Advantages and disadvantages

Polymer putty is a multifunctional preparatory coating with many advantages. Due to its high characteristics, it can be used for interior and exterior work. Its elastic structure with high adhesion allows you to create an even layer on the surface. Let's note the main advantages.

- This material can be used in different types of rooms: it can be used to correct problem areas on the surfaces of walls, ceilings, partitions, ledges or niches.

- You can use polymer putty to prepare for facing work in different rooms (living room, study, bedroom, nursery, hallway, corridor, home library, kitchen).

- It reliably protects the surface from the formation of an environment for the proliferation of microorganisms (fungus and mold).

- The material does not shrink during the drying process, which simplifies the correction of cracks and chips and eliminates repeated leveling of the surface.

- This material is characterized by resistance to high temperatures: the application layers will not deform in heated rooms.

- This material is resistant to moisture, so polymer putty can be used to treat problem areas of the walls and ceilings of bathrooms and toilets.

- The prepared material retains its properties for 12 hours if it is in an airtight container. During this time, problem areas of the foundation can be corrected.

- Polymer putty dries quickly and evenly. This is convenient for subsequent surface finishing work.

- It is characterized by high adhesion to the treated surface: it does not move away from the base after drying.

- It is resistant to chemicals, harmless to health, and does not release toxins into the air during application and operation.

- Polymer putty is easy to apply: even a beginner can correct the surface with its help.

In addition to its advantages, this material has several disadvantages. For example, if you use it for other purposes, leveling a metal base with a universal compound, you cannot count on reliable adhesion of the putty to the surface. The same can be said about wooden mixtures, for the processing of which a specialized composition is used. Other disadvantages of this material include the high cost when adjusting large areas.

Criteria for choosing putty

- First of all, you should consult with experienced finishers about the type of putty. If the walls and ceilings are uneven, then rough leveling using a starting compound will be required first. Then you can bring the surface to perfect evenness and smoothness using the finishing mixture. Some all-purpose putties combine the capabilities of starting and finishing products. But they are recommended only for relatively flat walls.

- The compositions also differ in the degree of readiness. The easiest way to work is with ready-made mixtures, which just need to be mixed before use. But dry powdery materials must be properly mixed with water to obtain a homogeneous viscous mass.

- Putties vary significantly in recipe. Cement-based mixtures are considered inexpensive and durable. A bright white surface can be obtained using a gypsum composition. Polymer and acrylic putties perfectly combine plasticity and versatility. But in cost they are superior to cement and gypsum materials.

- Based on applicability, a distinction is made between products for interior use, which are susceptible to exposure to moisture and temperature changes, and mixtures for external use. This feature must be taken into account when finishing a bath or kitchen.

Our review included the best putties. When compiling the rating, the following criteria were taken into account:

- appointment of the composition;

- readiness degree;

- chemical composition;

- price;

- expert opinion;

- consumer reviews.

Putty work

Puttying walls with your own hands is quite doable and is not a difficult task. The base must be dry and clean

This is important to remember and know, otherwise the entire puttying process will go down the drain.

Tools and materials

To carry out puttying work you will need:

- narrow (10-15 cm) and wide (40-60 cm) spatulas;

- putty material (starting, finishing);

- sanding block (with abrasive mesh);

- containers for diluting putty;

- foam sponge;

- drill, hammer drill, screwdriver;

- brushes, roller for priming walls;

- sandpaper or grout mesh;

- level.

Stage-by-stage execution of work

- Preliminary preparation. Initially, you should clean the surface, dry it, remove areas of grease, old putty, and paint. The surface should never be dirty, wet or frozen. This negates the degree of adhesion of any putty material. As a result of such an error, the putty may fall off in entire layers.

- Surface primer. This stage should not be neglected. The primer is applied between all putty layers, as well as after the final finishing layer before wallpapering. It provides additional strength to the connection.

- Applying putty. Depending on the base and purpose of the room (the choice of putty has already been discussed), one or another type of putty is applied, as well as the required number of layers. Each layer must dry well and then be treated with a primer. The starting putty is applied with a large spatula in portions, diagonally. In order to avoid visible transitions, each portion is applied with a slight influx onto the previous layer. The tool must be held at an angle of 30-35º relative to the surface. The finishing layer is applied no earlier than a day later. A narrower spatula is used, and the layer thickness is reduced to 2 mm.

- Final primer. It is carried out immediately before wallpapering the walls.

Puttying corners

Smooth and clear corners are very important for walls on which you plan to glue wallpaper. This process is very responsible and a little time-consuming for beginners.

If necessary, you can use a silicone tube or a plastic pastry syringe, through which the required amount of putty mixture is squeezed out. Next, the corners are sharpened with abrasive.

Slope putty

Slopes are puttied using the same method as corners or walls. However, the process itself is quite painstaking, and it is quite difficult for beginners to cope with slopes. It is recommended to use an angled spatula and check the evenness with an abrasive.

Types of putties

Today, manufacturers offer the following types of putty depending on its composition:

- Plaster.

- Cement.

- Polymer.

In addition, as can be seen in the photo of putty mixtures, they are divided into:

- leveling;

- decorative;

- universal.

Leveling putties also have another name - starting or first layer putties. Purpose – leveling the wall surface after applying plaster. A distinctive feature is strength and high adhesion. Most often, cement-based mixtures are used as leveling.

Decorative compositions are used for finishing walls, before wallpapering or painting. They are applied on top of the leveling putty. Such mixtures are distinguished by a small fraction of the constituent components. Thanks to them, ideal evenness of the wall can be achieved.

Universal type putties are complex mixtures. This is a good solution for those who are new to renovation. Such compositions can be used to seal cracks, remove chips, and fasten gypsum blocks. In addition, they can be used for decoration.

The best starting putties

The distinctive features of starting putties are high strength, excellent adhesion and large grain size. Such compositions are used when leveling walls and ceilings after plastering or for application to an unprepared base. The experts selected several high-quality compounds.

Volma Standard

Rating: 4.9

Volma Standard starting putty is well known to builders, both in Russia and abroad. The material has proven itself to be excellent for leveling the surfaces of ceilings and walls. Experts recommend using the composition on concrete and gypsum-containing bases located in dry rooms. The putty deservedly became the winner of the rating.

Professional finishers manage to create an ideal coating using the starting composition, after which you can begin wallpapering or painting. The mixture is perfectly applied thanks to the binder gypsum and the introduction of special modifiers. Additional advantages of the material include high thermal insulation properties and ease of grinding.

Advantages

- versatility of use;

- plastic;

- affordable price;

- ease of application;

Flaws

- takes a long time to dry.

Features of polymer mixtures

In the photo we see how to properly dilute and apply polymer finishing putty to a spatula

Polymer putty for interior work is a relatively new phenomenon in the construction market, but quickly gained popularity.

Finishing specialists often advise using it, since the polymer lasts much longer and has a number of positive qualities:

- It does not shrink naturally and does not deform when drying, as often happens with cement-based mixtures.

- Has high adhesion to any mineral surfaces, be it cement, stone or concrete.

- It has high vapor permeability, so it can be used on external walls without additional insulation.

- The polymer mixture dries evenly, so you don’t have to worry about the appearance of various defects.

- Very simple application instructions. Even a beginner can handle the job, unlike cement or gypsum, which requires experience and knowledge.

- High resistance to mechanical damage.

Application of polymer finishing putty does not require special skills or tools

Simply put, polymer putty is considered one of the best on the modern market, and its only significant drawback is its relatively high price. As for application, due to the long hardening time in diluted form, it is very convenient to work with the polymer; it can be stored in a container for up to 12 hours, and to make sure of the ease of application, we suggest you watch the video in this article, which shows and explains everything in detail .

Also, the disadvantages include the impossibility of applying putty to non-mineral surfaces, with which it has very poor adhesion

Therefore, if your walls are built of wood or metal, then it is better to pay attention to other mixtures; polymer putty will not suit you

Composition of finishing material

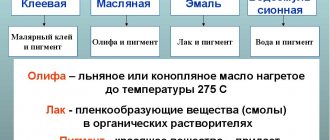

The types of putties depend on what material is the binding component in them. There are three types in total:

- Cement. As the name implies, the binding material in it is cement. This material shrinks, so it must be applied in several layers. It tolerates exposure to water and temperature changes well, which allows it to be used in exterior decoration;

- Plaster. Accordingly, the binding component here is gypsum. Unlike cement ones, they do not shrink. However, they can only be used for interior work, since they absorb water well and are destroyed over time;

- Polymer . Artificial materials such as latex and acrylic are responsible for the connection of the components in it. A universal finishing material with virtually no disadvantages. The only thing, perhaps, is the higher price. However, the material is used quite economically, and working with it is easier and faster.

Choosing putty for drywall

The main mistake when choosing building materials used for processing plasterboard materials is that, according to the majority, such work is pointless. During the renovation process, you may find that the wallpaper refuses to come off the walls. This is due to the fact that the gypsum mixture is glued to the paper. Wetting the material will not give any result, since gypsum board is an incredibly soft material, which will leave indentations from the tools used.

To remove seams and other irregularities, it is better to use professional products. This is especially true in cases where the working coating will be painted, but filling the voids alone may not be sufficient. In some cases, you should use reinforcing tape. Before wallpapering, you can only treat the most obvious irregularities, and level the rest with starting plaster. It should be understood that the quality of inexpensive products is questionable, and since repairs are carried out infrequently, you should not save.

Advantages of modern finishing materials

To date, three types of putty have been developed. They differ in their composition, purpose and method of application.

These include:

- latex;

- acrylic;

- polymer.

For finishing the external walls of a building, it is recommended to choose acrylic or cement-based polymer compounds. The difference between polymer putty is the addition of a large number of different polymers, which ensure tight adhesion of the components to each other.

The main advantages of this material are:

- can be used for any type of finishing work. The material fits perfectly on the concrete base without any defects;

- has increased adhesion;

- moisture-resistant coating;

- without harmful odors;

- excellent vapor permeability;

- uniform drying of the treated surface;

- environmentally friendly composition. There are no toxic components present here;

- withstands sudden changes in temperature;

- does not deform on the plane;

- resists chemical reagents.

The main purposes of polymer putty are finishing concrete walls and cement structures. The finished material forms a smooth surface and helps to get rid of visible wall defects indoors.

It is not recommended to be applied to wood or metal surfaces. The fact is that they are not suitable for such material. After some time, the layer will peel off or numerous cracks will appear around the entire perimeter of the treated area.

Which putty should I choose in which situation: gypsum or polymer?

Knowing the differences between gypsum and polymer putties, it’s time to stop asking the question which is better, and choose the right material depending on the situation.

Remember:

- for a gypsum base - gypsum finishing composition, for a cement base - any option;

- for wallpaper - plaster, for painting - polymer (the fineness of the fraction of the polymer solution will ensure an ideal surface);

- in a dry room - gypsum, in a damp room - polymer (it will protect against moisture, mold and mildew);

- for ordinary drywall - gypsum, for moisture-resistant drywall - polymer;

- for old plaster (or putty, paint) - only polymer;

- for plywood and chipboard - only polymer, pre-impregnated with an antiseptic;

- outdoors - only acrylic polymer.

Is it possible to apply finishing polymer putty to gypsum putty?

We won’t ask why, but will simply answer) Experts do not recommend laying a polymer layer on top of the gypsum layer for three reasons:

a composition with a lower pH value cannot be coated with a composition with a higher pH value;

the strength of the base must be higher than the strength of the new layer;

lower vapor permeability of the top layer can provoke peeling if the base is wet or moisture can come from the other side of the wall.

What are the advantages of polymer putty?

First of all, this is, of course, versatility. If in the case of other types of this material it is necessary to precisely select depending on the type of work (leveling, finishing), as well as the location where it is carried out, then the polymer version is used everywhere. But most often it is used in finishing, when you need to create an even, visually attractive layer.

The plastic structure and good adhesion of the putty allows it to fit equally well on any surface. Cement, plaster, gypsum, concrete and even polyurethane. If the container is closed, then the already diluted putty can be stored for up to 12 hours and successfully used after that without losing its performance characteristics.

The absence of shrinkage and cracking is also important, as it allows the material to be applied in one layer. Finally, this putty hardens quickly, which significantly reduces working time.

Material properties

If we talk about the composition, it includes various plasticizers, antiseptics, binders and hardeners. The connecting link is the polymer component, thanks to which the use of latex putty allows you to protect walls from high humidity due to the formation of an elastic layer, which is durable and easy to process (see also the article “Materials for finishing ceilings - a huge selection for every taste”).

The main advantages can be considered the following factors:

- With this composition you can apply the thinnest layers, even if they are thinner than a millimeter, the coating will be reliable and durable. Therefore, if you are faced with the choice of latex or acrylic putty, and want to cover the walls with the thinnest layer, then the choice is obvious. Acrylic cannot be applied in a thin layer without losing its strength properties.

- Wide choice of colors. You will avoid unnecessary costs, time and money on purchasing paint and coloring, since you can purchase a latex composition of the desired color. In fact, this is a very big advantage that no other type of mixture can provide.

In the photo: this group of materials gives the surface the desired color

The material is very convenient to work with - the mixture is sold ready-made, so it is impossible to make a mistake when diluting and creating the wrong consistency. Simply open the bucket and get to work

The elasticity of the composition simplifies its application, which is very important when doing DIY work

Different packaging of the material will help you purchase the right amount, which will save significant money.

Another very important property is the highest adhesion to almost any substrate. The composition works on the principle of liquid rubber - it fills all cavities and irregularities and adheres tightly to the surface. When hardened, the putty forms a film that does not crack or crumble, which distinguishes it favorably from acrylic and cement compositions

You do not need to be afraid that in places where the layer is thin, cracks will form and the coating will crumble.

This type of product also has some disadvantages, but they are few, which once again indicates high quality:

The biggest drawback is the price. But if you take into account such factors as complete readiness for use immediately after purchase, ease of use even for inexperienced specialists and ready-made color, then it becomes clear that the cost is completely justified. And one more important factor: if the composition freezes during storage, its properties deteriorate significantly.

You are unlikely to be able to work with such a mixture, so it is better to check the production date when purchasing and pay attention to the conditions in which the products are stored; in a cold pavilion, as a rule, such goods deteriorate.

What is the best way to use putty for interior finishing?

Both dry gypsum and polymer-based putty are prepared only before using it for finishing. To do this, prepare the necessary equipment: a container in which the solution will be mixed, an electric drill with an attachment to give the substance the desired consistency, and a bucket of water for rinsing the attachment.

According to the instructions, pour the mixture into a prepared container with water and give it a little time to swell, then mix using a drill attachment. It is better to knead several times with minute breaks.

For startups, preference is given to gypsum-based putty. Before applying the material, the walls must be cleaned of dirt and primed with a deep penetration compound. If you use plasterboard for finishing, you must cover the joints between the sheets and the screw caps with a solution, having previously glued a sickle mesh to them.

If the quality of the surface is low, then the walls are treated in several layers, using a wide spatula. Be sure to dry each layer before applying the next one. Then they are polished using a special grater with an abrasive cloth. You can sand the walls with ordinary sandpaper or a mesh adapted for this purpose.

The finishing layer is used to finally level the walls, and it is made either with gypsum putty or with a polymer base. The latter does not require additional processing and has a dazzling white color. In addition, polymer is easier to work with: they are more elastic and have constant strength, so they can be sanded at any convenient time.

And the gypsum must be observed in terms of its adhesion to the base. You can’t let it dry as much as possible, otherwise you won’t be able to sand the surface. This happens approximately 4 hours after applying the last layer.

Gypsum and polymer putties have different layer thicknesses, which can be applied to the surface during interior finishing. Gypsum is applied in a thicker layer, so significant defects can be eliminated quickly. But it is not recommended to apply a solution thicker than 10 millimeters, because the strength of the plaster will decrease.

Working with gypsum and polymer putties.

But the polymer composition has a thin layer of application, and it is difficult and time-consuming to repair a significant defect. Of course, such putty is consumed per square meter in smaller quantities than on a gypsum base.

Surface putty technology

Application of polymer mixture

When applying polymer putty, the most important thing is to adhere to the basic rules:

1. Apply the solution only to the prepared wall. It is necessary to remove dirt, grease stains, mold, etc. To degrease walls, gasoline or acetone is recommended. This is a very important stage, on which the adhesion of the putty to the surface completely depends.

2. Pre-treat the wall with a primer that contains antiseptics, which will be the best prevention of the formation of mold or mildew in the future. A primer is also needed for better adhesion of the solution to the surface.

3. Dilute the putty as described in the instructions. The finished solution should not spread, but remain plastic.

4. Apply the polymer mixture to the wall with a spatula (no thicker than 3 mm) and after drying, sand it with coarse sandpaper.

5. Apply a layer of primer again. Repeat alternation until the finishing layer.

6. If there is a finishing layer: after some time, treat the surface with sanding paper (zero). Using circular movements, it is easy to achieve a perfectly smooth snow-white surface.

If you strictly follow the sequence when performing work, you can achieve perfectly smooth walls that will not need alteration or restoration for many years.

Applying gypsum mortar

The layer of gypsum material is much thicker; serious flaws can be quickly eliminated with its use. A single application layer of no more than 1 mm to avoid possible cracks. The polymers are applied in a very thin layer, which virtually eliminates the possibility of eliminating large defects. This is possible, but it will be very expensive and too expensive.

Important! Gypsum mixture and polymer-based putty are applied in different layers when working on the surface of the walls.

Gypsum putty is ideal for applying the starting leveling layer. Having thoroughly cleaned the walls of dirt and primed them with a deep penetration agent, you can begin applying the solution:

1. If you are puttingtying drywall, you need to cover with the mixture the joints of the drywall sheets and the holes above the screw heads. To do this, you must first stick a sickle mesh onto the treatment areas.

2. When finishing surfaces of poor quality, they are treated with a wide spatula, applying several layers of mortar.

3. Before laying the next layer, it is necessary that the previous one becomes completely dry. The last layer is sanded using a special grater with an abrasive cloth. Sandpaper is also suitable for these purposes.

The most popular brands of polymer putties

The best putty mixtures based on polymers are the following brands of putty:

Vetonit

Vetonit polymer putties have the following advantages:

- naturalness of the composition;

- environmental Safety;

- ease of application;

- ease of grinding;

- good sound insulation properties;

- efficiency;

- possibility of application in two ways – manual and mechanized;

- reliability and convenience of packaging.

Hercules

Polymer putty Hercules is characterized by high strength, resistance to low temperatures, and moisture resistance. It is convenient to apply. Used for interior and exterior work. Application thickness varies from 0.1 to 5 mm.

Bergauf

The advantages of Bergauf polymer putty are its snow-white coating, ease of subsequent processing, quick drying, and strength. It is intended for finishing putty.

Shitrock

Shitrok polymer putty is a material used for interior decoration.

Polymer-based putty materials are an excellent choice. They are appreciated by both professional builders and novice amateurs.

The main rule when choosing polymer putty is to focus on products from trusted brands. A well-known brand is a guarantee of quality.

Advantages

Polymer putty has the following advantages compared to other types of putties:

- Stability and reliability.

- Fast drying.

- No shrinkage during drying.

- Zero chance of cracking and shedding.

- Ease of application on various types of substrates.

- Ideal for indoor work.

- Possibility of independent use. No skills or experience required.

- High adhesive properties.

- Versatility. This product can be applied to various surfaces.

When comparing gypsum and polymer putty, it is necessary to note the higher degree of moisture resistance of the latter. Therefore, polymer-based materials can be safely used when finishing bathrooms and toilets.

Cement-based putty mixture

Cement putty, sold in the form of a dry mixture, is universal; it can be used for both interior and exterior work. The solution prepared for puttying is a mixture of sand filler, binder (cement) and solvent (water).

Its main advantages:

- Good strength indicators.

- Excellent moisture resistance.

- Possibility of eliminating irregularities greater than 1 cm.

- Low price.

Main disadvantages:

- The structure is more grainy than other putties.

- The applied mixture often shrinks after drying, which is why it is necessary to make a second layer.

- Cement putty is inelastic and may develop microcracks over time.

- Cannot be used on wooden surfaces.

- Difficult to process.

- Has a yellowish tint.

Which is better?

Latex and acrylic putties cannot be applied to surfaces thicker than 3-5 millimeters. If you need to hide large errors on the surface, or there are serious defects on it, it is best to use a polymer-cement type of putty, which can be applied in a layer of up to 20 mm.

Speaking about polymer-cement putty, it is important to note that its technical characteristics are much higher compared to others. This variety is considered frost-resistant, moisture-resistant, moisture-repellent and environmentally friendly in composition

Before purchasing putty, be sure to consider the following points:

for what finishing work you will need it; in what conditions will the surface treated with putty be located (it is important to take into account the regular temperature regime, as well as its changes); You should choose the right manufacturer to purchase high-quality building materials that will serve you for many years.

Manufacturers offer two types of putty: dry and ready-made. Of course, there are fewer problems with the second one, because you just have to open the jar of the mixture, and the first one will need to be diluted according to the instructions. However, the compositions of these products are almost identical. Ready-made options are a little more expensive, and dry ones will require additional time and effort to prepare.

Uneven walls and ceilings

I would like to remind you that in order to smooth out all the unevenness and discrepancies of the ceilings and walls (from 5 to 60 mm), as well as to seal the seams and cracks, we first use plaster.

Leveling walls with plaster

It is this that allows you to obtain a smooth but slightly rough surface. However, ideal surface smoothness can only be achieved by leveling with putty.

Putty is represented on the Russian market by many manufacturers, including the well-known KNAUF, as well as Volma, Saint-Gobain - the brand "weber.vetonit", "Stroymontazh MS", "Starateli" - the brand "Osnovit" , "GK Keraton" - the "Litokol" trademark, "United States Gypsum" - the "Sheetrock" trademark, "Henkel", "Unis" - the "Ceresit" trademark, "Ural Construction Mixes" - the "Bergauf" trademark.

Material characteristics

Polymer putties are intended for high-quality finishing of surfaces, filling small cracks, leveling depressions or for leveling unevenness with an ultra-thin layer, as finishers say, “to tear off”. Apply the putty to a layer of gypsum, cement plaster or directly on smooth bases (concrete, gypsum board, gypsum fiber board) after priming the surface with the appropriate composition. For monolithic concrete, a soil is used that creates roughness and increases the contact area of the base with the putty, and for plaster, gypsum board, gypsum fiber board - it reduces absorbency.

The basis of the mass of polymer putties is the filler. This can be finely ground marble, limestone, dolomite and similar light-colored materials. In addition to them, the composition includes polymer glue, stabilizer, plasticizer, and modifying additives. Putties are produced in the form of dry mixtures and plastic, ready-to-use masses.

ScionFresh putty stains can be removed with water, while dried ones can only be removed mechanically.

ShutterStock

When working with putties, tools made of stainless materials are used.

ShutterStock

Containers and tools are washed with water after completion of the process.

ShutterStock

To prepare a solution from a dry mixture, the contents of the package are poured into a container with water in the proportions specified by the manufacturer and stirred with a construction mixer until a homogeneous mass is obtained. In this case, obtaining high-quality putty largely depends on the qualifications and conscientiousness of the master.

Some manufacturers of ready-made putties allow them to be diluted with small portions of water (from 30 to 50 ml per 1 kg of weight). This way you get the most comfortable solution consistency for work. But due to excessive addition of liquid, the putty may lose its beneficial properties. This usually leads to increased shrinkage of the material and deterioration of its adhesion to the base. It is strictly not recommended to add anything other than a small amount of water to the putty. These actions may damage the product.

Ready-made polymer putties (paste-like) are prepared in production. To obtain a homogeneous mass from the filler of the smallest fractions and other components, a certain mixing speed and a special temperature regime are required, which cannot be achieved on site. Therefore, ready-made putties are somewhat more expensive than dry mixes.

However, they also save effort at the stage of preparing the mixture. It is not difficult to restore their uniform consistency and working properties of the composition after storage. It is simply mixed with a construction mixer at low speed. The elastic pasty mass is easily distributed over the base in a thin and even layer. It simultaneously levels out unevenness and eliminates the smallest surface defects, which is necessary for subsequent painting and wallpapering.

Sheetrock SuperFinish

On the Russian market, ready-made polymer putties are represented by many companies, including Knauf, Cedrus (Osnovit brand), Saint-Gobain (Weber brand), Starateli, Bergauf, Danogips, Henkel.

Ready-made putties

| Name | Rotband Pasta | Vetonit LR paste | LR pasta | SuperFinish | Ceresit IN 95 | "Elisilk" PA39 W |

| Manufacturer | KNAUF | Weber "Saint-Gobain" | Bergauf | Danogips | Henkel | "Osnovit" |

| Layer thickness, mm | 0,2—2 | 0,2—3 | 0,1—1 | Up to 2 | Until 3 | 0—2 |

| Consumption per layer 1 mm thick | 1.6 kg/m² | 1 l/m² | 1 kg/m² | 1 l/m² | 1.7 kg/m² | 1.6 kg/m² |

| Drying time 1 mm, h | 24 | 8 | 4 | 24 | 4,5 | 24 |

| Allowable freezing/thawing cycles | 5 | 10 | _ | 5 | Up to 5 | 10 |

| Packaging, kg | 18 | 20 | 25 | 18,1 | 25 | 28 |

| price, rub. | 831 | 1094 | 1037 | 1071 | 1485 | 1354 |