OSB, or OSB, is an oriented strand board, which got its name because of the production method: pressed chips are oriented in strictly specified directions and laid in several layers. The material is most often used as internal fences and ceilings; it has advantages over plywood and chipboard.

Oriented Strand Board.

Preparatory work

Before you begin work, you should know what preparation should be for painting and finishing OSB boards. Its quality determines the further consumption of the paint and varnish and its appearance.

Preparation stages:

- The sheets are polished to remove manufacturing defects.

- Fill cracks with sealant.

- Level the surface with putty (it is recommended to use an acrylic composition for this purpose).

- Sand the dried layer with fine-grained sandpaper.

- Apply primer.

Before painting OSB indoors, you should pay attention to the commercially available primer options. They come in three types:

- acrylic;

- alkyd;

- adhesive.

Acrylic primer is odorless. This primer is easy to apply and wash off from tools. The line of acrylic compositions includes antiseptic mixtures that prevent the appearance of fungus and mold. They are suitable for processing OSB sheets inside the house and for work related to wallpapering.

Alkyd primer. It is used only in conjunction with alkyd paints. This type of primer is universal: it is good for both interior work and when processing facade panels. The only drawback is the strong smell.

Adhesive primer. This composition is almost never used when painting OSB boards inside a building due to the quartz filler included in the base of the primer mixture. After using adhesive agents of this type, additional sanding of the surface is required.

How to paint an OSB board inside a house

When painting OSB boards indoors, it is important to select a non-toxic composition, and also take into account the specific use of the surface being painted.

Possible options:

- acrylic paint;

- stain and varnish;

- glaze azure.

Acrylic paint is considered the best option for interior work . Contains water and acrylates. After application to the surface, the moisture from the paint evaporates, and a protective polymer layer is formed on the OSB board.

Useful: Linen insulation: natural and environmentally friendly

Pros of acrylic paint:

- good adhesion and wear resistance;

- color variety;

- vapor permeability;

- UV resistance, color retention;

- protection of wood boards from damage;

- affordable price.

Acrylic paint can be used to paint the walls and floors of a room. After OSB treatment, the boards acquire a uniform tone.

Combining stain and varnish allows you to preserve the OSB pattern . This method is often used to make the coating original. First, a stain with a patina effect is applied, and then covered with polyurethane or vinyl varnish.

Glazing azure allows you to emphasize the OSB pattern and make the coating wear-resistant. For interior work, flowing acrylic compounds are used. Glaze strengthens the surface and gives the coating a rich shade.

Primer application method

Procedure for priming the surface:

- They prepare the area for the upcoming work: they clean out roughness and unevenness. Dust is collected with a vacuum cleaner. Joints and cracks are sealed with sealant.

- Mix the primer thoroughly until a homogeneous mass is obtained.

- Apply the composition with a brush or roller in an even layer, in the direction from joint to joint.

For rooms with high humidity, it is recommended to additionally treat the timber with a primer concentrate of the VGT group (for example, “Waterstop-acrylic”), since OSB releases resin that can bleed through the primer.

Technology of painting OSB boards

Before painting OSB floors or walls, you must carefully prepare the base. The uniformity of paint distribution and the stability of the coating depend on the quality of the work Experts recommend painting after installing OSB boards.

Useful: Plasterboard ceiling: do-it-yourself cladding

Surface preparation

The order of work does not depend on what to paint with - alkyd, acrylic or oil composition. The sequence of preparatory actions can be divided into two stages:

- surface cleaning;

- masking seams.

Sanding allows you to smooth out the uneven texture of the slab , hide its texture and ensure uniform coverage of the surface with paint. For work, it is better to use a sander and a medium-grain attachment (P120).

If it is necessary to obtain the smoothest possible coating, then first sand with large grains (P80), and then with fine grains (P200).

To mask seams and screw heads, use elastic putty, special tape or sealant. Work order:

- Clean the seams with a long-bristled brush. For large areas it is better to use a compressor with a thin hose .

- Fill the voids with putty. Seal joints with a width of 5 mm or more with a mixture of putty and sawdust.

- After drying (after 1-2 days), re-treat the surface with a sander.

Base primer

Before painting OSB boards, the surface must be primed. The following can be used as a primer mixture:

- water-based varnish intended for wooden products - acrylic-polyurethane or acrylic composition is diluted with water in a ratio of 1:10;

- alkyd varnish is an affordable alternative to the previous option; Before use, it is advisable to dilute the composition with white spirit;

- Adhesive primer - optimal for light-colored paints , as it protects against visible resin stains on the surface of the finishing layer.

The primer is distributed over the slabs using a roller or brush. Painting begins after the composition has completely dried.

Paint selection

When choosing paint for interior decoration, the following factors are taken into account:

- type of wood pulp and polymer included in the particle board;

- type of decoration;

- characteristics of the room.

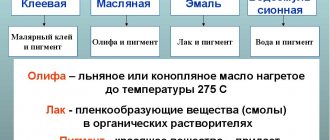

Before painting the OSB board inside the house, you should consider the main characteristics of commercially available LCS.

Oil paint

This type of material is rarely used due to its disadvantages: it takes a long time to dry, quickly loses its original appearance, and contains toxic substances. Most often, this paint is used to cover OSB floors or ceilings in the country.

Alkyd

A universal product, an alternative to oil formulations. Enamel penetrates deeply into the structure of OSB tiles and increases its service life.

Water-dispersed

This coating is not recommended for painting plywood. The coloring mixture, in addition to pigment and polymers, contains water, which deforms the layer.

Latex

This type of water-based paint contains latex. Eco-friendly and durable dye.

Varnishes, impregnations

They protect the surface from external influences. Aqualak applied over the paint will add an even glossy tint to the base color or emphasize the texture of the slab.

Impregnation for this type of building material should be based on resin solutions. Such mixtures are good at preventing the appearance of lignin (yellow spots).

Alkyd impregnation is incompatible with latex.

Features of painting wood boards

When thinking about how to paint OSB panels, you must remember that the material consists of 90% wood . Therefore, most paints intended for woodwork are suitable for painting. However, OSB boards have several features:

- Low adhesive ability. Some compounds do not adhere well to slabs. This is due to the presence of binding components in the panels. Resins do not absorb coloring enamel well.

- Texture of the coating. The surface of the building material is rough and uneven. This feature requires more thorough preparation of the base - grinding is required. In addition, pronounced texture increases paint consumption.

- Age of the slab. The older the OSB sheet, the worse the paint adheres to it. The surface quality of used slabs deteriorates over time, especially if the material has been outdoors. Therefore, it is better not to delay painting and do it immediately after installing the OSB.

For painting, it is better to use polymer-based paints, and it is better to avoid compositions with a water-soluble base - they protect wood boards from moisture less well.

Features of applying compositions to OSB boards with your own hands

Work is carried out in warm, dry, windless weather, preferably cloudy

Painting work begins in warm, windless weather, recommended air temperature is +10-25°C. It is advisable to avoid direct sunlight, which will lead to uneven drying. First of all, the composition is applied to the edges of the panels. These areas are characterized by the greatest absorption. Then the entire surface is evenly covered with paint. Movements with a brush (roller) are performed in one direction. It is recommended to apply a thin first coat and avoid wide overlap of stripes. After the paint has dried, a second layer is applied. If the expected result is not achieved, a third coat will be required.

There are several coloring options that can be used to finish the slabs.

Applying stain

The application of stain will allow you to emphasize the structure of the material, giving it a deeper shade. The composition is diluted with a solvent and applied with a spray gun. After drying, the surface is coated with polyurethane varnish.

Artificial aging

Artificial aging

To give the slabs a stylish decorative effect, special varnishes and patinas are used. The process is complex and consists of many stages:

- the surface of the plates is polished;

- a barrier primer is applied;

- the slab is coated with a white matte primer;

- the top layer of the coating is removed with a grinding wheel;

- the plate is treated with acrylic varnish in 2-3 layers;

- A black patina is applied to the OSB using a sprayer;

- The surface is polished to provide an aging effect.

The work takes a lot of time, it is necessary to take breaks and wait for each applied composition to dry. Artificial aging preserves the texture of OSB, but without noticeable chip protrusions.

Painting with primer paint

Facade primer-paints for OSB combine the properties of a finishing coating, primer and bioprotection. They have the necessary adhesion and good hiding power. They are applied to the textured surface of the slabs in two layers, in one the stripes are placed vertically, and in the second horizontally. The work is performed with a fur or foam roller, previously soaked in water. Before use, the primer paint is stirred until smooth. After drying, the result is an elastic, non-flammable and vapor-permeable coating with a service life of up to 10 years. The OSB texture does not show through it. The composition is sold in white, but there are thousands of color options.

Relief paint

Relief paint

To create a relief coating, silicone, latex or alkyd water-dispersed paints are used. Thick viscous compounds do not need to be diluted. They are applied to the primed surface with a wide spatula or roller. The layer should be 1.5-2 mm. The relief is created by mineral chips or filler fibers. The design is created manually by treating the surface with a dry roller. The intensity of pressure regulates the depth of the texture.

Painting slabs indoors

The process can be performed in two ways, depending on preference. But preliminary preparations are carried out, almost similar to those for external areas. The only difference is that moldings are not used to hide seams inside the house, unless provided for by the interior design.

Classic method

This method involves simply applying OSB paint to the wall surface. After preparing the base, the decorative mixture is mixed and applied evenly and sequentially in several layers to all treated areas. If putty was previously used, the painted surface will be uniform, but if it is absent, a strong or weak texture will be observed, depending on the amount of material applied.

Painting OSB without prior puttying allows you to preserve the texture of the material

It is much easier to treat the floor: after sanding, it is prepared and covered with 4-5 layers of clear varnish.

Decorative method

To decorate the base of oriented strand panels beautifully, you can use various techniques. For example, aging of the coating. Instructions:

- The slabs are carefully sanded and primed until smooth.

- Acrylic patina is being prepared. It is quickly applied to the desired areas or the entire surface. The longer the mixture sits on the base, the richer the color becomes.

- The solution is wiped off with a rag.

- Next, you need to paint the material with a light shade to highlight the darker areas.

An alternative method would be to simply layer several colors, but each subsequent layer should be “softer” than the previous one.

What paint compositions are used for OSB boards

Compositions based on water, acrylic and oil bases, resins and polymers are suitable as dyes. For better adhesion of paint to the rough surface, it is advisable to use a primer.

Variety of suitable coatings

Paints and varnishes.

Several types of paints and varnishes can be used to paint OSB:

- acrylic - they are environmentally friendly and moisture resistant; when hardened, they harden and polymerize into a durable layer;

- latex - have increased elasticity, are resistant to cleaning agents, non-toxic;

- alkyd – do not contain toxic components, have high strength, moisture resistance, and are resistant to ultraviolet radiation;

- polyurethane – are a protective and decorative coating for interior wall decoration;

- oil-based - they are thick, more difficult to apply than other types of paints, they are moisture resistant, but not quick-drying, unlike other types of paints, they give the painted surface water-repellent properties.

In addition to the listed compositions, primer paint is used for painting, which is characterized by increased adhesive properties, good vapor permeability, environmental friendliness, elasticity, resistance to fading and moisture. Primer paint is available in white; if necessary, a color of the desired shade can be added to it.

Criteria for choosing paint for interior work

Paint and varnish materials for surface treatment of OSB boards should be selected taking into account the following factors:

- purpose of the premises;

- type of surface (walls, floor, ceiling);

- the type of chip layer and binder used when pressing the boards.

Choice of paint.

When choosing a painting material, it is recommended to pay attention to the coefficient of adhesion to wood and the presence of additives. In addition, it is worth considering the number of layers for painting in order to calculate the total material consumption. This value can be calculated using the data indicated by the manufacturer on the packaging (paint consumption per 1 m² per 1 layer).

In addition, you should take into account the aesthetics of the finish depending on the type of interior - you can make the surface smooth or leave a relief structure.

Coloring materials are selected depending on the type of composition. For example, alkyd paints are suitable for painting any surface, creating a durable coating, but their consumption will exceed that of oil-based paint. Oil paints will have lower consumption and absorption coefficient, so they are recommended to be applied to floors.

Pay attention to: How to paint a toilet in the country

Water-based and acrylic-based emulsions are a good material for finishing OSB ceiling boards in a children's room or bedroom, since they are environmentally friendly.

Polyurethane dyes are suitable for rooms with high humidity, such as bathrooms and kitchens. Coatings made from polymeric coloring materials are durable and wear-resistant.

If the interior involves the use of natural materials, then a coating of transparent water-based varnish will help preserve the natural appearance of the wood. In addition to aesthetics, this varnish will protect the surface from moisture and minor mechanical damage.

For rooms where OSB is installed as a finishing floor covering, a smooth floor with a water-repellent effect is required. For these purposes, a thick layer of transparent epoxy is applied to the chip surface; after hardening, this coating becomes dense, hard and waterproof.

To improve the appearance and preserve the natural structure of the panels, they can be covered with stain and then secured with vinyl varnish or glaze. It will emphasize the naturalness of the finish, highlighting the color of the wood.

You should pay attention to the age of the panels: the older the OSB boards, the worse the paint will adhere and more thorough surface preparation will be required.

Why do you need painting?

OSB boards are painted for many reasons.

- Firstly, a layer of paint forms a stable, dense film on the surface, which provides additional protection from exposure to excess moisture and ultraviolet rays;

- Secondly, some coloring compositions have a fairly dense texture, which allows you to completely smooth out the uneven surface of the slabs. Not many people like the pristine appearance of this finishing material;

- Thirdly, painting is the most cost-effective way to protect and decorate the surface of OSB boards. Often this reason plays a decisive role.

Painting technology

How high-quality the coating will be in the end depends not only on the process of applying the paint and varnish material, but also on how correctly the surface was prepared.

CAREFULLY!

It is recommended to paint OSB boards only after they have been installed.

Preparatory work

The preparatory work stage includes several activities that should be performed in a certain sequence:

- Using sandpaper, you must carefully sand the surface of the slabs . This is necessary to smooth out the characteristic texture of the slab and prevent the penetration of primer and paint coating materials into its structure.

- alignment _ At this stage, the surface is cleaned of various irregularities and dimples in the areas of fastening with self-tapping screws. To do this, use an oil-adhesive putty mixture , and there is no need to fill the recesses between the slab elements with the mixture, since the seams will still become noticeable after painting. To obtain a perfectly smooth surface, it is necessary to sand off the completely dried putty;

- primer _ One of the easiest ways to prime a slab surface is to use a mixture of water and a water-based alkyd or acrylic polyurethane varnish designed for wood surfaces . The ratio in which the mixture is diluted is 1:10. Application is carried out as carefully as possible to obtain a uniform layer. An alternative impregnation method is a mixture of alkyd varnish and alcohol.

Main process

The process is a sequence of actions:

- The process begins by painting the perimeter of the slab . The edges are painted in 2-3 layers, after which, using a roller, the paint composition is evenly distributed over the rest of the surface.

- Next, they begin to apply the composition to the side of the slab that has not been sanded , and the layer of material should be very thin. The paint is applied in one direction.

- The next step is drying the painted slabs . At the same time, drafts and sudden changes in temperature should not be allowed.

- After the 8 hour period has passed, begin applying the next layer of paint , while you can maintain or hide the texture of the material as necessary.

What to consider when choosing a protective coating

The material for making OSB is mainly aspen; other species are used less frequently. Resins and polymeric substances are used to connect the chips. It is this feature that ensures that the surface is not wetted or impregnated with a large amount of products. It is also strictly not recommended to paint the slab with compounds that dissolve in water. For this purpose, products containing polymers are used.

A special feature of OSB boards is increased roughness and a large number of irregularities on the surface. Before painting, it is worth carrying out preparatory work. This will reduce the amount of paint and improve the quality of the protective layer.

If OSB was used for work outside and did not provide additional protection, then the quality of the slabs, as well as the appearance, decreased significantly. Before starting painting work, the material should be cleaned of dirt, sanded, treated with antiseptic substances, and after that painting begins.

The primer or paint should be applied in an even layer in one direction Source nashaotdelka.ru

For painting, it is worth purchasing compounds that protect the material from the sun, otherwise the slab will begin to delaminate and will require re-treatment after a short period of time.

The most suitable paint option for OSB for exterior use is a product that is made on the basis of polymer substances and is intended for application to wooden surfaces. Before painting the surface, preparatory work should be carried out. It is leveled, puttied and primed.

By painting you can even turn the surface into a “tiled” one Source i.pinimg.com

With the help of OSB you can realize the most daring and unusual creative ideas Source drevplity.ru

Choosing paint for exterior work

You need to choose a paint that is resistant to UV radiation. Otherwise, the paint and varnish material will quickly delaminate under the influence of sunlight, and the walls will need to be painted again.

For exterior work, it is better to choose polymer-based dyes that are suitable for coating wood surfaces. Such paints will reliably protect the surface from precipitation and the influence of ultraviolet radiation. They apply well and are used sparingly.

Before application, it is necessary to prepare the slab, level it, and then prime it. Large dents, holes, and OSB joints are best sealed with putty.

On the facade and external walls it is better to use oil, alkyd, acrylic, latex paints and others.

Oil paints. This type of dye is poorly absorbed into the surface and has good viscosity. It takes a long time to dry, but after drying it forms a dense protective layer with increased performance properties. Disadvantages: high cost, relatively short service life, long drying time, severe smudges. The dye mixture has a pungent odor and is toxic to humans, so it must be applied to a protective mask or respirator. To reduce the number of smudges, this dye needs to be applied 2-3 times. If you apply the coloring agent to a damp surface, it will quickly peel off. The drying time of the layer is at least 1 week.

Alkyd paints and enamels. Facade paint of this type penetrates deeply into the OSB, increasing its service life. After painting, the facade does not need to be varnished. This allows you to save on finishing. Alkyd dyes are low-toxic and dry quickly, but they can only be applied to a dried surface. Bubbles appear on wet slabs after applying enamel. After rain, the façade can be coated with alkyd paint no earlier than 2 weeks later. The composition is resistant to sunlight and low temperatures down to -35°C. After applying the mixture, the surface becomes flammable, since it contains flammable resins. To prevent accidental fire, a layer of fire-resistant emulsion must be applied over the alkyd paint.

Acrylic dyes. They easily smooth out roughness and paint the surface a uniform color. If the walls are primed with a composition that is not susceptible to mold, they can then be painted with waterproof façade acrylic paint. It is environmentally friendly, easy to apply, durable. Thanks to its water base, acrylic dye is highly resistant to fire, temperature changes, and UV radiation. The presence of water in the composition is a disadvantage, as it can cause swelling of the wood.

Latex water-based solution based on silicone, color, vinyl or polyvinyl. The material is environmentally friendly, elastic, resistant to mechanical damage, moisture, and household chemicals. Does not emit a pungent odor. Has a palette of colors. Apply with a sponge roller with large pores or a spray gun. The only drawback is the high price.

- Impregnations based on tall or linseed oil. They hide the natural texture of the slab and create a matte or slightly glossy protective film on its surface.

- Electrically conductive paint (conductive). Contains metal. Gives the coating greater strength and protects wooden slabs. Application requires complex preparation.

- Antipyretics. Protect wood boards from fire.

OSB walls are better protected from moisture penetration and exposure to UV radiation by polymer-based paints. Water-based compositions cope with this task worse. Surfaces coated with acrylic paints are easy to clean. But coatings made of alkyd resins and polyurethane reliably protect against mechanical influences.

Why and how to paint the facade

Lightweight OSB boards are formed from chips and wood shavings by pressing and gluing. This is an environmentally friendly material, warm, breathable, but susceptible to atmospheric agents.

This is due to its design: two outer layers consist of longitudinally directed chips, and the third, inner one, of transversely directed chips. Layers of wood chips are impregnated with glue, but are still susceptible to moisture, fungus, and other negative influences, and it also looks unattractive. The owners prefer to paint the outside of the slab:

- for protection from moisture and destruction;

- as an antibacterial treatment;

- to give the facade an attractive appearance.

If necessary, we will paint it, we will try to turn our house into a cozy, beautiful little house.

Let's try the slab to the touch - it is uneven, rough, on both sides. Is it good or bad:

On the one hand, painting will not be easy - the paint only applies smoothly to a surface that is perfectly free of dust, burrs, puttied, and primed. And what we have are continuous tubercles and pits.

On the other hand, everything even and smooth is boring. And we can create something unique. So it turns out that painting OSB (as OSB board is also called) is a troublesome, but interesting task. Then we will choose what to paint OSB on the outside of the house.

Features of OSB boards

The board is made up of wood chips joined and sealed with synthetic wax. The chips on the outer layer are located in the longitudinal direction, and in the inner layer in the transverse direction. There are types of OSB used for specific situations:

- OSB 1 Designed for use in dry rooms. Used as packaging or discreet furniture parts. It has low density.

- OSB 2 is used for the construction of load-bearing partitions in dry rooms, as internal wall cladding.

- OSB 3 is used for the construction of load-bearing structures in a humid environment. It is considered moisture resistant and is used for the construction of external rough cladding and strengthening of load-bearing structures.

- OSB 4 The strongest of the OSB options offered, but the disadvantage is the high cost. Designed for use in aggressive environments, when using mechanical stress, and at high humidity.

The thickness of OSB boards varies. Slabs of 6, 9, 12, 15, 18 and 22 mm are sold. To select the thickness of the slab, you need to know in advance what loads will be applied to it subsequently. So, for installing OSB boards in subfloors in walkable rooms and connecting racks when building a frame house, it is better to take boards with a thickness of 18 and 22 mm.

When constructing interior walls, slabs with a thickness of 9 and 12 mm are installed. When installing a rough ceiling, you can also use OSB 12-15 mm. For installation, the distance between the supports on which the OSB will be attached is determined. The greater the distance, the thicker the slab used should be.

What are the advantages of painting

The structure of the material ensures easy painting of OSB boards indoors with any paint and varnish materials. Painting OSB boards has the following advantages:

- simplicity and ease of paint application;

- increasing the moisture-resistant properties of the material;

- reduction of deformation due to water-repellent properties;

- aesthetic appearance;

- the ability to create any interior using painted flat surfaces;

- painted slabs are distinguished by their durability.

Pay attention to: How to paint a kitchen countertop

It is recommended to use pigment dyes for painting - the finish will last longer and will not lose its original appearance.

It is advisable to paint an OSB board after careful preparation of the rough surface: the unprotected material becomes dirty, is exposed to the negative effects of moisture, and the adhesive properties of the wood are reduced.