What is latex putty and its features

Latex putty is a solution used to eliminate defects in the base and level it. It is used for finishing ceilings, walls, and other structures after rough preparation.

The basis of the substance is a dispersed emulsion of polymer particles dissolved in water. The mixture also contains plasticizers, antiseptics, antifungal components, elasticity enhancers, and adhesion to the base. Due to its special properties, the material can be used for finishing surfaces in rooms with high humidity.

Latex putty is a popular material that is used to level walls and ceilings.

The material is biologically stable, so mold does not develop on the treated substrate.

How to apply

Working with polymer putty does not require high qualifications or special tools. The technology for applying the solution is as follows:

- Before use, buckets with the finished material must sit indoors. Suitable temperature for work: from +8 to +30ºC.

- The surface to be treated is cleaned of contaminants: dust, oil stains, etc.

- After this, a layer of deep penetration primer is applied to the wall.

This increases adhesion to the base and reduces moisture absorption. If you need to putty gypsum board sheets, then the joints between them are pre-glued with serpyanka. - Before application, thickened latex putty can be diluted with clean water to 10% of the volume.

Note: Any dried particles in the solution should be removed with a spatula. Otherwise they will leave scratches on the wall.

- The putty is applied to the wall with a spatula and leveled.

- Drying time depends on the thickness of the layer. Usually it is 4-6 hours. This is followed by finishing decorative finishing.

The developing lamp helps control the evenness of the material application during operation.

Expert opinion

Sergei Shablovsky

Plasterer

Often latex (and any other polymer) putty is used as decorative plaster. If the material is tinted, it can be applied in a thin layer like “Venetian”, imitating polished marble.

What is the difference from acrylic plaster

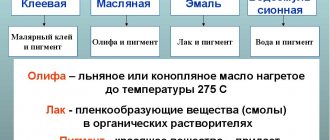

Latex putty contains a synthetic polymer. The acrylic mixture contains a polymer based on acrylic acid. The solutions have the following differences:

- latex material is more expensive;

- it can be used for treating any surface, but for wooden bases it is better to choose an acrylic mixture;

- latex solution forms a thin protective film, it is more elastic;

- acrylic composition has the best vapor permeability;

- latex is more resistant to moisture and wear, it is durable, and dries faster.

The main difference between acrylic and latex putty is the polymer base used in the manufacture of materials

Latex putty is the finishing putty, and acrylic composition is used for rough leveling.

Description of material

Latex putty is a popular type of mortar designed for leveling surfaces, filling cracks and small defects before final finishing and decoration. The material allows you to make walls, ceilings and other structures perfectly flat, smooth, suitable for absolutely all types of cladding. Putty will correct defects that still remain after rough leveling and can be very noticeable after painting and gluing thin wallpaper.

Latex-based finishing composition

The basis of latex putty is latex - a synthetic substance, an emulsion of dispersed polymer particles in an aqueous solution. In addition to the binder component, the construction mixture also includes other substances - hardening regulators, plasticizers, antiseptic additives and fungicides, elasticity, strength, adhesion enhancers, etc. Due to the presence of antiseptics and moisture resistance, the material is ideal for use in wet rooms, and the finished coating will be absolutely not susceptible to the appearance of fungus and mold.

Characteristics

Latex putty is suitable for indoor use. It is compatible with all substrates except metal. It is used for sealing seams in plasterboard sheets. This putty is distinguished by a wide range of colors.

The material is sold ready-made. It is packaged in plastic buckets of different sizes. The maximum layer thickness is 1 mm. The putty does not deform and is destroyed under the influence of temperature fluctuations. After latex, the surface can be finished with alkyd or oil paints, water-based emulsion.

Latex putty is sold ready-made, so it does not require any additional mixing.

Latex putty Tex

All the above characteristics fully apply to such a composition as Tex latex putty from a leading manufacturer of high-quality paint and varnish products in Russia.

All products of this brand, including putties, are certified and time-tested. Under the Tex brand, ready-to-use putty mixtures are produced for both interior and exterior work; for leveling and finishing various surfaces; for dry and wet rooms.

- Among all the putty compositions of this company, the Universal latex putty stands out, developed according to the recommendations of professionals, and which has earned the title “People's Brand”.

- This mixture in finished form and in different weights (from 1.5 to 30 kg) is packaged in appropriate containers, which is very convenient. When it is necessary to carry out small restoration work, it is enough to take a small container; To process large surfaces, large batches of putty mixture will be required.

A universal putty of white color with a cream tint is ready for leveling work in dry rooms on wall and ceiling surfaces made of concrete, brick, plasterboard, fiberboard, MDF and other materials for subsequent painting or wallpapering.

The putty mixture is easy to apply, economical in use and cools quickly. The drying time for latex putty is 4 hours. For subsequent priming or facing work, it is necessary to wait at least 12 hours.

Kinds

Latex-based mixtures vary in composition. They are similar in binding component, but may have different properties. According to consistency, there are such mixtures: ready-made and dry. The first type can be used immediately after purchase. Dry putty must be diluted with water in the proportions indicated on the packaging.

Depending on the conditions of use, the following compositions are distinguished:

- for internal or external work;

- universal;

- for rooms with high humidity;

- for living rooms.

Types of latex putty vary depending on the location of application and the type of surface being treated.

Latex mixtures are used to finish porous surfaces that must first be coated with a primer.

Characteristics of latex-based putty

The description of latex putty can begin with the disclosure of its component composition. As is already clear from the name, the main component of this putty mixture is synthetic latex.

It has excellent binding properties; resistance to water, alkalis and oil; It is resistant to atmospheric influences, ultraviolet radiation, and mechanical influences.

To regulate the properties of latex, other components are added:

- Plasticizers,

- Thickeners,

- Purified water,

- Stabilizing substances

- Fillers,

- Antiseptics,

- Modifiers, etc.

Thanks to plasticizers, the plastic and strength properties of the finished putty mixture are increased and the possibility of cracking is reduced. Antiseptic substances help prevent the appearance of mold on surfaces covered with latex-based putty.

All components in the total mass determine the properties of the finished putty mixture and the coating made from it, and also determine the scope of application of the latex putty.

Advantages and disadvantages

The material has the following advantages:

- minimal shrinkage, which protects the coating from cracks;

- high adhesive qualities - the putty is well fixed, penetrating into the structure of the base, and does not crumble;

- preservation of operational characteristics during temperature fluctuations;

- Possibility of purchase at any hardware store;

- richness of colors;

- easy and uniform application;

- resistance to moisture, direct sunlight, chemical inertness;

- elasticity - the coating can stretch along with the base;

- the possibility of applying a thin layer without loss of strength characteristics;

- ease of application - beginners can use a ready-made solution;

- high drying speed;

One of the advantages of latex putty is a wide palette of colors.

- Possibility of use in rooms with high humidity;

- ease of sanding the finished layer;

- compatibility with other materials;

- environmental cleanliness;

- abrasion resistance;

- Possibility of application for walls and ceilings;

- duration of storage in closed containers;

- the formation of a protective film on the surface of the base (it does not deform or collapse over time).

The putty has increased plasticity, which greatly facilitates the application of the solution to the walls.

The latex coating is suitable for subsequent application of paints and varnishes.

Putty can be purchased in buckets or bags of different sizes, so there is no need to overpay for the material. In the store you can buy as much mixture as you need at a specific stage of finishing work.

However, the material has disadvantages:

- if it freezes, the putty loses all its properties - when purchasing the solution, you must check whether it was stored in an unheated room;

- Latex finishes are expensive.

However, the consumption of the mixture is small, so it quickly pays for itself.

Advantages of latex putty

This composition has a number of advantages. These include: low consumption; good adhesion to any materials such as wood, concrete, plasterboard, chipboard; resistance to external influences, such as humidity, frost, temperature changes; possibility of applying the solution in a thin layer; minimal shrinkage during hardening.

When applied, the solution penetrates perfectly into cracks and acquires high strength after hardening, which reliably protects the surface from further shedding.

Scope of application

The material is intended for interior decoration. It is applied to the following surfaces:

- concrete;

- brick;

- tree;

- drywall;

- plastered surface.

Types of wall surfaces for applying latex putty

Latex putty is used for the following purposes:

- sealing plasterboard joints;

- finishing window slopes;

- forming the basis for subsequent application of paints and varnishes;

- restoration of wooden structures;

- sealing cracks in a concrete wall, the depth of which does not exceed 5 cm;

- creating a textured surface.

The mixture is used to process papier-mâché figures.

Application area.

Tex latex putty is indispensable for interior work, for high-quality finishing of walls, corners, ceilings, holes in them, and sealing seams between panels. Indispensable when creating relief on the surface. Profi putty has a wide range of applications; it is used as a material for finishing putty on plasterboard, wood, concrete, and mineral substrates.

The Tex brand provides a diverse range of latex putty. For me there are no limits to its use; it is applicable in almost all types of finishing work.

Specifications

Parameters vary depending on the manufacturer. However, you can consider the general characteristics:

- Consumption - depends on the structure of the base, its condition at the time of repair work, as well as on what layer the mixture is applied. To treat 1 m2 of area, 0.8-2.2 kg of solution will be required (provided that the thickness of the layer does not exceed 1 mm).

- Drying time - up to 3 hours (at a humidity of 65% and a temperature of +20°C). It will take a day to fully gain strength.

- Storage - the period is 1-2 years if the mixture is in the original closed container. Freezing the mixture is prohibited.

- Layer thickness varies between 0.5-3 mm.

- Material weight - 1-30 kg.

To create a layer of 3 mm, the consumption will be 5 kg.

The time for complete drying of the putty is 3 hours

If it comes into contact with the skin, the putty can cause irritation, so you need to wear gloves and protective clothing when working.

Scope of use

This type of finishing material is applied after laying the main leveling layers. The use of latex putty has a wide range. It can take a long time to describe, but in particular it is used for:

- filling joints (for example, in plasterboard sheets);

- elimination of small (up to 5 mm) coating defects;

- giving different surfaces a relief structure;

- filling cracks in concrete, plaster and other types of materials;

- processing niches and corners.

Note! Latex putties are absolutely not suitable for use on metal surfaces.

On video: how to choose putty.

Manufacturers

When choosing a putty, you need to pay attention to the manufacturer’s reputation and look at customer reviews.

"Tex"

The brand offers high quality material for outdoor use. You can buy 2 varieties of the mixture: “Pro” and “Universal”. The solution is applied in 1 layer. After drying, no cracks form on the surface and it can be sanded. The material is characterized by a long period of operation. The solution can be stored for at least 2 years, but the bucket must be tightly closed.

Tex putty is intended for exterior finishing of walls and ceilings

The disadvantage is the loss of technical characteristics if the putty freezes. The material is expensive.

"Profilux"

The material can be purchased in buckets weighing 15 kg and 16 kg. In this case, 1 kg is enough for 4-5 m2. The mixture can be dissolved with water. The putty is white in color, but after drying it becomes matte. Full strength gain occurs one day after application. The putty practically does not shrink and has a high degree of adhesion to the base.

Putty "Profilux" allows you to get a perfectly white coating

The material can be used to treat wooden surfaces. For such purposes, the solution is packaged in 250 g buckets. It is environmentally friendly. It can be combined with other finishing materials.

"Lakra"

This mixture is sold in plastic containers. 3 kg of composition is consumed per 1 m2. "Lakra" is intended for interior finishing work. The material is resistant to negative temperatures and is well fixed to the base. This is a finishing putty that can be used to eliminate cracks and irregularities on concrete walls, ceilings, and plasterboard sheets.

Lakra putty is used for indoor work

The finished mixture is characterized by a homogeneous consistency, but if necessary it is diluted with water. Even inexperienced craftsmen can work with it, since the solution is easily distributed over the surface of the base.

"Optimist"

A domestic product intended for interior work. The composition contains acrylic latex, thickener, fillers. White putty. The mixture must be applied in a layer of up to 3 mm. If the coating is too thick, it will crack and fall off. It takes a day for the solution to dry.

Putty "Optimist" is intended for interior finishing in dry rooms

The material is packaged in plastic buckets of 5 kg, 9 kg, 18 kg. It is suitable for finishing plasterboard sheets, chipboard, hardboard. The product can withstand 5 cycles of freezing and thawing. In summer, it is stored at a temperature of +5-30°C in a tightly closed container. Per 1 m2 of area, the consumption is 0.8-1 kg of solution. The shelf life of the material does not exceed 1 year.

"Hermes"

The product is intended for residential and technical premises. The mixture consumption is small: only 700 g per 1 m2 of area. You can purchase putty in 15 kg plastic containers. The thickness of the layer ranges from 0.5-1.7 mm. It takes 12 hours for the finish to dry. After this, the wall is further strengthened with a reinforcing primer. The shelf life of the product is 1 year.

Hermes plaster can be used in residential and technical premises with normal and high humidity

"Knauf"

A product from a German manufacturer with high adhesive properties. After drying, the putty does not lose its technical properties for a long time. However, it can only be used by professional craftsmen, since the work requires certain construction skills.

The advantage is the plasticity of the solution, so it easily falls on the surface and is distributed over it. The putty is intended for interior work. This is the best option for finishing surfaces for painting. The material can be purchased ready-made or in the form of a mixture that requires dilution with water.

Knauf putty is a plastic solution that has a high degree of adhesion to any type of material

The disadvantage of putty is the difficulty in sanding the layer.

"Vetonit"

"Vetonit" is a putty of medium price segment and quality. It is easy to work with, so even beginners can handle the finishing. It can be diluted with water. The mixture is intended for preparing internal wall surfaces for painting. You should not glue wallpaper onto the treated base, as the solution will be removed along with the finishing.

Vetonit latex mixture is suitable for puttying surfaces, but only indoors

The material can be purchased in 5 kg bags, although there are other packaging options. It is used for leveling plastered and concrete bases, plasterboard sheathing.

Vetonit should not be used in rooms with high humidity.

"Shitrock"

This material is supplied by Russia and the USA. It fits well and is evenly distributed over the surface of the base. There are no difficulties with further sanding. The solution is used for finishing plasterboard and concrete bases. It can also be applied to plastered and painted surfaces.

“Shitrok” is a white mixture that is used for puttying plastered and painted walls

This putty does not tolerate moisture, so it is not used for finishing bathrooms. After drying and sanding, the wall can be painted or wallpapered.

Wood putty Colorika Aqua

The product is environmentally friendly. It is sold in plastic buckets and is ready to use immediately after opening the package. This finish is optimal for wooden bases, but is also suitable for concrete and plasterboard surfaces. The mixture is odorless, has slight shrinkage, and dries quickly. It is easy to sand.

Colorika Aqua wood putty is intended for sealing cracks and preparing the surface for further painting.

General information

Peculiarities

As with all putty mixtures, the latex composition contains:

- Specialized substances that will impart plasticity and elasticity to the material.

- Additional additives that will give the material certain qualities.

- All kinds of fillers.

The main component in the manufacture of latex-type coatings is an emulsion of dispersed polymer particles in an aqueous solution. There are several varieties of latex depending on what type was used in the production of the composition, and the characteristics as well as the properties of the enamel will depend. Specialized components, for example, antiseptics, are often added to latex formulations. Such additives make it possible to use this material in a room with a high level of humidity, because the resulting coating will be resistant to the appearance of mold and fungal colonies.

Varieties

There are no big differences in the latex mixtures produced. Depending on the composition and manufacturing company, certain qualities of the material may differ. Based on the form of release, the following types of products are distinguished:

- A ready-made solution that can be applied immediately.

- Dry mixtures from which you need to make a solution yourself.

Latex compounds are available in a wide range of colors, making it easy to choose the perfect shade. In addition, latex compositions differ from each other in the volume of products produced. By area of application, the following compositions can be distinguished:

For wet areas.- For dry rooms.

- Universal type mixtures.

- For outdoor construction work.

- For interior decoration.

Now about the pros and cons.

Advantages and disadvantages

Like all types of putty mixtures, latex-based compositions have certain positive and negative sides. The advantages of the composition include the following characteristics and properties:

- Coatings can have a minimal degree of shrinkage.

- Certain varieties of latex coating are incredibly resistant to temperature changes. This quality makes it possible to use the material not only for interior, but also exterior wall decoration.

- Resistance to atmospheric precipitation.

- Large color palette.

- High adhesion to surfaces of different materials.

- Due to the viscous consistency of the solution, it will easily penetrate and fill cracks on the surface.

- When dry, a coating with high strength appears.

- Excellent elasticity.

- Ideal as a base for painting. Such a coating will not absorb paints and varnishes, which makes it possible to reduce paint consumption during final finishing.

- Ease of performing construction work.

- The resulting coating will not crack and will not crumble.

Despite the many advantages of latex material, it has certain disadvantages. Let's look at the main disadvantages of latex putty for walls:

- The prepared solution cannot be exposed to low temperatures. When frozen, the materials will lose certain qualities, and therefore even if the solution is thawed, it will no longer be suitable for use.

- The cost of such a coating exceeds the price of most types of putty composition. But such material can be applied in a layer 0.1 cm thick, unlike cement or acrylic putty, which makes it possible to significantly reduce consumption.

Now let's talk about the scope of application.

Area of use

Latex compounds can be used for both external and internal construction work. The mixture has excellent adhesion to almost all other materials. Metal surfaces in this case are an exception - it is not recommended to putty them with latex compounds. Such products are ideal for the following materials:

- Brick walls.

- Plastered surfaces.

- Concrete.

- Drywall sheets.

- Tree.

The scope of use of latex material is not limited to leveling surfaces. A similar mixture is used for the following purposes:

- Making a base for painting with alkyd enamels, oil-based compositions or water-dispersed compositions.

- Sealing joints from drywall sheets.

- Elimination of cracks and various defects on the surface.

- Puttying the slopes of window openings.

- Repair and restoration work for wooden structures.

- Creating different textures on surfaces.

- Finishing objects from papier-mâché.

Now about the manufacturers.

Tips for choosing

To choose the right finishing material, you can use the following tips:

- Determine the type of base. You should not buy a latex mixture if you plan to process a metal surface. For a wooden base, it is better to choose an acrylic option.

- Take into account the operating conditions. If all types of putty are suitable for interior work, then for exterior work you need to buy only those mixtures that are appropriately labeled.

- Give preference to a brand with a good reputation. But you shouldn’t overpay either. Today there are a lot of inexpensive materials that are not inferior in technical characteristics to popular brands.

- Do not buy material in stores that are not heated.

- Check the expiration date indicated on the packaging.

Buy latex putty only in heated stores

It is better to buy latex putty from certified sales points that can provide all the necessary documents and a guarantee.

Peculiarities

Latex putty is easy to apply. Proper preparation is a condition for successful repairs. To facilitate the work, you need to pay enough attention to the choice of manufacturer.

The material has recently appeared on the construction market, but is already popular.

The binder base of the mixture is latex, made from synthetic rubber. It allows you to obtain a material with unique properties, characterized by good strength and ductility.

Polymer additives are needed to improve the binder component, accelerate setting, and impart antiseptic and adhesive properties.

How to prepare and dilute thick latex putty

If the mixture has thickened, you can add water at room temperature and stir thoroughly. The container in which the remaining solution is stored must be tightly closed. To dilute the putty, use a drill with a special attachment. The amount of liquid added depends on how dense the composition is.

In most cases, to obtain the desired consistency, the mixture is diluted with water in a 1:1 ratio. The finished putty is pasty. Breeding is carried out in a closed room. The air temperature does not exceed +8 °C. Instead of water, you can use a soap solution, wallpaper glue, or antifungal primer.

A construction mixer should be used to mix the putty.

What is elastic putty

Elastic putty is understood as a putty solution based on synthetic polymers, which has high ductility, resistance to damage and cracking due to its ability to stretch. This material can bend, repeating the shape of the base, fully performing its functions and without deteriorating under the influence of surface tension.

The use of elastic compounds opens up new possibilities for finishing and protecting various materials and substrates. The mixtures hide defects or completely eliminate them, seal seams, and also protect problem areas from mechanical damage and weather conditions. Even dissimilar surfaces can be covered with a continuous layer of such putty - cracks will not appear after many years.

It is especially recommended to apply products with high elasticity in fragile areas, as well as for additional protection of monolithic structures. Otherwise, elastic compounds have all the properties of conventional putties, while being easy to level and have a long service life.

Latex putty application technology

To prevent latex putty for interior work from coming off the base after a short period of time, the application technology must be followed during its use.

Preparatory work

First, calculate the required amount of finishing material. The consumption indicated on the packaging, the type of base and its condition are taken into account. It is better to buy 15-20% more putty. To work you will need the following tools:

- narrow and wide metal spatulas (for applying and rubbing the mixture, treating hard-to-reach places);

- tool for forming corners;

- polyurethane float for sanding the dry layer (you can use a foam sponge);

- fine-grained sandpaper;

- roller or brush for treating the base with a deep penetration primer.

You will also need sickle tape to reinforce joints and seams.

Tools for applying latex putty

Procedure for the preparatory stage

Before applying putty, it is necessary to carry out the following preparatory measures:

| 1. Clean the surface from dust, dirt, grease stains. If the base is painted or plastered, the peeling areas need to be removed. To do this, use a narrow spatula. To remove paint you will need a hair dryer. The glossy surface is sanded to make it rough. In this case, the adhesion of the putty increases. | |

| 2. Treat the surface with a fungicidal composition if fungus or mold appears on it. | |

| 3. Apply a water-dispersion primer with deep penetration. It is necessary for removing dust and reinforcing the surface, increasing the adhesion of the base to the putty. Allow the primer to dry completely before applying the solution. | |

| 4. Seal deep cracks and joints. To do this you need a putty solution and a serpyanka. | |

| 5. Re-treat dried seams with primer. |

The material must be left for a day in the room in which it will be used: the mixture must acclimatize.

Application technique

The work is carried out according to the following instructions:

| 1. Preparation of the solution. This stage concerns dry mixtures that need to be diluted with water. You should not prepare a large amount of putty at once, as it hardens quickly. If the room is too hot, it is better to moisten the wall with a spray bottle. To prepare the composition, use only clean filtered water. | |

| 2. Applying the mixture to the surface. It is taken with a narrow spatula and transferred to a wide one, and then to the wall. The tool can be moved horizontally or vertically. The angle of inclination of the spatula is selected individually. A rule is used to check the level of finishing. | |

| 3. Surface grinding. It is carried out after the finish has completely dried. To do this, use a damp foam sponge. |

After completing the work, the tools are immediately cleaned of any remaining solution.

Rules for using putty

First, you need to purchase a certain amount of putty mixture, for which you should measure the walls and calculate the volume of material (according to the consumption indicated by the manufacturer on the packaging). Professionals usually “fit” into the specified consumption figures, while beginners are advised to purchase an additional 15-20% of the mixture. Also for puttying you will need the following tools and consumables:

- deep penetration soil (especially important for porous bases);

- sickle tape for seams and joints;

- a set of spatulas - wide (35 cm) for rubbing putty, narrow (10 cm) for applying mass and processing hard-to-reach places, corner for finishing corners;

- polyurethane float or foam sponge for grinding the putty layer;

- fine sandpaper;

- roller and brush for applying primer.

Surface preparation

Before starting repair work, you need to carefully prepare the foundation. To do this, remove all dirt and dust from the walls or ceilings. Unstable layers of whitewash, paint, and old putty are removed; if necessary, individual areas or walls are plastered in advance. Smooth, glossy substrates are sanded using sandpaper to improve the quality of adhesion to the building mixture. The joints of the plasterboard sheets are sealed - serpyanka is glued on, covered with putty, dried and carefully sanded.

After cleaning, the surfaces are carefully inspected again for the presence of mold and mildew. The walls are completely or partially treated with specialized compounds with fungicides.

Next, they are covered with a deep penetration water-dispersed primer, which will bind dust residues, strengthen the base, and reduce the absorption of pores. Allow the primer to dry completely, and only then proceed to the main stage of work.

Cleaning the surface before puttying

Preparing the mixture

If the mixture is sold in dry form, it must be diluted with water strictly according to the instructions. Add the powdered mass to the water in small portions and mix using a construction mixer. After receiving the putty with the desired consistency, the process of applying it to the walls begins.

The finished compositions are brought into the room 2-3 hours before puttying, so that the mass has time to reach room temperature. If the putty is too thick, it can be diluted a little with water (no more than 5%). It is recommended to put portions of the composition in a small container if the store container has a significant volume. When the putty is not covered with a lid, it quickly hardens and becomes crusty.

Surface application

Scoop latex putty from the container with a small metal spatula, apply the mixture onto a wide tool and rub it over the surface in a thin layer (no more than 3 mm). If the room temperature is more than + 30 degrees, periodically spray a little water from a spray bottle onto the walls, otherwise the putty will set too quickly.

When several layers are required, the first is allowed to dry for 3 hours, then the second is applied. At the end of the work, the surface is sanded with a construction float or a damp foam sponge (if the coating requires ideal smoothness for painting).

The putty is applied using a wide spatula

Precautionary measures

The material does not emit toxic substances, but to work with it you must follow some rules:

- Do not allow the mixture to come into contact with exposed skin. It can cause irritation or allergies. If this cannot be avoided, the skin should be cleaned and rinsed with water.

- Ventilate the room periodically.

- Do not throw the remaining mixture into the sewer or pond.

- Wear gloves, safety glasses and clothing.

When working with plaster mixture, the builder must wear goggles and special clothing to protect skin and eyes from contact with chemicals

There are a large number of materials with which you can not only prepare the base, but also make a fine finish. L atex putty is easy to use and does not cause difficulties during the application process. It is the best option for preparing the surface for further finishing.

Have you used latex putty for finishing work? What features of working with her did you notice? Share your opinion in the comments.

Why do you need putty?

Depending on the task performed, the masses are divided into:

- leveling,

- specialized,

- finishing,

- universal.

Specialized

With their help, certain tasks are accomplished, for example, sealing seams of gypsum panels without the use of reinforcing tape, “breathing” cracks, or joints of floor slabs. This category also includes dispersion putties for linoleum and laminate.

For window frames, wood putty, such as Olimp, is recommended

Leveling

The most extensive group of putties, their action is aimed at leveling the base. The choice of a particular mixture depends on the characteristics and characteristics of the surface, as well as operating conditions.

Oil-adhesive base putty TEX

Requirements for leveling putties:

- good adhesion (cohesion of surfaces) to the base and full compatibility with it;

- easy and reliable filling of all base defects;

- sufficient strength and durability.

In modern realities, putties are becoming increasingly popular, allowing the application of a layer of variable thickness from 1 to 25 mm.

Should reinforcing materials be used? If you have high-quality putty in your hands, additional meshes lose their relevance. The characteristics of the mixture should ensure the absence of cracks and shrinkage under standard operating conditions. Reinforcing materials are designed to work in areas with increased structural deformations or in difficult conditions.

From personal experience I can say that mixtures with a long and precisely standardized time of use have a slight advantage. For a standard working day and large volumes of work, putties with a “lifetime” of 8 to 24 hours are suitable. If we are talking about urgent work, I advise you to take a closer look at the materials in the “from 30 minutes to 4 hours” category.

Mechanized leveling putty has quite great prospects for speeding up finishing work. Its use makes it possible to produce up to 400 m² of area in one shift.

White leveling putty TEX

Finishing

Finishing putty for interior work is intended to obtain a surface ready for applying a finishing coating.

| Coverage type | Characteristics of putty |

| Under paint | The main requirement is the smoothness and evenness of the surface, which means our attention should focus on such an indicator as the size of the filler grains. The finer it is, the smoother the layer will be. A perfectly smooth, silky surface that does not require sanding is obtained by using putty with a grain fraction of up to 100 microns. Knauf and Pufas materials receive excellent reviews and my personal recommendations. They are quite plastic, easy to apply, have a long life time, during which they do not lose their qualities. Not the last place in the choice belongs to the issue of compatibility with the base and coating. Remember that paints have different penetrating, solvent and pH levels. I have often seen paint eat away at plaster, resulting in uneven coloring and staining. If there is a significant difference in the vapor permeability of the paint layer and the putty, peeling of the finishing layer may occur, the so-called “stocking” effect. |

| Under the wallpaper | The size of the filler grains in this case is not so important, however, I would not recommend taking materials with a fraction higher than 250 microns (for fabrics and thin wallpaper - up to 150 microns). The putty must be compatible with wallpaper adhesives, so I recommend choosing from a variety of latex and plaster adhesives.

|

| For wood | Acrylic, epoxy, polymer, oil and gypsum putties are suitable for preparing wood.

|

We recommend: Do-it-yourself wax for plaster – features of the material

Universal

A universal putty can perform the functions of finishing and leveling, and in some cases even special. Convenient enough for non-professional use and simple surfaces. However, you must understand that it will always be inferior to specialized mixtures.