The question of plastering gypsum boards

Good day to all.

I looked through a bunch of sources, but didn’t find anything intelligible, that’s why I’m here. Situation: I was doing soundproofing in a room, one of the elements of which is plasterboard. I used this gypsum board to cover the walls and ceiling. The walls turned out to be smooth, but when installing the ceiling, an error crept in and the middle turned out to be 1 cm lower than the edges (the first time I did this). I decided to correct the mistake with plaster. Attention, question: will the rotband adhere normally to the ceiling if ceresite tst17 is used as a primer, given that the layer of plaster does not exceed one centimeter? And is it possible to apply rotband to drywall at all? Doubts began after reading the instructions for the rotband - among the surfaces on which it can be applied there is not a word about gypsum board. On the Internet they recommend using concrete contact in such cases, but I have a small problem - I have already primed everything with ceresite. And on the manufacturer’s website (Knauf) it is written about concrete contact: “Designed for pre-treatment for gypsum plaster of dense, smooth, weakly and non-moisture-absorbing bases, for example, concrete, cement plasters.” But gypsum plasterboard absorbs moisture well, not cement and a smooth material, why not use a regular acrylic primer? But, again, somewhere it was not recommended. Overall, I'm confused. Help me please. Go over the ceiling - it will be faster to remove a couple of sheets and straighten the guide than to plaster. Moreover, it is impossible to plaster gypsum boards. The basic rule is to go from more durable to less durable. Although many people do it, it’s impossible, but if you really want to... More than once I’ve seen that gypsum boards are also plastered, but never the ceiling.

I would have gone over it long ago and not suffered, but:

- two layers of drywall

- the cavity is filled with glass wool

- no assistants

- walls are attached to it

- everything is puttied i.e. in order to fix what it hangs on, you have to break everything and start over. I don’t really want to put plaster on the ceiling, but I don’t have the time and money to redo the whole room, so I’m looking for other options. Before that, I worked with Volma in a layer, but it failed and I hate to deal with it in the future, maybe this is not the most insidious surprise yet. Rotband is somewhat different from Volma layer in properties, so I think it will be suitable.

Hypo-cardboard can be plastered.

Drywall can be easily plastered with gypsum plasters. The main thing is that the drywall is not puttied. Here is a photo showing that the layer of plaster is 2 cm. [

C2h5-OH wrote: change the city in your profile, otherwise you will be banned.

OK. You can plaster - it's getting closer. But the topic is not disclosed. Will plaster fall on my head (Volma doesn’t fall, I’ve never used a rotband) if I have a deep-penetrating acrylate primer between it and the drywall, ceresit tst17

no, it won’t fall, but I would use betocontact.

Ind1g0 wrote: Will plaster fall on my head (Volma doesn’t fall, I’ve never used a rotband) if I have a deep-penetrating acrylate primer ceresit tst17 between it and the drywall

It won't fall off, I always use a deep penetration primer.

If you are very worried, then use a fiberglass mesh with a cell of 5x5 mm for additional reinforcement.

To begin with, prime the entire surface of the gypsum board with tifeng primer, stick punched tape on the joints, then putty with a 5 x 5 mm mesh. Uniflot, or Pufas. Then equalize either by beacons or by the Pufas rule. Plaster to plaster is a homogeneous material, everything will be ok. Checked Then finish and repair interlining. Painting

Labor without art is barbarism!

I'm afraid we can't find a pofas here. We don’t have Rotband in every store. I filled all the joints with uniflot putty, without mesh, as it allows. So far, not a single crack (it's been a year already). I will use the rule for lighthouses, the lighthouses have already been frozen. What do you mean by serpyanka mesh? Okay, let me put the question this way: is rotband very different from Volma layer in properties?

Rotband is very different from Volma layer in properties?

What didn’t you like about Volma? Volma is more “long-lasting”, i.e. easier for an unprepared person. In terms of strength it seemed weaker than Rotband, although according to the documentation almost everything is the same. Rotband is like the “ancestor” of gypsum plasters. The main thing is to make sure that it is not counterfeit or expired.

The following mess happened with Volma: in the summer of 2013, I took 4 bags of Volma layers and two ten-liter canisters of soil in castoram. The soil already smelled of rotten meat, but I managed to buy one canister of lime almost immediately after purchase. After 4 months of standing in the room, it completely went rotten, the lid swelled and smelled strongly, I had to throw it away. (and it costs almost a coat for the cylinder) Although the production date is indicated as 05/03/13, i.e. She could stand for another six months. I took ceresit tst17 instead of Volma, it costs the same, but there is more trust. Of the four bags of Layer, I only managed to use half a bag; the ones I smeared along with the first canister of soil were smeared normally. Half a year later (i.e., the other day) I started to smear it again - the volma from the open bag dries at the speed of ordinary plaster, I didn’t even have time to mix it before it set, the mixer almost bricked it up. I thought it was because the bag was standing open, and I opened another bag - the same nonsense. However, as in the third and fourth. This is where I became annoyed, read fifteen hundred pieces of wood for the trash and sabotaged work. But the plaster was released on 07/01/13, lay in a dry and heated room (in my room), and the shelf life is stated to be 12 months. I wrote to them on their website - no answer. He waved his hand at the Volma, because it costs a little less than the same Knauf, and that’s what it can afford. I decided to give fifty dollars more, at least the Knauf won’t let you down. By the way, it honestly states that it can only be stored for half a year.

Plastering a plasterboard ceiling with Rotband

Anyone who has ever dealt with drywall knows that this material is capricious. Particular difficulties arise when it is necessary to cover the surface with plaster. Due to the fact that it is a fairly fragile material, drywall can become damaged and change shape under the influence of the heavy weight of the applied layer of finish. Using a material such as drywall, everyone who makes repairs with their own hands asks whether it is possible to plaster drywall with a rotband and how to plaster it with a rotband, avoiding damage. There is only one answer - technology.

Finishing walls and ceilings with plasterboard is very popular due to its ease of installation and low price. However, you should be careful when plastering drywall.

Plasterboard sheets are the most popular finishing material, affordable for most consumers, and also allowing one to achieve excellent results in finishing premises in a short period of time.

Drywall allows you to quickly and perfectly level the walls and ceiling.

After finishing with plasterboard, there is only one problem left - visible joints between the sheets and recesses from the heads of the screws. These irregularities can be eliminated by plastering the plasterboard covering.

Finishing with decorative plaster

This is probably the only case when we can talk about gypsum board plaster in the literal sense of the word. This is a finishing material, like wallpaper or ceramic tiles. Now we will look at how to properly plaster drywall and learn how to apply decorative plaster.

Preparation

As with any type of finishing, the plasterboard surface is prepared. To do this you need:

- Prime the joints (seams) between the sheets.

- Fill them with putty.

- Apply bonding tape.

- Apply another layer of putty.

- Cover the installation areas of the self-tapping screws with putty solution.

- After drying, lightly walk over the putty areas with sandpaper.

- Apply primer to the entire surface of the wall. The main purpose of this layer in this case is to protect drywall from moisture, which is present in decorative plaster.

Main process

First of all, it is necessary to answer the question, at what temperature can you plaster walls? Of course, we mean decorative mortar. Let's put it this way - the temperature should be positive, not lower than +5C. The highest limit is determined by the manufacturer. Basically, for almost everyone it is +35C.

Now as for the material itself. Manufacturers offer two types depending on the condition of the material:

- A dry mixture that will have to be diluted with water. The proportions are indicated on the packaging.

- Ready product. Let us immediately make a reservation that this material is almost twice as expensive as dry material.

As for application. There are two options here. The first is manually, that is, plastering drywall with your own hands. The second is with a spray bottle.

Option #1: manual application

You can use different tools for this. Most often they use a grater or spatula. In fact, the whole process is reminiscent of applying putty or plaster to a wall. That is, the mixture is lifted out of the container with a narrow spatula, applied to a wide spatula or on a grater and distributed across the width of the working edge.

After which, with chaotic hand movements, decorative plaster is applied to the surface of the wall. It is important to observe the thickness of the applied layer. Each species has its own. For example, there are decorative plasters that contain mineral inclusions. These are stones of different types. So the thickness of the layer should exceed 1.5 times the size of the grains.

If gypsum plaster is used, then its layer can vary within 1-3 mm. By the way, many experts recommend using gypsum solutions for plastering plasterboard walls.

Next, until the mortar on the wall has dried, you can do whatever you want with it. Use your imagination or use the experience of the masters. For example, use a special roller with patterns on it or a regular roller with high pile. This causes smudges of material to form on the wall. They can be left as is or smoothed a little with a spatula.

If pure white decorative plaster is used, it can be painted.

Option number 2: using a spray bottle

This is a more complex process. To do this, first the plasterboard surface is treated with adhesive mastic. While it is not dry, apply the plaster solution from a spray bottle. In this case, a dry mixture is used, not mixed with water.

To carry out this option, a lot of experience is needed. Therefore, we do not advise beginners to do it. Yes, and experienced masters ignore this method. It will be easier to open a ready-made jar of the mixture and apply it immediately.

And one more very important piece of advice. All decorative mixtures have a certain drying time. For many of them it is half an hour. Therefore, you need to work with this material quickly, but carefully.

Probably, this is how you can answer the question of whether it is possible, and if it is possible, then how to plaster drywall. Most likely, some of our readers will have doubts or questions. Some will have a negative attitude towards this process, others will raise two pros, based on their experience. Therefore, we propose to discuss the topic raised.

Drywall (photo) is gaining popularity. This material is simply irreplaceable when you need to level the surface. Easy to install, it is suitable for all types of decoration. The surface of such sheets can be painted or covered with wallpaper. You can install a finishing film or facing tiles on the GC, or you can decorate its surface with a decorative mixture

After you have covered the surface of the walls with plasterboard sheets, it is time to think about finishing.

Further work on finishing the walls will depend on what you plan to see in the end. In the case when wallpapering is chosen, you will need a simple putty that will seal all the joints and remove unevenness. If you plan to paint the walls, then it is easier and more interesting to decide to finish the surface with a decorative mixture.

Whatever finishing material is chosen for finishing drywall, there are certain requirements for rough finishing of walls with drywall material.

Recommendations for using drywall

A general recommendation for working with any drywall is that before starting work, drywall sheets should not be placed on edge, as this can lead to their deformation. You need to stack them on top of each other.

If it is necessary to plaster drywall, it must be of a moisture-resistant grade to avoid the penetration of moisture from the plaster mixture.

In most cases, it is impossible to perfectly level the walls or ceiling only by installing plasterboard sheets - you will also need to putty the cracks and dents. Therefore, it is better to use moisture-resistant drywall, since plastering is a wet process. If during operation it absorbs a lot of moisture, then deformation of the material may occur during the drying process. This is especially important when leveling ceilings, since it is on the ceiling that the highest bending load exists for the sheets.

Common questions about plaster

- What materials are best to use? For drywall, gypsum-based plaster is most often used. It is sold in bags of thirty kilograms. The service life of a solution from a dry mixture before setting is half an hour.

- Is it possible to glue drywall to plaster? This is very dangerous; plaster is a very unreliable material for such purposes. It is better to screw drywall sheets using self-tapping screws, using a metal guide profile for drywall.

- Is it possible to use plaster to level walls instead of drywall? Yes, you can. But this work is very labor-intensive. Drywall is installed much easier and faster.

We plaster the walls and ceiling from plasterboard

As we have already established, only drywall that has moisture-resistant properties can be plastered correctly. Almost exactly this material is used for ceilings in residential premises, because moisture accumulates at the top of the room from human activity. When purchasing materials for repairs, you must choose moisture-resistant sheets that have special markings.

It is important to use special primers that have deep penetration properties. To problem areas (potholes and dents), apply the plaster in a thin layer several times, not forgetting to let the previous layer dry completely.

Decorative plaster has a very thin layer and dries quickly, so there should be no problems applying it to drywall.

It is recommended to use a variety of decorative plasters for finishing drywall, while adhering to the application recommendations given in the manufacturer's instructions. A ceiling with this finish will look more interesting.

It is allowed to repair small dents and potholes that formed on the drywall as a result of improper storage, errors during the installation process, or violation of transportation rules. In this case, the surface must first be primed, then a layer of putty must be applied and, after a little time, a thin layer of plaster. However, you need to remember that the putty layer should not be more than 3 mm. If the depth of the pothole is much greater, then only plaster should be applied to the ceiling.

Gypsum plaster Rotband (Knauf)

This is a dry universal plaster mixture with high adhesive properties based on gypsum with the addition of light aggregate and chemical polymers.

Rotband plaster is ideal for plastering walls and ceilings in rooms with normal humidity levels, as well as in kitchens and bathrooms.

More and more people, when making renovations, give their preference to gypsum plaster. With its help, you can perfectly level the walls and hide any defects and cracks. Having good adhesion to any surface, gypsum plaster is ideal for finishing ceilings. In addition, such plaster is absolutely environmentally friendly and difficult to ignite.

This type of plaster helps control the level of humidity in the room. At high humidity, it absorbs excess, but as soon as the air in the room becomes very dry, moisture leaves the walls. Gypsum not only helps maintain humidity levels, but also retains heat in the room, as it has low thermal conductivity.

Features of using gypsum plaster for facade work

Fokina combined flat cutter and how to use it. Flat cutters types and descriptions Fokina and others

Gypsum has a high coefficient of water absorption, so compositions based on it will inevitably be hygroscopic. Thanks to polymer additives and mineral plasticizers, it was possible to increase the level of moisture resistance and frost resistance of plaster mixtures. However, this is not enough for a complete finishing of facades using gypsum compounds. To use these materials, additional protection of the walls from moisture is required.

Gypsum plaster can be used for exterior work only as an intermediate layer, provided that the facing layer has good vapor permeability. For this reason, despite all the advantages of gypsum compositions, they are rarely used for finishing facades.

Bolars - facade plaster

Mixtures for external use, in addition to the main binder, must include additives such as gypsum polymer or GPCV (gypsum-cement-pozzolanic binder). In this case, the gypsum plaster will acquire properties that ensure proper resistance to adverse environmental influences. But all manufacturers of gypsum-based compositions warn that their products are intended only for interior decoration. This is another reason for uncertainty about the suitability of gypsum plaster for facade work. However, for regions with a dry climate, facade mixtures can be used without fear.

Founds gypswell

A few more important advantages of the Rotband mixture

- The consumption of this mixture is 2-3 times lower than the consumption of conventional cement-sand plaster.

- Rotband can be used both for simultaneous plastering and puttying of plasterboard surfaces, and for the manufacture of decorative elements.

This coating is very smooth and does not require additional processing. This plaster dries very quickly, after a couple of days you can start wallpapering or painting the walls. A relief method of applying gypsum plaster is also used, which allows you to make the design of your room unique.

But it is worth considering some nuances when working with this material. Gypsum coating is not as durable as cement; under strong mechanical stress, dents may form. Despite its moisture-absorbing properties, it should not be used in rooms with very high humidity. It may get wet and fall off. This plaster also strongly corrodes metal objects: fasteners, nails and screws located under the plaster, they rust very quickly, and yellow spots may appear on the wall.

Functions performed by plaster

Before gluing wallpaper on plasterboard walls, it is necessary to prime the surface, then use a spatula to putty all the cracks and irregularities.

- Decorative. Plaster allows you to create a variety of decorative effects. The plastered layer can be given different textures and structures and painted with paints of different shades.

- Protective and structural consists of protecting walls from excessive moisture, fire, and retaining heat in the room using plaster.

- The sanitary function is that with the help of plaster, a perfectly smooth, even surface is obtained, which can subsequently be covered with various wallpapers, painted in any colors, or tiled.

Using a thick layer of plaster is not recommended to hide frame installation errors that led to the formation of obvious uneven walls. For some time, this will hide the defect, but over time, the sheets of drywall may not withstand the weight of the applied plaster. They will become deformed, cracks will appear, and the plaster layer will peel off. Therefore, if large distortions have been identified, it is recommended to correct installation defects as quickly as possible and replace sheets with defects with high-quality material.

Alignment of walls by Rotband using beacons

Until recently, leveling was carried out only with cement or lime-cement plaster mortars. Now there is an alternative in the form of high-tech gypsum mixtures. One option is to level the walls with Rotband , a product from Knauf.

This plaster compares favorably with traditional compositions because it has: – good adhesion to most substrates; – plasticity; – no shrinkage; – resistance to cracking and delamination; – relatively low weight of the plaster layer; – relatively fast drying. Plastering work should begin with preparing the base. We clean it of weakly adherent layers, all kinds of contaminants, and remnants of old coatings. Particular attention must be paid to protruding metal elements (protruding reinforcement, lintels over door and window openings from the corner, embedded parts, nail heads and screws...), it is recommended to clean them and paint them with a special primer , otherwise rust may appear on the front surface. Walls made of smooth concrete should be treated with a primer containing quartz sand - Betonkontakt or ST16. Porous substrates are carefully primed with deep-penetrating compounds, for example, CT17Ceresit.

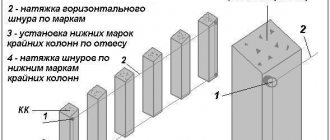

Now you can install beacons; for Rotband you can use guides with the smallest edge height - 6 mm. Initially, using a plumb line or a long slatted level, it is necessary to diagnose the rough plane - hang the wall in different places to find its most protruding section. Next, we mark the installation locations of the beacons - usually 200-300 mm from the corners of the room and 1.3-1.8 meters between them (depending on the length of the working rule). We make vertical ridges on the wall from the plaster composition, about 40-50 mm wide, and press the guide profile into it. Using a long level, we rub it against the wall, constantly monitoring the verticality.

Having installed the outer beacons, we pull control cords along their working edges, relative to which we fix the intermediate guides. Sometimes internal beacons are placed according to the rule.

We prepare the solution in a plastic container, strictly following the manufacturer’s recommendations. Pour the mixture into the required amount of water and stir with a powerful drill or a construction mixer with a frame or auger attachment.

After 5-7 minutes, the plaster is mixed again. We have 25-30 minutes to apply the finished mixture to the wall.

Using a plaster ladle, trowel, wide spatula or metal trowel with some excess, apply the solution to a small section of the wall (50-100 mm) between two beacons.

We start work from the floor. We press the trapezoidal aluminum rule tightly against the guides (beacons) and, moving from bottom to top, level the plaster mark, removing excess mixture, which we return to the bucket for further use. We repeat this set of operations until we reach the ceiling.

Several passes should be made, filling gaps in the plaster layer and large sinks with the mixture as necessary. We process the remaining fields between the beacons in the same way.

If the thickness of the plaster exceeds 50 mm, then the work is carried out in two stages, and notches must be made on the surface of the first layer.

As soon as we have covered the entire wall and the mortar has set, we should remove the beacons and seal the resulting grooves flush with the plane (by analogy with the technology of pouring screed ). In a wall intended for tiling, the guides can be left.

Surfaces that will be covered with wallpaper can be almost completely prepared by “glossing”, bypassing the puttying stage. To do this, no earlier than 2-3 hours after the start of work, the plaster is generously moistened with water and rubbed in a circular motion with a sponge grater. Please note the opportunity to save on the entire stage of applying the finishing putty! At the same time, the cleanliness of the surface formed with the help of Rotband, with a certain skill, turns out to be of very high quality, suitable for wallpapering.

Direct glossing is carried out with a high-quality spatula or metal trowel.

Note that most practicing craftsmen still prefer to apply one or two layers of putty, especially for walls that are being prepared for painting.

After 7-10 days, the plaster will dry and leveling the walls with Rotband can be considered complete. For subsequent finishing it is recommended to prime it. Now you can paint or wallpaper.

Stages of applying plaster to drywall

- Apply the prepared plaster for drywall with a spatula, completely filling the recess between the sheets of drywall.

- Apply serpyanka (tape for sealing seams) to the still wet plaster and press it with a spatula. This tape will further protect the walls and ceiling from the formation of cracks. You need to apply 1 more layer of plaster on top of the tape and level it using a wide spatula.

- To obtain a perfect finish leveling of the wall surface, it is necessary to apply a fine-grained putty (thin layer) to the drywall.

- After all layers are completely dry, use a grater with a sanding mesh inserted into it to remove any unevenness in the dried putty.

- After completing the puttying process, the drywall is ready for final finishing - painting, wallpapering, etc.

Why seal seams?

The joints of drywall sheets are a problem area. Difficulties may arise during installation:

- The ends may crumble and break due to mechanical stress.

- The edges of the sheets at the junction are subject to deformation (bend).

- When temperature changes, it changes its width, which leads to the appearance of cracks in the finish and swelling of the edges of the sheet.

- The unsealed gap allows moisture to accumulate, causing staining and peeling of the finish, as well as the formation of mold and mildew.

- Inaccuracies in the joint make the surface of walls and ceilings uneven.

Thus, the lack of proper sealing of the gaps between the sheets of drywall leads to damage to the finishing coating, gradual destruction of the material itself, and deterioration of its appearance. It is important to properly seal joints when preparing the surface for painting.

Sealing drywall joints includes several requirements:

- Correct installation of drywall. The precise location of the profiles and the rigidity of the frame play a primary role. The joint must be in the middle of the U-shaped profile area (i.e., the edges must rest on a rigid platform), and the sheathing must have sufficient stability. Otherwise, the edges of the sheet will be deformed, and the seam will diverge due to vibrations of the coating.

- Reliability of drywall fastening. The seam will diverge due to insufficiently strong fastening of the sheets to the frame profiles.

- Alignment accuracy. Any steps at the joint worsen the condition and quality of the seam.

- Width. The gap at the joint should not exceed 7-10 mm. A wide seam is more difficult to seal.

- Presence of chamfer. It is necessary to increase the area in the joining zone and improve adhesion. Standard sheets with high-quality factory bevel. Do-it-yourself finishing is necessary after cutting drywall.

These requirements oblige the seal to be carried out reliably and efficiently. Without it, it is impossible to ensure the attractive appearance and durability of a plasterboard structure.

Tool for plastering work

To work with plaster you need:

- bucket;

- drill mixer;

- trowel;

- plaster falcon;

- grout;

- rule;

- ironer;

- spatulas.

Plastering the ceiling

To understand what you are doing and not get confused in concepts, it is worth knowing that plastering and putty are two different things, performed using different technologies and for different purposes.

Preparing solutions should not cause any difficulties, since any package with construction mixtures always contains instructions written in accessible and understandable language. Application to the ceiling is also not difficult: the finished mixture is applied using a spatula and leveled with a metal tool.

There are several plastering methods, which depend on the quality of the surface. It happens that the ceiling does not require complete plastering, but partial, when after priming the mixture does not cover the entire area, but only a specific unevenness. This method is suitable for relatively flat ceilings that have only a small number of flaws (cracks, for example, or gaps between sheets of drywall, as in our case).

In my living room I made a two-level ceiling from plasterboard. True, I decided not to skimp on the strength of the ceiling. Therefore, I placed the CD profiles of the frame of the first level at 40 centimeters without jumpers, but the U-shaped suspensions at 30 centimeters from each other on two dowel nails, the second level I attached it partly to the first level, and partly to the main ceiling in the same way (well, the design is complicated and that’s not the point). The ceiling was sewn up with ordinary plasterboard from the Plato company, 12.5 millimeters thick, using a bunch of screws. But then I glued fiberglass mesh to the entire ceiling for plastering work. The edges of the plasterboard sheets were first cut in such a way that the plasterboard sheets would not suddenly touch each other, and then bevel the edges at an angle of 45 degrees and these places were simply puttied with “Rotband” and the screws were covered. And gluing the mesh takes a long time, but it’s simple, you prime the drywall, apply a little “Rotband” solution, press down the mesh and then push the putty through the cells with a spatula through the mesh, overlapping in places the junction of the parts of the mesh is at least 10 centimeters. After drying, apply a second layer of “Rotband” to close the mesh. After complete drying, after 7 days, touch the ceiling with a spatula to remove rough irregularities, prime again and after the primer has dried, apply layer by layer, letting each one dry layers, three layers of super-finishing putty. And then you rip and sand the entire ceiling with a special trowel, eliminating small flaws, which you smear and sand right away. After removing a ton of dust, you again need to carefully prime the ceiling and then you can paint it with acrylic paint twice, Well, then install the lamps. It’s been standing for three years and there’s not a crack anywhere, because the sheet of plasterboard is still thick and the sheets don’t interfere with each other, this isn’t 9 millimeters of ceiling plasterboard and it’s also not afraid of wet putty - it won’t get wet or fall off - it is screwed securely and the sheets do not interfere with each other, but what’s wrong is that it’s the fiberglass mesh that will take the stress, plastic mesh is no good in this case. A bit expensive? A little!

Rotband plaster on drywall.

Sinks made of stone TM Solid

New at Atlant - modern bathroom furniture from

Which underlay for laminate flooring should you choose?

On a construction site, like in a kitchen, there are incompatible products, in our case materials. Although individually they are simply wonderful. Here, for example, is drywall and Rotband plaster. Both can simply be called a great invention of mankind, but if you combine one with the other, then someone somewhere made a marriage. The fact is that Rotband is necessary where it is necessary to level the surface of walls with a thickness of 2 or more centimeters. If a master created a partition from plasterboard that gives such unevenness, then he is not such a master. Permissible differences in plane and deviation from level along plasterboard partitions should not exceed 10 mm. And such a layer is leveled with ordinary putty.

Practice of leveling walls with Rotband plaster

Next, using a simple ruler, the most protruding section of the wall is determined and a decision is made on the advisability of cutting it. How much can you save “Rotband even if you cut off only 1 mm of the protruding section of the wall and the cost for leveling you can calculate using the online calculator below. The second wall of the beam is leveled in the same way, and along the formed corners, like beacons, using a wide spatula it is leveled bottom of the beam.

The end of the mandrel and the wall adjacent to the right were used as beacons when leveling the walls of the beam. As you can see, the beam has changed beyond recognition. An example of moving an outlet from one place on the wall to another is described in detail in the website article “How to connect, move and repair an electrical outlet.” If you need to connect an additional socket to an already installed one or power a wall lamp with a stationary switch on the wall from the socket, then an example of such a connection can be seen in the article “How to install a hidden switch or socket on the wall.”

It should be noted that it is necessary to fill the void of the second face of the corner profile and level the adjacent wall only after the gypsum plaster has completely dried, about a day later. The corner profile is made of thin steel and when pressed it will move, breaking the tightness of the Rotband applied to the previous edge. But if you need to level a horizontal surface, for example a ceiling or beam, then it’s difficult to do without a construction ruler with a water level.

The longer the construction ruler with the level, the more accurately it will be possible to level the ceiling.

Why Rotband?

But, as they say, anything happens in life. If such a problem occurs and the plasterboard partition produces differences in plane or level of more than 20 mm, and it is not possible to redo the entire structure, you will have to use Rotband (by the way, in such a situation Rotband would be the optimal solution). I'll explain why.

Rotband belongs to the category of lightweight plasters and has really good adhesion to various surfaces, including cardboard. When applying a layer of plaster or putty to drywall, it is critical that the layer adheres well and is not heavy, otherwise it will simply pull away from the base. The second important point with the finishing of drywall is that no matter how moisture resistant it is, prolonged exposure to moisture on drywall leads to its deformation. Simply put, plaster absorbs moisture and simply begins to twist in different directions.

The thicker the layer of plaster or putty is applied to the drywall, the longer it takes to dry. It becomes covered with a crust on top (any material of this kind) and a significant part of the moisture goes into the wall. That is, in drywall. And this, as already indicated, leads to its deformation. You get the following picture: you level the surface with putty, check it, put it under a thread, and the next day the wall is crooked again, as if no one had leveled it at all. The reason is simple - the drywall was twisted. This means you need a material that will dry quickly. And Rotband is again a very good option here.

Applying plaster.

So, Rothband. Gypsum plaster, not heavy in weight, dries quickly and is capable of maintaining a layer of application without falling off, up to 5 cm. Excellent. There is only one caveat: when applying Rotband to the surface of a plasterboard partition, do not get carried away with the thickness and do not try to correct all sins at once. Apply a layer of plaster no thicker than 5 mm. Place the wind heater near the wall and let this layer dry. The second layer, after the first has dried, can be up to 10 mm. But no more. Again, let the whole thing dry for about a day. Only the third and subsequent layers can be applied up to 15-20 mm thick.

Yes, this process will take at least three days. But believe me, in this case, haste will cost you even more time. And by the way: if the total layer of plaster on a plasterboard surface exceeds 50 mm, it is better to stick a mesh after the first layer (which is 5 mm). It won’t ruin the mess, that’s for sure, and with a large layer of gypsum plaster, the reinforcement will protect against cracks.

Considering the way of working with Rotband, namely banal spatulas, with plaster you can bring the level to almost ideal. All that remains is to create one or two layers of finishing putty, with intermediate sanding and primer, just to make the surface smooth. Still, Rotband remains plaster and cannot be used to create a smooth surface for painting. And that's it, you can paint it.

Features of Rotband plaster and putty

Plaster is a universal composition based on gypsum, which contains special additives that help increase adhesion. This allows you to use Rotband plaster for treating surfaces made of brick, fiber board, foam blocks, expanded polystyrene, concrete, and cement. With its help you can plaster horizontal and vertical bases. In one pass, a layer of 5-50 mm is applied.

Rotband Paste Pro putty is used on a leveled base to eliminate minor defects and obtain a perfectly smooth surface. This composition is used to prepare the surface for painting or wallpapering. The application thickness is 0.3-2 mm. Unlike gypsum plaster composition, putty has a finer grain size. Its use provides a thin, high-strength layer without defects (maximum quality indicator according to the German quality scale Q4).

How to work with Rotband plaster

The work algorithm includes the following steps:

- Preparing the base The surface is cleaned of old finish, paint and dirt. The base is primed with special compounds;

- Installation of beacons and corners. Installation of profiles is carried out using a plumb line and level. The optimal distance between beacons is 1.3 m;

- Preparation of the mixture. The dry mixture is added to the water in the proportion of 0.75 liters of water per 1 kg of mixture. The composition is thoroughly mixed, left for several minutes to “ripen”, after which it is mixed again;

- Application. A layer 5-30 mm thick is applied to the prepared surface (in some places - up to 50 mm). The solution is applied to the wall surface with a spatula using upward movements. You can also apply the composition to the wall using a trowel. The consumption (per 1 sq.m) of the finished mixture is 8.5 kg, subject to applying a layer 1 cm thick;

- Alignment. Alignment of ceilings is carried out by moving towards you. The walls are “stretched” from top to bottom in a zigzag motion, after which they are “trimmed” with a metal rule. If the work is carried out along beacons, it is better to choose a rule with a length of 1.5 m. When applying plaster directly to the base or plaster mesh, a rule with a length of 2.5 m is used;

- Grout. After the layer of plaster has begun to set, it is moistened with water and “glossed” using a sponge trowel. It is better to complete the work within 12 hours after applying the plaster. The maximum period during which the plaster can be “glazed” is one day from the moment of application;

- Surface structuring. A surface that has set but has not yet dried can be given relief. For this purpose, rollers with embossed coats, brushes, sponges, combs, and special molding devices are used.

The drying time of Rotband plaster depends on the level of humidity and temperature in the room. It takes up to a week to dry completely.

How to work with Rotband on concrete

Thanks to its high technical characteristics, the Rotband mixture performs well even on smooth concrete bases. To ensure maximum adhesion, before starting priming, craftsmen advise making notches in the concrete. It is best to prime the surface with ConcreteContact from Knauf. After drying, Rotband plaster is applied in the standard way.

The advantages of using this composition for concrete are

- excellent adhesion,

- no shrinkage,

- crack resistance,

- the ability to achieve a flat, smooth surface.

Working with Rotband putty

If there is a need for finishing leveling, the Putty Paste Profi Rotband from Knauf is best suited. This fine-grained ready-made vinyl-based composition allows you to obtain a thin layer (from 0.2 mm). The mixture is applied to a previously plastered surface using a spatula. After processing, the base acquires ideal smoothness and gloss. When applying a layer 0.3 mm thick, the consumption (per 1 sq.m.) is 0.48 kg.

Conclusion

Using Rotband products and strictly following the instructions for use, even a novice master can achieve high results. Using universal materials from Knauf, you will simplify and speed up processes in the field of repair and construction, and make the work more enjoyable.

Rotband plaster on drywall.

Sinks made of stone TM Solid

New at Atlant - modern bathroom furniture from

Which underlay for laminate flooring should you choose?

On a construction site, like in a kitchen, there are incompatible products, in our case materials. Although individually they are simply wonderful. Here, for example, is drywall and Rotband plaster. Both can simply be called a great invention of mankind, but if you combine one with the other, then someone somewhere made a marriage. The fact is that Rotband is necessary where it is necessary to level the surface of walls with a thickness of 2 or more centimeters. If a master created a partition from plasterboard that gives such unevenness, then he is not such a master. Permissible differences in plane and deviation from level along plasterboard partitions should not exceed 10 mm. And such a layer is leveled with ordinary putty.

Why Rotband?

But, as they say, anything happens in life. If such a problem occurs and the plasterboard partition produces differences in plane or level of more than 20 mm, and it is not possible to redo the entire structure, you will have to use Rotband (by the way, in such a situation Rotband would be the optimal solution). I'll explain why.

Rotband belongs to the category of lightweight plasters and has really good adhesion to various surfaces, including cardboard. When applying a layer of plaster or putty to drywall, it is critical that the layer adheres well and is not heavy, otherwise it will simply pull away from the base. The second important point with the finishing of drywall is that no matter how moisture resistant it is, prolonged exposure to moisture on drywall leads to its deformation. Simply put, plaster absorbs moisture and simply begins to twist in different directions.

The thicker the layer of plaster or putty is applied to the drywall, the longer it takes to dry. It becomes covered with a crust on top (any material of this kind) and a significant part of the moisture goes into the wall. That is, in drywall. And this, as already indicated, leads to its deformation. You get the following picture: you level the surface with putty, check it, put it under a thread, and the next day the wall is crooked again, as if no one had leveled it at all. The reason is simple - the drywall was twisted. This means you need a material that will dry quickly. And Rotband is again a very good option here.

Applying plaster.

So, Rothband. Gypsum plaster, not heavy in weight, dries quickly and is capable of maintaining a layer of application without falling off, up to 5 cm. Excellent. There is only one caveat: when applying Rotband to the surface of a plasterboard partition, do not get carried away with the thickness and do not try to correct all sins at once. Apply a layer of plaster no thicker than 5 mm. Place the wind heater near the wall and let this layer dry. The second layer, after the first has dried, can be up to 10 mm. But no more. Again, let the whole thing dry for about a day. Only the third and subsequent layers can be applied up to 15-20 mm thick.

Yes, this process will take at least three days. But believe me, in this case, haste will cost you even more time. And by the way: if the total layer of plaster on a plasterboard surface exceeds 50 mm, it is better to stick a mesh after the first layer (which is 5 mm). It won’t ruin the mess, that’s for sure, and with a large layer of gypsum plaster, the reinforcement will protect against cracks.

Considering the way of working with Rotband, namely banal spatulas, with plaster you can bring the level to almost ideal. All that remains is to create one or two layers of finishing putty, with intermediate sanding and primer, just to make the surface smooth. Still, Rotband remains plaster and cannot be used to create a smooth surface for painting. And that's it, you can paint it.

Decorative plaster on the walls

Decorative plaster on drywall comes in several types, let’s look at them.

Structural plaster

This is a heterogeneous plaster mass with a granular structure. Granules that look like small pebbles or pieces of quartz are added to it.

How to apply it?

- For such plaster, a perfectly flat surface is not at all necessary. The most important thing is that the walls are dry and clean.

- First, we strengthen the base of the drywall with a special primer. And thus we create a protective intermediate layer that will prevent moisture exchange between the decorative plaster and the wall.

- Structural plaster on plasterboard walls can only be applied to a completely dry primer.

- The composition of the special finishing mixture is laid in one layer, using a trowel (trowel) or spatula. The texture depends on what technology you use. The mixture can be applied in circular or straight movements.

- After two to three hours, the coating will become durable, but will completely harden only after a week.

Textured plaster

Using this mixture you can give the walls a relief original texture. The complexity of the design depends on the tools used and the composition of the mixture.

What does that require?

- For this type of plaster, you should also clean and dry the walls and apply a primer.

- On the dried primer we apply a special base paint with sand, this is necessary to increase adhesion (good adhesion of the plaster mixture).

- Then we apply one or two layers of plaster using different tools, giving the desired pattern. The more complex the texture you want, the more layers of plaster you should apply (but the layers should be very thin).

Venetian plaster

This is a special “transparent” mixture made from marble flour. When applied to a wall, this plaster creates the appearance of marble. It is clear that not everyone can afford the price.

How to apply it correctly?

- For this type of plaster, the surface of the drywall must be extremely flat.

- Apply a thin layer of Venetian plaster to the dried primer layer with a spatula, let it dry completely, and clean the surface, eliminating all roughness and unevenness.

- We do this with each layer (there can be from five to twelve, depending on the desired result).

Advice! After applying all layers, we clean the surface with fine sandpaper in a circular motion. This is necessary to give perfect evenness to the walls.

- Apply a layer of white wax. Ready!

Look at the photo of the final result.

Is it possible to plaster drywall: how to do it correctly and with what?

Many novice craftsmen who have started DIY repairs are interested in how to properly plaster drywall. Indeed, after installation, plasterboard sheets require some manipulations before finishing: sealing and reinforcing seams, filling in recesses from self-tapping screws, and final leveling of the entire plane. But not everyone knows what material is used for these purposes - plaster or putty. Let's figure out whether it is necessary to plaster drywall, what materials are used for rough processing, and consider the case when plaster is really necessary.

Do I need to plaster drywall?

The most frequently asked questions regarding gypsum board plaster will be as follows:

- How to plaster drywall under wallpaper?

- How to plaster a ceiling and drywall?

- How to plaster plasterboard walls?

In the vast majority of cases, the answer will be the same: not at all. Drywall is sometimes called drywall because the plasterboard sheets attached to the frame perform the same function as the plaster mixture applied to the wall: level it. And these questions arise because not everyone sees the difference between plaster and putty.

Plaster is a material for rough rough leveling. It has a coarse-grained structure, can be applied in a fairly thick layer and is designed to eliminate significant defects in the base. Even the finest-grained gypsum plaster mixture cannot serve as a substitute for putty when processing plasterboard, since it cannot be applied in such a thin layer.

Putty is a finely dispersed construction mixture, due to which it can be applied in a layer only a few millimeters thick. It is the putty that, after drying, allows us to obtain a perfectly smooth surface, which we expect to see after finishing the walls with plasterboard.

Thus, walls, ceilings and any other plasterboard structures should not be plastered, but puttied. And if you come across advice about the rules for plastering gypsum boards, do not trust such an article - it was written by an incompetent author.

Plaster is applied to drywall only in one specific case, which is rather an exception to the rule and will be described below.

Eliminating irregularities

Applying plaster to drywall is a simple process, but requires certain knowledge.

So, our task is to seal the seams, screw heads, potholes and roughness.

- To begin with, you need to clean the entire surface from dust generated during installation of drywall

. This can be done using a special construction vacuum cleaner, but if you don’t have one, don’t be upset - a damp rag will do just fine. - Then we prepare the solution for plaster

. There are two options: prepare it yourself from a dry mixture or purchase a ready-made liquid solution. You should choose high-quality and proven material; in this sense, the Knauf company has proven itself well.

Important to remember! The plastering solution must be diluted with water immediately before starting work and in the proportions indicated on the packaging.

- Before you start plastering plasterboard walls, you need to glue all joints with a special mesh. It is sold in a convenient roll and has an adhesive backing. Particular attention should be paid to the corners: carefully glue the mesh, then draw it with a spatula on one side of the wall and on the other to give the corner the correct shape.

- The preparatory work has been completed, we begin plastering the drywall

. Carefully apply the solution to the seams between the sheets, trying to fill the empty space as thoroughly as possible.

Note. The main thing is to avoid lumps from the solution on the surface. If there are any, it is better to remove them immediately using a wide spatula.

- After plastering the drywall seams is completed, we proceed to plastering all the irregularities on the sheet (cracks, potholes).

Please note: there are two types of plaster used, one for seams, the other for surface finishing

- We wait until the first layer dries, after which it is necessary to repeat the work in areas where the plaster has not completely filled the empty “channels”.

Voila! The wall is ready, it can be covered with wallpaper. It is better to use moisture-resistant ones, they will last longer, and their material is more reliable.

Plasterboard putty

So, we found out that instead of plaster, putty should be applied to the gypsum board. In this case, the question may arise as to how much it is really needed. Some people believe that it is enough to apply a primer to the surface of the plasterboard wall under the wallpaper, but this decision cannot be called correct.

Putty in the case of gypsum plasterboard performs the following tasks:

- Fills seams between sheets, strengthening weak joints.

- Masks recesses from self-tapping screws, with the help of which plasterboard sheets are attached to the frame, prevents the appearance of rust from screws on the finish.

- Hides small cracks and dents that may appear during installation.

- Allows you to make a surface for painting so that it looks perfectly even and smooth.

- When preparing gypsum board for wallpapering, it forms a protective layer that prevents the wallpaper material from sticking “tightly” to the cardboard surface. If you skip the puttying stage, during subsequent repairs you will not be able to remove the wallpaper from the plasterboard wall without damaging it.

Important! Various putty mixtures are used to seal the seams between sheets of drywall and putty the entire surface. In the first case, you need to use a special putty for the seams, for example, Knauf Uniflot; in the second, a finishing thin-layer putty mixture.

You can read about the rules for sealing seams using paper tape or sickle tape here.

The technology for puttingtying drywall from “A” to “Z” is described in detail here.

How to Caulk Drywall Joints: Workflow

Sealing drywall joints includes the following steps:

- Preparation . Work begins with thoroughly cleaning the work area from dust and dirt using a brush. Burrs are removed with a knife.

- Unstitching . When joining factory sheets, it is not required. The cut ones must be chamfered at an angle of 45 degrees. The chamfer size (width and depth) is 3-5 mm. It is better to use a plane, but you can also remove the chamfer with a knife, using extreme caution.

- Primer . The composition should have a concentration convenient for application. If necessary, the mixture is diluted according to the attached instructions. The primer is applied with a paint brush in a thin layer. Carefully coat the entire seam, as well as the surface of the sheet at a distance of 12-16 cm from the edge. To speed up the work, you can use a brush or a narrow paint roller.

- Filling the seam with putty . After the primer has hardened, the putty mixture is pressed into the gap with a narrow spatula (preferably rubber). We must strive to completely fill the joints.

- Sticker of tape or serpyanka . Reinforcing tape is glued to the filled seam. Perforated or serpyanka is pressed into the still uncured putty solution. If a solid paper tape is used, then a layer of glue is applied over the putty. PVC can be used. The tape is glued over the seam. The width is selected so that it covers the gap by 3-5 mm. The recommended length of one piece of tape is no more than 3 m.

- Sealing with putty . After all layers of the seal have hardened, the work area is leveled with putty. The solution is applied with a wide spatula and carefully leveled.

- Finish sanding the dried joint with emery cloth . Final processing is carried out by finishing sanding using sandpaper or a sanding tool. As a rule, manual sanding with emery cloth is used in several stages. First, it is produced with coarse sandpaper No. 50-80. Cleaning is carried out in small sections, movement is carried out in one direction - from top to bottom. Next, the seal is sanded with fine-grained sandpaper No. 300-400 until the unevenness is completely eliminated. The seam should be completely level with the surface of the wall or ceiling. Sanding is done using gentle circular movements, starting from the edge of the area and moving towards the center of the joint.

When is it permissible to apply plaster to drywall?

Plasterboard walls and ceilings can be plastered in one single case: when the structure is installed unevenly and of poor quality. If mistakes were made during the installation of the frame, the profiles or wooden beams were not level, the finished plasterboard surface may have deflections and protrusions, and it may be filled up.

In this case there are two ways:

- Remove plasterboard sheets, disassemble the frame and mount everything again.

- Level the surface with plaster.

Since they can be damaged during the process of dismantling and reattaching the sheets, in some cases it will be easier to plaster the surface.