Over time, a wooden house not only loses its attractiveness, but also loses ground in terms of thermal insulation. The wood begins to crack, sag, and rot in places, which leads to loss of heat in living spaces. A way out of this situation can be a beautiful brick cladding.

Thus, a wooden house lined with brick not only acquires a renewed appearance, but also becomes much stronger, given that during masonry both parts of the house are tied together. In addition, an additional foundation must be installed under the new brick lining, which increases the load-bearing capacity of the building.

Below you will find information on how to veneer a wooden house with brick so that it has a good appearance and appropriate strength.

Does a wooden house need brick cladding?

The compatibility of a wooden house and brick cladding quite naturally worries owners of wooden estates, because in their structure wood and brick are completely different materials.

Although brick itself is an excellent building material, building an individual residential building from this element alone, especially taking into account our climate, is not the best option. Because artificial stone has high thermal conductivity, and it is for this reason that the outer walls must be thick enough. But using it as a façade cladding for a wooden frame is a more profitable and effective method. With proper insulation, this method will help to significantly save on heating costs and give the building a clear view of a permanent structure. Therefore, along with modern plaster mixtures, sheathing and PVC lining, brick cladding is very often done.

However, when constructing such reliable protection, it is necessary to take into account some nuances. For example, the physical properties of wood or the specifics of using vapor barrier.

If the technology is followed, a vapor barrier and insulation are laid between the brick and wooden walls Source stonemuseum.org

An incorrect approach to combining materials can cause certain difficulties: from increased humidity in the premises to fungal damage to wall elements. And this will eventually lead to the destruction of the frame. Therefore, it is important to entrust construction work to qualified specialists.

Pros and cons of a wooden house lined with brick

The need to combine building materials that are completely different in all respects is a responsible job, and not everyone is capable of such a task. Therefore, it is worth thoroughly weighing the advantages and disadvantages of such a solution before coming to final conclusions about the advisability of facing a house with brick.

The positive aspects include the following factors:

- Improving the appearance of the building. If the house is made of gas or foam concrete, then it needs cladding in any case - for protection from moisture and simply for beauty. But wooden houses are built precisely because of their original appearance, which many would consider blasphemy to cover with brickwork. However, if the building is old and has lost its visual appeal, then in this case, facing the house with brick will not hurt, the photo below is an example of such a case.

If the boards of a wooden house are darkened and weathered, then facing with brick will hide all the flaws Source postroiv.ru

- Reducing the likelihood of fires. In fact, this is not such an important argument, because many wooden houses have been standing for decades. In addition, in the vast majority of cases, fires start from the inside.

- Significant reduction in building heating costs. But this is only possible if high-quality insulation is used - otherwise, a noticeable effect from a decorative brick wall is unlikely to be achieved.

- The wooden frame is perfectly protected from the damaging effects of precipitation. This is a fairly serious argument in favor of cladding - unlike siding and similar coatings, the strength of brickwork is much higher.

There are also plenty of disadvantages:

- Wooden buildings are characterized by some changes in size during their operation. Therefore, a rigid connection to the brickwork is not made - the facing material and the wooden frame must be independent of each other, and this is a rather complex technical task.

- Brick belongs to the category of heavy materials. Therefore, when facing a new house, it is necessary to calculate the foundation accordingly - both in width and load-bearing capacity. If the cladding is done to an old house, then the foundation will have to be strengthened.

If the foundation was initially designed for light walls made of wood or cellular concrete, then for an additional brick wall the foundation of the house will have to be strengthened Source besplatka.ua

See also: Catalog of companies that specialize in facade materials.

- When constructing a residential building, in order to maintain an optimal microclimate, one must be guided by the rule: the vapor permeability of the building materials used changes from lower to higher values in the direction “from inside to outside.” If artificial stone is used to protect the log house, the situation will change in the opposite direction. As a result, condensation accumulates in the insulation. In winter, it turns into ice and destroys the structure of mineral wool. During the warm season, it creates comfortable conditions for the formation of mold and, as a result, rot. To avoid these consequences, façade ventilation must be installed.

In general, we can draw the following conclusion. Covering a wooden house with brick is not the most optimal solution. If building a house is still only in plans, you should think carefully and weigh the pros and cons. Perhaps a more rational solution would be to build a structure from gas silicate blocks, and then work on the facade. Bricks and gas silicate blocks serve as a good complement to each other.

When building a house from blocks, brick finishing can be done parallel to the construction of walls Source blokerstroy.ru

It is worthwhile to cladding a wooden house with bricks only if the building is old, the wooden frame has darkened, and you want to have a more attractive façade of the building.

We calculate the material

To properly veneer a wooden structure with brick blocks, you need to select the right amount of material

To properly clad a wooden structure with brick blocks, you need to select the right amount of material. It is worth remembering that a supply of building materials will allow you to avoid unpleasant surprises at the construction site.

So, the calculation of standard bricks is made according to the principle of block consumption per 1 m2. It is generally accepted that there are about 50-55 blocks in this area. Therefore, it is worth determining the area of each wall of the house, summing them up and, as a result, simply multiplying the resulting number m2 by 55. At the same time, it is advisable to buy a reserve of 10-15% in case of an unexpected battle at the construction site.

Important: when making calculations, do not forget to deduct window and door openings from the total area of the walls.

- The ready-made cement mortar for bricklaying is calculated according to the principle of 2 kg of ready-made mixture per 1 m2 of cladding.

- The masonry mixture is mixed from sand, lime and cement in a ratio of 9:2:1. All bulk ingredients are combined using a construction mixer and diluted with water to the consistency of soft sour cream.

Important: ready-made mortar can also be used for laying bricks. But its cost is several times higher than preparing a cement-sand mortar with your own hands.

Do not forget about the amount of ready-made concrete mixture for pouring the foundation. It is calculated by multiplying the perimeter of the base by its width and depth. As a rule, these parameters for the Moscow region are 0.3 meters and 0.5 m.

Facing brick: features and varieties

The industry uses completely different technological approaches in the production of various types of facing bricks. This affects the final cost of the product. It is often difficult for a consumer to understand the huge range of artificial facade stones, so you need to know at least its main varieties.

- Ceramic . Relatively cheap finishing material of this line. A rich color palette, a variety of various shades will not only significantly improve the facade of the building, but also lay out certain patterns. However, a significant drawback of the product is its high hygroscopicity. If water gets into the pores, then there is a high probability that at temperatures below zero the material will begin to crumble. After laying this façade element, the best solution would be to cover the wall with a water-repellent mixture (the main requirement is that such a composition does not form a vapor-proof film).

Ceramic facing brick Source grand-srv.ru

Insulation

Before facing with brick, it is most likely necessary to insulate the timber walls. By itself, facing brick will not provide almost any additional insulation. If you used timber with a thickness of 150 or 200 mm - this is the most common size in construction, then insulation is definitely necessary.

Of course, first do not forget to treat the timber with antiseptics and fire retardants. Then the walls must be caulked, covered with insulation and windproof film. And after that you can start brick cladding.

How to choose facing bricks for your home

Before you start work, you need to decide on the type of brick. First of all, everything depends on the goals and objectives that the owners of the estates set for themselves. If the goal is to improve performance characteristics, even sand-lime brick will do. And if the façade is important to the owners and you want to add your own flair to the exterior design of the building, it’s better to go with clinker or ceramic. In the case when it is planned to use other finishing materials after lining a wooden house with facing bricks, you can use artificial stone of any brand. Only in this case do you need to take into account the additional costs of plastering or other finishing options.

Methods for lining a house with facing bricks

There are many methods for lining a house with bricks. Let us review just a few:

- Path laying method.

- Block method.

- Cross version (similar to block).

- Gothic masonry.

- Chain (Brandenburg).

- Messy styling.

Professionals master almost all methods, and, if necessary, can combine them.

Types of laying facing bricks Source iz-kirpicha.su

How to cover a wooden house with bricks

The process of cladding a wooden house comes down to the following main points:

- Calculate the required amount of bricks;

- It is advisable to purchase goods in one batch (there may be a discrepancy in tone);

- Before starting work, it is necessary to treat the wooden frame with a special compound;

- If necessary, you need to strengthen the foundation or pour a new tape nearby;

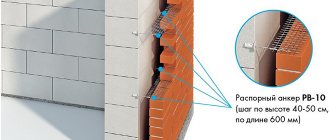

- There should be an air gap (thickness - 3-5 cm) between the brickwork and the wooden frame; insulation should be used if necessary;

- Laying must be done at positive temperatures (not lower than +5);

- Before you start laying the first row, you need to level the base;

- They start with the corners next to each other (height - 5-6 bricks). To make the connection more reliable, halves of artificial stone are not recommended;

- The lining is done along a cord that is pulled between two corners.

Ventilation gap

To prevent the timber and insulation from becoming damp, rotting and mold, it is necessary to leave a ventilation gap between the timber wall covered with insulation and brick, where the air can move freely, taking moisture with it.

Special openings are made in the top and bottom rows of brickwork for free air circulation. Such openings must be covered with rodent bars.

By facing a house made of timber with brick, you can make the house beautiful and durable like a brick one. In this case, you will spend significantly less money.