For waterproofing, bitumen-based mastic is often used. It is produced by many manufacturers, but must be produced taking into account the requirements of the state standard. This indicator gives the buyer confidence that the product has been tested and meets the necessary standards. And the processing result will be effective. How the GOST bitumen mastic is described in it will be discussed in detail below.

What is GOST

The meaning of this abbreviation is the quality standard adopted by the state. Waterproofing mastic is determined according to GOST 30693-2000, where the main requirements for the composition are indicated, and the division by type is prescribed. For example, there is a polymer type with bitumen.

GOST specifies the rules for using products, what quality they should be, how they can be transported, stored, and other important issues that help to understand the standards for using various means. All these requirements are developed taking into account technological aspects, nuances studied in practice, etc.

The meaning of this abbreviation is the quality standard adopted by the state.

Purpose of GOST for bitumen mastics

GOST mastic is divided into several types; the basis for classification can be the purpose of the substance, for what surfaces and conditions it will be used. The following options stand out here:

- For the roof, this includes means for working with roofs, their repair or installation;

- For the purpose of waterproofing surfaces, substances that are coated on the base, creating a waterproofing layer;

- Serves as an adhesive to secure a variety of materials to protect surfaces from various factors, including roll types;

- For vapor barriers that provide this protection.

GOST mastic is divided into several types.

Areas of use of waterproofing mastics

TechnoNIKOL compositions are divided into several types depending on the area where it is used. To better understand the issue, it is necessary to specifically consider each type of bitumen waterproofing material.

TechnoNIKOL mastic No. 21 for roofing

Technomast No. 21 mastic is used as a material for waterproofing work on the roof. The composition of the finished substance includes bitumen, artificial rubber, mineral fillers, and specialized additives. TechnoNIKOL No. 21 waterproofing mixture is distinguished by unique characteristics of elasticity and heat resistance. It also adheres perfectly to any base surface, regardless of the material.

This type is used for pouring and repairing mastic roofs, as well as processing concrete and metal structures that are planned to be buried in the ground. To improve the technical characteristics of the waterproofing layer, in addition to mastic, roofing felt RPP 300 and fiberglass are used. It is not necessary to add the listed materials; the composition copes with its functions without them.

Important! TechnoNIKOL No. 21 mastic can be used as an anti-corrosion agent for metal surfaces (for example, cars or water pipes).

The consumption of the composition for waterproofing is about 3.5 kg per 1 sq. m. For roofing, these figures are higher and average 5 kg per square meter. m.

Let's identify the technical characteristics of this type of waterproofing from TechnoNIKOL:

- Adhesion indicators with concrete – 0.6 MPa, with metal surfaces – 0.9 MPa.

- The strength when gluing between layers of rolled material is 0.3 MPa, and with concrete 0.4 MPa.

- The maximum possible temperature limit is 110 degrees Celsius.

- Strength – 1 MPa.

- The elongation rate before breaking is 500%.

- The content of non-volatile substances in the composition is 50%.

- Moisture absorption in the first day of being on the base is 0.4%.

- The curing time is 24 hours.

The material must be applied using a brush or spatula onto a dry and leveled surface and leveled according to the rule.

Important! When used in cold weather, the mastic must be heated to 60 degrees.

TechnoNIKOL mastic No. 24 for foundation

TechnoNIKOL produces this material under number 24. The substance is a ready-made composition of petroleum bitumen. This mastic contains mineral fillers, various types of solvents and special additives that improve the quality of the material. This waterproofing mastic does not contain polymers, therefore it is classified as a hard coating and is not elastic.

Important! Waterproofing mastic TechnoNIKOL No. 24 is not used for processing metal products.

This mastic is intended for creating waterproofing on brick plinths and other structures that are made of concrete and located outside the building. The material consumption is not so large - it is only 1 kg per 1 sq. surface meter.

The technical characteristics of the material are as follows:

- The displacement strength of the glued section is 2.0 kN/m.

- Moisture absorption on the first day is 0.4%.

- Heat resistance – 80 degrees.

- Adhesion to metal and concrete – 0.1 MPa.

- Operation is possible at temperatures from -20 to +40 degrees.

Mastic TechnoNIKOL No. 27

In the manufacturer's assortment you can find material with serial number 27. It also has its own specific use. The product contains a solvent that is suitable for external use only. “TechnoNIKOL No. 27” is also called an adhesive composition, which is used for installing extruded polystyrene foam, waterproofing foundations and plinths, as well as sewer systems. Paired with product No. 71, it is suitable for hydro- and thermal insulation of the roof. If necessary, can be used to seal swimming pool bowls.

Most soft roofing materials are susceptible to UV rays. Composition No. 27 is able to create an additional protective layer that extends service life. The product does not require preheating before use, which greatly simplifies the application process. The composition can be applied to the surface for gluing in stripes or dots, which will depend on the type of surface. Consumption varies depending on the application method and can reach a kilogram per square meter.

Mastic TechnoNIKOL No. 31 for bathrooms

This product is supplied under number 31 and is a ready-made emulsion with bitumen and artificial modified rubber in the composition. This mastic is perfect for interior work, as it does not contain solvents. Due to the water component, the mastic is applied to a damp, but not damp surface using a brush.

This substance is intended for installing a waterproofing layer on loggias, bathrooms, basements, swimming pools and other interior rooms. It can also be used for roofing, covering plinths and foundations, as well as other structures that are exposed to moisture. The finished coating has maximum elasticity, high quality and technical characteristics, strength, heat resistance and the ability to adhere to a variety of substrates.

To treat surfaces you need approximately 3.5 kg of such mastic per 1 square meter. meter, for the roof you will need an average of 4.5 kg.

Product technical data:

- Adhesion – 0.45 MPa.

- Strength 0.5 MPa.

- Elongation at break of material – 700%.

- Heat resistance - 95 degrees.

- Moisture absorption in 24 hours – 1%.

- The proportion of binder-type substance in the composition ranges from 50 to 70%.

TechnoNIKOL mastic No. 33 for concrete

Water-emulsion bitumen mastic from TechnoNIKOL No. 33 includes latex and polymer modifiers. Perfectly suitable for mechanized application in combination with a coagulant, which is a saline solution. For it, take 4 kg of salt per 25 liters of water. In this case, 1 part of the mastic and 8 parts of the coagulant are diluted.

Due to the fact that this mastic contains no solvents, it can be used for interior work: waterproofing basements, loggias and balconies, as well as for waterproofing mastic roofs and other structures.

The consumption of such mastic for the coating layer is approximately 4 kg per 1 sq. m. surface meter.

Technical characteristics of mastic No. 33:

- Adhesion to concrete – 0.6 MPa.

- Strength – 0.7 MPa.

- The maximum temperature that the layer can withstand for 5 hours is 140 degrees.

- Maximum stretch at break is 900%.

- Complete hardening time is from 24 to 72 hours.

- Maximum strength indicators appear after a week.

Mastic TechnoNIKOL No. 41 for hot use

Roofing waterproofing TechnoNIKOL No. 41 is made from roofing bitumen with mineral and polymer fillers. This mastic is fully compatible with any roofing material produced by Technonikol. Mastic can provide the most reliable layer, which will become roofing waterproofing for any structure.

Bituminous mastic number 41 is used for roofing work, in particular, for installing and repairing the roof, making a hermetically sealed connection to drainpipes and other parts of the roofing pie. Proper application involves heating the mixture to 160 - 180 degrees before use.

Mastic TechnoNIKOL No. 71 with additives

Mastic of bitumen-polymer type with various improving additives. Helps repair damaged roofing, fill voids between edge strips and corners, and eliminate gaps when installing additional elements.

Among the technical characteristics of this type of waterproofing substance are:

- Adhesion with metal – 0.4 MPa, with concrete – 0.8 MPa, between two layers of rolled material – 0.3 MPa.

- Strength – 0.2 MPa.

- Stretch to break – 100%.

- Non-volatile substances in the composition – from 80 to 90%.

- Moisture absorption over 24 hours – 2%.

Mastic TechnoNIKOL No. 45 butyl rubber

This product is also sold under number 45, as waterproofing mastic from Technonikol. It is a viscous mass of white or gray color, which contains fillers, technical additives and an organic solvent.

Intended for sealing various types of seams, in particular, on metal, concrete structures, as well as window and balcony blocks, creating waterproofing of concrete or metal and protection against corrosion.

The material has the following technical characteristics:

- Strength – 900 – 1100 kg/cubic. meter.

- Tensile strength 0.2 MPa.

- Complete drying within 1 hour.

- Stretch to break – 100%.

- Durability of the finished coating at temperatures from -45 to +45 degrees Celsius.

- Temperature during work is from -20 to +40 degrees.

What information can be obtained from GOST

Roofing mastic GOST determines not only the rules of storage, transportation and labeling. But also technical conditions, characteristics, safety measures, requirements for materials.

It also describes how testing of products should be carried out and what frequency should be used when checking quality. What requirements must the mastic layer meet, etc. All these norms help to understand what result will be obtained in the end.

Roofing mastic GOST determines not only the rules of storage, transportation and labeling.

Application area

This standard applies to roofing and waterproofing mastics intended for gluing rolled roofing and waterproofing materials, installation of protective layers of roofs, installation and repair of mastic roofs, installation of mastic layers of waterproofing and vapor barrier of building structures, buildings and structures, and establishes classification, general technical requirements, safety requirements, acceptance rules, test methods, transportation and storage requirements, and instructions for use.

The requirements of this standard, set out in sections 4-, are mandatory.

Quality indicators required for all mastics and for specific groups of mastics are given in Appendix A.

Stamps

According to the marking division, it is stated here that bitumen mastics can be divided into five types. They differ in the level of heat resistance. So mastic with the brand MBK-55 can withstand temperatures of +55 degrees. The degree step is +10 degrees in this gradation.

Mastic with the brand MBK-55 can withstand temperatures of +55 degrees.

APPENDIX 1 Recommended

RECOMMENDED AREA OF APPLICATION OF MASTIC

1. The scope of application of mastic, depending on the construction area and roof slope, is indicated in the table.

| Construction area | Mastic for the device | |||

| roofs with a slope, % | places | |||

| less than 2.5 | 2.5 - less than 10 | 10 — 25 | adjacencies | |

| 1. North of geographical latitude 50 degrees. for European and 53 degrees. for the Asian part of the USSR | MBK-G-55 | MBK-G-65 | MBK-G-75 | MBK-G-85 |

| 2. South of these areas | MBK-G-65 | MBK-G-75 | MBK-G-85 | MBK-G-100 |

2. Mastics of the MBK-G-55 and MBK-G-65 brands should be used for gluing antiseptic roofing felt, glass roofing felt and roofing felt materials, and mastics of the MBK-G-55A and MBK-G-65A brands - for gluing non-antiseptic roofing felt; mastics of the MBK-G-55G and MBK-G-65G brands - for installing a protective layer on roofs.

Technical requirements

To understand what standards a mastic mixture should be, you need to understand the requirements for it. This is how GOST defines the technical requirements described below:

- Substances must be homogeneous, there are types that may have some impurities, but not exceeding the standards;

- Due to ease of use, there can be ready-made formulations, or from several components that are supplied in one package;

- The degree of flexibility, this factor is determined by bending on the beam, the radius should be five millimeters, exposure to certain temperatures is applied;

- Harmful elements should not be released excessively;

- Degree of water resistance. Roofing mastics can withstand exposure to water of 0.1 atm for 72 hours, for waterproofing 0.3 atm for ten minutes;

- If the mastic mixture is colored, then it must last for 120 minutes to test the color fastness;

- Rolled products must be firmly glued with mastic.

Substances must be homogeneous, there are types that may have some impurities, but not exceeding the standards.

TEST METHODS

5.1. Checking the appearance (uniformity of the mastic, the presence of foreign inclusions and particles of filler, antiseptic or herbicide not covered with bitumen) is carried out visually.

5.2. Determination of heat resistance

5.2.1. Equipment and accessories

Laboratory drying cabinet with perforated shelves, ventilated, allowing automatic adjustment of the set temperature.

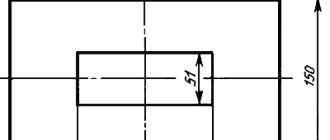

A flat metal plate with dimensions of (50´100´2) mm.

5.2.2. Preparing for the test

To determine heat resistance, a uniform layer of 8-10 g of mastic, preheated to a temperature of 140 ° C - 160 ° C, is applied to a glassine sample measuring 50 x 100 mm. A piece of glassine of the same size is placed on top and pressed with a load of 2 N (2 kgf) for 2 hours. The load is applied through a flat metal plate measuring (50´100´2) mm.

The drying cabinet is heated, depending on the brand of mastic, to the temperature indicated in the table. 2.

5.2.3. Carrying out the test

After 2 hours of exposure, samples with mastic grades MBK-G-55 or MBK-G-65 are placed in a heated drying cabinet on an inclined stand (20%). and with mastic of the MBK-G-75, MBK-G-85, MBK-G-100 brands - on an inclined stand (100% at an angle of 45°).

The samples are kept in the cabinet for 5 hours at a given temperature, after which the samples are removed and inspected.

The mastic is considered to have passed the test if it does not flow or begin to slide.

5.3. Definition of flexibility

The method is based on bending a glassine sample with mastic applied to it along the semicircle of a rod of a certain diameter at a given temperature.

5.3.1. Equipment and accessories

Thermometer according to GOST 28498.

Rods with a diameter of 10, 15, 20, 30, 40 mm.

Vessel for water.

5.3.2. Preparing for the test

8 - 10 g of mastic, preheated to 140 °C - 160 °C, is applied in a uniform layer to a glassine sample measuring 50 x 100 mm.

After this, the sample is kept for 2 hours at a temperature of 18 ± 2 °C in air. Then water is poured into the vessel, the temperature of which should be 18 ± 2 °C.

The samples and the rod are placed in a vessel with water and kept in it for 15 minutes.

5.3.3. Carrying out the test

After soaking in water, the sample is slowly bent along the semicircle of the rod for 5 seconds with the front surface (mastic) upward. The time from the moment the sample is removed from the water and bent along the semicircle of the rod should not exceed 15 s.

The mastic is considered to have passed the test if no cracks form on the surface of the sample.

5.4. Determination of the adhesive properties of mastic

The essence of the method is to determine the load required to break two glued samples of a certain length and width.

5.4.1. Equipment and accessories

Explosive testing machine of the RT-250M-2 brand or similar machines having a working part of the scale from 0 to 100 kgf with a division value of no more than 0.2 kgf, with a permissible reading error within the working scale of ±l%.

Laboratory drying cabinet with perforated shelves, ventilated, allowing automatic temperature control.

Metal plate.

5.4.2. Preparing samples for testing

Two samples of glassine measuring 50 x 140 mm, cut from a roll in the longitudinal direction, are glued together with mastic over an area of 50 x 60 mm. Mastic heated to 140 °C - 160 °C in an amount of 4 - 6 g is applied to the surface of both samples so that one end of each sample remains uncoated with mastic. The glued samples are pressed with a load weighing 10 N (1 kgf) through a metal plate and kept for 2 hours at a temperature of (20 ± 2) °C. Three samples are prepared for testing.

5.4.3. Carrying out the test

2 hours after gluing, the samples are placed in the clamps of the tensile testing machine without distortion.

The sample is tested at a constant speed of movement of the movable clamp of 50 mm/min until rupture, which should occur on the glassine.

5.5. Determination of filler content after heating

The filler content is determined by the combustion method according to GOST 2678 with the following addition. A mastic sample is poured into a split cylinder with a diameter of 20 mm and a height of 150 mm, which is placed in a drying oven, heated to a temperature of 160 °C (when using a surfactant, up to 130 °C) and maintained at this temperature for 5 hours.

After cooling to room temperature, the mastic is removed from the cylinder and samples weighing at least 1 g each are taken (from the bottom and in the middle of the cylinder). The test results must comply with the requirements of clause 2.6.

5.6. Determination of the softening temperature of mastic - according to GOST 11506.

5.7. Determination of filler content - according to GOST 2678.

5.8. Determination of water content in mastic - according to GOST 2477.

Safety requirements

Hot bitumen roofing mastic GOST is characterized by high-temperature effects. For this reason, the master must be protected, wear protective clothing, as well as personal protective equipment. Shoes must also withstand such exposure.

If a small fire occurs, then you should act in the following way: sand, felt, special powders, and foam fire extinguishers are used to extinguish the fire. For large fires, a foam jet and water from fire monitors are used.

The master must be protected, wear protective clothing, as well as personal protective equipment.

APPENDIX 2 Recommended

RECOMMENDATIONS FOR THE COMPOSITION AND PREPARATION OF BITUMEN ROOFING HOT MASTICS

1. Mastics should be prepared in factory conditions (for example, in asphalt concrete plants), in centralized installations of construction trusts in heated containers equipped with mixing devices. It is allowed to produce mastics under construction conditions.

2. The process of preparing bitumen binder consists of dehydrating and melting bitumen, fusing bitumen, and introducing surfactants and plasticizing additives into the bitumen or alloy.

3. Initially, low-melting bitumen is loaded into the container, which is dehydrated at a temperature of 105-110 degrees C, after which bitumen grade BNK 90/30 (BNK 90/40) is loaded and with constant operation of the mixer, the temperature of the bitumen binder is brought to 160 - 180 degrees. WITH.

4. The amount of roofing bitumen grade BNK 90/30 (BNK 90/40) introduced into the molten low-melting bitumen depends on the softening temperature of the mixed bitumen and is determined by the formulas:

where Bt is the content of more refractory bitumen in the alloy (grade BNK 90/30),%;

Bm is the content of low-melting bitumen in the alloy, %;

t is the softening temperature of the bitumen binder for the preparation of mastics, assigned in accordance with table. 3 of this standard;

tt, tm are the softening temperatures of refractory and low-melting bitumen, respectively.

5. To prevent bitumen from foaming when heated, add a defoamer of the SKTN-1 brand at the rate of 0.01 g (2-3 drops) per 1 ton of bitumen.

6. Surfactant additives introduced to reduce the sedimentation of the filler when transporting mastics at a temperature not exceeding 130 degrees C should be added directly to the bitumen binder or with the filler.

A surfactant is introduced into the bitumen binder in an amount of 1.5 - 2% by weight of the bitumen binder.

The surfactant is introduced into the filler during grinding in an amount of 0.15 - 0.2% by weight of the filler.

7. By agreement with the consumer, for work in winter conditions it is allowed to introduce plasticizing additives in an amount of 3-8% by weight of the bitumen binder. When introducing plasticizing additives, surfactants should not be added to the bitumen binder.

8. After sampling and determining the softening temperature of the bitumen binder, the filler is introduced in separate portions with constant stirring.

9. The amount of filler loaded in each portion should be 1/3 -1/4 of the required estimated amount. If the foam rises intensively, the introduction of the filler is stopped until the foam level drops, after which the filling of the filler is resumed.

10. After loading the last portion of filler, cooking of the mastic is continued at a temperature of 160 - 180 C with constant stirring until a homogeneous mixture is obtained and the foam has completely settled.

11. Antiseptic additives in the amount of 4 - 5% or herbicides in the amount of: simazine 0.3 - 0.5%, amine (sodium) salt 2.4D 1 - 1.5% by weight of the bitumen binder is introduced in separate portions of 2 -3 reception with constant stirring before finishing the preparation of the mastic.

Acceptance rules

The manufacturer must test the mastic produced. The product is tested in batches, which includes those that were produced from identical materials and according to the same recipes. For testing, 3% of the volume is taken.

They control external data, heat resistance, softening temperature indicators, flexibility. Also, batch tests are carried out periodically; if there are shortcomings, then the tests are repeated with the selection of a greater percentage of mastic twice.

For testing, 3% of the volume is taken.

Packaging, labeling, transportation and storage

The packaging can be steel and wood barrels, a wooden drum, or paper bags with an anti-adhesive layer. It is important that some characteristics are marked on the packaging, including: brand, manufacturer's name, batch number, filler name.

Transportation can be carried out using any vehicle. Mastic must be stored indoors according to the brand.

Transportation can be carried out using any vehicle.

GOST 2889-80 Hot bitumen roofing mastic. Specifications

STATE ST ANDART OF THE USSR UNION

BITUMEN ROOFING MASTIC HOT

TECHNICAL CONDITIONS

GOST 2889-80

STATE MANAGEMENT COMMITTEE OF THE USSR FOR CONSTRUCTION

Moscow

DEVELOPED by the Central Research and Design and Experimental Institute of Industrial Buildings and Structures (TsNIIpromzdany) of the USSR State Construction Committee

PERFORMERS

M.I. Povalyaev

, Ph.D.

tech. Sciences, O.K.

Mikhailova ,

L.G.

Gryzlova , Ph.D.

tech. Sciences, L. M. Leibengrub

INTRODUCED by the Central Research and Design-Experimental Institute of Industrial Buildings and Structures (TsNIIpromzdanii) of the USSR State Construction Committee

Deputy Director S. M. Glikin

APPROVED AND ENTERED INTO EFFECT by Resolution of the USSR State Committee for Construction Affairs dated March 24, 1980 No. 39

STATE ST ANDART OF THE USSR UNION

| BITUMEN ROOFING MASTIC HOT Technical | GOST 2889-80 In return GOST 2889-67 |

By Decree of the USSR State Committee for Construction Affairs dated March 24, 1980 No. 39, the introduction date was established

from 01.01. 1982

Failure to comply with the standard is punishable by law

This standard applies to bitumen roofing hot mastic, which is a homogeneous mass consisting of bitumen binder and filler and used in a hot state.

Mastic can be made with the addition of antiseptics and herbicides.

The mastic is intended for installation of roll roofs, as well as mastic roofs reinforced with glass materials.

The scope of application of the mastic is given in Appendix 1 to this standard.

1.1. Mastic, depending on heat resistance, is divided into grades and, indicated in the table. 1.

Table 1

| Brand | MBK-G-55 | MB K-G-65 | MB K-G-75 | M BK-G-85 | MBK -G- l 00 |

| Heat resistance, °C | 55 | 65 | 75 | 85 | 100 |

1.2. The symbol for mastic brands consists of its name, hot bitumen roofing mastic, and a number indicating the heat resistance of a certain brand of mastic.

In the designation of brands of mastic with additives of antiseptics or herbicides, after the designation of heat resistance, the letters A and G are added, respectively.

An example of a symbol for mastics with a heat resistance of 55 °C:

MB K-G-55

The same, with the addition of an antiseptic:

MB K-G-55A

The same, with the addition of herbicides:

MB K-G-55G

2.1. Mastic must be manufactured in accordance with the requirements of this standard according to technological regulations approved in the prescribed manner.

Recommendations for the composition and preparation of mastics are given in the recommended Appendix 2 to this standard.

2.2. Depending on the brand, the mastic must meet the requirements of Table. 2.

Table 2

| The name of indicators | Standard for mastic grades | ||||

| M B K-G-55 | MBK-G-65 | M B K-G-75 | MBK-G-85 | M B K-G-10 0 | |

| 1. Heat resistance for 5 hours, °C, not less | 55 | 65 | 75 | 85 | 100 |

| 2. Softening temperature using the “ring and ball” method, °C | 55- 60 | 68-72 | 78-82 | 88-92 | 1 05-1 10 |

| 3 Flexibility at temperature (18 ± 2) °С on a rod with a diameter, mm | 10 | 15 | 20 | 30 | 40 |

| 4. Filler content, % by mass: | |||||

| fibrous | 12-15 | 12-15 | 12-15 | 12-15 | 1 2-15 |

| dusty | 25-30 | 25-30 | 25-30 | 25-30 | 25-39 |

| 5 Water content | Footprints | ||||

2.3. In appearance, the mastic should be homogeneous without foreign inclusions and particles of filler, antiseptic or herbicide, not coated with bitumen.

A mastic cut with an area of 50 cm2 should not contain more than two unimpregnated particles of filler, antiseptic or herbicide larger than 0.4 mm in size.

2.4. The mastic must firmly glue the rolled materials. When testing glassine samples glued with mastic, tears in and splitting of the samples should occur along the glassine.

2.5. The mastic must be easy to apply: at a temperature of 160 - 180 °C, mastic weighing 10 g should flow freely over the surface of glassine measuring (50 x 100) mm in an even layer 2 mm thick.

2.6. When transporting mastic in a hot state, the filler may settle. In this case, the amount of filler (at different levels of the vehicle) may differ from that indicated in the table. 2, respectively, for a fibrous filler by no more than 3%, and for a dust filler - 10%.

2.7. Requirements for materials for preparing mast.

2.7.1. Bituminous binder

2.7.1.1. As a binder for the preparation of mastic, petroleum roofing bitumen should be used that meets the requirements of GOST 9548, and their alloys, as well as petroleum road bitumen in accordance with GOST 22245 and their alloys with roofing bitumen grades and BNK 90/30 (BNK 90 /40).

2.7.1.2. To reduce the sedimentation of fillers, surfactants (surfactants) should be introduced into the bitumen binder.

Anionic or cationic substances should be used as surfactants.

The list of products used as surfactants is given in Appendix 3 to this standard.

2.7.1.3. The bitumen binder used for the production of mastics in winter conditions should contain: coal oil for wood impregnation in accordance with GOST 2770, shale oil for wood impregnation in accordance with GOST 10835-78 or kukersol varnish according to the technical specifications approved in the established ok.

2.7.1.4. The temperature of softening and brittleness of bitumen binder for the manufacture of mastics of different brands must satisfy the requirements of Table. 3.

Table 3

| Mastic brand | Softening temperature of bitumen binder using the “ring and ball” method, °C | Brittleness temperature of bitumen binder, °C, not higher |

| MBK-G-55 | 45-50 | -18 |

| MBK-G-65 | 51-60 | -15 |

| M BK-G-75 | 61- 70 | -13 |

| MBK-G-85 | 71-80 | -12 |

| M BK-G-100 | 85-95 | -10 |

Note

. When introducing plasticizing additives into bitumen binder, its softening temperature can be 3-5 °C lower.

2.7.2. Filler

2.7.2.1. To prepare mastics, fibrous or dusty fillers must be used.

Chrysotile asbestos, grade 7 according to GOST 12871-67, should be used as a fibrous filler.

As a dust filler, finely ground talc or soapstone in accordance with GOST 21235-75, shale rocks, limestone, dolomite, tripolite or chalk should be used according to technical specifications approved in the prescribed manner.

2.7.2.2. To reduce the sedimentation of the filler during its grinding, a surfactant based on synthetic fatty acids specified in Appendix 3 to this standard can be introduced. In this case, surfactants are not introduced into the bitumen binder.

Note

. In the case when shale rocks are used as a filler, surfactants are not introduced.

2.7.2.3. The filler for making mastic must meet the requirements of Table. 4.

Table 4

| Name of indicator | Norm |

| 1. Density (specific gravity), kg/m3 (g/cm3), not more than | 2,7 |

| 2. Humidity% by weight, not more than: | |

| fiber filler | 5 |

| dust and ide filler | 3 |

| 3. Grain composition: | |

| fiber filler | Passes completely through a sieve with mesh no. 04 |

| dust filler | Passes completely through a sieve with mesh No. 02, and the remainder on the sieve with mesh No. 009 is no more than 10% |

2.7.3. Antiseptics and herbicides

2.7.3.1. Sodium fluoride in accordance with GOST 87-77 or sodium fluoride in accordance with GOST 2871-75 should be used as antiseptic additives.

Antiseptic agents are not added to mastics with plasticizing additives.

2.7.3.2. Simazine according to GOST 15123-78 or amine (sodium) salt of dichlorophenoxyacetic acid (2, 4D) should be used as herbicides according to technical conditions approved in the prescribed manner.

The amount of antiseptics and herbicides in the mastic must comply with the requirements of SNiP II-26-76.

3.1. Bituminous roofing hot mastic is a flammable material with a flash point of 240-300 °C. When manufacturing and using mastics, the requirements of Chapter SNiP III-A.11-70 must be observed.

3.2. When producing, draining, filling and sampling mastics, workwear and personal protective equipment should be used in accordance with the “Standard industry standards for the free issuance of workwear, safety footwear and safety equipment”, with the addition to them approved by the resolution of the USSR State Committee for Labor and Social Issues and the Presidium All-Union Central Council of Trade Unions July 6, 1978 No. 226/P9-4.

3.3. If small quantities of mastic catch fire, the fire should be extinguished with sand, felt felt, special powders, and a foam fire extinguisher; developed fires - with a foam stream or water from fire monitors.

1.1. The mastic must be accepted by the technical control of the manufacturer.

Reception and delivery of mastics is carried out in batches.

The batch size is set in the amount of replacement production of mastic prepared according to the same recipe, technology and from the same components.

4.2. To check the compliance of the mastic with the requirements of this standard, 3%, but not less than three packaging units, are selected from each batch, and the weight of each sample taken at three different levels must be at least 0.5 kg. When transported by special vehicles, a sample is taken before loading into the vehicle in the amount of 1.5 kg.

4.3. All selected samples are fused at a temperature of 120-130 °C, thoroughly mixed and divided into two equal parts. One of these parts is tested, the other is marked and stored in a clean, tightly closed container in a dry and cool room for control testing.

All tests are carried out on 3 samples.

4.4. Acceptance of mastic is carried out by carrying out acceptance control for the following indicators: appearance, heat resistance, softening point and flexibility.

4.5. The manufacturer is obliged to conduct periodic tests of the mastic according to the following indicators:

content of filler and water in the mastic - once a month;

determination of adhesive properties and workability - when changing the recipe, but at least once a month.

4.6. If unsatisfactory test results are obtained for at least one of the indicators, repeat tests for this indicator are carried out on a double amount of mastic selected from the same batch.

The results of repeated tests are final.

4.7. The consumer has the right to carry out a control check of the mastic in accordance with the requirements of this standard.

5.1. Checking the appearance (uniformity of the mastic, the presence of foreign inclusions and particles of filler, antiseptic or herbicide not covered with bitumen) is carried out visually.

5.2. Determination of heat resistance

5.2.1. Equipment and accessories

Laboratory drying cabinet with perforated shelves, ventilated, allowing automatic regulation of the set temperature.

Metal flat plate with dimensions (50x100x2) mm.

5. 2.2. Preparing for the test

To determine heat resistance, a uniform layer of 8-10 g of mastic, preheated to a temperature of 140-160 °C, is applied to a glassine sample measuring (50x100) mm. A piece of glassine of the same size is placed on top and pressed with a 2 kgf load for 2 hours. The load is applied through a flat metal plate measuring (50x100x2) mm.

The drying cabinet is heated, depending on the brand and mastic, to the temperature indicated in the table. 2.

5.2.3. Carrying out the test

After 2 hours of exposure, samples with mastic grades MB K-G-55 il and MBK-G-65 are placed in a heated drying cabinet on an inclined stand (20%). and with mastic brands MB K-G-75, MBK-G-85, MB K-G-100 - on an inclined stand (100% at an angle of 45 °).

The samples are kept in the cabinet for 5 hours at a given temperature, after which the samples are removed and inspected.

The mastic is considered to have passed the test if it does not leak or begin to slide.

5.3. Definition of flexibility

The method is based on bending a glassine sample with mastic applied to it along the semicircle of a rod of a certain diameter at a given temperature.

5.3.1. Equipment and accessories

Thermometer according to GOST 2823-73

The rod has a diameter of 10, 15, 20, 30, 40 mm.

Vessel for water.

5.3.2. Preparing for the test

On a sample of glassine measuring 50x100 mm, apply 8-10 g of mastic, preheated to 140 - 160 °C, in an even layer.

After this, the sample is kept for 2 hours at a temperature of 18 ± 2 °C in air. Then water is poured into the vessel, the temperature of which should be 18 ± 2 ° C.

The samples and the rod are placed in this vessel with water and kept in it for 15 minutes.

5.3.3. Carrying out the test

After keeping in water, the sample is slowly bent along the semicircle and the rod for 5 years with the front surface (mastic) upward. The time from the moment of removing the sample from the water and bending it along the semicircle and the rod should not exceed 15 s.

The mastic is considered to have passed the test if cracks do not form on the surface and sample.

5.4. Determination of the adhesive properties of mastic

The essence of the method is to determine the load required to break two glued samples of a certain length and width.

5.4.1. Equipment and accessories

Explosive machine brand and R T-250 M-2 or similar machines, having a working part of the scale from 0 to 100 kgf with a division value of no more than 0.2 kgf, with a permissible error of indication within the working scale ± l %.

Laboratory drying cabinet with perforation and shelves, ventilated, allowing automatic temperature control.

Metal plate.

5.4.2. Preparing samples for testing

Two samples of glassine measuring 50x140 mm, cut from a roll in the longitudinal direction, are glued together with mastic over an area of 50x60 mm. Mastic heated to 140-160 °C in an amount of 4-6 g is applied to the surface of both samples so that one end of each sample remains uncoated with mastic. The glued samples are pressed with a weight of 1 kg through a metal plate and kept for 2 hours at a temperature of (20 ± 2) °C. 3 samples are prepared for testing.

5.4.3. Carrying out the test

2 hours after gluing, the samples are placed in the clamps of the tensile testing machine without distortion.

The sample is tested at a constant speed of movement of the movable clamp of 50 mm/min until rupture, which should occur on the glassine.

5.5. Determination of filler content after heating.

The filler content is determined by the combustion method according to GOST 2678-76 with the following addition. A mastic sample is poured into a split cylinder with a diameter of 20 mm and a height of 150 mm, which is placed in a drying oven, heated to a temperature of 160 °C (when using a surfactant, up to 130 °C) and maintained at this temperature for 5 hours.

After cooling to room temperature, the mastic is removed from the cylinder and samples weighing at least 1 g each are taken (from the bottom and in the middle of the cylinder). The test results must comply with the requirements of clause 2.6.

5.6. Determination of the softening temperature of mastic - according to GOST 11506-73.

5.7. Determination of filler content - according to GOST 2678-76.

5.8. Determination of water content in mastic - according to GOST 2477-65.

6.1. Mastic can be packed in steel barrels with a removable bottom, in wooden barrels or drums, or in paper bags with an anti-adhesive layer.

To construction sites located near centralized production sites, mastic should be transported heated to 160-180 °C in special vehicles equipped with mixers. Travel time should not exceed 3 hours.

6.2. The packaging of the mastic must indicate indelible paint:

name or trademark of the manufacturer;

brand of mastic;

name of the filler;

batch number and

6.3. Each shipped batch of mastic must be accompanied by a document certifying the quality, which indicates:

name and trademark of the manufacturer;

the number of seats in the party and their mass;

brand of mastic;

on the names of fillers and their percentage content in the mastic;

name of the antiseptic or herbicide and their percentage in the mastic;

test results;

designation of this standard.

6.4. Packaged can be transported by any type of transport.

6.5. Mastic should be stored separately by brand indoors.

7.1. The manufacturer guarantees that the mastic meets the requirements of this standard subject to the conditions of transportation and storage.

The guaranteed shelf life of the mastic is one year from the date of manufacture. After the expiration of the guaranteed storage period, before use, the mastic must be checked for compliance with the requirements of this standard.

Recommended

RECOMMENDED AREA OF APPLICATION OF MASTIC

1. The scope of application of mastic, depending on the construction area and roof slope, is indicated in the table.

| Construction area | Mastic for the device | |||

| roofs with a slope, % | junction places | |||

| less than 2.5 | 2.5 - less than 10 | 10 — 25 | ||

| North of geographic latitude 50° for the European and 53° for the Asian part of the USSR | MBK-G-55 | MBK-G-65 | MBK-G-75 | MBK-G-85 |

| South of these areas | MBK-G-65 | MBK-G-75 | MBK-G-85 | MBK-G-100 |

2. Mastics of the MBK-G-55 and MBK-G-65 brands should be used for gluing antiseptic roofing felt, glass roofing felt and roofing felt materials, and mastics of the MBK-G-55A and MBK-G-65A brands - for gluing non-antiseptic roofing felt; mastics of the MBK-G-55G and MBK-G-65G brands - for installing a protective layer on roofs.

Recommended

RECOMMENDATIONS FOR THE COMPOSITION AND PREPARATION OF BITUMEN ROOFING HOT MASTICS

1. Hot roofing bitumen mastics should be prepared in factory conditions (for example, at asphalt concrete plants), at centralized installations of construction trusts in heated containers equipped with mixing devices. It is allowed to produce mastics under construction conditions.

2. The process of preparing bitumen binder consists of dehydrating and melting bitumen, fusing bitumen, and introducing surfactants and plasticizing additives into the bitumen or alloy.

3. Initially, low-melting bitumen is loaded into the container, which is dehydrated at a temperature of 105-110 ° C, after which bitumen grade BNK 90/30 (BNK 90/40) is loaded and with constant operation of the mixer, the temperature of the bitumen binder is brought to 160 - 180 ° C.

4. The amount of roofing bitumen grade BNK 90/30 (BNK 90/40) introduced into the molten low-melting bitumen depends on the softening temperature of the mixed bitumen and is determined by the formulas:

(1)

(2)

where B

T is

the content of more refractory bitumen in the alloy (grade BNK 90/30),%;

Bm -

content of low-melting bitumen in the alloy, %;

t—

softening temperature of bitumen binder for the preparation of mastics, assigned in accordance with table. 3 of this standard;

tT,

tm is

the softening temperature of refractory and low-melting bitumen, respectively.

5. To prevent bitumen from foaming when heated, you should add a defoamer of the SKTN-1 brand, at the rate of 0.01 g (2-3 drops) per 1 ton of bitumen.

6. Surfactant additives introduced to reduce the sedimentation of the filler when transporting mastics at temperatures not exceeding 130 ° C should be added directly to the bitumen binder or with the filler.

A surfactant is introduced into the bitumen binder in an amount of 1.5 - 2% by weight of the bitumen binder.

The surfactant is introduced into the filler during grinding in an amount of 0.15 - 0.2% by weight of the filler.

7. By agreement with the consumer, for work in winter conditions it is allowed to introduce plasticizing additives in an amount of 3 - 8% by weight of the bitumen binder. When introducing plasticizing additives, surfactants should not be added to the bitumen binder.

8. After sampling and determining the softening temperature of the bitumen binder, the filler is introduced in separate portions with constant stirring.

9. The amount of filler loaded in each portion should be 1/3 - 1/4 of the required estimated amount. If the foam rises intensively, the introduction of filler is stopped until the foam level drops, after which filling of the filler is resumed.

10. After loading the last portion of filler, cooking of the mastic is continued at a temperature of 160 - 180 ° C with constant stirring until a homogeneous mixture is obtained and the foam has completely settled.

11. Antiseptic additives in the amount of 4 - 5% or herbicides in the amount of: simazine 0.3 - 0.5%, amine (sodium) salt 2.4D 1 -1.5% by weight of the bitumen binder is introduced in separate portions in 2 - 3 reception with constant stirring before the final preparation of the mastic.

Information

LIST OF PRODUCTS USED AS SURFACTANTS

| Product name | Regulatory document |

| Anionic type of higher carboxylic acids: | |

| gossypol resin (cotton tar) | OST 18-114-73 |

| fat tar | OST 18-114-73 |

| synthetic fatty acids C17 - C20 | OST 38-7-25-73 |

| Cationic: | |

| type of higher aliphatic amines (BP-Z) | TU 382-01-170-74 |

| type of four substituted ammonium bases (alkyltrimethylammonium chloride) | TU 3840798-78 |

Appendix 3 (informative), list of products used as surfactants

Surfactant products are also important; there is a narrow list of elements suitable for this purpose. If desired, they can always be studied in the state standard; they help to obtain the desired result after applying the product.

Surfactant products are important, there is a narrow list of elements suitable for this purpose.

Thus, GOST strictly regulates the production of mastic products. And manufacturers who produce mastics according to these standards guarantee compliance and quality of their products. The consumer can be confident that the product has passed the required tests and will meet the stated characteristics.

Hot mastic TechnoNIKOL - material for professional use

Cold roofing bitumen mastic is a ready-to-use material, while hot bitumen mastic is melted before application, which requires special equipment. Heating temperature – up to 180 °C. The duration of heating is indicated by the manufacturer, since this not only liquefies the material, but also dehydrates it. In this case, they do not talk about melting the bitumen, but about “cooking” it.

The material is applied in a liquid state, which allows it to fill cracks and voids in the surface, causing the coating to become airtight.

Preparation of material for coating

In liquid form, cold bitumen mastic hardens as the solvent evaporates, and hot bitumen mastic hardens as it cools, so the latter hardens faster after application. At the same time, when the mastic hardens, it does not shrink, since it does not lose volume in the form of evaporating solvents.

The resulting coating has the following properties:

- resistance to external aggressive factors;

- light weight and thickness;

- elasticity;

- strength;

- resistance to corrosion, rotting;

- does not undergo oxidation and is not destroyed under the influence of ultraviolet radiation.

This coating does not have joining seams; it covers surfaces with a protective film, especially pipe outlets and interpanel seams that are difficult to seal.

Hot roofing bitumen mastic, according to GOST No. 2889-80, contains a minimum of additional components. The cost is much lower than cold-applied material and therefore it is used for large volumes of work.