The finishing material of the facade is one of the most important elements of any building. It not only shapes the external appearance of the building, but also protects internal elements, structures and premises from the negative influences of the external environment. Porcelain tiles for the facade are a win-win option. Porcelain tiles are made in a variety of colors, patterns and formats. Facade porcelain tiles can be indistinguishable from natural stone, wood, concrete or even metal. This type of facade tile can be used without fear in our harsh climate - porcelain stoneware is frost-resistant and has water-repellent properties, resistant to aggressive chemicals. This facing tile is easy to clean and will cost much less than natural stone. The number of joining seams on the facade can be reduced to a minimum - a modern porcelain stoneware slab can exceed three meters in height!

- Manufacturing technology and main types

- Physical characteristics of porcelain stoneware

- Dimensions

- Color solutions

- Advantages and disadvantages of porcelain stoneware

- Types of porcelain stoneware installation Mechanical fastening

- On glue

- Combined method

- Ventilated façade

- Fastening to the facade

Manufacturing technology and main types

Porcelain tiles are made by mixing clay, quartz sand, feldspar, kaolins and mineral dyes. The resulting mixture is pressed and fired in a kiln. Both the pressure force and the firing temperature are much higher than in the case of conventional ceramic tiles. Thanks to this, porcelain stoneware slabs can be safely used for façade cladding. Facade porcelain tiles are quite heavy, so this load must be taken into account when designing the building. As a rule, a porcelain stoneware façade should be no thicker than one centimeter. Nowadays, options with a thickness of 6-7 mm are also available, which significantly lightens the weight of the slab.

When tiling a house with porcelain stoneware, it is important to choose a suitable tile surface. The following types exist:

- Matte is the natural surface of porcelain stoneware obtained after firing without any additional processing. The most budget option.

- Glossy – polished smooth surface with a bright shine. Easy to clean and looks luxurious. However, scratches are more visible on its surface. A very expensive type of porcelain tile.

- Satin is a surface with a delicate shine obtained by applying mineral salts or acids to the slab.

- Lapped – semi-gloss option. The surface has a soft wavy unevenness, as if rubbed with wax. It costs more than matte tiles, but is much cheaper than gloss.

- Structured - tiles with a relief, rough surface. Thanks to her, stone-like porcelain tiles begin to look especially believable. Has anti-slip properties. The most expensive option, difficult to clean. When choosing this material, it is important to take into account the permissible weight of the building and the thickness of the slab - as a rule, such a surface is made of two-centimeter tiles.

Types of façade porcelain tiles

Dimensions

Facade porcelain tiles, the sizes of which can be different, have the shape of squares or rectangles.

Slabs are available in the following sizes (in mm):

- 300x300;

- 300x600;

- 400x400;

- 450x450;

- 600x600;

- 1000x1000;

- 1200x600;

- 1200x1200;

- 1200x1800.

The dimensions of porcelain stoneware allow you to design different floors of the building depending on the developed plan

Important ! Dimensions of porcelain stoneware slabs in different sources are given in different units of measurement. Often they use centimeters rather than millimeters. Then the size 600x600 will look like 60x60.

In some countries, the design of porcelain tiles is preferred to resemble natural stone.

In our country, neutral light and dark colors are most often used. The beige color option is most often chosen. The thickness of the porcelain stoneware slabs produced is from 7 to 30 mm. The thickness of porcelain stoneware for facades most often lies in the range of 8-10 mm. Ceramic granite has a high specific gravity, and heavier slabs require greater frame strength, which means the slabs and installation are more expensive. But facade porcelain tiles are so durable that such a thickness of the slab is quite enough to guarantee the preservation of all operational characteristics for many years.

If you look at the ventilation façade from a close distance, you can clearly see the fasteners and seams. But this should not be a concern, since it does not affect the functionality and aesthetic side of the building design

This photo allows you to confirm that the large one is visible from a distance and the fasteners are absolutely invisible

Color and surface types

Porcelain stoneware facade tiles delight with the variety of their colors. They range from black to white to red. In addition, the slabs differ in texture and surface treatment.

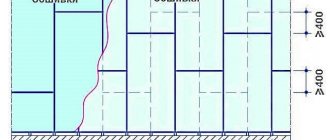

A diagram showing the placement of porcelain tiles using guides

The following types of slabs are produced:

- Matte slabs are the most common and cheapest option, since such slabs do not undergo additional processing after firing.

- Polished slabs - after firing, undergo a grinding operation using a diamond tool. The result is a matte and somewhat rough surface.

- Polished slabs undergo two additional operations: grinding and polishing. Polished slabs are produced uniformly and with a pattern applied. The design often imitates some natural material, such as stone or wood. Polished slabs reflect sunlight very well, so in hot climates, buildings with such cladding are cool.

- Semi-polished slabs are made using a very interesting technology: the surface of the slab is cut off in some places (not all!), and the cut areas are polished. The result is an unusual texture.

- Specially aged (rustic) slabs are the most expensive surface treatment option. They are used in special cases when they want to give the facade the appearance of an ancient building. Such slabs perfectly imitate ancient architectural reliefs (masonry, different types of stone, wooden surfaces).

Buildings made of porcelain stoneware are changing the appearance of cities. Porcelain tiles are often combined with glass decoration

Physical characteristics of porcelain stoneware

A facade made of porcelain stoneware is a reliable and durable solution due to the universal properties of this tile. All types of porcelain tiles have the following characteristics:

- Frost resistance. Porcelain tiles are not afraid of temperature changes; they can be safely laid in the most severe climatic conditions.

- Strength. If installed correctly, porcelain tiles will be very difficult to damage due to mechanical impact. This property is achieved by particularly intense pressing and firing. A side effect is the very large weight of porcelain stoneware slabs.

- Water resistance. Porcelain tiles have zero porosity, which means they do not absorb or retain moisture.

- Fire resistance. This material is not flammable and does not emit toxic fumes when exposed to flame.

- Chemical resistance. Porcelain tiles do not require particularly gentle cleaning agents.

Technical characteristics and properties

Ceramic granite is made from stone chips with the addition of clay, sand and dyes. Molds are poured, pressed, then the products are fired in a special oven to give them strength.

Facade facing porcelain tiles do not absorb water at all , therefore they will not be painted

in mass over time. Facades, for example, fiber cement, are painted; they absorb rusty stains from metal slopes and dust. Porcelain stoneware is superior to fiber cement in this parameter.

Porcelain tiles are hard, durable, but fragile. To install a suspended ventilated façade, everyone strives to use materials that exceed the strength parameters of porcelain stoneware.

After all, the facade is not only at a high level, but the first floor and entrance area are subject to more severe use. Often it is necessary to replace a broken facade slab.

Porcelain tiles for installing curtain wall facades can be used in all climatic regions of Russia. Because it has 100 freeze/thaw cycles.

Dimensions

Porcelain tiles for facades today have the widest selection of formats. The most common dimensions today are 60x60 cm and 120x60. Moreover, smaller formats are becoming less and less common - the trend is for a minimum number of tile joints! “Slabs” - large-format slabs two to three meters high (240x120 cm, 320x160 cm, and so on) are becoming increasingly popular. The widest selection of porcelain stoneware formats will allow you to find options for finishing any facade.

Differences from other types of facade tiles

Porcelain tile cladding has two main competitors - natural stone and ceramic tiles (regular, clinker, terracotta). When comparing a product with a natural analogue, the first thing I would like to note is the more favorable price of the artificial material.

As already mentioned, porcelain stoneware costs much less than natural stone, but its properties are practically not inferior to it . Moreover, the strength of the artificial material is superior to its natural counterpart.

Another point is the appearance of the products.

Porcelain tiles compete with such types as:

When comparing porcelain tiles with ceramics, there is nothing to say about the superiority of the former in terms of strength - it is indisputable. There is a significant difference between analogues in the level of water absorption: in the first case this figure is up to 0.5%, in the second – up to 10% .

Hence the conclusion - porcelain stoneware is much better suited for façade cladding than ceramics. True, the latter also has a noticeable advantage - due to its higher porosity, it weighs less than ceramic granite.

Color solutions

Today, porcelain tiles on facades can have almost any aesthetic properties. Finding a color and texture that goes well with your building is easy. The following options exist on the market:

- Plain. Tiles of any color, without pattern. Can have any type of surface. Perhaps the most popular option, especially when it comes to small formats.

- Imitations of other materials. Modern technologies make it possible to accurately recreate the texture of any other material on a slab. Often, the true essence of a slab can only be determined by touching it! The advantage of porcelain stoneware over most natural materials is enormous: it is unpretentious, easy to use, costs much less and, often, is even more beautiful than the original. The most popular object of imitation is marble. Other types of stones, wood, concrete and even metal are also very popular.

- Designer tiles. Porcelain tiles with a unique pattern or design.

- Salt pepper. Technical porcelain tile with a very neutral pockmarked pattern. Typically used for low-cost public buildings.

What kind of material is this?

Porcelain stoneware is a very durable , top-class material used for cladding floors, interior and exterior walls of buildings, etc.

For its production, mixtures of various rocks (spar, quartz), as well as clay and natural mineral dyes are used.

One of the main advantages of porcelain stoneware (or kerogranite) is its zero water absorption coefficient. Most of the characteristics of the material are not inferior to natural granite.

Contrary to misconceptions, it does not contain granite , although the physical properties are very close to natural material.

Advantages and disadvantages of porcelain stoneware

Like any material option for cladding facades, porcelain stoneware has its pros and cons. Its advantages include:

- Durability. Porcelain tiles withstand almost all possible negative environmental factors, due to which its service life is 40-60 years, or even more. But this is subject to correct and high-quality fastening of porcelain stoneware to the facade.

- Huge selection of designs. There are a huge variety of colors, patterns, textures, textures and surfaces of porcelain tiles on the market.

- Lightness, relative to natural stone.

- Quick and easy installation. Porcelain tiles are easy to cut without chips or cracks, and also weigh relatively little. Modern devices for ventilated facades make it possible to install panels quickly and efficiently.

- Fire resistance. The material is non-flammable and non-toxic. It is even recommended to use it to create fire barriers.

- Environmentally friendly. Porcelain stoneware does not emit harmful substances, which allows it to be installed in any area and room.

The disadvantages are the following:

- Quite a big price. Porcelain tile can hardly be called a cheap material, although it is cheaper than natural stone. Thanks to the huge selection of manufacturers and formats, it is quite possible to find a price that you can afford. In addition, the durability and quality of the material completely justify the cost!

- Weight. Porcelain tile is lighter than stone, however, it still remains a very heavy material. Before cladding, you need to make sure that the walls and foundation are able to withstand its load. Ideally, the weight of the required porcelain stoneware should be taken into account at the design stage.

Calculation of the required number of tiles and adhesive composition

One of the main indicators in the calculation is the amount of adhesive used for installation. So, if the weight of a package of 60/60 slabs is 36 kg, and the package contains 4 slabs, then one tile will weigh 9 kg.

The weight of 30/30 tiles is calculated in the same way. Porcelain tiles of this size are usually packaged in 8 pieces, which means the weight of 1 unit will be 1.5 kg. As a rule, 1 package holds 1.2-1.44 m².

When purchasing glue, you need to study the information on the packaging regarding its consumption: the manufacturer must indicate how much adhesive is required to lay a certain number of slabs. On average, 2.5-5 kg of glue is required per 1 m².

According to European standards, the specific gravity of porcelain stoneware is approximately 2400 kg/m² . This data allows you to calculate approximately how much the purchased tile will weigh and what kind of machine you need to hire to transport it.

When purchasing porcelain stoneware in the form of flat tiles, to calculate the material consumption, you will need to multiply the length of the base by its width. The result will be a value equal to the area of the base. Accordingly, the area of the tile will be the same, plus you will need to add 5% for trimming.

Types of installation of porcelain stoneware

Finishing facades with porcelain stoneware is a difficult and responsible job that should only be done by people with experience! Installation of porcelain stoneware can be done in several ways:

Mechanical fastening

Mechanical fastening for porcelain stoneware is installed on the wall of the building in the form of longitudinal and transverse profiles. The slabs are later installed directly on this frame. This type of fastening makes it easy to replace slabs in the event of a breakdown, which is why it is very often used when finishing high-rise buildings. Types of metal fasteners can be invisible from the outside or visible. The latter option is, of course, cheaper. To make external fasteners less noticeable, you can match them to the tile.

Collet mount

A very expensive fastening method. Cone-shaped holes are drilled in the slab using special equipment. An anchor collet is inserted into them, rotating and expanding. This is a reliable and durable mount.

Installation using clamps

Installation of porcelain tiles with clamps also begins with the installation of longitudinal and transverse load-bearing profiles. A clamp or clamp is a special fastener into which the plate will be inserted. They are installed in those places where the corners of the slabs should be. Clamp “ears” support two adjacent slabs.

On glue

The fastest and easiest way to lay porcelain tiles. Its downside is that it is not very reliable. Over time, the glue may lose its properties under the influence of temperature changes, and the tiles will begin to peel off. Therefore, with this method, you need to pay close attention to the choice of glue!

Combined method

The plates are glued to the profile and fixed with anchors. This is a very reliable method, ideal for large format material.

Ventilated façade

A ventilated facade is one of the most profitable ways of cladding a facade, even if at the beginning it seems labor-intensive and costly. It provides additional thermal insulation and sound insulation. In addition, the requirements for the quality of the building walls are very democratic. When installing a ventilated facade, air circulates freely between the wall and the facade structure, which has a positive effect on the safety of the building, increasing its service life. The costs will be recouped by the long service life of the facade and reduced costs for heating the premises.

General concept

DIY porcelain tile polishing

Porcelain stoneware is a new finishing building material that is becoming increasingly popular both in the regions of Russia and around the world due to its excellent qualities. This is an artificial material that imitates natural marble or granite, which in composition and formation technology corresponds to rocks.

Porcelain tiles are becoming increasingly popular in our country, thanks to their excellent qualities.

Its manufacturing technology involves exposing kaolin, clay, metal oxides and feldspar to high temperatures and pressure, which causes the components to interact at the molecular level. As a result, they are sintered and form a mass of a single structure, from which slabs of the required size are subsequently formed. Igneous rocks are formed in a similar way, the only difference is time: a natural granite layer takes millions of years to form, while porcelain stoneware takes a matter of hours. You can familiarize yourself with the material about the features of facing facades with porcelain stoneware.

Installation of porcelain tiles

When installing a porcelain stoneware facade, the tiles are attached either directly to the facade or to profiles installed on it. Of course, the installation steps depend on the technology chosen.

Fastening to the facade

The surface of the wall is leveled (if necessary) with plaster and primed. If a thick layer of mortar is required, then a reinforcing mesh is used.

Glue is applied to the prepared surface and to the back side of the slabs using a notched trowel. According to the technology of façade cladding with porcelain stoneware, tiles should be laid from the corner. To ensure that the thickness of the seams is the same, special plastic crosses are used.

After installation, the tiles are left alone for several days, and then proceed to grouting the joints. The seams are filled with the mixture using jointing or a construction gun.

Fastening to the profile

Fastening porcelain stoneware to a profile has two big advantages. Firstly, the facade wall does not need pre-treatment. Secondly, in addition to tiling, you can carry out additional insulation and sound insulation of the building by placing insulation in the gap between the tile and the facade.

Before installation, the wall is marked for installation of profiles, depending on the size of the slabs. Next, the brackets for the profiles and the profiles themselves are installed.

When insulating the facade, insulation boards are installed in the profiles. This is usually polystyrene foam or mineral wool. The insulation is covered with a windproof membrane.

According to the technology for installing a façade made of porcelain stoneware, slots are made in the porcelain stoneware slabs for brackets. The tiles are fixed to the brackets using self-tapping screws.

Possible errors during the installation process

To avoid mistakes, it is better to install the system only in good weather. Otherwise, it is easy to make violations in the installation technology, make mistakes when marking or fixing the frame. The rule of good weather is especially relevant when working with insulation. It absorbs moisture very well and takes a long time to dry, especially when already covered with porcelain stoneware. If the water remaining there begins to freeze and melt under the influence of temperatures, this will lead to rapid destruction of the insulation.

Method for arranging a ventilated facade made of porcelain stoneware

The technology for installing a ventilated façade involves installing the cladding onto a frame, due to which a gap is formed between the tiles and the outer wall. Free space prevents condensation from accumulating under the finish and damaging the walls. In addition, the ventilation facade system creates an additional soundproofing barrier, reduces heat loss, and ensures a comfortable climate in the interior.

Figure 2. The technology for installing a ventilation façade involves installing the cladding on a frame.

Figure 3. Vertical ceramic fastening system.

1. At the first stage of installing a ventilation façade, the wall is prepared for cladding; brackets for the frame system are fixed in the wall.

2. At the second stage, sheets of insulation are laid between the brackets, which are covered with a vapor barrier.

3. Next, proceed to the installation of the frame. It is best to choose a galvanized metal profile or an aluminum profile.

4. Porcelain stoneware slabs are installed on the finished frame system.

This is a short list of activities. In fact, each stage has its own characteristics.

At the preparatory stage, it is important to assess the condition of the walls and take measurements. You need to choose tiles in such a way as to minimize the need for cutting the material. It must be a multiple of the length of the facade wall, taking into account allowances and seams. The cracks in the walls need to be repaired and treated against fungus with a special compound. The wall needs to be marked by placing beacons where the frame will be attached.

The best insulation option for a ventilated façade is basalt wool. It does not cake like mineral ones, but at the same time it allows steam to pass through just as well. Penoplex and polystyrene foam do not allow steam to pass through and are not suitable for ventilated facades.

After the insulation is laid and fixed, you can begin installing the guides. It is most convenient to use a combined mounting option using anchor dowels and glue. This way the loads on the material are distributed most evenly.

Combined fastening is implemented in two ways:

1) Start by attaching the vertical guides, and then move on to the horizontal ones. The method is suitable for heavy, thick slabs, as it reduces the load on the frame system. Its disadvantage is that vertical air circulation may be insufficient.

2) Vertical ones are attached to the horizontal guides. So there are no barriers to air circulation, but more metal is needed for implementation. Increasing the amount of material increases the cost of cladding, but the quality of the result is higher.

Figure 4. Combined fastening is implemented in two ways.

The slabs themselves are fastened in an open or closed way. For open installation, rivets, clamps, and self-tapping screws are used. After finishing the cladding, their protruding parts are painted in the color of the façade slabs.

For hidden fastening, glue and pins are used, which are inserted into the slots at the ends of the plates. The hidden method gives a more aesthetic result, but it is more difficult to implement. In addition, repairing such a facade is a labor-intensive task.

TIP: For a ventilated façade, choose smaller porcelain stoneware façade panels. They are easier to work with and the load on the frame is reduced. However, minimalism is also not appropriate here. If you take panels measuring 30x30 cm, the facade will visually look like a sheet from a math notebook. For the most interesting solutions, it is better to combine rectangular and square panels.

Calculations

To decorate a facade with porcelain stoneware, you first need to find out how much material is required. The quantity of tiles is usually measured in square meters. Having calculated the area of the facade, you need to subtract the area of the openings (doors and windows) from it. Next, to the resulting number you should add 10% -15% of the margin for pruning, breaking and errors on the part of the builders. If you do not take into account the supply in advance, a situation may arise later in which you will have to buy additional tiles. And this is a waste of time. In addition, when purchasing porcelain tiles from different batches, slight differences in tone may be noticeable. Porcelain tiles are made from natural components, which makes it extremely difficult to reproduce the same color in different batches without any changes.

For construction companies that require a special tile testing certificate confirming that the porcelain tiles produced by the selected manufacturer can be used for facades, we provide it upon request.

If you purchase material not from a retailer, but from third-party sales organizations, a test certificate is not provided.

This certificate is a service advantage only for companies that purchase porcelain stoneware for facades from TD Toscana LLC.

Useful video

In this video you will learn how to install porcelain tiles for a facade:

The lower part of the building is the basement, which protects it from moisture and cold. Covering the foundation helps prevent its destruction due to temperature changes, high humidity and other negative external influences, and also gives the building an aesthetic appearance.

A variety of materials are used to finish the base, including porcelain stoneware.

What features does this material have, what types exist, and how to carry out finishing work correctly, we will consider below.

What you need to know about tiles

Which adhesive to choose for porcelain tiles

What exactly are ceramic tiles? If we study its composition, it turns out that we have simple clay with special additives. With their help, ceramics become durable and acquire the required color and texture.

The most important stage of its production is firing. The workpiece is exposed to a temperature of about 1000-1500 degrees Celsius. This allows the material to sinter at a structural level and combine clay with additives. As a result, we have a material that is not much inferior in its properties and characteristics to natural stone. A worthy competitor is porcelain tiles.

The higher the firing temperature, the stronger the material will be.