface and insert small self-tapping screws (it is important to prevent them from coming out from the back side). When using screws, immediately drill out the areas reserved for handles and locks.

The work is finished - now we mask the joints and edges using plastic or metal corner profiles, attaching them with the same mounting adhesive that was previously used to attach the panels.

Installation technology

MDF panels for metal doors are mounted using a fairly simple technology:

- To do the job most efficiently, you should remove the canvas. This method will allow you to avoid distortions that may appear if you try to carry out the process by weight. All protruding elements are removed from the part. Before starting finishing work, it is necessary to remove the door leaf from the hinges

- The canvas is laid on a flat and stable surface.

- It all starts with sanding all areas well. It is necessary to remove old paint and possible traces of corrosion. Next comes cleaning and degreasing.

Now you should prepare the panel itself. On the reverse side, it is wiped well to eliminate any contamination that could lead to peeling. Next, a special adhesive is applied to the door base. It is selected taking into account the materials used. It is distributed in waves, and all edges must be well coated. The choice of glue should be approached very carefully, otherwise all the work may be in vain. For greater convenience, the location of all door connectors is marked in advance. The panel is laid on the surface. They carefully align it and begin to press it

It is important to ensure that the MDF lies clearly in its place. To get the job done faster, clamps are used. Holes are drilled around the perimeter, the distance between which should be ten to eleven centimeters

They will allow for additional fixation with self-tapping screws. If additional screws were used, then further work is carried out immediately. They consist in drilling out places for handles and locks. MDF panel for the door - installed.

It is necessary to take into account that a significant problem may arise - the handles do not fall into place. This will mean that the thickness of the overlays is chosen incorrectly. But it happens that it is impossible to find another one. Then the holes for the handles are milled, which are recessed into the panel.

Door trim with MDF panels in detail

Metal doors have many advantages, so installation is the right solution for installation. However, they are not always attractive and often lack insulation. In order not to destroy the sequence of correct actions, the next step should be, for example, finishing the doors with MDF panels or other high-quality material.

Preparation for installation of finishing and detailed instructions

This type of upholstery is a modern alternative to all kinds of soft upholstery, which quickly deteriorate, lose their attractiveness and are damaged by pets.

Advantages of the material:

- MDF panels are easy to clean.

- Installation does not take much effort and time compared to other options.

In addition, steel entrance doors made of metal inexpensively Moscow with MDF finishing look much more attractive and neater than other options.

Note. Manufacturers of building materials offer a lot of color options that will suit any interior, and embossing, texturing and volumetric decorative elements expand the choice.

Table: Main construction characteristics

Sheet edge chipping

Up to 2 mm from the edge of the slab

No more than 1.2 mm per 1 m

No more than 10% of the slab surface

No more than 2 pieces up to 20 cm long

At home, adjusting building materials is quite difficult. Therefore, before purchasing it, you need to take measurements with great accuracy with your own hands, taking into account all allowances and angles.

Or call a specialist from the chosen company who will do it professionally. Precisely cutting the panels will allow you to avoid installation problems in the near future.

Preparatory moments

All the benefits that come from lining the slopes of external doors with MDF panels can be demonstrated during installation. Therefore, before starting work, you can study a video of exactly how slopes are made at the front door. Wood fiber panels come in 2 options:

- Designed for finishing work (they have an L-shape).

- Wall panels.

Measuring the doorway

Most novice craftsmen have a completely natural question about how to sheathe the slopes of an MDF entrance door correctly. First you need to do some detailing. To make door slopes from MDF, you need to take the dimensions of the opening, which should be drawn on paper. Based on the transferred data, each element should be schematically depicted. It is recommended to take into account the following points:

- Presence of a threshold.

- The order of placement of parts.

- Opening width and angles of inclination.

After installing the door, all gaps between the wall and the frame must be sealed with foam. After the foam has hardened, all excess should be cut off.

Plaster

A gradually disappearing method of finishing the slopes of the front door from the inside. There are several reasons for this:

- The work is very dirty.

- Cracks often appear if you do not use fiberglass or reinforcing mesh.

- The plaster of the entrance door slopes may become damp.

Besides, the savings are imaginary. You will need to buy: building mixture, fiberglass or mesh (sold only in rolls), concrete contact, putty to cover the rough layer. The solution is decorative plaster. It is a little more expensive, but it does not crack and you can decorate it with a structural roller.

Installation of slopes using a frame method

Slopes from fiber panels can be made using the frame and glue method. Do-it-yourself installation of slopes from MDF panels using a frame method is carried out using the following technology:

- Along the edges of the slope, both inside and outside, use dowels to secure wooden slats, which must be covered over time with MDF panels. The bars should be level. To avoid distortion of the structure between the skeleton and the opening, wedges must be driven in.

- Cut 3 sheets from MDF (2 for vertical mounting and 1 for horizontal mounting).

- The parts should be attached to the opening and points for cutting should be marked.

- Trimming should be done strictly to the size of the door opening.

Installation of wooden slopes

- Apply liquid nails to the inner edge of the panel and attach to the frame.

- The panels should be aligned so as to achieve a minimum gap between them.

- Fixation can be strengthened using self-tapping screws that are screwed into the upper and lower parts. The screw caps are decorated with special elements.

- The final point is attaching the platbands.

If the depth of the opening does not exceed the width of the MDF, then in this case it is possible to fix it in a seamless manner by installing it vertically.

Finishing the slopes after installing the door

In most cases, the doorway is located in a load-bearing wall, the thickness of which is at least 40-60 cm. The frame of a metal door is 60-70 mm; installers traditionally install it flush, which greatly simplifies the finishing of the opening with platbands from the outside. They are used to close the technological gaps between the frame and the wall. From the inside of the room, a recess is formed in the load-bearing wall, the width of which often exceeds 30 cm. Previously, the problem of finishing this space was solved by installing a second door, which provided the necessary level of thermal insulation and sound insulation, and also guaranteed additional protection.

Modern entrance doors with MDF panels are highly reliable, durable and provide the necessary thermal characteristics with a thickness of 40-70 mm.

As a result, slopes are formed, the finishing of which requires additional finishing. All manufacturers of entrance doors produce them; there are standard products of different widths. The buyer has the opportunity to order accessories of the required dimensions. This will not only significantly simplify installation, but will also make the finish of the doorway more attractive.

What are MDF boards? This is a narrow panel characterized by high strength and rigidity. The slopes bear a significant load, so these characteristics are very relevant. Quite often, the entrance door slopes are finished with MDF panels intended for wall cladding. This option is affordable, but it has a number of disadvantages. The thickness of standard wall panels is 4-6 mm, which is not enough to support the weight of a person leaning on the slope. The owner of a house or apartment will have to make frequent lathing on which the wall panels are mounted, or level the walls and glue the cladding onto them with liquid nails. All this causes a lot of problems; it is much easier to order MDF slopes from door manufacturers.

Companies that produce MDF doors offer panels made of slabs with a thickness of 8 mm or more. These components have their advantages:

- high strength characteristics;

- compliance with the design of the door leaf;

- ease of care;

- easy installation.

The use of extensions will make the doorway complete, practical, and beautiful. MDF slopes have a long service life; they do not have to be changed every time the wallpaper in the hallway is re-pasted or the walls are painted a new shade with interior paints.

Entrance doors with MDF cladding are the best choice, attracting not only their price, but also their aesthetic qualities. The advantage of this product is a wide range of finishes, its practicality and the presence of high-quality additional elements. If installed correctly, such a door will last for several decades.

Installation of slopes using the adhesive method

If preference is given to the glue method, then you should familiarize yourself with the tips for installing the front door and MDF slopes. Work algorithm:

- First of all, for the glue method, you need to plaster the slopes.

- It is recommended to treat the prepared surface with a primer. After priming, the surface must be waited until completely dry.

- Install beacon profiles according to level. To install profiles on slopes, apply a solution and level the beacons in all directions. Give the solution time to set.

- The solution is applied to the slopes and leveled along the beacons with a spatula. After the manipulations, the slopes should be left for 2 days until the solution completely sets.

- The inside of the part is coated with glue and pressed to the surface.

- When all the elements are installed, the resulting joints are sealed or covered with overlays.

Important! After completing all the manipulations, you can proceed to the exterior decoration of the door structure. For this purpose, it is possible to cover the surface with platbands or level the surface using putty. On the Internet there are photos, videos and reviews that describe in detail the entire step-by-step process of the frame and glue method.

How to bend MDF

Sometimes it becomes necessary to trim elements of a round or semi-oval configuration with wood fiber sheets. Naturally, the question arises of how to bend the material and whether it is possible. It should be noted that it is possible to bend MDF if thin panels are used (the average value should not exceed 3 mm).

How to bend an MDF panel at home

To bend the panel, perform the following steps:

- Manufacturing blanks from fiberboard.

- Make notches in the sheet across the bend.

- Cut pieces of MDF to the required dimensions.

- At the bend points, apply lines at intervals of 5 mm. The undercut should be 1 mm.

- The resulting shavings must be collected and mixed with glue until a paste-like mixture is formed, which fills the holes.

- Place the MDF sheet on the template and fix it with nails. The nails do not need to be driven deep for ease of removal.

- The last stage is removing the workpiece, sanding and painting.

By following the recommendations, you can effortlessly sheathe slopes with MDF panels or other building materials yourself. Anyone can do all the manipulations with their own hands, despite the fact that finishing slopes with a material such as MDF is a painstaking and time-consuming process.

Door trim with MDF panels

Finishing doors with MDF panels is an excellent solution that allows you to refine a wooden or iron entrance door. Of course, if you wish, you can also work with interior fabrics, but they are less suitable for such procedures. The advantage of the finishing material used is that it is possible to cover an outdated or boring surface in a short time and relatively inexpensively.

Replacing the MDF panel on the door

A situation may arise when the MDF trim on the metal entrance door has been damaged and needs to be replaced. This process is simple and you can handle it yourself.

You need to measure the canvas, after which it can be purchased at any specialized store. In addition, you will need a solution for degreasing the metal door and means to protect it from corrosion.

- Preparing the door leaf. At this stage, the old lining is removed, after which the surface is degreased, and then it is painted or a protective film is glued.

- Holes for self-tapping screws are made on the canvas along its perimeter.

- Lubricate the surface of the lining with glue, and then use clamps to fix it on the door leaf.

- Fix the cover using self-tapping screws. The inner panel is installed first, and then the outer panel.

Before replacing the MDF lining, all fittings must be removed

This simple procedure allows you to completely renew your metal front door and give it a beautiful and aesthetic appearance. In addition, the presence of MDF linings can significantly increase the heat and sound insulation characteristics of entrance doors, so living in such a house becomes more comfortable and cozy.

Video: replacing MDF panels in metal doors

Covering the front door with MDF panels is an excellent solution that allows you to give the canvas a beautiful and attractive look. In addition, its heat and sound insulation characteristics are improved. MDF panels can also be used to finish a doorway. If everything is done correctly, you will create a beautiful entrance to your home with your own hands.

The door leaf today acts not only as protection, but also as a decorative element in the room. But many metal models do not have an elegant design, since manufacturers focus on burglary resistance and strength parameters. Today there is a way to solve this problem by covering the canvas with MDF panels. Using this material, you can radically change the design of a product and improve its technical parameters.

What are the advantages of MDF panels for door cladding?

Front door panels are overlays that are installed on the surface. This option allows you to transform the interior, as well as give the structure additional protective properties. The popularity of this method lies in the material, which has numerous advantages.

Overlays from MDF panels for doors

So, the general advantages of MDF are:

- Wide decorative range. The products have many colors and textures. If required, you can select various types of imitations of natural materials. Thus, the surface to be finished will be completely transformed.

- Durability. The material has a long service life. It perfectly withstands various mechanical loads, temperature changes, and does not fade when exposed to sunlight.

- Safety. The panels do not contain substances harmful to human health.

- Easy to care for. The surface is very easy to care for. It does not absorb various household odors. Care consists only of occasional wiping with a damp cloth.

- Ease of installation. All work is carried out exclusively with your own hands. There is no need to purchase a special tool for this. But keep in mind that extreme care will be required.

MDF door finishing options

Panels can be covered not only with a film of melamine paper; for this, manufacturers use veneer of expensive wood species or laminate - artificial veneer. This not only expands the product range, but also allows you to select a model for an exclusive exterior. Natural veneer glued onto an MDF panel requires careful care. Its advantage is the unique design of each door, since the cut of natural wood has its own characteristic pattern.

If the exclusive nature of the finish is not of interest, but there is a desire to have a finish that maximally imitates natural wood, then it is better to use laminate for cladding MDF panels. This material is made of thick PVC, it is durable, easy to care for, and can be washed using household chemicals. The significant thickness allows you to clearly draw the texture of natural wood. Thanks to this, it is difficult even for a professional to distinguish artificial veneer from natural one.

Different types of material

There are various panels for door trim. They differ in appearance, which must be taken into account in each specific situation. Depending on needs, the cladding can be as follows:

- Covered with natural veneer.

- With a layer of lamination applied.

- With a vandal-resistant plastic surface.

For door trim, you can choose MDF with different coatings.

On a note! All options are available in sizes that fit standard door dimensions. If the design has other parameters, then the overlay will need to be made to order.

Veneered panels

The material is distinguished by the fact that its surface is covered with a thin cut of wood. The use of such panels allows you to completely transform the doorway. It takes on a more noble and respectable appearance. Naturally, such products have a lower cost than natural wood.

The following advantages of veneer should be noted:

- Excellent decorative options. Indeed, the look of natural wood is very difficult to compete with.

- Environmentally friendly. Considering that the MDF base is completely safe, in combination with veneer this is the best solution.

- Good resistance to various types of damage.

Veneered MDF panels are an environmentally friendly material that is resistant to damage

There are also some disadvantages:

- The surface must not be maintained with abrasive substances. If you allow them to be used, the coating will become covered with numerous scratches.

- Peeling at high humidity limits the scope of use.

- Exposure to direct sunlight is an undesirable factor that can lead to defects.

On a note! The veneered option is excellent for apartment buildings, as well as private buildings, provided that the door does not come into direct contact with the outdoor environment.

Door with veneered MDF finish

Laminated panels

Products are obtained by applying a special laminating film to an MDF board. This method makes it possible to produce panels that are inexpensive. It should be noted that the technology makes it possible to imitate almost any texture. Although there are the following varieties:

- Completely smooth.

- With relief milling.

- With inserts that can be made in different colors.

This material has many advantages:

- A large number of design solutions. This makes it possible to choose the most optimal option for each interior.

- Creating additional sound insulation.

- Durability. The service life can be decades.

Laminated MDF is a very practical and durable material

It is also necessary to note the disadvantages, which are expressed in the fact that the product is unstable in high humidity, and, in addition, does not tolerate constant temperature fluctuations.

On a note! Laminated MDF panels are used only for finishing the surface of entrance doors that are located indoors. Such products are a more economical alternative to veneer.

Laminated panels allow you to create an excellent decorative coating

Anti-vandal panels

This material is produced by a method that involves covering a wood fiber sheet with a laminated plastic. The coating turns out to be very reliable. Although this product has many other positive factors.

Among them are:

- Very high strength. The surface is characterized by almost perfect resistance to mechanical stress.

- Resistance to ultraviolet radiation and high temperatures.

- Often, there is a complete absence of damage if chemicals enter.

Indeed, this option does not even have any particular disadvantages. But it is important to understand that the price of the product can be very high.

On a note! This type is ideal for finishing the outside of a door that interacts with the outside environment. Due to the fact that such a surface is very difficult to damage, it is called anti-vandal.