Indicators reflecting the consumer properties of VDLKM, and test methods

Table B.1

| Indicator name | Test method |

| 1 Covering power | According to GOST 8784 |

| 2 Dynamic viscosity | According to ND or TD for a specific material |

| 3 Adhesion | According to GOST 15140 |

| 4 Hardness according to a pendulum device | According to GOST 5233 |

| 5 Elasticity when bending | According to GOST 6806 |

| 6 Impact strength | According to GOST 4765 |

| 7 Conditional light fastness | According to GOST 21903 |

| 8 Shine | According to GOST 896 |

| 9 Density | According to GOST 28513 |

| 10 Fire hazard: | |

| film smoke coefficient | According to GOST 12.1.044 |

| toxicity indicator of film combustion products | According to GOST 12.1.044 |

| 11 Sandability | According to ND or TD for a specific material |

| 12 Penetration | According to GOST 5346 |

| Notes 1 The mandatory nature of the indicator is determined by the area of application of the product. 2 Determination of indicator 10 is carried out only for materials intended for interior decoration of buildings. 3 Additional indicators not provided for in this appendix are indicated in the ND or TD for a specific brand of product depending on the area of application. | |

2 Normative references

This standard uses references to the following standards:

GOST 9.104-79 Unified system of protection against corrosion and aging. Paint and varnish coatings. Groups of operating conditions

GOST 9.401-91 Unified system of protection against corrosion and aging. Paint and varnish coatings. General requirements and methods of accelerated testing for resistance to climatic factors

GOST 9.403-80 Unified system of protection against corrosion and aging. Paint and varnish coatings. Test methods for resistance to static effects of liquids

GOST 9.407-84 Unified system of protection against corrosion and aging. Paint and varnish coatings. Methods for assessing appearance

GOST 12.1.005-88 System of occupational safety standards. General sanitary and hygienic requirements for the air in the working area

GOST 12.1.016-79 System of occupational safety standards. Work area air. Requirements for methods for measuring the concentration of harmful substances

GOST 12.1.044-89 (ISO 4589-84) System of occupational safety standards. Fire and explosion hazard of substances and materials. Nomenclature of indicators and methods for their determination

GOST 12.3.002-75 System of occupational safety standards. Production processes. General safety requirements

GOST 12.3.005-75 System of occupational safety standards. Painting works. General safety requirements

GOST 12.4.011-89 System of occupational safety standards. Protective equipment for workers. General requirements and classification

GOST 12.4.021-75 System of occupational safety standards. Ventilation systems. General requirements

GOST 896-69 Paint and varnish materials. Photoelectric gloss determination method

GOST 4765-73 Paint and varnish materials. Method for determining impact strength

GOST 5233-89 (ISO 1522-73) Paint and varnish materials. Method for determining hardness using a pendulum device

GOST 5346-78 Plastic lubricants. Methods for determining penetration using a cone penetrometer

GOST 6128-81 Metal cans for chemical products. Specifications

GOST 6388-91 (ISO 8627-87) Toothbrushes. General technical conditions

GOST 6589-74 Paint and varnish materials. Method for determining the degree of grinding using the “Wedge” device (grindometer)

GOST 6709-72 Distilled water. Specifications

GOST 6806-73 Paint and varnish materials. Method for determining film elasticity during bending

GOST 8420-74 Paint and varnish materials. Methods for determining conditional viscosity

GOST 8784-75 Paint and varnish materials. Methods for determining coverage

GOST 8832-76 (ISO 1514-84) Paint and varnish materials. Methods for obtaining paint coatings for testing

GOST 9147-80 Porcelain laboratory utensils and equipment. Specifications

GOST 9825-73 Paint and varnish materials. Terms, definitions and designations

GOST 9980.1-86 Paint and varnish materials. Acceptance rules

GOST 9980.2-86 (ISO 842-84, ISO 1512-74, ISO 1513-80) Paint and varnish materials. Sampling for testing

GOST 9980.3-86 Paint and varnish materials. Package

GOST 9980.4-2002 Paint and varnish materials. Marking

GOST 9980.5-86 Paint and varnish materials. Transportation and storage

GOST 14192-96 Marking of cargo

GOST 15140-78 Paint and varnish materials. Methods for determining adhesion

GOST 15150-69 Machines, instruments and other technical products. Versions for different climatic regions. Categories, operating, storage and transportation conditions regarding the impact of environmental climatic factors

GOST 17537-72 Paint and varnish materials. Methods for determining the mass fraction of volatile and non-volatile, solid and film-forming substances

GOST 19007-73 Paint and varnish materials. Methods for determining drying time and degree

GOST 21903-76 Paint and varnish materials. Methods for determining conditional light fastness

GOST 24104-2001 Laboratory scales. General technical requirements

GOST 25336-82 Laboratory glassware and equipment. Types, main parameters and sizes

GOST 28246-89 (ISO 4618-1-3-84) Paints and varnishes. Terms and Definitions

GOST 28513-90 Paint and varnish materials. Density determination method

GOST 29251-91 (ISO 385-1-84) Laboratory glassware. Burettes. Part 1. General requirements

GOST 29319-92 (ISO 3668-76) Paint and varnish materials. Visual color comparison method

GOST R 51121-97 Non-food products. Information for the consumer. General requirements

3 Definitions

This standard uses terms in accordance with GOST 28246, as well as the following terms with corresponding definitions:

3.1 primer:

A product that, when applied to a surface, forms a hard transparent or opaque film with protective or special technical properties, intended to increase adhesion to the painted surface and coating layers.

3.2 putty:

A product of paste or liquid consistency, used to eliminate surface defects before painting, to level walls and ceilings before applying wallpaper, and to seal seams.

3.3 water-dispersed paint and varnish material:

A paint and varnish product whose film-forming substance is an aqueous dispersion of synthetic polymers with the addition of various auxiliary substances (emulsifier, stabilizer, etc.).

4 Classification

4.1 VDLKM are classified by type: varnishes, paints, primers and putties.

4.2 Classification and designation of VDLKM by type of film-forming substance and purpose - in accordance with GOST 9825 (Appendix A).

4.3 Classification of pigmented VDLKM by color: achromatic (black, gray, white) and colored.

5 General technical requirements

5.1 VDLKM are manufactured in accordance with the requirements of this standard, normative document (ND) or technical document (TD) for a specific brand of product according to the recipe and technological regulations approved in the prescribed manner.

5.2 The ND or TD for a specific brand of VDLKM indicates the scope of its application and the conditions for the formation of coatings.

5.3 Characteristics

5.3.1 VDLKM comply with the requirements and standards specified in Table 1.

Table 1

| Indicator name | Meaning for | Test method | ||||

| varnish | paints | primers | putties | |||

| 1 Color | Not standardized | Must be within the permissible deviations established by the Card Index color samples (standards) or approved control color samples | Not standardized | According to GOST 29319 | ||

| 2 Appearance of the coating | After drying, the VDLKM should form a homogeneous surface, without craters, pores and wrinkles | According to 9.3 | ||||

| 3 Mass fraction of non-volatile substances, %, not less | 30 | 50 (33) | 28 | 70 | According to GOST 17537, section 1 | |

| 4 pH | 6,5-9,5 | Not defined | According to 9.4 | |||

| 5 Drying time to degree 3 at temperature (20±2)°С, hours, no more | 1 | 12 | 24 | According to GOST 19007 | ||

| 6 Conditional viscosity at temperature (20.0±0.5)°С according to a VZ-246 viscometer with a nozzle diameter of 4 mm, s, not less | 30 | 14 | Not defined | According to GOST 8420 | ||

| 7 Degree of grinding, microns, no more | Not defined | 70 | Not defined | According to GOST 6589 | ||

| 8 Film washability, g/m, no more | Not defined | 3,5 | Not defined | By 9.5 | ||

| 9 Resistance to static action of water at a temperature of (20±2)°C, h, not less | 24 | 12 | 24 | According to GOST 9.403, method A, and 9.6 of this standard | ||

| Notes | ||||||

| 1 The value of indicator 3, indicated in brackets, is normalized for paints modified with solvent-based resins. | ||||||

| 2 For varnishes, paints and primers using modified alkyds, it is allowed to increase the value of indicator 5 to 24 hours. | ||||||

| 3 Indicators 8 and 9 are not determined in paints for dry rooms and ceilings. | ||||||

5.3.2 Additional indicators reflecting the consumer properties of VDLKM and test methods are given in Appendix B.

5.3.3 Depending on the purpose, VDLKM in terms of protective and decorative properties must comply with the requirements and standards specified in Table 2.

table 2

| VDLKM Group | Group designation | Indicator name | Meaning | Test method |

| Weatherproof | 1 | Service life, year, no less, under operating conditions: | According to GOST 9.401 and 9.7 of this standard | |

| U1, HL1, UHL1 | 2 | |||

| B1, O1, T1, OM1 | 1 | |||

| Limited weather resistance | 2 | Service life, year, no less, under operating conditions: | According to GOST 9.401 and 9.7 of this standard | |

| U2, U3, HL2, UHL2, HL3, UHL3 | 2 | |||

| B2, B3, O2, T2, T3, OM2, OM3 | 1 | |||

| Special | 5 | 1 Washability, g/m, no more | 3 | By 9.5 |

| 2 Frost resistance, cycles, not less | 5 | According to 9.8 | ||

| Note - The primary purpose of special VDLKM is the coloring of fruit and ornamental trees and shrubs. | ||||

5.4 Packaging of VDLKM - according to GOST 9980.3.

5.5 VDLKM marking - according to GOST 9980.4.

5.5.1 For VDLKM intended for retail trade, information for the consumer is in accordance with GOST R 51121.

5.5.2 Transport marking - according to GOST 14192.

6 Safety requirements

6.1 Production of VDLKM must comply with the requirements [] and [].

6.2 Initial materials for the manufacture of VDLKM are used only in the presence of sanitary and epidemiological conclusions.

6.3 Safety of work related to the production, testing and use of materials - in accordance with GOST 12.3.002 and GOST 12.3.005.

6.4 The toxicity of a specific brand of VDLKM is indicated in the ND or TD, which provides:

— information about the toxic components that make up the VDLKM, indicating their hazard class, physical state, maximum permissible concentration in the air of the working area;

— types and consequences of dangerous effects on the human body of toxic components;

— personal protective equipment in accordance with GOST 12.4.011.

6.5 Concentration of harmful substances in the air of the working area and approximate safe exposure levels (SAEL) VDLKM - according to [] and [].

6.6 Monitoring of the content of harmful substances in the air of the working area is carried out in accordance with GOST 12.1.005.

6.7 Determination of the content of harmful substances in the air of the working area is carried out in accordance with GOST 12.1.005 and GOST 12.1.016.

6.8 All work related to the manufacture and application of VDLKM in premises must be carried out with general supply and exhaust and local ventilation operating in accordance with GOST 12.4.021.

6.9 The ND and TD for a specific brand of VDLKM must indicate the primary fire extinguishing agents and fire extinguishing compositions used in production.

7 Environmental requirements

7.1 In order to protect the atmospheric air from pollution by emissions of harmful substances from enterprises, control over compliance with the standards for emissions of pollutants into the atmospheric air, established in accordance with the requirements in the field of atmospheric air protection, must be organized.

7.2 The concentration of harmful substances in emissions from enterprises producing VDLKM is determined according to measurement methods certified in the prescribed manner, or according to [].

7.3 In order to protect the environment from pollution by wastewater, industrial environmental control must be organized to monitor compliance with established standards for the maximum permissible discharge of pollutants into wastewater.

7.4 All liquid waste generated during filtering of VDLKM, washing of equipment and communications, in the form of contaminated wastewater, is returned to production, neutralized or collected in a special container and sent for disposal.

7.5 The placement, storage and neutralization of waste generated during cleaning of equipment and containers is carried out in the manner established by regulatory legal acts in the field of industrial and consumer waste management.

8 Acceptance rules

8.1 Acceptance rules - according to GOST 9980.1.

9 Test methods

9.1 Sampling - according to GOST 9980.2.

9.2 Preparation of samples for testing

Samples for testing are prepared in accordance with GOST 8832.

The material of the surface to be painted, method of application, coating thickness, number of layers and drying conditions are indicated in the ND or TD for a specific VDLKM.

9.3 Evaluation of the appearance of the coating

The appearance of the coating is determined visually in diffuse daylight or artificial daylight at a distance of about 0.3 m from the test sample. In case of disagreement, the appearance of the coating is assessed in diffuse daylight.

9.4 Determination of pH

9.4.1 Measuring instruments, reagents and materials

pH meter with a set of glass electrodes, measurement error no more than 0.1 pH.

Glass glass V-2-50 according to GOST 25336.

Distilled water according to GOST 6709.

9.4.2 Test performance

VDLKM is poured into a glass with a capacity of 50 cm, thoroughly washed with distilled water, and the pH value is measured.

9.4.3 Processing results

The result of pH measurement is taken as the arithmetic mean of the results of two parallel determinations, the absolute discrepancy between which should not exceed the permissible discrepancy equal to 0.1 pH.

The measurement result is rounded to the first decimal place.

The permissible total error of pH determination results is ±0.08 with a confidence level of .

9.5 Determination of washability

9.5.1 Measuring instruments, auxiliary devices, reagents and materials

A device for determining washability of the UDS-1 type, providing a carriage stroke length of (100±10) mm, a number of double strokes per minute of 30±5, and a load on the brush (100±5) g.

A three-row toothbrush with natural bristles, length (11±2) mm, in accordance with GOST 6388. By agreement with the interested parties, the use of other brushes is allowed, the quality and size not worse than the one specified.

Stopwatch with an error of no more than 0.2 s.

Burette with a capacity of 25 cm according to GOST 29251.

Evaporating cup 3 according to GOST 9147.

Water bath, sand bath or electric stove.

Electric laboratory drying cabinet, providing heating to a temperature of (105±2) °C.

Laboratory scales in accordance with GOST 24104 of medium accuracy class with the largest weighing limit of 200 g.

Desiccator, version 2 according to GOST 25336.

Distilled water according to GOST 6709.

9.5.2 Test performance

Before testing, the brush is kept in distilled water for 10 minutes, the evaporation cup is dried in an oven at a temperature of (105±2)°C to constant weight.

The painted plate is placed in the sample holder of the washability device, the brush is set in motion, and the stopwatch is started at the same time. Then, within 30 s, 25 cm of water is supplied to the top of the plate from a burette. The rinsing water is collected in an evaporation cup located under the plate. After 30 s, the brush is stopped and washed with small portions of water until the VDLCM particles are completely removed. All wash water is collected in the same cup and evaporated in a water bath or hotplate until the water is removed, then the cup is kept in a drying oven at a temperature of (105 ± 2) ° C until constant weight, cooled to room temperature and weighed.

9.5.3 Processing results

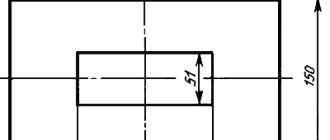

Washability of VDLKM, g/m, is calculated using the formula

, (1)

where is the mass of the cup with the remainder of the VDLKM, g;

— mass of the cup, g;

— area of the test sample, m.

The test result is taken as the arithmetic mean of the results of two parallel determinations, the absolute discrepancy between which should not exceed the permissible discrepancy of 0.3 g/m. The measurement result is rounded to the first decimal place. The permissible total error of the washability determination results is ±0.2 g/m at a confidence level of .

9.6 Determination of the resistance of the film to the static effects of water is carried out according to GOST 9.403, method A, on plates. The material and dimensions of the plates must be specified in the ND or TD for a specific brand of product.

After testing, the samples are kept before inspection at a temperature of (20±2) °C for 3 hours.

Lightening of the VDLKM film is allowed.

9.7 Determination of the expected service life of the coating is carried out according to GOST 9.401. A coating based on VDLKM is exposed to artificial climatic factors, after which the safety of the protective and decorative properties of the coating is assessed in accordance with GOST 9.407. Test methods and the number of cycles are selected depending on the operating conditions of coatings in accordance with GOST 9.104, types of atmosphere in accordance with GOST 15150.

9.8 Determination of frost resistance

9.8.1 Measuring instruments and auxiliary materials

Freezer chamber providing a temperature of minus (40±2)°C.

Metal can according to GOST 6128 or polyethylene.

Glass plate.

Glass rod.

9.8.2 Test performance

The test water-dispersion material is filled with a jar up to half the volume, closed with a lid, placed in a freezer and kept for 6 hours at a temperature of minus (40±2)°C, after which the jar with the test sample is removed and left at room temperature for 18 h. Place the jar back in the freezer for 6 hours. The freezing-thawing cycle is repeated five times.

Then the VDLCM is mixed and applied to a glass plate, evenly distributing it with a glass rod (test sample). Similarly, prepare a control sample from the test material that has not been frozen. The test sample is compared with a control sample in diffuse daylight or artificial daylight.

VDLKM is considered frost-resistant if, after five cycles, no lumps appear in a thin layer of the tested material. In case of disagreement in the assessment of frost resistance, comparison of the test and control samples is carried out in diffuse daylight.

10 Transportation and storage

10.1 Transportation and storage - in accordance with GOST 9980.5.

10.2 VDLKM are transported at temperatures above 0°C.

10.3 VDLKM is stored in tightly closed containers in warehouses at temperatures above 5°C.

11 Directions for use

11.1 Application is indicated in the ND or TD for a specific material. In this case, VDLKM is used for outdoor work at an ambient temperature of at least plus 8°C.

12 Manufacturer's warranty

12.1 The manufacturer guarantees compliance of the VDLKM with the requirements of this standard, ND or TD for a specific product, subject to the conditions of transportation and storage.

12.2 The guaranteed shelf life must be indicated in the ND or TD for a specific VDLKM.

APPENDIX A (required)

Designation of VDLKM provided for by this standard according to the type of film-forming substance in accordance with GOST 9825

Table A.1

| Name of VDLKM according to the type of film-forming substance | Designation VDLKM | Name of the main film-forming substances |

| Polyvinyl acetate | AT TWO | Polyvinyl acetate |

| Polyacrylic | VD-AK | Copolymers (and polymers) of acrylic and methacrylic acids, their esters and other derivatives with styrene, vinyl acetate and other vinyl monomers, as well as those cured with isocyanates |

| Rubber | VD-KCH | Divinylstyrene, divinylnitrile and other latexes, chlorinated rubber, cyclo rubber |

| Vinyl acetate copolymers | VD-VS | Copolymers of vinyl acetate with other vinyl compounds |

| Pentaphthalic | VD-PF | Modified alkyd resins |

| Note - When designating a material, it is allowed to additionally assign a proprietary name to the material. | ||

Purpose

The surface treated with the Nortex-Grunt primer has the following advantages:

- becomes stronger due to filling the smallest pores;

- there is a similarity with the material of the subsequent finishing, which improves the adhesion of the layers;

- prevents the appearance of cracks in the finish coating;

- not susceptible to microorganisms;

- saving subsequent material by blocking its penetration.

Acrylic primer "Nortex-Grunt" has universal strengthening and penetrating properties. Suitable for processing at all stages of finishing, from rough walls to finishing coating. These are the following types of base: wood, brick, stone, gypsum, concrete, wallpaper for painting, plaster, putty.

The use of acrylic primer increases the service life of the finishing coating and saves finishing materials such as glue, paint, and decorative plaster.

Excluding the priming step will compromise the integrity of the layers, and the decorative coating may peel and fall off. The lack of deep antiseptic treatment threatens the appearance of mold, darkening and other changes in the surface.

Working with Nortex-Grunt

Apply primer using a spray gun or brush. The recommended minimum ambient temperature is plus 5 degrees. If the surface to be treated is very uneven, full of cracks and seams, putty work must first be done, after which two layers of primer are applied. To dry the next layer, an interval of 30 minutes is maintained.

Further processing of the primed surface is carried out no earlier than an hour later, so that the primer dries well. And in cases of low temperature (less than 15 degrees) and high humidity (more than 80 percent), the drying period should be increased to a day. Doors and windows are covered with film to prevent the primer from getting on them and leaving stains.

The primer is tinted using color pastes used with water-dispersion paints. Primer consumption when applying one layer:

- for wood flooring – 90 g/m²;

- for concrete – 120 g/m²;

- for stone or brick – 120 g/m²;

- for plasterboard – 60 g/m².

Store “Nortex-Grunt” in a well-closed container, at a temperature of at least five degrees Celsius and away from heating appliances. Transport the primer in tightly closed containers. The shelf life of the soil is one year.

Why do you need a primer?

A primer is a specialized liquid composition applied to structures before subsequent finishing. The purpose of the primer mixture is to improve adhesion to the final finishing material (varnish, paint, plaster) and reduce the risk of mold and mildew.

The surface must be primed before applying any material: paint, plaster or tiles. This is an important process, if you skip it, you will be disappointed with the result of your work in the near future.

The most popular types of primers are universal. These are specialized mixtures that penetrate deeply into the base and make it stronger. And on the treated surface a polymer film is created that protects against moisture penetration and prevents the formation of fungi and mold.

Externally, primers resemble milk; they have a specific but mild odor. If stored inappropriately, such mixtures quickly lose their beneficial properties, which produces a more pungent and unpleasant odor. Proper storage is in a cool, dark place, in a well-closed container.

Specifications

What is the advantage of “Nortex-Grunt”? The technical characteristics comply with GOST and consumer requirements, the price of the solution is very affordable, and the quality of the coating is high.

Acrylic primer "Nortex-Grunt" has the following properties:

- The color is white, it can be tinted in any shade to match the color of the finishing coating, which makes possible damage invisible.

- When dry, the surface is colorless (without adding color).

- The density of the solution is 1 g per cubic cm, which facilitates dilution while maintaining properties.

- The alkaline balance of the composition is 7-9, which is close to neutral and safe for the skin.

- Viscosity is 40-42 sec, which is convenient for application.

- Consumption for wooden base or concrete 90 g per sq.m.

- Consumption for plaster or brick 120 g per sq.m.

- Consumption per hl 60 g per sq.m.

- The minimum temperature for application and storage is not lower than +5°C.

- Drying time 30 minutes.

- Can be applied with a spray gun.

- Shelf life is two years, including after opening, but in a tightly closed container.

The coating turns out colorless without the use of tint, and any desired shade during tinting. The choice of color depends on the finish coat. The manufacturer recommends computer tinting using the Tikkurila color palette.

Tinting the acrylic primer is recommended when covering with paint or decorative plaster so that the base does not stand out when chipping occurs. The “Nortex-Grunt” primer is thick, diluting it with a high-quality colorant will not affect its properties. Dilution is possible up to a 1:1 ratio.

The decorative properties of the acrylic primer "Nortex-Grunt" meet the high requirements for substrates for painting or thin wallpaper - the surface is smooth and fills all pores and cracks. The base is convenient for spreading paint and trimming wallpaper patterns.

Characteristics of the “Nortex” primer

Acrylic primer "Nortex-primer" is used before coating with water-dispersion varnishes and paints. Since the primer is made on a similar base, it forms a colorless coating on the surface and protects the coated material from atmospheric influences.

The acrylic primer lays flat on the surface without forming lumps, craters or folds. For subsequent painting, it is recommended to tint the primer mixture. recommends mixing paints.

Advantages of the “Nortex-primer” primer:

- water-dispersion base, which provides good compatibility with paints and varnishes on a similar basis;

- good adhesion (adhesion) of finishing materials to any treated surface;

- excellent protection against fungus, especially in humid environments;

- strengthening the base of the processed material by filling pores and cracks with a polymer suspension;

- increasing the service life of the paint layer due to strong adhesion to it;

- reducing the consumption of paints and varnishes and preventing their cracking.

Compound

"Nortex-Grunt", like all acrylic water-dispersion primers, is made on the basis of water, acrylic copolymers and a wetting agent. Special biocide additives increase the service life of the base and protect it from the harmful effects of the environment, while not affecting vapor permeability.

Compliance of the composition of “Nortex-Grunt” with sanitary, epidemiological and hygienic requirements is confirmed by a certificate of state registration and a quality certificate. Tests have shown its safety; the use of Northex acrylic primer is permitted in children's institutions and public places.

Additional Information

The "Nortex" primer is used to treat fragile and hygroscopic structures, this provides savings and uniform distribution of subsequent coatings applied to the surface. If you need to prime a smooth surface, then “Nortex” can be diluted with water approximately 1:1.

Take some precautions when working. If a certain amount of primer accidentally gets inside, the stomach is washed with water, then with a 2% solution of baking soda with activated carbon. Contact with skin is not recommended, otherwise wash with soap and water. Remove spilled primer with an adsorbent.