Special odorless paint for interior work allows you to apply a protective coating to walls or window frames in apartments or office spaces. The materials are characterized by increased safety, but when carrying out repairs it is necessary to ensure ventilation of the rooms. There are special water-based materials that do not have a negative impact on human and animal health.

Odorless paint allows you to apply a protective coating to the walls.

Features of odorless paints

Odorless paints and varnishes are based on organic or aqueous solvents. To remove aromatic components, enamel undergoes chemical and thermal treatment cycles, which increases production costs and the final price.

The paints are environmentally friendly and allow you to carry out painting work indoors without losing comfortable conditions. Depending on the components, enamels are intended for painting plastered walls, wooden window frames or doors, ceilings or wallpaper.

Advantages and disadvantages

Advantages:

- absence of paint odor during application and polymerization;

- speed of solvent evaporation;

- ease of removing stains from interior items, linoleum or clothing (until polymerization);

- increased service life (subject to application technology).

The paint is odorless during application and polymerization.

Flaws:

- high price (compared to standard enamels that have a smell);

- narrow specialization of each type of enamel;

- indoor use (there are certain types of odorless paint for external use).

What compositions are quick-drying?

The time until the surface dries completely depends on the composition of the material, as well as the temperature conditions in the room. The most common quick-drying paints are:

1) Nitro paints. The drying time of the first layer when sprayed from an aerosol can is no more than half an hour, the subsequent layer takes twice as long to dry. In the liquid version, nitro paints dry more slowly, taking several hours. Disadvantages - they have a sharp toxic evaporation and an unpleasant aroma.

When working with this material, you must strictly observe safety precautions.

2) Acrylic. The first layer dries in 4 hours. Advantages – does not have a strong aroma, safety and moisture resistance.

3) Water based. Drying time for the first layer is half an hour. Advantages: odorless and non-toxic.

4) Latex. Dries in 60 minutes. Advantages: odorless, safe and moisture resistant.

| Time for 1 layer | Toxicity | Smell | Moisture resistance | |

| Nitro paints | 30 minutes | + | + | – |

| Acrylic | 4 hours | – | – | + |

| Water based | 30 minutes | – | – | – |

| Latex | 60 minutes | – | – | + |

Types of odorless paints for interior work

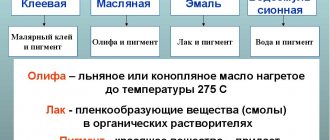

Enamels without a pronounced aroma include the following materials:

- on pre-cleaned alkyd varnish;

- on drying oil that has undergone a cycle of chemical treatment to remove odor;

- on a mixture of pigment dispersion and water;

- based on acrylic, resistant to external influences;

- using silicon-silicate resins that can withstand high humidity;

- based on synthetic latex;

- on a polyurethane basis.

Alkyd

The paints are based on a specially treated alkyd varnish that is odorless. The composition contains pigment and additives that accelerate and stabilize the hardening process. Designed for processing metal products; the layer formed after polymerization withstands cyclic temperature changes. Additional advantages are reduced price (compared to analogues) and increased service life.

Alkyd paint is based on a special varnish.

Oily

Materials based on purified drying oil are odorless, and the pigment introduced into the composition ensures the required enamel color. The paints are intended for treating wooden surfaces (for example, door panels or window frames).

When applied to metal, the material takes a long time to dry because the drying oil evaporates slowly at room temperature.

Water-dispersed

To obtain paint, a dispersion of pigments in water is used with the addition of additives that ensure the mechanical strength of the coating. It is completely safe and suitable for painting ceilings and walls in children's rooms. After hardening, a uniform layer with a matte tint is formed; the paints are not intended for application to metal structures.

Water-based paint is safe.

The surfaces can be washed without the risk of damage; the base color is white; tinting is required to obtain a different shade.

Acrylic

Acrylic quick-drying enamels are used both for domestic purposes and in the construction of buildings. Correctly diluted paint will have good adhesion; additional additives increase resistance to ultraviolet radiation. The coating is classified as washable (both with tap water and solutions with disinfectants).

Silicone

The paints are based on silicon-organic resins dissolved in water with the addition of pigment and stabilizers. The coating is not afraid of exposure to water and detergents, the enamel has good adhesion to wood or concrete. Basic white paint is suitable for ceilings located in damp rooms or in hallways with unstable air temperatures.

Silicone paint contains organic silicon resins.

Latex

Materials based on polymer latex have increased wear resistance and are suitable for painting walls with a porous or rough surface. Enamels are recommended for use in rooms with high humidity (for example, in bathrooms or showers). Painted surfaces can withstand prolonged exposure to water and detergents without the risk of peeling off from the base. Latex-based materials are characterized by a rapid polymerization process, taking from 20 to 60 minutes.

Polyurethane

The enamels are based on a synthetic rubber base with improved adhesion. After polymerization, an elastic layer is formed that is resistant to temperature changes and mechanical stress. The materials are used for painting domestic premises with high humidity, food blocks and surfaces that are in constant contact with humans. Disinfection of paintwork using special solutions is allowed; polyurethane paints are resistant to alcohol (ethyl or isopropyl).

Polyurethane paint has improved adhesion.

Without smell

Odorless paints and varnishes include those types that do not have toxic fumes and are therefore safe.

The following varieties are distinguished: 1) Water-based (water-dispersed). The base is water, so there is no strong aroma, and it dries quickly.

2) Acrylic. It is odorless, non-toxic and dries quickly.

3) Latex. It is an improved water-dispersion version. The latex base dries quickly, the treated surface has increased moisture and wear resistance.

How to find out whether there will be a smell or not

The manufacturer will call the enamel odorless, but due to individual characteristics, a person can feel the aroma of the material both during application and during the polymerization process. To check, it is necessary to treat with the material a small fragment of ceramic tile with glaze, preheated in an oven to +50...+60°C.

Accelerated evaporation of an organic solvent or aqueous base will determine the presence of an unpleasant odor during polymerization.

Specific features of alkyd paints

Some people are accustomed to using alkyd paints—varnish-based paints—to paint wood. They consist of resins, glycerin, rosin and vegetable oils. However, the composition may also contain other components, thanks to which the paint acquires certain properties. It will take about two to three days for alkyd dyes to dry completely; they cannot be called quick-drying.

Alkyd paints can last for many years, and are cheaper than water-dispersion paints. They reliably protect the wood from rotting, make it resistant to water and mechanical stress - in general, this is an acceptable material for processing wooden interior elements.

However, we must remember that almost all alkyd dyes smell strongly during the application stage. They cannot be called absolutely harmless, since an organic solvent is used in their production. However, after drying the smell disappears.

Popular manufacturers

The brands in demand include:

- Dutch Dulux, which supplies high-quality waterproof paints, it is possible to create an individual color using pigment;

- Finnish Teknos, specializing in the production of paints and varnishes for 70 years;

- Russian KrasKo, which produces special materials for dry or wet rooms;

- Luxens, which produces paints that can withstand up to 3 years of use when applied to the external walls of houses;

- Italian Aquastrong, offering odorless acrylic paints for external and internal work;

- Finnish Tikkurila, which produces base materials without color, pigments are introduced into the solution to obtain the desired shade (according to the Tikkurila Symphony, NCS or RAL catalogs).

Dulux supplies high quality waterproof paints.

Review of manufacturers

The market for paints and varnishes is very capacious. Both imported and domestic manufacturers are widely represented there, and they are increasingly promoting their brands.

The first 3 places in the ranking of the best suppliers of quick-drying enamels are occupied by the following companies:

- "Tikkurila" - Finland. It is a leading exporter of paints and varnishes to Russia. The company has a wide selection of high-quality, quick-drying enamels, presented in all price segments;

- "Hammerite" - UK. One of the best manufacturers of anti-corrosion enamels for metal protection;

- Yaroslavl paints are one of the largest manufacturers in the Russian Federation. The assortment of this company is popular among buyers, which is why the plant ranks 3rd in the ranking of the best suppliers of paints and varnishes in Russia.

Rating of the best odorless paints

The top popular odorless enamels include:

- Vinyl Matt and Diamond materials produced by the Dulux division, part of the Dutch chemical concern AkzoNobel;

- Elegant Vaggfarg Matt and Beckerplast 3 paints produced by the German company Beckers;

- Harmony enamels from the Finnish manufacturer of paints and varnishes Tikkurila.

Dulux Diamond

The material from the Dutch concern AkzoNobel belongs to the premium category and is characterized by increased wear resistance (10 times higher than that of standard interior paints). The service life reaches up to 25 years, the coating is designed for repeated cleaning using abrasives without the risk of loss of pigmentation. After polymerization, which takes up to 6 hours, a matte-type layer is formed; the manufacturer recommends applying the enamel 2 times (with intermediate drying). Dulux Diamond waterborne products are available in 130 different colours.

Dulux Diamond is a premium paint.

Dulux Vinyl Matt

Dulux Vinyl Matt paint forms a smooth matte finish, its increased density allows it to fill and mask small irregularities. The layer is designed for delicate washing using soft preparations. Vinyl Matt materials contain a copolymer dispersion and water and require 4 hours to dry completely. Enamels are designed for use in rooms with moderate air humidity and average operating load. There is a certificate allowing use in children's or medical institutions.

Beckers Elegant Vaggfarg Matt

Beckers Elegant Vaggfarg Matt paint for ceilings and walls is based on a mixture of acrylate latex with the addition of pigment and distilled water. The polymerization time is 4 hours, the layer can withstand up to 2 thousand passes with a brush (according to the manufacturer’s measurements). It is allowed to paint furniture components or surfaces made of plasterboard or chipboard. Before application, it is necessary to remove dirt and fill up uneven areas with latex putty; the final evaporation of traces of solvent occurs 30 days after application.

Beckers Elegant Vaggfarg Matt – matte paint for ceilings.

Beckerplast 3

Beckerplast 3 water-based matte enamel based on latex allows you to obtain a washable coating. The paint is recommended by the manufacturer for ceilings; it can be applied to pre-plastered walls made of concrete or finished with fibreboard, chipboard or plasterboard sheets. When applied and polymerized, a slight odor is released, hardening occurs after 3-4 hours.

During operation, the paint coating does not change color and does not peel off from the base under the influence of water vapor.

Tikkurila Harmony

Matte paint Tikkurila Harmony allows you to give the surface a velvety effect, suitable for lining, previously painted or plastered partitions. The manufacturer does not recommend using enamel for painting door panels or furniture. Distilled water is used for dilution; drying time from dust is 30 minutes. The paintwork is resistant to mild detergents; after treatment, the gloss of the coating can change.

Tikkurila Harmony gives the surface a velvety effect.

Paint selection

The next question that an interested person needs to solve is how to choose the right paint. In this situation, you can use the recommendations and advice of knowledgeable people, choose according to the opinion of buyers, but in order to avoid mistakes when choosing, it is better to understand this matter well yourself. Therefore, you should get acquainted with the assortment of the market, with the assortment of popular models, with the properties of different paints, with the specifics of their application. You should take advantage of the overview of descriptions and characteristics. You need to understand for what purposes the paint is chosen and what to pay attention to. You have to choose paints for concrete, wood and metal. Some of their characteristics include color, weight, and how much it costs. Their advantages and disadvantages should be critically examined.

It is necessary to make a choice taking into account your economic capabilities. To estimate the approximate cost of painting work, you need to know the average price of paints. Often you have to settle on budget options.

As a rule, a person collects available information using reference books, the Internet, and advice from friends. This article provides information on the rating of high-quality, quick-drying, inexpensive popular paints.

Properties of paints

Paint is a multi-component material designed to give an object the desired color and a whole range of new properties. Paint is determined by a whole set of properties.

The color of an object is an element of its design. Paint colors fill the entire visible range of the physical spectrum from black to violet. In addition to color, paints differ in visual perception by the presence or absence of shine, the appearance of a matte surface, the richness or dullness of appearance. Paints come in gloss, semi-gloss, matte, semi-gloss, eggshell, and hammer. According to this parameter, the market provides endless choice.

The technological properties of paints include their chemical composition, type of solvent, thickness, viscosity, heat resistance, weather resistance, and resistance to biological pests. Paints have specific properties - film-forming ability, covering power, hiding power. Properties such as odor and drying time are very important.

In order to maintain the elegant appearance of an object for a long time, the paint must be wash-resistant.

The main component of paint is considered to be a film former or binder. This component determines the adhesion of the paint to the substrate, and thereby the service life of the coating. The appearance and its preservation for a long time, the duration of drying also depends on the binder. The quality of the binder itself is determined by its chemical composition and preparation technology. The main types of paints - oil, alkyd, epoxy, emulsion, silicate - are determined by the chemical nature of the binder.

The color of the paint is determined by the pigment used. The heat resistance of the paint and its resistance to atmospheric influences are determined by the filler used - crushed mica, clay, talc, chalk.

Solvents are added to the paint to dissolve the binder. Thinners are used to reduce viscosity. The type of solvent determines the class of paint - water-dispersion or solvent-soluble.

Hiding ability characterizes the ability of paint to hide the real color of the surface being painted from an external observer. To assess this indicator, there are four classes of coverage and four gradations of contrast ratio. These indicators are taken into account when determining paint consumption per 1 square. m of surface.

The degree of gloss determines the amount of light reflected from the painted surface that falls on it.

German standards regulate the resistance of painted surfaces to wet abrasion. The indicator determines how suitable the paint is for surfaces that need to be washed frequently.

The suitability of paint for outdoor use is determined by its weather resistance rating. Determines the safety of the coating under prolonged variable climatic influences of sun, wind, rain, temperature, dust, and aggressive gases.

Sunlight and its ultraviolet component lead to discoloration of paints, and even to the destruction of the paint layer. Resistance is increased by special additives.

The surface of hydrophobic paints is not wetted by water. Water immediately flows down from a vertical surface or collects in drops on a horizontal one. This property is taken into account when choosing paint for the facade.

Adhesion determines the ease and strength of paint adhesion to a surface. In order to improve the manufacturability of the painting process, they try to improve adhesion in various ways.

An indicator that must be present in the set of paint characteristics is its environmental friendliness. The paint must not contain traces of mercury, lead, zinc, chlorinated phenols, or cadmium compounds. Substances whose fumes cause allergic reactions in people are not allowed in the paint.

Drying speed is one of the most important technological indicators. The productivity of painting work depends on it. After all, breaks waiting for the paint layer to dry greatly increase the duration of the entire work. Drying rates for quick-drying paint are as follows: drying from dust adhesion 0.5 - 1.0 hours, interlayer drying 1 hour, complete drying 4 - 6 hours. For comparison, not quick-drying paints dry from dust in 3 hours, between layers in a day, but completely dry in 1 month.

Features of finishing work

When carrying out finishing work, paint is applied to previously prepared and cleaned walls and ceilings. A layer of dust impairs the adhesion of enamels (regardless of the type of solvent and consistency); during operation, the paintwork will move away from the base. To remove material from the skin of your hands or tools, use warm running water and detergents.

To paint plank flooring, it is recommended to use drying oil paints that are highly resistant to abrasion and can withstand cleaning with detergents. Before starting work, it is necessary to seal cracks and holes from knots with putty, clean the boards from traces of rot and loose paintwork. To reduce absorption, it is necessary to cover the floor covering with antibacterial primer; after polymerization, a glossy varnish can be applied over the paint.

Required materials and tools

To apply, you will need a brush with synthetic bristles or a roller with a coat matched to the base solvent. To paint large surfaces, you will need a sprayer with an electric compressor to speed up the job while maintaining high quality. There are materials in aerosol cans with a capacity of 200 ml to 1 liter, but the container is suitable for painting small areas.

To apply paint you need a special brush.

When applying with a brush or roller, you need a tray with a separate ribbed plane that allows you to regulate the amount of paint on the pile or coat. The dimensions of the tool are selected depending on access to surfaces. For example, to paint narrow cavities you will need a roller or brush with a reduced width of the working section and an elongated handle. If you plan to apply a pattern, you should prepare a stencil or adhesive tape to mark the boundaries between surfaces of different shades.

Floor paints

Choosing floor paint is a multifactorial task. A wide variety of materials are used for the floor - planed boards, parquet, plywood, chipboard, cork, linoleum, concrete. Different rooms, living room, kitchen, have different requirements for the floor. For the bathroom, high humidity should be taken into account. Each room, each type of floor material has its own requirements for paint. Therefore, there are a huge number of types of floor paints.

There are two types of paints used for floors – transparent varnishes and opaque paints. Varnishes are short-lived and need to be renewed every two to three years. Dispersion acrylic paints are elastic, dry quickly, and withstand the effects of many chemicals. Serve up to 10 years. Alkyd enamel paints are not suitable for wooden floors; they take up to 20 hours to dry.

The Best Paints for Concrete Floors

Aquastrong

Aquastrong odorless floor paint made in Russia. This acrylic paint is used for painting cement-concrete and brick floors. Has good wear resistance. It has a gray and brown color and is matte in appearance. Complete drying time is 24 hours. Packages 2 kg, 6 kg, 12 kg.

Volume 6 kg costs 2896 rubles.

Aquastrong floor paint

Advantages:

- High wear resistance;

- Withstands several cycles of freezing and defrosting;

- Without smell;

- Resistant to aggressive liquids.

Flaws:

- Not marked.

Enamel for concrete floors “Profi” Tex

Penetrates deeply into concrete and wood. It does not dry very quickly and is used for painting floors in garages and warehouses.

A 0.9 liter jar costs 330 rubles.

Enamel for concrete floors “Profi” Tex

Advantages:

- Resistant to household loads;

- Good resistance to washing.

Flaws:

- Flammable;

- Harmful if inhaled.

Drylok Latex Concrete Floor Paint

The finest American made premium paint. It is considered the most wear-resistant. It dries completely within 5 hours after painting. When painted, it forms an abrasion-resistant coating. Has good water resistance.

A 3.78 liter can costs 5,110 rubles.

Drylok Latex Concrete Floor Paint

Advantages:

- No pre-priming required;

- Exceptional wear resistance;

Flaws:

- High price.

The best paints for wood floors

Betolux Aqua Tikkurila

Finnish fastest drying paint. The second layer can be applied an hour after the first. Absolutely odorless. Applicable for indoor use only.

A 9 liter package costs RUB 9,960.

Betolux Aqua Tikkurila

Advantages:

- The second layer can be laid 1 hour after the first;

- Does not require solvents other than water;

- Can also be used on concrete floors

- Completely odorless.

Flaws:

- Do not use where it may get accidentally wet.

Enamel acrylic paint “Profi” VD-AK-1179

Russian-made paints and varnishes.

A capacity of 10 kg costs 2650 rubles.

Enamel acrylic paint “Profi” VD-AK-1179

Advantages:

- Ease of application;

- Does not leave streaks or smudges;

- Absolutely odorless;

- Hypoallergenic;

- Increased light and water resistance.

Flaws:

- Not marked.

Which quick-drying floor paint did you choose?

How to speed up the drying process of paint

To speed up the process of solvent evaporation, it is necessary to increase the air temperature in the rooms and ensure air circulation along the painted surfaces. Electric radiators are used for heating, and the flow is created using fans. The procedure allows you to speed up the polymerization of paints based on drying oil or distilled water by 20-30%. It should be noted that with accelerated hardening, cracks or depressions may appear on the surface. The factory containers with paint indicate the necessary conditions for normal polymerization.

The best quick-drying paint for wood and chipboard

Painting wooden surfaces has its own nuances - the composition must provide reliable protection against moisture, mold, mechanical damage, and also adhere well to the wood.

Marshall Export Aqua

White, odorless paint, which, when applied to wooden or metal surfaces, forms a durable coating that is resistant to scratches and other mechanical damage. The enamel is easy to apply and dries quickly, has no odor.

Marshall Export Aqua

The paint can be used for furniture, doors, wooden windows, furniture, fences. Consumption: consumption up to 12 m2/l in 1 layer. For ferrous metals, Hammerite anti-corrosion primer is needed, for wooden surfaces for outdoor work - Pinotex wood-protective primer.

Pros:

- durable coating, resistant to impacts and scratches

- heat resistance +90°C;

- does not turn yellow;

- no pungent odor.

Tikkurila Pika-Teho

Acrylate, quick-drying paint for wood and for fiberboard, chipboard, odorless, from a well-known Finnish manufacturer, which adheres well to the surface and does not leave smudges. Drying period 2-4 hours.

Tikkurila Pika-Teho

The main purpose of the material is external painting of treated or untreated wooden bases - fences, walls, cladding boards. Completely matte Pika-Techo paint can be tinted in 120 colors from the Tikkuril “Wooden Facades” catalogue.

During the painting process, the air temperature should be no lower than +5°C, humidity – no more than 80%. Dries touch-free in 4 hours, completely dry in 10 hours. Consumption for a sawn surface is 4-6 m2/l, for a planed and painted surface – 7-9 m2/l.

Pros:

- almost no smell;

- fits well;

- Easily washes off hands and tools.

HUSKY SIBERIAN

Odorless, quick-drying wood paint for exterior use, based on linseed oil and alkyd resins. This composition can be used to treat building facades, doorways, fences and picket fences, stair railings, wooden ceilings and walls (not suitable for floors).

HUSKY SIBERIAN

Among the advantages of the material are the following:

- excellent adhesion;

- possibility of tinting;

- effective protection of wood for 10 years;

- high concentration of protective additives against rot, fungi, mold and insects.

Consumption for sawn wood is 1 liter per 5-7 m2, planed wood is 1 liter per 10-13 m2.

Pros:

- no odor, absolutely safe;

- 100% covering ability;

- no smudges, stains;

- washes well.

Additional recommendations

Recommendations for novice painters on applying odorless enamels for interior work:

- pour paint in portions into a flat tray equipped with a plane for removing excess from a brush or roller;

- The material should be applied to previously cleaned and prepared surfaces;

- during the painting and drying process, ensure ventilation of the room, despite the use of odorless paint;

- when performing painting work, use protective gloves or goggles with a respirator when using a spray gun;

- When painting, have a supply of solvent ready;

- apply enamel in 2-3 layers with intermediate drying (in accordance with the manufacturer’s recommendations);

- Freezing of paint during storage is not allowed; when ice crystals form, an irreversible decrease in the characteristics of the material occurs;

- Before painting, the glossy base must be sanded and wiped with a damp cloth to remove traces of dust;

- walls coated with lime should be brushed and soaked with soil.

Types of quick-drying paints

Each manufacturer has a range of quick-drying paints. They are convenient to use, their characteristics are at a high level, and most importantly, they make it possible to quickly complete repairs. Among the main types are:

Acrylic paints

Odorless acrylic paint is recommended for finishing rooms with high humidity. Thanks to the special components included in the composition, it is resistant to moisture and high strength.

Water-based

They are odorless, made on the basis of water with the addition of polymers and colored pigments, and are used for interior work. The main advantage of this material is safety; it contains no toxic components.

Decorative

Paints of the latest generation, which have the unique ability to provide not only the desired shade, but also highlight the texture - create an imitation of stone, velvet, silk, etc.

Types of interior work using paints and varnishes

Before starting interior work, you should decide which surfaces you will paint. The fact is that for different surfaces it will be better to use those types of paints that are best suited for them.

The most common surfaces that are treated:

- Batteries.

- Paula.

- Ceiling and walls.

- Window frames.

All of these surfaces are different in that they use different materials that will be exposed to different temperatures and humidity levels. For this reason, different types of paints, tools and different technologies are used during processing.

Quick-drying paints

Each of us makes repairs from time to time, or at least refreshes the previous one. Sometimes there is a desire to completely change the interior and improve the environment. Bringing interesting design projects to life is exciting, but the whole picture is spoiled by unpleasant chemical odors, which are always a faithful companion when painting windows, ceilings, radiators or floors. Most materials are characterized by their toxicity and the presence of toxic fumes, and this is unacceptable for use in a residential area.

But progress moves forward and does not want to stand still, so now you can easily buy odorless window paint that will dry quickly and is not so harmful. This simplifies the work of painters and is less harmful to health. In addition, you will be able to complete all painting work in the house without any discomfort.

At first glance, it is easy to choose odorless paint, but this is not entirely true, because the choice of material is also influenced by the surface that you plan to paint.

Among the harmless ones, several types of paint can be distinguished:

- Acrylic.

- Oily.

- Latex.

- Water-dispersed.

Each of the materials has its own distinctive qualities and properties, so it is simply impossible to single out something best from all.

The best quick-drying paint for the bathroom

A bathroom is a room with high humidity, so when choosing paints and varnishes you should be careful, giving preference to special compounds that protect the surface from moisture and mold.

TEX Profi Moisture resistant

Odorless bathroom paint from a domestic manufacturer that applies well, forming a breathable coating that is resistant to condensation.

TEX Profi Moisture resistant

The consumption for covering the surface in one layer will be about 7 m2 per liter, and when applied, as required to create a durable coating - in two layers - about 4.5-5 m2. Gloss level: matte. Touch dry time – 1 hour.

SHERWIN-WILLIAMS BATH PAINT

Washable, odorless, quick-drying wall paint that contains special antibacterial components that protect wet rooms from mold. The main purpose is to treat the walls and ceilings of bathrooms, toilets, basements, and laundries.

SHERWIN-WILLIAMS BATH PAINT

Designed for application to the following surfaces: wallpaper for painting, plaster, drywall, fiberboard, brick and stone masonry, metal and plastic, pipes and radiators heated to 80°C. Material consumption: 8.6-9.8 m2/l, drying time – 1 hour. Apply the composition using a roller or brush.

Pros:

- It washes great and leaves no stains at all.

Minuses:

- for rich color and smooth surface you need 2-3 layers.

Dulux Willow

An odorless, water-based coating that protects the surface from stains, repels moisture and withstands the effects of steam. Suitable for application on different types of surfaces - plaster, plaster, concrete.

Dulux Willow Tree

It is recommended to apply in two layers at temperatures from +5 to +30 degrees. Celsius, relative air humidity from 40 to 80 percent. To strengthen the base surface, increase adhesion and reduce paint consumption, it is recommended to prime the surface with a deep penetration primer.

Material consumption - 10-12 sq.m/l.

Pros:

- ideal;

- doesn't shine

- fingers don't remain

- if something touches the walls, it is easy to clean and the paint does not rub off