Factors affecting thickness

There are no general recommendations for calculating the required amount of solution, because cladding is not a typical job. The thickness of the glue can be several millimeters or exceed a centimeter. The thickness of the layer will depend on the size of the material used. The smaller the tile, the thinner the solution is applied. It is worth considering the type of facing material. To lay porcelain tiles you will need less glue.

Other important factors on which the thickness of the tile adhesive depends include the type and quality of the base. The consumption of the solution when facing concrete and drywall will be different.

The thickness of the tile adhesive on the floor should be selected taking into account the height of the coverings in other rooms. The laid tiles should be located approximately on the same level as laminate, linoleum or parquet. Otherwise, thresholds will form at the joints.

Cladding work should be carried out taking into account the type of glue. The amount of solution will depend on the components included in its composition. The cement mortar can be applied in a thicker layer.

Type and size of tiles

The thickness of the tile adhesive layer is calculated taking into account the dimensions of the facing material. For small-format tiles (up to 10×10 cm) it should not exceed 2 mm. The thickness of the solution for small square elements with sides from 5 to 7 cm after pressing is 1.1-1.3 mm.

When laying medium-format and large-sized materials, a thicker layer of glue will be required. When facing with square tiles with sides from 20 to 30 cm, after pressing it will be 2.5-3.5 mm. The consumption of the solution will depend on the angle of inclination of the spatula. Large-format facing material with sides from 30 to 50 cm is laid on a layer of 3.5-4 mm. When using rectangular tiles, the thickness of the mortar is calculated based on the area of the element. Tiles with sides of 20 and 25 cm (most often used for finishing walls in the bathroom) are laid on a layer of 3 mm.

The type of facing material must also be taken into account. Tile has high porosity, which leads to strong water absorption. Therefore, when laying it, more solution may be required. The structure of porcelain stoneware is different. This material almost does not absorb liquid, which leads to less glue consumption.

It is also worth taking into account such a parameter of the tile as thickness, since its weight depends on this value. For heavy facing materials, more mortar is needed to ensure they adhere more firmly. It is recommended to lay porcelain tiles on a layer of glue, which is 40-60% of its thickness.

What base is used

Each type of tile adhesive is designed for different types of substrates. The scope of application of the composition and its consumption are indicated by the manufacturer on the packaging.

In the case of plasterboard cladding, the thickness of the mortar for good adhesion should not exceed 5 mm. When laying medium-format tiles on such a base, it is recommended to apply a layer of 3-4 mm. Then it is leveled with a comb with 6 mm teeth. The solution can be applied in a thicker layer to concrete, plastered base or screed.

Before tiling, you should examine the walls and floor. The thickness of the glue also largely depends on the quality of the base. In the absence of differences and unevenness, the solution consumption will be minimal. To cover an imperfect surface, you should choose a leveling adhesive. There are compositions that can be applied in a layer of 1.5 cm. However, it is better not to use such a solution for novice craftsmen.

Without experience in tiling, it will be difficult to lay tiles on a thick layer due to shrinkage. If the differences exceed 3 cm, then leveling with glue should be abandoned. In this case, the quality of the surface can be improved by plastering or screeding.

Laying wall and floor tiles requires different volumes of mortar. In the second case, the layer should be thinner so that the tile does not fall off from the base.

Humidity and moisture absorption of the adhesive

When carrying out repair work, you need to monitor the moisture content of the tile adhesive. Dry mortar cannot be applied to walls, because there will be no good adhesion to the facing material. It is also necessary to take into account such an important characteristic of the base as moisture absorption. It directly affects the consumption of tile adhesive. Porous substrates have high moisture absorption. These include sand-lime brick and some types of concrete.

High moisture absorption increases the thickness of tile adhesive when laying tiles. The situation can be corrected using a primer.

Composition of adhesive

The tiles are laid using various types of adhesive mixtures. They are divided into thick-layer and thin-layer. For plasterboard substrates, you can choose a resin-based adhesive. Its thickness when applied should be 3-5 mm.

Two-component mixtures are also available on sale. They consist of a catalyst, as well as a resin-based paste, quartz filler and additives. Such a solution does not shrink when dried. This means that the thickness of the adhesive when laying the tiles will remain unchanged. The two-component mixture is applied in a layer of 2-5 mm.

Curvature and differences can be dealt with using a cement mixture, which is classified as thick-layer. It is sold dry and consists of sand, cement, and plasticizers. Its thickness can be up to 14 mm. This mixture is applied to floor tiles, which weigh a lot. For wall cladding, 5-7 mm is enough.

Comb tooth size

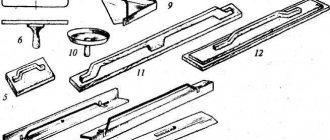

You can get the correct layer thickness using a special tool for applying glue - a notched trowel. It must be selected based on the size of the material that will be required for cladding. Spreading small tile adhesive with a large-notched trowel results in excess adhesive in the joints. A small comb is not suitable for dimensional facing material, because... When applied to the base, projections are formed that are too low.

The height of the spatula teeth of 5-6 mm is optimal for wall cladding. For working with mosaics, it can be 2-3 mm. The adhesive mixture is applied to large-format tiles with a larger notched trowel (with a comb of 1-2 cm). Similar combs are also used for floor tiles. For small square tiles, it is recommended to choose a trowel with 4 mm teeth. For medium format tiles 20x20 cm, a size of 6 mm is suitable.

It is worth purchasing spatulas with different teeth. The surface may be uneven, causing the need to apply an uneven amount of adhesive.

We count the glue consumption

In addition to the number of tiles, before starting repair work, you should also calculate the amount of glue required. The indicator will be significantly affected by the quality of the subfloor, the installation method, as well as the quality of the tile itself. And, of course, the experience of the master. For beginners, the consumption of the adhesive component is usually higher than for experienced specialists.

The consumption of tile adhesive can also be calculated

Table

What affects glue consumption and why is it important to consider these factors?

| Factor | Explanations |

| Tile porosity | The glue will not only be on the surface of the ceramic product, but will also partially penetrate the structure. Also, such tiles usually absorb moisture from the adhesive more strongly. |

| Uneven subfloor | Cracks, chips, and unevenness can significantly increase consumption, since all identified voids will be filled with glue, and in places with unevenness, a lot of glue will have to be applied. If the difference in floor heights is no more than 3 mm, then you can still use a small amount of glue. But the more curved the base, the more glue will be spent. Otherwise, it will not be possible to make an even floor covering. |

| Uneven tile surface | The voids present on the back side of the ceramic product will also be filled with glue at the time of its application. |

| Dimensions of floor elements | The larger the tile, the more glue it needs. For example, when laying ceramics measuring 10x10, the thickness of the adhesive layer should be about 2 mm. With tile dimensions of 20x30 cm, this layer will reach 3 mm. If the ceramics are even larger, the glue is applied in a layer of up to 5 mm, but not less than 4 mm. |

Ceramic tile sizes

The amount of glue per 1 m2 is calculated as follows: the thickness of the tile is measured and divided by 2, the average value of the consumption of the adhesive composition is taken. The values are multiplied, and the final figure will be equal to the glue consumption. But it is quite approximate, and it is better to buy material with a small margin.

The glue, which is made on the basis of cement, is calculated as follows: take the weight of the bag (the best option is to purchase 1.3 kg bags) and multiply it by the recommended thickness of the glue. The result is a number approximately equal to the glue consumption. Sometimes you can determine the cost of glue using a calculator.

Tile adhesive calculation

Calculator for calculating the amount of adhesive for laying tiles

Go to calculations

After the tiles have been laid, it is necessary to form the seams between the floor elements. To do this, purchase a special grout for joints. It is not difficult to calculate the required amount of this material - for this, the perimeter of one ceramic element is calculated and divided by 2. Then the resulting figure is multiplied by the area of one tile. The final value should be multiplied by the thickness of the ceramic element, and then the new figure is multiplied by the width of the seam that remains between adjacent tiles. The next resulting value is multiplied by the material shrinkage coefficient equal to 1.5. The result of all these calculations will be the required mass of grout, which can be used to process up to 1 square meter. tiled surface area

Features of adhesive compositions

The thickness of the layer of adhesive mixture under tiles or porcelain stoneware can vary dramatically. Of course, the key factor here will be the facing material used and its individual characteristics, but much also depends on the adhesive composition itself.

There are three main types of tile adhesive:

- Cement . Standard dry mixture of Portland cement, sand and modifying additives with plasticizers. An alternative is a homemade mortar made from cement, sand and slaked lime. At the same time, working with such glue is quite simple and convenient.

- Two-component . These are predominantly epoxy compounds, which include an epoxy resin and a catalyst. The result is a viscous adhesive that provides effective adhesion of surfaces with minimal mixture consumption.

- Dispersive one-component . These are ready-to-use mixtures, which mainly consist of resin components of one type or another. They can also be based on polymer components, for example, latex.

Types of adhesives for tiles

When applying cement mortar, you will need a larger layer compared to other types of mixtures, but the material itself has a lower cost, which allows you to compensate for its high consumption.

What affects the thickness of the adhesive layer

There is no universal thickness, just as there is no single thickness of tile materials. You can get the necessary information on the packaging with the mixture, but in most cases it will depend on the size and weight of the facing material. And even the purpose of the tiles does not matter here. Correct application of glue will largely influence the consumption of material, as well as the subsequent operation of the tile. Each manufacturer indicates the approximate consumption on the packaging, so it is not difficult to calculate the required amount of mixture for laying the purchased material. True, these data are averaged and do not take into account some features that will affect not only the thickness of the applied mixture, but also its consumption as a whole.

The basic rule that works when choosing the thickness of the adhesive is that the larger the tile, the thicker the adhesive layer will be.

If the surface to be coated is uneven, then the thickness of the applied adhesive will vary depending on the existing differences. To minimize material consumption, it is sometimes advisable to resort to leveling the base with plaster mixtures, plywood or plasterboard

It is worth paying attention to the material itself. It has been proven that laying tiles requires a smaller layer of adhesive layer, but its inner surface is quite porous, which entails excessive consumption of glue prepared without following the technology

But this cannot be said about porcelain stoneware, since its installation requires a smaller layer of adhesive solution.

All adhesive mixtures can be divided into one- and two-component ones. The first option is ready-made solutions that contain resins or polymer components. Two-component formulations include an epoxy resin and a catalyst. When working with adhesive compositions, the applied layer depends directly on the size of the tile itself. An important aspect when choosing an adhesive will be the temperature and humidity of the room where the work will be done, and the base on which the tiles will be laid. Thus, for pools and bathtubs it is rational to use waterproof compounds, and for stoves, fireplaces and heated floors, heat-resistant adhesive is considered the best choice.

Much depends on the manufacturer of the mixtures. Only a high-quality product guarantees reliable adhesion of the material to the surface, and a homogeneous composition will help not only save the mixture, but also apply it in a minimal layer. The most popular among domestic craftsmen are adhesive compositions from companies Knauf, Ceresit, Yunis, Osnovit, Ivsil, etc.

Cement mortar is perfect for laying “light” tiles, as well as for work in basements and non-residential premises

Until recently, few people thought about buying expensive mixtures - but now they have become available to the majority. Previously, cement mortar was used for cladding, which has not lost its relevance today. It is perfect for laying “light” tiles, as well as for work in basements and non-residential premises. The mixture is prepared very simply and includes cement itself, sand and various types of plasticizers, which are responsible for better adhesion. You can prepare a similar mixture yourself. To do this, take a mixture of sand and cement in proportions 1: 4 (this is the classic version), water and slaked lime. Some craftsmen use a weak aqueous solution of PVA glue instead of water. If you prepare solutions that are too greasy, then severe shrinkage of the finish may occur and the adhesion of the tile to the base will be disrupted.

When choosing a dry mixture, pay attention to the shelf life of the product. For most mixtures it ranges from 6 months to a year

The fact is that since most dry adhesive compositions are cement, it is worth knowing that every month cement loses its active qualities by about 5%, not to mention modifying additives. The product must be stored exclusively in premises where humidity and temperature standards are observed. It is better to avoid goods sold in markets where they lie outside in cold weather. It is almost impossible to determine by eye whether a mixture is suitable for use - this can only be determined experimentally.

The expiration date is the manufacturer's recommendations for storing the product under ideal conditions, so always pay attention to the production date of the product!

Characteristics of porcelain stoneware

Initially, porcelain stoneware was produced as a particularly durable tile for technical use in public and industrial buildings. Surprisingly, in Europe such material is considered an ordinary tile, only in the CIS countries it was given a separate name.

It is produced by semi-dry pressing under a pressure of 400-500 kg/cm2 and then fired at a temperature of 1200-1300 degrees.

Press powder is made from slip - a homogenized mixture of white-burning clay, kaolin, quartz sand, feldspars, pegmatites and water. Coloring oxides are often added to the composition, which allow the material to be given the desired shade.

Table of technical characteristics of floor coverings

Technical characteristics of porcelain stoneware floor tiles:

- Water absorption: 0.05-0.01%.

- The bending strength of imported collections is 500-600 kg/cm2, while domestic analogues have indicators of 470-550 kg/cm2.

- Hardness on the Mohs scale: 6-8 (domestic analogues 5-8).

- Degree of wear resistance: 3-5 (for ceramic tiles this indicator is 1-5).

- The number of frost resistance cycles is 3-4 times higher than that of conventional tiles: from 100 to 300 cycles at temperatures from -5 to +5 degrees.

Necessary equipment

Ceramic tile adhesive is sold dry. Accordingly, for use you need to obtain a liquid mass. Depending on the volume of the prepared solution, the tools required for this work will depend.

If you need less than 10 liters of glue, then you should use a rectangular trowel. This is the name given to a steel paddle with a curved handle.

The movements are similar to stirring porridge. From the bottom of the bucket it is necessary to lift all the particles that the moisture has not reached. Stir until the mixture is smooth and free of lumps.

For large volumes, you will have to purchase professional construction equipment. This refers to a paddle attachment for mixing the solution.

You will also need a drill to which the attachment will be attached. It is very important to buy a paddle for grout, not paint. Specialists use a construction mixer with a whisk to obtain an adhesive mass with the desired properties.

You should pay attention to the quality of mixing and the speed of rotation of the nozzle. It is necessary to stir the tile adhesive no faster than 300 rpm, and the blade is completely immersed in the solution to avoid the appearance of air bubbles.

What base is used for the tiles?

Another important factor on which the thickness of the adhesive layer for tiles depends is the quality and type of base on which the tiles will be laid.

Tiles can be glued to various substrates, each of which has its own type of glue with a specific composition and consumption. For example, for drywall, the maximum thickness of tile adhesive when laying tiles should not exceed 5 mm. For medium format tiles, the layer thickness is chosen to be about 0.3-0.4 cm. The adhesive layer is leveled with a special comb with teeth. The adhesive can be applied in a thicker layer to a concrete base, screed, or plastered walls.

The quality of the base directly affects the glue consumption and the quality of the work performed. That is why it is important to carefully examine the floor and walls before tiling. If they are even, then the glue consumption, as well as its thickness, will be minimal.

If the base is uneven, then you should give preference to leveling glue, which can be applied as much as 1.5 cm thick. These compounds are treacherous, so it is better to work with them only for an experienced craftsman, and not for a beginner.

If the base has differences of several centimeters, then it cannot be leveled with glue. In this case, plastering the surface (walls) or screed (floor) will help. The maximum thickness of tile adhesive on a wall is less than what you will glue tiles on the floor.

Security measures

Although there is no need to worry about protection from harmful fumes when mixing cement mortars, there is still another problem - dust, which can be protected from with the help of a properly fitted dust respirator. It is also best to wear rubber seals when working with cement mortars, since cement mortar is caustic and very difficult to clean off the surface of the skin once it dries. If you think that gloves interfere with your work and because of them you cannot do it accurately and accurately, then keep a bucket of clean water next to you and wash your hands in it from time to time.

Practical tips for choosing the thickness of porcelain tiles

You should not immediately buy thick porcelain stoneware slabs; the strength of the floor depends not only on this indicator, but also on compliance with masonry technology. If the master does not use a special comb to apply an even and uniform layer of glue, but “sculpts” it with a staple only in a few places on the tile, then even thick material in the gaps can crack from relatively small efforts.

Working with adhesive for porcelain tiles

It is recommended to check the integrity of the performers. This can be done in two ways: watch their work or check the already installed tiles. The first option is not always possible, but it’s never too late to check the floor. The tiled floor needs to be tapped, the sound over the entire surface of the tiles should be the same and dull. If there are places with a loud knock, then the work was done by an unscrupulous or unskilled performer; between the tiles and the base there are large air chambers not filled with glue.

Diagram of the stages of laying porcelain stoneware

When purchasing material, be sure to pay attention to the linear dimensions. The thicker the tile, the more complex the annealing technology, the higher the risk of getting defective. Take two tiles from different packages and place them facing each other. Wobbling or gaps between them are strictly unacceptable; the edges must be smooth and match perfectly. Porcelain tiles are much more difficult to level than ordinary ceramic tiles; because of this, the requirements for linearity and flatness are more stringent.

The thickness of the tile has a significant impact on the price, with all other indicators being the same. Practitioners know that properly laid porcelain tiles 7 mm thick can withstand the same forces as tiles 12 mm thick, but made with defects. And in price these materials differ significantly. Conclusion - a professional tiler can save significant money, and the strength of the flooring will meet the required parameters.

Laying ceramic tiles.

You can start laying tiles from anywhere, even from the middle, but usually you start laying tiles from one of the corners of the room so that you finish laying the tiles near the doorway. You can draw a line on the floor indicating the edge of the first row of a whole tile, but it is better to pull a thread (dowels are driven into the walls for quick installation or nails, if the walls allow, a thread is pulled over the dowels). It will be even easier to work if you pull the thread at the level of the new floor mark + 3-5 mm. This will allow you to monitor not only compliance with the pattern, but also the horizontalness of the new floor. In all options, a row of whole tiles is laid first, and then a row of pieces.

Usually tile adhesive is used for a layer thickness of up to 1 cm, but I often lay tiles on a layer of glue up to 2-3 cm, so as not to mess with the cement screed. You just need to let the glue dry for 3-5 days, the thicker the layer, the longer the glue hardens . There have been cases when I laid tiles on a layer of glue up to 5 cm, in these cases I apply one layer of glue, lay old or broken tiles so that the distance between the pieces of tile is 2-5 cm, then another layer of tile glue, another layer of broken tiles, another layer of glue and finally the face tiles. Of course, I do this not over the entire area of the room, but where there are large holes, but their total area is less than 10-20%. In such cases, there is no desire to tinker with a cement screed, especially since it should take at least 5-10 days to gain strength (after 7 days, the cement mortar gains 50% of the design strength, and full strength after 28 days).

If you need to lay tiles on a screed that strengthens the base, then in these cases I (or my assistants) mix separately a thick cement mortar for the screed (self-leveling floors are not suitable for this case) and separately tile adhesive and make the screed in strips so that it can be literally immediately laid on Screed the tiles with tile adhesive. After a week, you can safely walk on the tiles laid on an 8-10 centimeter total layer of cement mortar and tile adhesive - at least that’s what I did at my dacha - nothing happened to the porcelain tiles in 3 years. This approach allows you to save a lot of time.

The glue can be applied both to tiles and to the floor, whichever is more convenient for you. If the thickness of the adhesive layer is 2-6 mm, then the adhesive is applied completely and then thinned out with a notched trowel. This will allow you to change the height of the tiles when laying by 1-5 mm, which is especially important when laying the first tile.

There can be an infinite number of tile laying sequences, but the most optimal in my opinion is the following (as an example, a room with a general laying scheme No. 3 was taken):

Consistency of tile adhesive

The consistency of tile adhesive is:

- liquid _ These are mixtures that are already sold ready-made. There is a saving of time and a reduction in the risk of doing something wrong, but you have to pay for convenience. Separately, we can highlight liquid nails, which are used for fastening small parts and fallen tiles;

- dry. Sold in powder form, diluted with water. It is distinguished by its low price, ease of transportation, versatility, reliability and the ability to be used on surfaces with level differences and cracks.

What types of adhesives are used to install floor tiles?

As noted earlier, modern building materials stores offer a wide range of different adhesive mixtures for tiles, including those for installing floor tiles. But there are only four main types of glue:

Cement

Cement-based tile adhesive

This is the most popular type. It is produced on the basis of cement and fractional sand with the addition of various modifying additives, which give the solution various properties - elasticity, increased strength, improve adhesion, etc.

Cement adhesive can be called universal because it is suitable for laying any type of tile on any surface.

It is most often sold in the form of a dry mixture, which is subsequently diluted with water until a homogeneous mass is obtained, and then applied to the base of the installation.

Experts say the main advantage of this glue is strength and durability, as well as an affordable price.

Epoxy

Epoxy glue

This adhesive is sold as a ready-made solution and its main area of application is cladding ceiling surfaces. For laying tiles on the floor, such adhesive is used extremely rarely - it is impractical and expensive.

Dispersive

This type of adhesive is called the ideal solution for installing vinyl tile floors.

It is also recommended for tiling plasterboard and chipboard surfaces.

Polyurethane

Polyurethane glue

This adhesive is recommended for installing tiles on surfaces that are subject to heavy loads and are prone to deformation.

This type of adhesive is highly elastic and is often used for laying floor tiles.

But it is not cheap, so it is rarely used for finishing bathrooms - mainly for more “presentable” rooms.

Preliminary preparation

At first glance, it seems that all the walls are smooth. Based on this, the average thickness of the tile adhesive is selected. But place one square in different places and try to wiggle it a little. If it lies perfectly flat everywhere, then you are lucky, or you have already leveled the surface. Most often, the tiles begin to “play,” which means that all the gaps and depressions will be filled with glue, which will significantly increase consumption.

But this is the worst option, because after gluing the tiles on the wall will lie unevenly, which will greatly worsen the impression. Therefore, we arm ourselves with any material (gypsum, Alinex, Vetonit) and begin leveling the surface. When it becomes completely smooth, let it dry, and you can get down to business.

Minimum and maximum values

Although the thickness of the adhesive composition can be varied during operation, there are some standards and restrictions. First of all, this concerns the laying of porcelain stoneware slabs.

The smallest amount of adhesive mixture is calculated individually and depends on the tile format. Conventionally, you can use the following indicators:

- For ceramic tiles and decorative inserts, a two-millimeter layer of adhesive is sufficient.

- For large and heavy facing elements, for example, porcelain stoneware floor slabs, the minimum adhesive layer increases to 4-5 millimeters.

An increase in the nominal layer is carried out in cases where it is necessary to level the surface before facing, and a screed cannot be used. This is possible with small irregularities, cracks, and depressions. For large deformations, the use of glue is pointless.

All the slightest irregularities are noted on the surface being treated. Among them, the highest is selected. This is the top point to which the glue layer will be reached. All cracks and depressions are filled with the mixture.

Experts have developed recommendations for the maximum thickness of the adhesive layer for all types of slabs:

- When laying small-sized wall tiles, the thickness of the adhesive should not exceed 10 millimeters.

- When installing floor tiles - 15 millimeters.

- When installing ceramic granite, the thickness of the adhesive layer can reach up to 20-25 millimeters, but no more.

If these indicators are exceeded, the adhesion of surfaces deteriorates with a significant excess of glue.

Humidity and moisture absorption

Two more estimates are worth making when deciding how much solution to apply. This is the humidity of the solution and the moisture absorption of the base. When laying ceramics on a wall, you should not use a semi-dry solution; moreover, the wall must be primed, if necessary several times, until the strong absorption of the surface stops.

With high absorbency, you have to increase the thickness of the glue so that the tile simply does not fall off when it dries. Pouring water will not help much, especially if the base consists of ordinary cement-sand plaster with a low cement content.

When laying ceramics on the floor, a drier solution is allowed than on the wall, but only if the moisture absorption of the floor is low. Therefore, the floor base should also be primed.

Some builders pour water excessively on the walls, on the floor, on everything around, thinking that it will be better, but no, due to excess moisture, the glue loses its properties. You need everything in moderation, as they say.

5a. Laying the first tile.

- Spread tile adhesive onto the tile (or base). If the thickness of the adhesive layer is up to 5-7 mm, then it is better to apply the adhesive to the tile; if it is more than 7 mm, then the adhesive is applied to the base. It is convenient to apply the glue with a spatula 40-60 mm wide, and if the thickness of the adhesive layer is large, then it is better to apply the glue with a trowel, so that the surface of the glue after application resembles a mountainous terrain or a washboard, this will allow you to set the tiles in the design position without much effort.

- Thin the glue with a notched trowel if the thickness of the adhesive layer is 2-6 mm.

- Place the tiles on the base in the design position along the x and y axes. In other words, so that the tile is where it should be according to the drawing.

- Check the position of the tile along the z axis (height). Using a level, check the height of the front surface of the tile using a thread or marks on the wall. After this, the horizontality of the tile along the x and y axes is checked. Simply put, the level is applied to the tile, first parallel to one wall (x axis) then parallel to the other wall (y axis).

- If the tile immediately falls into the designed position, congratulations, I have never done this before.

- If the tile is slightly higher (1-5 mm), but is in a horizontal position along the x and y axes. then you need to carefully press the tile in the center with two palms. In this case, the glue will spread a little (this is why the waves of glue were made) and the tile will sink into the design position, which again should be checked with a level along two axes.

- If the tile is slightly higher (by 1-5 mm), but is in a horizontal position along only one of the axes, then you need to carefully press on the edge of the tile that is higher. In this case, the glue will spread a little and the tile will sink into the design position, which again should be checked with a level along two axes.

- If the tile is 6 mm or more higher than the design position, then the tile must be removed and excess glue removed.

- If the tile is below the design position, then the tile must be removed and glue added.

Sometimes, if you overdid it a little and the tile turned out to be slightly lower (by 1-2 mm) than the design position along one of the axes, you can slip a small lining made of waterproof material under the tile, for example, a piece of ceramic tile or a piece of linoleum. The lining, entering under the tile, displaces the glue, but the glue is not squeezed out from the opposite side, but is redistributed and the thickness of the adhesive layer increases.

Laying the first tile takes the most time, but the quality of the entire floor depends on how you place the first tile.

Forms of porcelain stoneware cladding

Two types of floor coverings are used - ceramic tiles and porcelain stoneware. In the manufacture of the latter, pressing and subsequent very strong heating are used, or, to be more precise, baking. This allows you to create elements that can withstand significant loads.

The standard for the production of porcelain stoneware slabs is provided not only for the process itself, but also for their shape and size. They can have a square shape, be produced in the form of a pentahedron, hexagon, or octahedron. In addition, modules may differ in parameters (side length).

Additional dependencies

It is also worth considering other factors, since the size of the tile itself is not the only one among them. For example, when laying porcelain stoneware, the layer will be larger than when using tiles. In addition, it is important to consider where the tiles are laid, on the floor or on the wall. Thus, the thickness of the adhesive layer when laying tiles on the floor will be several millimeters greater than when working with wall cladding.

In addition, the base itself also affects the thickness of the tile adhesive. If the base is made according to the level, without any defects, then the thickness will remain unchanged. If they have any bulges, pits or other defects, then the thickness in some cases will need to be reduced, and in some places increased. Although, if there are defects, high-quality masonry is out of the question, so it would be advisable to perform leveling in order to save effort, time and financial costs, since the cost of glue is somewhat more expensive than mixtures for leveling.

The surface of the material also becomes an important factor. In some cases, porcelain tiles may have distortions, i.e. convexity or convexity in its surface. In such a situation, it is necessary to provide the same layer (no more than 10 mm) at the extreme points, and adjust the central one to the edges.

How to lay floor tiles?

Floor tiles are laid on a thicker layer of adhesive. Installation starts from the corner and is carried out towards the door, otherwise there is a danger of breaking the masonry.

To apply the adhesive mass, a coarse-toothed spatula is used. In case of significant differences, a screed is laid on the floor surface.

The dimensions and weight of porcelain tiles are larger than those of conventional floor tiles. Therefore, the glue layer should also be about one and a half times larger.

After laying porcelain stoneware on the floor, the slabs must be leveled and the voids underneath must be removed. To do this, the product is tapped with a rubber mallet. Excess glue is removed with a spatula.

Correctly selected thickness of tile adhesive will significantly facilitate the laying and allow you to create a durable and even surface.

Rules for applying the solution

Most often, purchased powder adhesives are used in repairs.

In order for them to acquire their properties, the mixture must be diluted with water according to the instructions before use. In this case, you should not immediately add the entire volume of liquid; it is recommended to knead a thicker mixture first, and then dilute it as necessary. After this, you should leave the solution to infuse for about 10-15 minutes so that all components bond well with each other and form a high-quality adhesive mass. To distribute the adhesive mixture over the surface as efficiently as possible, use a notched trowel. The number of the tool indicates the size of its teeth; the larger the tile, the larger they should be. It is recommended to apply the adhesive directly to the walls or floor. If you need to remove unevenness, then you can additionally lubricate the tile itself. A small spatula is used as an auxiliary tool.

To ensure even distribution of tile adhesive, it is recommended to apply it using a notched trowel.

In order for the glue to better adhere to the tiles and surface, it is recommended to wet them with water and dry them in advance. Please note that porcelain tiles practically do not absorb water.

Thickness of the tile adhesive layer for laying on the wall and floor

Installation of polycarbonate greenhouse vents, automatic and manual opening, comparison and tips for choosing a drive for polycarbonate greenhouse vents

Laying tiles

To accurately determine the thickness of the adhesive coating applied to walls or floors, you need to take into account a fairly large list of factors, since this procedure is one of the main ones when carrying out various types of finishing work.

Types of glue

First we need to decide what kind of glue we are going to use as a connector. There are three types: cement, two-component and one-component. The thickness in each case will naturally be different.

Let's take a closer look at the different types of glue:

Tile adhesive

- Cement. A simple combination of various plasticizers mixed with sand and Portland cement. You can also replace this glue with another, cheaper one. Mix regular cement with sand and add slaked lime. Working with this option is quite pleasant, as it does not have a strong odor.

- Two-component. An epoxy resin and hardener that does not dry out individually, but when mixed, becomes strong after a short amount of time. Less convenient to use than cement mortar, since you will have to constantly wash your hands if the glue gets on your skin.

- Dispersive. This is already mixed two-component glue. The disadvantage of this coating is that it will need to be used immediately upon opening, or it will simply harden.

Note: you will need much more cement solution than, say, dispersion glue. But it will be justified by the low price of the constituent elements of this mixture.

Adhesive coating thickness

Tile adhesive thickness

This parameter may vary during the process of laying tiles on the floor or walls, since a person is not a robot and simply cannot maintain exact units. However, there are minimum and maximum values that must be followed. Otherwise, the tile may fall off after the mortar dries, or the mortar will be squeezed out after pressing the tile to the surface.

To prevent this from happening, the following values exist:

Applying glue to the floor

- Minimum. For small tiles, the values vary around 2 mm, no less. If the thickness and weight of the tiles are quite large, then it is recommended to apply at least 4 mm of adhesive coating.

- Maximum thickness of tile adhesive layer. In order not to waste the solution, there is a system of maximum values. This factor depends on one nuance - the quality of the wall or floor. If you are laying tiles on a wall with depressions, you will need to add more coating to these areas than to the rest of the wall. In other places, it is not recommended to exceed a thickness of more than 1 cm when laying a wall. The thickness of the adhesive layer on the floor can reach up to 1.5 cm. Solid tiles can also raise the bar to a maximum of 2 cm in thickness.

Note: applying too much adhesive will not only result in wasted material, but also the risk of laying the tiles unevenly. There is also a deterioration in adhesion to the surface when the maximum thickness of the solution is exceeded.

How to calculate?

To determine the exact thickness of the solution, you will need to calculate some data:

- Tile size. Based on the quality of the cladding, determine the optimal thickness of the glue.

- Amount of glue. Many manufacturers indicate on packs of glue such a parameter as the number of kilograms needed per 1 meter of area if the thickness of the solution is 1 mm.

- Now let's use the data from the first two points and multiply them. The resulting value is the amount of glue that we will spend per 1 square meter. To get a more detailed picture, you need to multiply the resulting value by the area of the wall or floor.

- Add 5-10% error to the final result, since it will be better if there is excess glue left than if we don’t have enough for the last couple of tiles.

Now you know what is the optimal thickness of a layer of tile adhesive on a wall or floor. Now you have to go through the most difficult stage - styling. I hope this article answered all your questions and you learned something new.

SHOULD THE THICKNESS OF TILE ADHESIVE BE CALCULATED ACCORDING TO THE HUMIDITY OF THE ROOM?

It is humidity that is not the decisive criterion. Whether we are laying tiles in the bathroom (where, by definition, it is warm and wet) or covering a facade (which will be exposed to rain and other vagaries of the weather), the main thing is to choose the right adhesive composition: for interior or exterior work, for wet rooms or facades, etc. . P.

Bathroom tiles, if installed correctly and the right adhesive, will last for many decades.

Bathroom tiles, if installed correctly and the right adhesive, will last for many decades.

Therefore, a universal recipe: in order to lay tiles with high quality, without making mistakes, you need to strictly follow the manufacturer’s recommendations for choosing adhesive, its preparation and application, use only suitable tools with which you already have experience working with.

Calculation of the amount of glue

Which grout to choose for treating the surface of tiles in the bathroom

The quantity at a particular site may vary. The thickness of the adhesive layer depends both on the properties of the solution itself and on the base prepared for installation. An important condition is also the type of tiles being laid and weather conditions. If the tile base is made of concrete, the amount of adhesive used is less compared to a cement base. Porous tiles coated with glaze absorb more adhesive than glazed ones. Since in hot weather the evaporation of liquid is more intense, the adhesive must be applied in a thick layer compared to normal conditions.

How to distribute glue?

Almost all adhesive solutions are applied the same way. Tools such as toothed combs of various shapes are used for this purpose. The required amount of glue is applied with the even edge of the comb, then the already applied solution is, as it were, “combed” with the serrated side of the comb. At a certain angle, the ridges of the tool are formed at a certain height. Thin tiles are laid with a V-shaped tooth comb, large tiles with square teeth. A U-shaped comb is used for laying the largest tiles or those with irregular shapes.

The height of the comb teeth depends on the size of the tiles being laid. If you use a tool with a high profile, the resulting ridges will cover the back of the tiles as much as possible. Meanwhile, when applying the same solution to small tiles, excess glue may be observed, especially in the joints between the tiles. Small notches do not cover the entire area of a large tile, but are sufficient for smaller tiles. To apply glue, use the flat side of the comb, which must be held at an angle of 30 degrees. When applying glue, gradually press on the edge, this is how you can fill the pores and small holes on the surface. When covering the area with glue for subsequent fastening of the tiles, it is necessary to take such an amount of solution so that it is enough to form the teeth. The thickness of the adhesive between the tile and the base should be 2.5 mm. This amount will allow for high-quality setting.

To determine the area of the area for applying glue, it is necessary to determine not only the size of the tiles, but also know the temperature data in the room. As mentioned above, at high temperatures the glue sets faster. This means that a larger surface area will dry faster, and you will not have time to lay tiles on it. Therefore, many craftsmen work in an area of no more than 1 sq.m. for one installation. The serrated edge of the comb for forming combs is always kept at an angle to the base, and the smaller the angle, the lower the height of the comb. The angle of inclination must be the same and constant during the laying of the tiles. This will not only ensure the formation of ridges of equal height, but also a smooth surface of the tile.

What adhesive is suitable for quickly laying tiles.

Yes, there are adhesives for quickly laying tiles. They are used in cases where there is a short deadline for putting the premises into operation.

This tile adhesive dries very quickly, which, on the one hand, is good for timing, but on the other hand, it requires the accuracy and speed of the tiler’s work, which makes working with it more difficult.

Examples of such adhesives: Mapei Granirapid, Ultralite S1 Quick, Elastorapid.

Conformity class C2F S1, C2FT S1, C2FTE S2 .

______________________________________________________________________________________

The table below will also be useful, which conveniently provides information using Mapei glue as an example.

Most popular brands

There are many criteria for selecting material, for example, by sales volume, by recognition among craftsmen. At the same time, in terms of physical volume, cheap mixtures are in greatest demand among large construction companies, although when asked: “Have you started using this yourself?” the answer follows - “I would take that one, even though it is more expensive.”

Local producers also influence the ratings; common mixtures in one region will be unknown in another.

To summarize, most consumers will be familiar with the following brands and types of adhesives:

Kreps

Kinds:

- "Enhanced";

- "Standard";

- "Base";

Knauf

Cerezit

Video review

Sources

- https://IzPlitki.com/pered-ukladkoj/kak-razvodit-klej-dlya-plitki.html

- https://ilitkeramika.ru/kak-razvodit-plitochnyj-klej-proportsii.html

- https://FB.ru/article/402158/kak-razvesti-plitochnyiy-kley-pravilno-proportsii-i-opisanie-protsessa

- https://plitka-pol.ru/articles/klej/prigotovlenie-plitochnogo-kleya-kak-razvodit-klej-dlya-plitki.html

- https://delaypol.com/napolnaya-plitka/kak-razvodit-plitochnyj-klej.html

- https://biznesprost.com/otkryt-biznes/kak-razvodit-plitochnyj-klej.html

- https://plitkahelp.com/plitochnyj-klej/kak-razvodit-plitochnyj-klej-osnovnye-pravila

[collapse]

Laying tiles on drywall

Since the walls of the above-mentioned rooms under the tiles will be exposed to moisture, their plasterboard wall cladding should be made from moisture-resistant sheets. The peculiarity of this material is that cardboard is more water-resistant, as well as filler additives that perform hydrophobic and antifungal functions. The combination of moisture-resistant drywall with tiles makes the walls resistant to high humidity and mold formation. But, if necessary, the tiles can also be glued to other types of sheets, wall or fire-resistant. The tiles are glued to drywall using special compounds and after preparing the surfaces. Materials you will need: Laying tiles on walls is used as the main decoration of walls in rooms with high levels of humidity: kitchens, bathrooms and toilets. In other cases, other types of tiles can be used, most often gypsum, but they use slightly different compositions and technologies. The process of mixing adhesive for installing tiles

To lay the first row, you need to fix a wooden plank to the floor, which will serve as a level. This rail is set by checking the building level. When the starting strip is laid, glue is applied to the tile or directly to the drywall (both options are possible). After applying the adhesive, the tile is pressed against the wall, tapping lightly. You can check how smoothly the installation is done with a level. Quite often you can hear the question of how to glue tiles onto drywall, and what is needed for this? The wall material is very well suited for this type of finishing; the surfaces are perfectly smooth. Almost everyone who has done renovations does not ask whether it is possible to glue various types of tiles onto plasterboard surfaces, the main thing is how to do it. The technology for laying such finishing material is simple, but takes into account its nuances, which are inherent in any type of construction and repair work.

Additional information on the topic:

- Insulation of plasterboard partitions, price in estimate

- What profile is needed to level plasterboard walls?

- Is it possible to use moisture-resistant plasterboard on the ceiling in a bathroom?

- Is it possible to attach drywall to OSB without a profile?

- How to make a new wall in an apartment from plasterboard

- https://derevyannie-doma.com/materialy/tolschina-plitochnogo-kleya-steny-i-pol-keramogranita-sloy-maksimal-naya-ukladka-shpatelya-usadka-i-nanesenie.html

- https://obustroen.ru/stroymaterialy/otdelochnye-materialy/plitka/tolshhina-napolnoj-plitki-s-kleem.html

- https://kitchenremont.ru/remont/tolshchina-plitochnogo-kleya

- https://pol-exp.com/klej-dlya-napolnoj-plitki/

- https://sdelalremont.ru/kakoj-neobxodim-sloj-kleya-pri-ukladke-plitki.html

- https://fb.ru/article/323771/maksimalnaya-i-minimalnaya-tolschina-plitochnogo-kleya-pri-ukladke-plitki

- https://whitestrip.ru/tolshhina-plitochnogo-kleja-pri-ukladke-plitki-na-p01/

Correct layout of tiles of any size

There are many options for laying out tiles. It all depends on your imagination. There are the most popular options for styling patterns:

- Chess order. Tiles of two contrasting colors are used;

- Linear order. It is considered a universal option because it is suitable for any room;

- Ornament. Here it is important to make a large central part, this will make the floor prettier;

- Kaleidoscope. In this version, as many colors as your imagination requires are used.

Sources

- https://AmiPlus.ru/kuhnya/razmery-keramogranita.html

- https://GidPoKraske.ru/rabota-s-kleem/tolschina-kleya-dlya-keramogranita-na-pol.html

- https://kraskamiks.ru/klej/tolshhina-kleya-dlya-keramogranita-na-pol-sovety-i-pravila-rascheta

- https://pol-spec.ru/plitka-i-kafel/tolshhina-keramogranita-dlya-pola-primenenie-xarakteristiki-osobennosti-montazha.html

- https://str-mebel.ru/shkafy-i-komody/tolshchina-keramogranitnoj-plitki-dlya-pola.html

- https://www.uralgres.com/characteristics/tolshchina/

- https://OmShantiDom.ru/teplyj-pol/klej-dlya-keramogranita-na-teplyj.html

- https://lucheeotoplenie.ru/teplyj-pol/klej-dlya-keramogranita-na-teplyj-pol.html

[collapse]