In order for a house made of timber to be reliably protected from negative external influences and have a presentable appearance, it must be painted both inside and outside.

It doesn’t matter what type of wood the timber is made from, the coatings are the same for everyone. Wood paint can be used for exterior or interior use. Facade paint for outdoor work is more durable and resistant. Painting is the simplest, but quite effective way to protect the walls of a house. When choosing a suitable paint for timber, you need to understand that with its help you can not only hide various flaws in the wood, but also protect the timber from fungi and mold. This will significantly increase the service life of the timber.

Wood paint: types

When choosing a material for painting a house made of timber, you need to understand why this procedure is being performed. This may simply be protection from the influence of weather conditions and various insects, or it may be a way to hide flaws in the wood and decorate it.

All means for tinting walls outside the house differ according to several criteria:

- color;

- type;

- lifetime.

In order to preserve the appearance of the timber without changes, it is best to use transparent and translucent tinting compounds. These include:

Water-based wood paint

Water-based paint for wood contains water and some other components. These are coloring pigments, binding components, etc. After the “water emulsion” is applied to the surface, the water evaporates and the pigment is transformed into a film.

The composition of water-based paint may contain:

- sufficiently strong antiseptics that protect the tree from fungal attack;

- antifreeze, thanks to which the emulsion does not freeze;

- thickeners;

- defoamers that prevent the appearance of foam.

Due to their good technical characteristics, water-based paints are suitable for painting individual parts and for the facade of a house. Water-based paint for wood can be acrylic, silicate, silicone and mineral.

Silicate water-based paint contains pigments, water and liquid glass. This paint withstands even severe temperature changes and difficult weather conditions.

Silicone paint contains silicone resin and water. And mineral emulsion paint contains slaked lime or cement mortar.

The paints used to paint facades differ significantly from the paints used to paint surfaces inside buildings. These paints are less susceptible to ultraviolet radiation from sunlight and are quite resistant to temperature changes.

Such paints are low cost, they instantly penetrate deep into the wood and dry quickly. These paints require additional protection from moisture.

Acrylic paint for wood

If we talk about acrylic paint for wood, it is durable and flexible. The main binding component in this paint can be considered acrylic resin. More durable than oil and alkyd compounds. The high price pays off due to strength and durability. This is one of the options that is also suitable for painting wooden surfaces. Advantages of acrylic paints:

- air penetrates well into the wood structure through the protective coating;

- this is an elastic material, so cracks in the coating practically do not form;

- long service life.

Before painting with acrylic paint, the wooden surface must be treated with an antiseptic composition and coated with a primer.

Acrylic lacquer

Calibrated logs or laminated veneer lumber are usually not painted with opaque paints. They are coated with colorless varnish, then the surface will be covered with a beautiful gloss.

If the owners do not want to hide the natural structure of the wood, then transparent materials can be used. One of them is acrylic varnish for wood. A kind of transparent paint for interior work in a wooden house.

The composition of acrylic varnish includes:

- acrylic base;

- substances with antiseptic properties that can protect wood from the negative influence of various factors;

- special substances necessary to form a transparent layer that makes the coating durable.

Acrylic varnish has its advantages:

- easy to apply and does not require special care;

- has a low price and is therefore accessible to most consumers;

- dries instantly and has no odor;

- has high resistance to the harmful effects of climatic and biological factors;

- resistant to temperature changes;

- provides treated products with a long service life.

This varnish also has its disadvantages:

- during application there should be no drafts, direct sunlight in the room and the ambient temperature should be between +5C and +30C;

- Acrylic varnish cannot be stored at sub-zero temperatures, as in this case it becomes unsuitable for use.

Before you start working with such material, you need to read the manufacturer’s recommendations and follow them. Then the surface being treated will not be damaged.

The process of applying acrylic varnish

- the surface to be varnished is cleaned and polished;

- to reduce the consumption of coating material, you need to apply a special primer to the treated area and let the surface dry;

- cover the prepared area with a diluted varnish substance, which must be applied in two layers;

- leave to dry for 2-3 days.

Acrylic varnish is used not only to cover walls, it is also used to cover furniture. However, do not forget that such a coating is not resistant to abrasion and therefore will have to be renewed quite often.

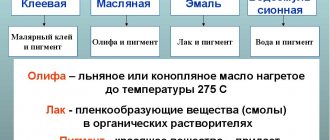

Oil paint for wood

Oil paints for painting wood have a number of advantages. These advantages make this paint the most popular today:

- it penetrates deeply into the wood structure;

- tolerates atmospheric changes well;

- is relatively inexpensive.

But there are also several disadvantages:

- the surface will have to be painted with such paints constantly as it wears out;

- Oil paints take quite a long time to dry.

Enamels

The enamels contain an increased content of film-forming components. These substances perform a protective function better than many of the paints used today. Therefore, enamel can be used to paint not only internal, but also external wooden surfaces.

Enamels have a strong unpleasant odor, but it disappears over time as the solvent evaporates.

Functions of protective compounds

A good wood preservative should have the following features:

extending the service life of the material and the house as a whole;- preventing the appearance of deformation and cracks;

- maintaining the original color of wood;

- the ability to paint wood in any color;

- brings variety to design;

- protection from the negative effects of moisture, temperature changes and pests;

- prevents the proliferation of fungus, mold and other microorganisms that can destroy the structure of the tree.

Go to the Leroy Merlin catalog =>>

For external wall treatment, wood paints based on acrylic, oils, rubber, and alkyds are used. Each of these finishing materials has its own advantages and disadvantages, so let’s try to dwell on all the nuances and decide on the further choice.

Important!

Before applying decorative paint to wood, coat the material with antiseptic protective compounds.

How much does it cost to paint a log house?

There are a large number of organizations that paint the walls of wooden houses. Average prices per square meter are as follows:

- Sanding – from 300 rubles.

- Treatment with a special brush followed by painting – from 850 rubles.

- Internal tinting – from 550 rubles.

- External chipping – from 600 rubles.

- Painting of platbands - from 450 rubles per piece.

Since in order to achieve the desired result, you won’t be able to get by with just one type of work, so it’s worth thinking about painting yourself.

Latex paint

Latex paint

The main component of this paint is latex, which makes the surface slightly porous after drying. This effect occurs due to the fact that latex is finely dispersed particles of rubber obtained through artificial synthesis.

Important! It is not harmful, does not have a characteristic colorful odor, and does not evaporate. These properties make it very convenient for interior decoration.

Advantages:

- mixes easily with other types of paints;

- forms a barrier to moisture;

- the dried layer is resistant to mechanical damage.

Flaws:

- may swell from heat, including from sunlight;

- Only a roller is used for application; the coating is formed in 2-3 layers.

This type of paint is perfect for treating surfaces in the bathroom and kitchen, that is, in rooms with high humidity levels. Surfaces treated with latex paint are easy to clean from dirt and are durable.

Important! Water-repellent properties are achieved due to the specific properties of latex. The smallest particles of polymer penetrate into the pores of the wood. Thus, the paint and wood form a single layer, which does not allow moisture to spoil the wood with mold and mildew.

Preparatory work before painting

Before you start painting wood, you need to carefully prepare the surface so that no problems arise later. Preparation for painting looks like this:

- Using a brush, clean the walls from dirt. It is advisable to vacuum the joints, since you cannot get there with a brush, and the most dust accumulates there.

- Next you will need to sand the surfaces. This must be done so that the surface becomes smooth and even. In addition, after sanding, the wood better absorbs protective compounds, which means its service life will increase.

- If there are still any defects on the surface, they need to be repaired with wood putty.

- The next step is the application of special wood preservatives. The product is selected depending on the surrounding factors. In order to prevent the development of mold fungi and other microorganisms, the surface is treated with an antiseptic. To get rid of the blue stain that forms over time on untreated wood, the walls are treated with a bleaching compound.

After all the preparatory work is completed, the wood should dry out. This procedure takes from 10 to 14 days. It is best to cover the walls with polyethylene at this time, making holes in it for ventilation.

Coating timber with antiseptics and bleaches

Despite the fact that the walls made of timber inside the house are not exposed to direct ultraviolet rays and other negative weather phenomena, it still makes sense to treat the timber with antiseptics.

An antiseptic is a special primer that well protects timber walls from mold, blue stains and various insects that feed on wood. The deeper this impregnation penetrates into the timber, the more it protects it.

Modern antiseptics contain two main types of protective substances:

- Fungicides are derivatives of phenols, copper and heavy metal salts. They prevent mold cells from feeding. Which leads to their starvation and subsequent death.

- Oxidizing agents – destroy the cells of harmful fungi.

All antiseptics are liquid, and this ensures that they penetrate as deeply as possible into wooden surfaces.

If, after treatment with an antiseptic, you do not plan to paint the timber house with other paints and varnishes, then any antiseptic will do. When you plan to further color the timber in the future, you should choose a suitable impregnation.

If the walls of a timber house were not treated with impregnation immediately after construction, then the wood usually turns blue and to remove it you will need to use a special wood bleach.

Popular paintwork materials

Let us dwell in detail on the most common paints that can be used for wood processing.

Acrylic paints and enamels. Acrylic paints and enamels are water-based and practically odorless, dry quickly, are environmentally friendly and durable. Such materials are usually excellent for exterior and interior use. Modern covering materials have a wide range of colors, while the brightness of the coatings is maintained for a long time. Any method (brush, roller or spray gun) can be used to apply the compositions. Facade covering paints perfectly withstand high and low temperatures, as well as direct ultraviolet rays, since their composition, as a rule, includes special additives (wax, oil, UV filters and light-resistant pigments). The paint protects the wood surface from destruction when exposed to moisture, without clogging its pores. It is prohibited to store water-based materials at sub-zero temperatures.

Alkyd paints and enamels. They are attractive due to their affordable price and variety of shades, and you can tint them yourself. Such materials are allowed to be used for both internal and external work, since they tolerate precipitation and other adverse external influences well. However, for indoor use, paints based on organic solvents are less preferable due to their pungent odor. Structures treated with this type of material can be used even at temperatures above -30 °C. This surface dries within 8-24 hours, but the paint almost does not penetrate the wood fibers. It is customary to use alkyd compounds for wooden street structures, entrance doors or window frames.

Oil paints. They perfectly protect wood from water, but in terms of performance they are in many ways inferior to other analogues. In particular, they take a relatively long time to dry, about 2 days, have a strong smell and often form smudges. You should also take into account their poor compatibility with other paints and varnishes and insufficient wear resistance. Inexpensive oil paints fade very quickly in sunlight. However, these materials also have advantages: low consumption and excellent elasticity.

Water-based polymer-based paints. The main advantages of these compositions are the absence of odor and environmental safety. They are not suitable for outdoor work because they do not tolerate high humidity and other unfavorable external factors. Because of this feature, they are not recommended for use in the kitchen, bathroom or bathhouse. However, some varieties, due to the presence of special polymers in their composition, acquire the necessary water resistance. But their cost is quite high compared to other paints of this type.

Polyurethane paints and varnishes. Often used to stain wood floors and furniture. These compounds are non-toxic, and the layer they form is resistant to mechanical stress and elastic. Polyester paints. These materials are made using polyester resins. They are expensive, so they are used mainly for restoration work on wood. They are also used for decorative processing of various products.

Nitrovarnishes. Used for decorative processing of wooden products and elements indoors. These compositions are flammable and susceptible to ultraviolet rays, so they are not used for outdoor use. Their main area of application is finishing wooden furniture and indoor elements.

Service life

Glazing (translucent) antiseptics can be used for 3-5 years. Covering antiseptics will last longer - up to 7-8 years. Oil paints last an average of 6 years. Acrylate paints – up to 12 years. As the surface wears out, it should be renewed with the same paint that was applied to the base. Of course, there are some exceptions in this regard.

Already at first glance you can understand what kind of wood paint was used on the surface. A surface coated with glazing antiseptics wears out very quickly. If the surface is glossy (coated with an antiseptic), paint with the same paint or oil-based paint.

If the wooden surface was covered with oil paint, then it is better to paint it with the same paint. Before re-painting, thoroughly clean the surface to remove any dirt. If there was acrylate paint on the surface, as it wears, cover the wood with the same or oil paint. Any surface before a new coating must be well cleaned of old paint and sanded.

Types of paints, classification

The door material plays a big role in the choice of covering. As a rule, the entrance ones are made of metal, and the interior ones are made of wood. The difference is significant - for iron models, an anti-corrosion component is always added. The classification of paints is as follows:

- Covering and glazing. The former have pigment - it is difficult to choose the color of the doors due to the variety; the latter are distinguished by a complete or partial absence of shades.

- Interior and facade. The former are intended only for interior work, the latter for exterior work.

- Protective. In addition to the usual functions, they prevent the negative impact of the environment on the door material - metal or wood.

Paint colors

Each composition contains components of others to one degree or another. For example, facade glaze is used on the surface of both a wooden entrance and interior door, has a protective antibacterial composition, and has any shade - walnut color, for example.

Types of paints for steel doors

The compositions are divided into main types, which serve as bases for coating options. Details:

- Nitroenamel or nitro paint. Cheap coverage. Used only for entrance doors and when there are no people in the living space for several days. It's all about volatile, harmful components and a pungent odor. There are more disadvantages than advantages: heterogeneity, susceptibility to aggressive influences - moisture and shock. The enamel is quick-drying - one layer per day.

- Acrylic. It is water-based, and therefore this paint for interior doors is odorless. They are successfully used in painting doors made of any material. It has a soft consistency, but at the same time it is one of the most durable, as it has great adhesion - adhesion to the surface. Application in several layers will allow the metal sheet to look decent.

- Hammer paint. It got its name because of the result of surface treatment - forging or hammering. Trade name: Hamerite. In addition to metal, it is also used on other surfaces. It has frost resistance, resistance to mechanical shocks, and moisture. Used on surfaces with defects - uneven welds, poor processing or cutting.

- Powder paint. The decorative appearance of the door leaf is impeccable. It is used in the manufacture of metal doors, applied in 1-2 layers, and owners will not have to worry about the condition of the surface in the future - durability is guaranteed. The disadvantage of the composition is the high price, which ceases to be a disadvantage due to its resistance to any type of influence.

Types of paints for steel doors

The first three options are also successfully used on wooden surfaces if the paints are labeled as interior paints. There is no need for an expensive fourth type to cover interior doors.

Types of paints for wooden interior doors

Models are solid solid canvas or MDF. Both need painting if the appearance is no longer attractive. But with solid wood this fact occurs much less frequently than with particle boards, so it is emphasized with all kinds of compositions that do not have a color - varnishes, glazes. More details:

Water-based. Colored or white enamel, inexpensive, environmentally friendly. They are applied to the surface, under the future layer of varnish, since the composition does not have strength and with great activity - opening and closing - it will peel off. If there is high humidity in an apartment or house, then this defect cannot be avoided.

This is important for wood structures and rooms where humidity is constant - kitchen, bath, toilets. Glazing

This is a paint for doors that looks like wood or is completely transparent. Gives the canvas a finished decorative look, emphasizing the natural beauty of the material. Unlike varnish, the composition is not transparent, which is why it has the characteristic of glaze. The components allow you to smoothly transition into shades and linger on the natural pattern. Flawless on all surfaces - solid, smooth or textured. Lucky. Inside the apartment, only water-based compounds are used - nitro varnish will not work.

Painted wooden doors

Glazing

In order for the internal surfaces of the house to retain their original appearance for a long time, as well as to increase the service life of wooden products, a glaze coating is applied. This method of coating wooden surfaces is made using special coloring compounds. They give the wood a natural shine and increase its service life.

Glaze paint for wood for interior work is designed to:

- emphasize the attractive appearance of the tree;

- protect from direct sunlight and other negative natural phenomena;

- create a protective layer that will protect the timber from the development of mold colonies and other fungal diseases.

How is glazing done?

Before applying to the surface to be painted, the glazing composition must be slightly warmed up. For application use a rag, swab or brush. The composition is applied in two to three layers. Before applying each subsequent layer, the previous one must be dried and sanded.

Alkyd

The main difference between alkyd paints and acrylics is the main component, which is the varnish of the same name, which is a thick mixture of resin with the addition of rosin, a complex of vegetable oils and liquid glycerin. Other components can also be added to their composition to achieve certain properties (for example, for increased paint resistance to mechanical loads). The homogeneity of the mixture is achieved by mixing with a solvent. Also, alkyd enamel dries much longer than acrylic enamel (up to 2-3 days) and has a more pronounced odor, but it costs much less and has a number of characteristic advantages:

- makes the surface waterproof and durable (lasts more than 4 years);

- withstands much greater temperature changes and tolerates both very high and extremely low temperatures;

- prevents wood rotting.

It is necessary to work with such a composition in well-ventilated areas. When choosing alkyd paint for interior woodwork, do not rush into the final decision in favor of the first one you like. Study the features of the presented samples in detail.

Coating timber walls with waxes

Treatment of surfaces in a timber house with artificial or natural wax is used to protect wooden surfaces from rot, mold, mechanical damage and insects that harm it. Wax is able to highlight the structure of wood and reliably protects it from moisture.

The composition of ready-made wax impregnations includes the following components:

- special oils;

- inorganic additives;

- beeswax.

After opening the jar, the solution must be used immediately. After treatment, the wooden surface becomes smoother and has a velvety tint. This processing method is suitable for wood of any species. Today, wax solutions of various colors are available in stores.

How does waxing happen:

- The first step is to remove all the old coating from the surface that you plan to coat with a wax composition and apply an oil impregnation.

- Next, the prepared wax paste is applied. This is done with a thick brush or washcloth.

- In order to treat fairly large surfaces, liquid wax is used.

- Wax products of different colors and shades are applied to surfaces made of different types of wood. This is done in order to “revive” the natural shade of a certain tree.

- To fix the wax coating, you can apply one or two layers of alcohol varnish to the treated surface. After this procedure, the surface becomes matte.

When treating wood with any protective compound, it is necessary to carefully treat all sides. All coloring and protective mixtures are applied to wooden surfaces in a thin layer along the fibers, otherwise the composition will be absorbed unevenly and this will negatively affect the overall appearance.

General features of wood paints

Painting of wooden products should be carried out with high-quality materials. This is necessary in order to preserve the positive properties of wood and not spoil its appearance. Moreover, without proper care, it is at risk of damage from fungi and pests. Therefore, when choosing paint for wood, you should pay attention to the following characteristics:

- texture - in order not to create streaks on the treated surface, it should be thick, uniform, without lumps or other foreign inclusions;

- fire resistance - to comply with fire safety regulations, wood should be covered with materials that do not burn;

- wear resistance - to prevent mechanical damage to the surface, the coating must have protective properties;

- moisture, heat and light resistance - these properties are important for some treated surfaces;

- safety - in order not to harm your health, painting wooden surfaces in the interior should be done with materials without harmful components;

- drying speed – quick-drying paint saves time;

- palette – the ability to select ready-made colors or mix the desired color.

Natural wood paints are especially valued. They are usually odorless, so a respirator is not needed when working with them.

Dyeing technology

In order to achieve better adhesion of the paint composition to the wood, a primer is applied to the surface. If the surface is pre-primed, the paint and varnish compositions will be used more economically, and the service life of this coating will increase significantly. Once the surface has dried after applying the primer, you can begin painting. Wood paint is applied in several layers (usually 2-3). It must be remembered that each subsequent layer is applied only after the previous one has dried.

Some tips for coloring:

- In order to obtain a uniform color, the paint must be stirred periodically.

- You need to choose a quality brush that will allow you to distribute the paint evenly over the surface.

- It is best to carry out painting in dry, windless weather, but the air temperature should not be too high, since the coloring agent should dry gradually.

- Any composition should be applied along the timber.

- Since during rain a large amount of moisture accumulates on the end sections of the timber, the primer must be applied to these areas in several layers.

In a house made of timber, painting must be done, because this fact will provide the wood with a longer service life. If the painting process is carried out in compliance with all recommendations, then a house made of timber will have a very attractive appearance, and this procedure will need to be repeated only after many years.

Color selection

If you have decided what type of paint to cover the wood, select the color. First of all, pay attention to natural colors.

If the facade of the house is lined with clapboard, use colorless impregnation or varnish. The gloss on such a surface will look very beautiful. But in many cases, wooden surfaces can also be painted with matte paints. In this case, the texture is preserved, but the shade changes.

Also, do not forget that the wood can be coated with colored varnish (the shade of the wood will be slightly changed).

If the walls of the building are lined with timber (new and smooth), paint it a dark color. But in some cases, a surface covered with light brown shades will look good. Today, construction markets provide consumers with a very wide palette of different colors and shades. Therefore, you should be very careful when choosing colors.

Manufacturers

When choosing the really best paint for wood, pay attention to its packaging, components, and expiration date.

Good manufacturers produce their products in sealed containers, convenient for long-term storage. They also label the product correctly, indicating on the packaging all the information necessary for the consumer.

Among the already established manufacturers of wood painting products:

- Tikkurila is a Finnish brand that specializes in the production of all kinds of finishing materials. Although its products have a fairly high price compared to others, it is fully compensated by quality. Painting wooden lining, ceilings, floors, furniture, windows and doors with materials from this manufacturer will give them an excellent appearance and protection from environmental influences;

- Alpina - products are manufactured in Germany, have an attractive price and good quality. The manufacturer produces materials for both exterior finishing of wooden buildings and interior work. The advantage is a wide color palette;

- Neomid is a domestic manufacturer that can easily compete with foreign companies. Neomid produces interior paint for wood with increased fire-resistant properties;

- Belinka is a medium-priced, high-quality product from Slovenia. It has a wide range of finishing materials for wood, including protection against fungus, moisture, sun, and chemicals. This product is easy to work with, as it has an optimal texture and does not spread on the surface.

Now you know that when choosing what paint to paint a wooden house inside or outside, you need to pay attention to the main characteristics and positive properties of the available range and purchase what is best suited for your case and budget. However, remember that good and correctly selected finishing materials will help keep the treated surface intact and neat for a long time and will allow you to make repairs much less frequently

For lovers of natural compositions, we recommend that you get acquainted with such a material as paint with wax for walls. This may be what you need. You may also be interested in learning how to paint the steps of a wooden staircase.

How to fix a painted surface

After you have painted the walls or facade, cover them with protective layers. Clean the wooden surface and you can apply a special protective compound to it. Don't worry, the glossy layer won't deteriorate. Now apply a protective coating or polyurethane. Let it dry thoroughly.

Wooden surfaces can be painted with a brush or roller. It all depends on what kind of paint for the wood. The roller is most often used when painting building facades (timber, lining). It is better to paint buildings made of logs with a brush, as there are more corners and seams. Do everything carefully, slowly. If necessary, the surface can be coated in two or three layers.

In many regions of our country, wood is a more popular material than brick or concrete blocks. If your house is lined with wood, then painted with paint it will acquire originality and style that will be absent from other houses.

It all depends, of course, on your taste and level of imagination.

Do-it-yourself painting of a wooden house inside

For a long-term effect, it is necessary to apply 2 - 3 layers of paint.

Algorithm for basic work:

- If the walls or floor are made of highly porous, soft wood, such as pine, the surfaces should be primed twice. The top layer of such wood absorbs the liquid composition like a sponge. If you immediately paint a pine or apple tree with paint, the latter is absorbed and you have to apply an additional layer.

- After the primer layer has completely dried, the first coat of paint is applied. Brushes or rollers are used. To paint a large, flat area, take a spray gun.

- Cover the wall with 2-3 layers of paint to achieve a good effect. Each subsequent layer is applied when the previous one is completely dry.

- If necessary, painted walls can be further decorated. To add shine, cover the surface with a shiny varnish. To create the effect of antiquity, paints of several similar shades are used.

Painting wooden walls and floors is a quick and practical finishing method. The paint layer protects the material, prevents the appearance of mold or fungi and gives a new look to the interior.

Acrylic paint

Interior acrylic paint

Titanium dioxide is a specific substance in the composition of acrylic paint. It is this that provides the rich white color. The properties of such paintwork materials provide complete antiseptics of the coated surface, and make acrylic paint suitable for wood, metal, concrete, polymers and other surfaces.

Advantages:

- its use is economical;

- dries quickly in the open air;

- not susceptible to ultraviolet radiation and cold;

- water resistant;

- not permeable to steam.

The paint has no toxic odor or properties and dries quickly on wood and concrete. Convenient for painting door and window openings.

Important! Acrylic paint in one layer creates protection from external influences, and several layers allow you to level out cracks.

The surface is well and easily cleaned from dirt. The texture resembles a thin layer of polymer.

Polyurethane paint

The basis of this paint is formed on water, but it also contains complex inorganic substances:

- hardener based on fine polymer chips;

- polyester resins;

- fillers and color dyes.

Important! The material is completely safe and suitable for finishing work indoors.

A layer with excellent protective properties is formed due to the fluidity and thickness of the paint and varnish material. The adhesion and cohesion of paint allow it to “stick” to the surface of the wood and penetrate into the pores. The main distinguishing feature of polymer paint is its strong resistance to all external influences.

What to look for when choosing paint

When choosing the appropriate composition, you should pay attention to several factors.

- Type of wood . Different breeds have their own characteristics, which affect the quality of coloring.

- Terms of Use . Surfaces indoors and outdoors are exposed to varying degrees of impact. When purchasing paints and varnishes, it is recommended to take into account: humidity, the presence of sunlight, exposure to smoke, temperature changes, mechanical stress and some other nuances.

- Preliminary surface treatment . For the most effective protection of wood and long service life, the surface must be primed before painting. This will enhance the protective properties and ensure the leveling of the absorbent base.

- Previously applied compounds . The primer must be compatible with the paint. Otherwise, it is better to completely remove the previously applied layer.

Rules for painting timber

The main conditions for successful painting are the correct choice of paint and strict adherence to all work rules. When choosing paint, it is important to consider its color so that the painted timber matches other elements of the interior or exterior.

Preparatory work

At the preparatory stage, you must first thoroughly clean and dry the surface to be treated. When working with log houses made of laminated veneer lumber, it is necessary to take into account that they are practically not subject to processes of reducing the moisture content in the material. Therefore, they are an ideal option for painting. First of all, the primer must be applied. It is best to use a fire-resistant and bioprotective composition as a primer. In addition, it is advisable to thoroughly treat the surface with an antiseptic.

Next is sanding, which is a mandatory preparatory step before painting. Proper sanding will make the surface smoother and at the same time reduce paint consumption. In addition, such a procedure will increase the depth of penetration of the varnish into the wood material. As a result, the service life of the timber will increase significantly. It is recommended that sanding be carried out before you install the doors and windows. This is due to the fact that this stage of work is very dusty. Therefore, the presence of a respirator and glasses for protection is necessary in this case.

Grinding affects the entire surface of the timber, including the ends. In some cases, it is necessary to paint the layer of wood covered with fungus. For grinding, it is recommended to use grinding machines or sandpaper with a degree of hardness in the range of 40-120. The final stage of grinding is polishing. It is carried out with the same tools as grinding work. The only difference is that sandpaper with minimal grit is used for polishing.

Before you start painting glued or rounded timber, you should also seal the ends. These areas are much more susceptible to moisture compared to the side parts.

Therefore, experts advise treating the ends with acrylic sealant. This must be done both outside and indoors.

Painting stage

Painting of profiled or log beams should be carried out at an ambient temperature of at least +5 degrees. In addition, timber should not be painted during rainfall, so the surface of the wood must be completely dry before finishing. Otherwise, the method of applying paint to timber is standard and is carried out taking into account the instructions for the specific paint composition.

The quality of paint is the main component of high-quality exterior finishing of a country house. When choosing this composition, you should take into account its external characteristics, wear resistance and vapor permeability.