Purpose of reinforcing materials

When dealing with the issue of repairing or constructing new building structures, many are faced with the concept of reinforcing mesh for plastering walls. These are canvases that have a cellular structure. They have high tensile strength, inertness to most mortars, flexibility and durability to varying degrees.

According to the technology, the mesh should be part of the concrete screed or leveling plaster layer. The dry residue itself begins to crack and crumble over time due to mechanical stress and temperature changes with humidity. Reinforcement allows you to increase the shear and compressive strength of the coating. There is also a reduction in the risk of damage to the integrity of the plaster and an increase in the service life of the surface.

Advantages and disadvantages

The advantages of the mesh include:

- light weight, which allows it to be used on any structure, including light interior partitions;

- ease of installation - different elements are used for mounting on the wall;

- affordable price - depends on the material, as well as the manufacturer;

- easy processing - easy to cut into pieces, which simplifies finishing work;

- Convenient packaging - available in rolls, which simplifies finishing;

- withstands significant weight of cement-sand mortar.

Each type has operational characteristics. Plastic does not rust, which prevents the formation of red spots on the finish. Metal cells are highly durable. Often used for finishing facades and structures with a large area.

The features also concern the weaknesses of the material. Metal mesh is susceptible to corrosion. You need to work with them carefully. Do not leave it outdoors for long periods of time.

Polymer materials are characterized by low strength. It is not recommended to use for applying a thick layer of plaster.

Types of reinforcing mesh

Marketplaces supply mesh for wall plaster made of various materials with square or diamond-shaped cells. Based on the composition and parameters of the holes, the paintings are classified according to their intended purpose. These may be options for facade and interior work, for rough or finishing.

Cloth for finishing Source yandex.net

The first reinforcement option was shingles. It consists of two-meter wooden slats measuring 3-5 * 10-20 mm. It is important to reject from the packaging (the material is sold in 50-100 pieces) strips with knots and areas of biological damage.

The sheathing is assembled in one or two layers (preferably). The first (underlayment) cover is assembled from thin slats with cells of about 45*45 cm; for the second, 5*15-20 mm slats are used according to a similar pattern, only with a shift of 20-25 cm. The angle of the shingles relative to the horizon is 45 degrees. For work, you will additionally need galvanized nails 1-1.8 * 20-40 mm.

Wooden shingles for plaster Source armadis.house

Metal

Metal mesh for plaster is conventionally divided into hard and soft. The first is sold in sheet form and is used more often for installing floor screeds. The second comes to the market in rolls. It is used when performing work on aligning walls with ceilings. The wire thickness of such meshes does not exceed 1.5 mm, and the cells - 30 mm. The most popular options are 5*5, 10*10, 25*25 mm.

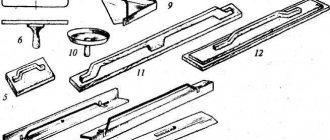

According to the structure, the classification of reinforcing materials is as follows:

- Welded . Suitable for strengthening foundations, brick and block structures, and finishing load-bearing walls. This fabric consists of rods of different diameters, which are connected to each other by means of a welding machine. However, the cells may not necessarily be identical. In its group, the reinforcement has a relatively light weight. The choice should be made in favor of stainless metals to eliminate corrosion processes.

Welded mesh Source stroimaterials.ru

- Woven . Belongs to the group of universal building materials. The name is obtained due to the characteristic textile interweaving of identical wires with identical cells throughout the entire fabric (square, rectangular). Stainless steel or low-carbon, non-ferrous metals are used for production. Painted options are available.

Woven fabric Source 2gis.com

- Exhaust, perforated or TsPVS . All-metal sheet up to 2 mm thick (usually 1.5 mm) with perforation. During the manufacturing process of the mesh, holes are cut in the sheets, and then the workpiece is stretched. The result is highly durable and flexible, and if one of the threads breaks, the rest of the area remains undamaged.

TsPVS grid Source dom.by

- Chainlink . Unlike analogues, this is the only mesh that is used as an independent material for constructing enclosing structures. It is made from stainless or galvanized round wire. Here weaving is carried out with bending or twisting of threads, which provides the fabric with flexibility, it can be stretched and is difficult to tear. For fences, the products have an additional polymer coating.

Universal chain-link Source stpulscen.ru

See also: Catalog of companies that specialize in redevelopment, insulation and finishing

Each option has its own disadvantages, which you need to familiarize yourself with in advance. Thus, welded mesh becomes deformed during long-term storage in a rolled state. And the joints can collapse, especially if it is a fine-mesh material. Such areas often begin to corrode. If the cells in the expanded mesh are bent, it is almost impossible to restore them. And installing a chain-link requires more effort, patience and fixing elements.

Mesh deformation Source belnovosti.by

Basalt

Mineral mesh for facade plastering is made from roving or twisted basalt threads. Weaving of nets is carried out with special knitting and stitching machines. Blanks for presentation are additionally treated with impregnations to increase resistance to aggressive operating conditions.

Basalt reinforcement Source stpulscen.ru

Among the advantages of this material are the following:

- high strength;

- durability (from 50 years);

- light weight;

- wide operating temperature range (-50-+80℃);

- inertness to alkalis, acids, corrosion, biological phenomena.

For plastering work, a mesh with cells up to 25*25 mm is more often used. In this case, the layer of mortar can exceed 3 cm. The canvases are used for facade work, finishing the base, strengthening waterproofing coatings and joints between cladding sheets, and increasing the endurance of load-bearing structures.

Fiberglass

Molten glass fibers, unlike brittle raw materials, have flexibility, elasticity and high tensile or shear strength. Impact resistance is also observed.

Fiberglass mesh Source stroyscan.ru

Features of mesh for reinforcement

There are two types of classification of this type of reinforcement - according to material and purpose. The mesh can be woven or welded from individual rods; each of its varieties has its own positive and negative sides, features of work, so their purpose is very diverse.

Materials used for manufacturing

Reinforced mesh can be made of metal, plastic and fiberglass.

Steel masonry mesh is one of the mandatory elements of brickwork; without it, buildings higher than two floors cannot be built. It is welded from steel rods with a diameter of 3 mm using argon welding. The cell can be up to 5 or 10 cm. Such reinforcement binds the rows of masonry very well, which is especially important if there is no full bandage in the masonry itself - in walls with cladding, for example. The only drawback of this product is that it is susceptible to corrosion.

Plaster mesh made of metal is made of thinner wire - 1.5-2 mm, and is often woven. There are also welded galvanized products, the cell size of which varies from 1 to 5 cm.

Fiberglass has been used for the production of reinforcement for a long time, and mesh is no exception. There is a wide range of them - both in rod thickness and cell size. Recently, composite products have been gaining popularity because inside structures they work no worse than steel reinforcement and have greater tensile strength , and corrosion is unusual for them.

Plastic meshes are made from polyethylene and polypropylene. They have a variety of cell shapes, small thickness, and are very flexible, but their main drawback is low strength.

Need for use in construction work

Reinforcement may be a necessary element of such work as:

- Construction of walls made of brick, ceramic and expanded clay concrete blocks;

- Installation of floor screeds;

- Plastering walls.

Reinforcement gives additional strength to the masonry, preventing it from stretching under the weight of the overlying structures. The need for reinforcement is indicated in the documentation, as well as its frequency. Sometimes the presence of reinforcement is mandatory in any case, for example, when erecting pillars. Fine-mesh mesh is laid between rows of hollow ceramic stones and blocks, this helps to reduce the consumption of the solution several times and preserve the thermal insulation qualities of such materials.

When installing floors, the mesh makes the cement-sand screed uniform, preventing the formation of cracks. It plays the same role in plaster, especially if its thickness exceeds 2 cm.

Technology of plastering walls with reinforcing mesh

All finishing work begins with preparing the base. It is necessary to remove weak areas affected by corrosion, mold, fungus, bacteria and treat them with protective compounds. Next, you need to apply primer to the surface to improve adhesion.

Primed base Source sakh.com

Video description

From the video you can learn how to reinforce a facade with foam insulation:

Methods of fastening reinforcing sheets

When the base is dry, you can begin to decide how to attach the mesh under the plaster on the wall. It is important to install the reinforcement correctly so that partial or complete detachment of the leveling layer from the base does not occur. The technique varies depending on the fabric chosen and the nature of the structures.

The first thing worth noting is that the mesh should fit as tightly as possible to the base without folds or bends. Individual canvases are fixed with an overlap of approximately 10-15 cm. Hardware, dowels and plaster mortar can be used as fasteners.

Metal and basalt mesh is attached to a wooden wall using self-tapping screws or construction staples.

Strengthening a wooden base Source blog.tam.by

Necessity of application

A limited number of construction operations involving the application of cement and concrete mortars to the surface can be performed without reinforcement. This is natural, since the mesh reinforcement installed in the cement composition helps to increase the strength properties. After hardening, the reinforcing structure unites the array into a monolithic structure, the integrity of which is problematic to disrupt.

Reinforced mesh is used to increase the mechanical strength of the cement composition when carrying out construction activities and repair work. Having analyzed the situations when it is advisable to use mesh reinforcement, the types of technological operations can be divided into the following groups:

- Carrying out measures to fill foundations that, without reinforcement, lose strength and crack prematurely. The reinforcing mesh ensures the durability of the floors, especially if the screed is insulated using brittle foam. In this case, its use is justified, regardless of the brand of cement mortar and its quality. Without mesh reinforcement, the fragile screed will be covered with a network of cracks in the first months of use.

- Work on applying plaster to the surfaces of walls located both indoors and outdoors.

The mesh design improves the contact between the wall surface and the plaster mortar. Its use is advisable when applying plaster in a layer more than 2 centimeters thick or when there is insufficient adhesion of the plaster mortar to metal, wood, foam or painted wall surfaces. Reinforcement of all kinds of solutions is used exclusively in two cases - when its high mechanical strength is needed and when there is a need to connect the unconnected - Production of finishing activities related to the need for reliable installation of decorative coatings on the surface. The reinforcing mesh plays a leading role in cladding processes, ensuring a high degree of adhesion of the cladding to the base. It is a connecting element; the mesh base effectively fixes the finishing material on a thick layer of plaster or adhesive.

- Carrying out work on plastering foam sheets. The operation will not provide the desired result without a mesh base used for plastering work. In the absence of reinforcement, cracking of the plaster will occur after the plaster composition hardens.

Video description

From the video you can learn about the installation of expanded mesh:

Fiberglass mesh for plaster is installed on walls by sinking a layer of about 5 mm into the solution. Apply it with a notched trowel to make it easier to level the canvas on the work surface. If you use a tool with a solid blade, you can damage or stretch the rolled reinforcement. The walls are leveled after the reinforcing coating has dried.

Installation of fiberglass mesh Source stpulscen.ru

What is reinforcement used for?

Reinforcement is used in the following cases:

- Uneven walls. In the process of leveling the walls, you may encounter very large irregularities, to hide which you will have to apply a large layer of plaster. But the plaster itself is very heavy and if the layer is quite thick, it can swell and peel off.

- The wall is too flat. In such cases, the mesh helps the mortar adhere more tightly to the wall.

- Cracks. Using mesh reinforcement, you can significantly reduce the size of large cracks, and if the cracks are smaller, then completely hide them. The mesh also prevents the appearance of cracks and microcracks if used during the construction process.