It is hardly possible to find a person now who does not know what putty is. Anyone who has been to a hardware store at least once in their life or thought about repairs has an idea of what we are talking about.

Putty or putty is a widely used building material in the form of a paste or powder, intended for leveling the surface with the further use of finishing materials (wallpaper, paint).

With the help of putty, both the smallest and quite large unevenness on almost any type of surface can be leveled. Let's take a closer look at the most popular types of putties for finishing apartments, compare their capabilities and application features.

Cement-based putty mixture

Cement putty, sold in the form of a dry mixture, is universal; it can be used for both interior and exterior work. The solution prepared for puttying is a mixture of sand filler, binder (cement) and solvent (water).

Its main advantages:

- Good strength indicators.

- Excellent moisture resistance.

- Possibility of eliminating irregularities greater than 1 cm.

- Low price.

Main disadvantages:

- The structure is more grainy than other putties.

- The applied mixture often shrinks after drying, which is why it is necessary to make a second layer.

- Cement putty is inelastic and may develop microcracks over time.

- Cannot be used on wooden surfaces.

- Difficult to process.

- Has a yellowish tint.

Polymer mixtures

As you can see in the photo of polymer-based putties, they are:

- Technical gases. What are they?

Roofing. What are they?

- Rolled sheet metal. What it is?

- acrylic;

- latex;

- polymer-cement.

Polymer putties combine all the advantages of their cement and gypsum counterparts. They are classified as universal materials.

Pros:

- good ductility;

- ease of application;

- economical consumption;

- can be used for finishing both internal and external walls;

- dry quickly;

- have high strength;

- give high quality results;

- moisture resistance;

- resistance to temperature changes.

There is only one minus - the high price.

Gypsum-based putty

Due to the physical properties of gypsum, this type of putty is used only for interior decoration - processing walls and ceilings.

Gypsum putty is an excellent material for finishing an apartment. It is a mixture of gypsum, polymer additives and mineral fillers (quartz sand or marble dust).

USEFUL INFORMATION: Stretch ceiling in the corridor: design, 9 photos

Gypsum provides natural regulation of humidity: excess moisture is absorbed and released back in dry air.

The main advantages of gypsum putty:

- Allows you to obtain a completely smooth surface free of roughness.

- Ideal for preparing walls for painting.

- Good thermal insulation and fire resistance.

- Fast drying.

- Has no foreign odor and does not cause allergies.

- Environmental safety, no synthetic additives.

- Cost-effective – consumption is 2–3 times less compared to cement putty.

Main disadvantages:

- Not suitable for rooms with large temperature changes and high humidity (bathroom, kitchen)

- Easily damaged.

Brands of polymer putties

Today, large manufacturers of building materials around the world produce high-quality polymer putties suitable for cladding any type of surface. Below are the best companies offering proven construction products.

GLIMS Styro Prime

GLIMS Styro Prime is a universal polymer product that is used to cover walls and remove uneven surfaces from them. The material from this company reliably protects the surface from damage and adverse effects of external factors. GLIMS Stypo Prime putty can be used as a facade and interior product for treating walls. Reinforcing putty provides a reliable level of thermal insulation.

The manufacturer provides all the necessary quality certificates confirming that this product can be used in residential areas. The putty does not cause allergies or adverse reactions. It is easy to apply, dries quickly and quickly sets to the base surface.

Sheetrock SuperFinish

American mortar for finishing construction work. It helps get rid of defects and cracks. The product has good adhesion and no shrinkage. Putty from an American manufacturer allows you to create a reliable and durable coating that will withstand high levels of humidity and temperature changes. After drying, the polymer solution can be painted or wallpapered.

White Hose

A universal building composition that is produced in Russia. The composition is used for both facade and interior work. It is quite resistant to precipitation, temperature changes, and moisture. Polymer products can be applied in a thick layer and cracks can be removed with it. White Hose dries quickly and does not change its structure after installation.

Knauf (Germany)

German putty Knauf is considered a universal finishing product. It is made on the basis of gypsum powder and polymer additives, which increase elasticity and resistance to damage. The product of this parka is used for interior and exterior work. It is considered quite resistant to moisture, so it is advisable to use it for treating walls inside the house. Knauf putty dries quickly and does not crack after application. It is applied to stone, gypsum and concrete surfaces.

Vetonit (Finland)

Finnish putty made from environmentally friendly raw materials. The product is used for cladding facade and interior walls in buildings. The material is also often used in the construction of swimming pools. The powdery product easily handles any type of surface, dries quickly and does not crack after installation. Vetonit putty reliably protects buildings from damage, precipitation, and high levels of humidity.

Ceresit

Finishing material for processing stone and concrete areas. The polymer composition is most often used for interior finishing work. It reliably protects walls from damage and prevents the appearance of mold and mildew. The putty easily adheres to the main surface, dries quickly, and does not crack during use. It is advisable to use the solution only in dry rooms.

"Prospectors"

Polymer composition for construction Prospectors is a Russian product used for finishing cladding. It is used for both external and internal decoration. The putty consists of polymer additives, natural fillers, reinforcing fibers and antiseptics, which provide a reliable and dense coating without visible defects. The product is easily distributed over the surface, dries quickly, and protects the building from severe frost, humidity, and the adverse effects of ultraviolet rays.

Ready mixes

Another popular type is ready-made mixtures, or so-called liquid putty. It can be recognized by its voluminous, tightly sealed buckets. Liquid putty has a creamy consistency and is very easy to use because, due to special additives, it does not dry out until it reaches the surface to be treated. These properties make it the best option for beginners.

Depending on its composition, liquid putty can be:

- acrylic;

- latex;

- polymer.

All these types of liquid-based putties have their own characteristic features.

- Acrylic putty is used for final finishing of walls or ceilings for painting. In essence, this is the final layer of surface finishing in the room. Its thickness is no more than 1 mm, the final result is an almost glossy surface.

- The latex mixture is very flexible. Used for processing drywall, seams, niches, arches. Suitable for puttying surfaces before painting with oil or water-dispersion paints.

- Polymer putty is a leader in terms of elasticity, is very easy to use and guarantees high-quality and durable results, but compared to other compounds it is significantly more expensive.

The main advantages of ready-made mixtures:

- Wide application. They can be used for finishing walls and ceilings made of a wide variety of materials; they are suitable for processing wooden structures, steel and aluminum parts, and plasterboard sheets.

- High moisture resistance, resistance to aggressive environments.

- Elasticity, efficiency.

- Self-leveling effect.

- Short drying time, saving time during work.

- There is no need to measure the components yourself and mix the putty solution.

- Durability, strength (the material does not crumble or crack).

USEFUL INFORMATION: Wall decoration ideas: decorating an apartment with your own hands

All types of putties sold in finished form have one common disadvantage - high cost. However, the higher price of liquid putty compared to dry mixtures is compensated by significantly higher quality properties.

Please note: the shelf life of different types of putties is approximately 6-12 months. After this time, the mixture begins to lose its properties. However, if little time has passed since the expiration date, the putty mixture was stored in a cool, dry room and has not changed its appearance (dry - not damp, not formed into lumps, liquid - has not changed color), it can be used.

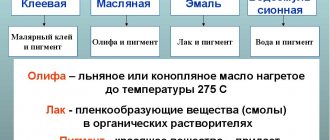

Differences in putty composition

For interior work, the following types of putties are used, differing in composition:

- Oil-glue. Used primarily for leveling wooden, concrete and plastered surfaces before applying enamel, oil and water-based paints.

- Plaster. This putty mixture is most often used for treating walls and ceilings in dry living rooms and corridors.

- Cement. Designed for finishing unheated or damp rooms, in particular kitchens, bathrooms and toilets.

- Water-dispersed. This putty composition is suitable for partially leveling and eliminating defects on concrete, plastered, brick, aerated concrete, wood, stone, painted and fiberboard substrates.

- Polymer. A universal putty composition that is used for finishing surfaces made of cement, concrete, gypsum and polyurethane.

Depending on the main component of the mixture, putties can be classified according to composition.

The most common materials for interior work are cement, gypsum and polymer mixtures - they have all the necessary characteristics to ensure high-quality leveling of walls and extend the service life of the final coating.

Gypsum mixture: characteristics and specifics of use

Gypsum putty is widely popular among builders for interior finishing of walls made of cement, plasterboard and gypsum fiber. This composition has many operational advantages at a relatively low price. In addition, even a beginner can putty with gypsum mixture - it is easily mixed and distributed on the surface.

Important! Gypsum has the ability to absorb moisture, as a result of which the coating begins to swell and peel off from the base. Therefore, it is recommended to use this mixture in rooms with normal and stable humidity and temperature.

Gypsum putty is environmentally friendly and safe for health, since it contains natural ingredients. The mixture is supplied in bags that can be stored for a long time even at sub-zero temperatures. Another advantage of gypsum is the absence of the risk of shrinkage and cracks, so this composition can be used for finishing putty. However, this material is afraid of mechanical influences and vibrations and, as a result, can peel off from the surface of the walls.

Cement putty for interior work

The main advantage of cement putty is its high resistance to moisture, but the main disadvantage is shrinkage during the hardening process with subsequent formation of cracks. It is for this reason that such material is not recommended for finishing living rooms, where the aesthetic appearance of the coating is very important. However, for damp and cold rooms you cannot do without this mixture. In addition, cement putty has a low cost, so it is ideal for large areas, for example, for treating walls in entrances or warehouses.

Features of the polymer mixture

The main and, perhaps, the only drawback of polymer putty compositions is their high cost, which makes it inappropriate to use this material for puttying large areas, as well as for the initial treatment of obvious defects. The main purpose of the polymer mixture is finishing putty on walls before finishing; it is especially indispensable before applying decorative coatings that require ideal smoothness of the base.

Advice! For those who are doing repairs for the first time, in particular, puttying work, the polymer mixture will be an ideal option - it is sold ready-made and has the optimal consistency for high-quality and convenient finishing.

Polymer-based putty is a multifunctional material that not only levels any surface well, but also increases sound insulation, provides high vapor and moisture resistance, prevents the appearance of fungus and mold and protects the structure from temperature changes. Thanks to these properties, it can be used not only for decorative finishing of dry rooms, but also for tiling bathrooms and kitchens.

Other types of putty

There are several other types of ready-made putty mixtures:

- Oil putty, consisting of drying oil, chalk and additives that accelerate drying, is used for working with wet surfaces.

- Glue and oil-adhesive putties are indispensable for interior work on surfaces intended for painting with enamels and oil paints.

Gypsum mixtures

This is a good choice if you need to prepare a surface for painting. Gypsum putty gives high-quality results.

Pros:

- high quality of work;

- no shrinkage;

- ease of alignment;

- high drying speed;

- non-flammability;

- safety from an environmental point of view;

- thermal insulation qualities;

- low cost;

- antiseptic properties.

Minuses:

- does not tolerate humidity and temperature changes;

- low strength;

- the ability to enhance corrosion damage to metal;

- cannot be used for outdoor work.

Types of putties by purpose (by fraction size)

There is another conditional classification of putties that takes into account the particle size of the mixture. This indicator affects the purpose and order of use of the finished solution. According to it, putties are divided into starting, finishing and universal.

Starting

They are used for rough leveling of the surface and are the basis for subsequent finishing putty.

If thick wallpaper is going to be glued to the wall, you can get by with just starting putty.

They have the following features:

- They have a larger particle size compared to finishing mixtures. They are more difficult to grind, as they create a rough surface after hardening.

- They have good adhesion characteristics.

- They are a solid basis for further work with any decorative materials.

- Apply a layer of 0.3 to 2 mm.

Finishing

Their purpose is to create the final base for demanding finishing (paint, textile wallpaper). Such mixtures have a number of features:

- Create a smooth surface for the use of decorative materials.

- Used on a surface previously leveled with the starting composition.

- Apply a layer of 0.1 to 0.4 mm.

- Easy to sand.

- Less durable compared to starting mixtures.

USEFUL INFORMATION: How to make a bas-relief on the wall

Classification by particle size

Dry or ready-made mixture (putty) that is used for interior work can be:

- rough-relief (used to apply the first layer, the thickness of which is from 0.5-2.5 mm);

- finishing (used when completing leveling work, layer thickness does not exceed 1 mm).

The layer of rough putty used for interior work must be plastic so that the applied mixture does not crack when drying.

How to choose the right putty depending on the type of work

When choosing a putty solution, take into account the type of material; the following types of compositions are selected based on the type of base:

- It is permissible to use different options for walls, but in living rooms gypsum is more suitable;

- Ceiling covering – acrylic and plaster;

- On acrylic-based plasterboard sheets;

- For wood – acrylic;

- For the facade, cement;

- For painting polymer and gypsum.

It is permissible to use different options for walls, but gypsum is more suitable in living rooms.

Putty compounds help to obtain a smooth base through which defects will not appear. There are finishing and starting types, the second is usually white in color so that it does not show up through the finish.

Which putty to choose, types for each stage

Since there is a large selection of putty for walls, it can be difficult for beginners to make a choice. In addition, each stage of work requires its own building mixture. There are some standards that employees adhere to. But this does not mean that each type cannot be replaced.

- Which putty is best for walls? In fact, each of them is suitable for this purpose. If we talk about the bedroom, living room, children's room or office, where humidity is minimal, then you can choose a gypsum-based putty. As for the kitchen or bathroom, where the humidity is high, it is better to choose acrylic or cement putty.

- The ceiling is most often treated with acrylic mixtures. This results in a perfectly even and smooth layer. The ceiling looks beautiful. An alternative is gypsum mixtures.

- The best putty for wood is acrylic. It is vapor permeable, so the tree can breathe. But, there is also epoxy putty. It is also ideal for wood.

- Experience shows that it is better to choose acrylic compounds for drywall. And if the room is dry, then plaster.

- Which putty to choose for external work? Cement compositions immediately come to mind. They withstand all the “hardships” of the street. The same can be said about acrylic compositions.

- Gypsum or polymer putty is suitable for painting. The fact is that they leave behind a perfectly smooth and beautiful layer. And if the finishing layer is wallpaper, then choose cement compounds, they are cheaper.

To start

To level the walls, it is better to choose a simple and cheap putty, but as an option, you can use acrylic compounds. For drywall, it is enough to cover the seams, screws and apply the finishing layer.

For the finish

The finish is selected depending on the characteristics of the room. Features of application: dry rooms are treated with gypsum or acrylic compositions of a universal type.

We recommend the article: How to properly putty walls for painting.

For grouting joints

There is an option to use putty instead of special compounds for sealing the seams between tiles. However, it is better not to do this, otherwise it threatens to cause the tiles to fall off. It’s the same with sealing joints between fiberboard sheets and gypsum boards.

However, for these purposes, the best option is elastic putty. It is this parameter that is important, as well as a good level of adhesion. Therefore, PVA-based adhesives are used. If we are talking about a bathroom, then you need a moisture-resistant putty. The composition must also contain antiseptics to prevent the formation of mold and mildew.

Calculation of the required amount of putty

To calculate the required amount of mixture to complete a specific amount of work, it is better to use a special online calculator. To do this, you need to enter in the fields provided the area of the surface to be treated, the thickness of the intended putty ball, the features of the base and the skill level of the performer. Next, the system will independently perform all the necessary calculations and display the result in kilograms.

Shelf life of putty

The shelf life of the mixture depends on the form of release. Dry masses can be stored under favorable conditions for an average of about a year, and ready-made solutions do not lose their quality for up to two years of storage.

Putty for interior work - what is it?

To understand why putty is applied, you need to understand what putty looks like. Usually this is a dry mixture, which can be powdered; a similar option is used immediately before finishing the base, for example, before painting. There are options with coarser grit, this is necessary to repair larger flaws.

Putty dry mixture for interior work must be diluted with water before use to obtain a solution for use. There are also ready-made solutions on the construction market; they are more convenient to use, they are immediately ready for application, but their shelf life is shorter.

Putty dry mixture for interior work must be diluted with water before use to obtain a solution for use.

Why is it needed, scope of application

Beginners often believe that using putty solutions is an optional step. The composition can be used to treat ceilings and walls; there are types for external and internal use. Selected for further application of the following finishing materials:

- Paint and varnish materials;

- Pasting wallpaper;

- Decorative plaster.

The putty composition can be in dry or liquid form, so the varieties differ in the form of release. The first type is more difficult to work with due to the need for preparation before use, the second is more convenient, but its cost will be higher.

It is recommended to prepare small volumes of the solution in order to have time to apply them to the surface before the composition hardens in the container and loses its properties.

Technical characteristics that are important for choosing a solution:

- Strength indicator;

- An elastic layer is required;

- How long can the ready-made solution be used?

- Flow level;

- The thickness created by the composition affects the size of the defects that can be corrected;

- Time required for drying;

- Temperature indicators at which work is allowed.

A certificate of conformity can be issued for any type of putty material. Although this document is not mandatory for formulations, therefore it is not available for all brands.

The composition can be used to treat ceilings and walls; there are types for external and internal use.

How to make the right choice?

Before purchasing this building material, carefully study the instructions, scope of application and properties. Based on your own preferences, decide whether it is better to buy dry putty or ready-made putty. Choose the composition in accordance with the type of surface, work conditions, and also take into account the purpose of the mixture.

It should be noted that if the surface needs to be prepared for wallpapering, then it is better to buy a dry mixture. Also in this case, the white shade of the putty surface will be a more optimal option.

When carrying out interior work, the use of putty with sand filler is not recommended. Experts advise purchasing putty materials from the same manufacturer, since they usually have the greatest compatibility.

You should also pay attention to the shelf life; as a rule, it is no more than 12 months. After the shelf life expires, the putty begins to lose its properties and its use will not be effective. Purchasing a universal mixture, for example, acrylic, which is recommended for use by beginners, will help reduce the risk of making the wrong choice.