Types of coatings

Of the large assortment of protective products for brick, varnish is popular among citizens involved in repairs. It is believed that the products are equally suitable for all types of brickwork. Construction professionals believe that coatings should differ in their composition. Each surface requires its own complex; individual components are not used anywhere else.

It should be noted that there are several types of brick varnish for interior work:

- Polymeric. This type is used in construction in large quantities. There are nuances: only brick walls are allowed to be coated with the mixture. A layer of varnish protects against rust and corrosion. The composition contains substances that allow you to work with the product even at sub-zero temperatures. The advantage of this type of varnish is that it hardens quickly, which saves time. It is usually used for rooms where heating is not provided. The varnish is easy to apply. After use, you don’t have to worry about corrosion. The price of polymer coatings is affordable for citizens with an average level of income. After application, a transparent film is formed, which is very durable. It reliably protects against various scratches and other possible damage.

- Acrylic-silicone. The product is usually used for interior work. After coating, the wall does not turn yellow over time. Special dyes are added to it, so you can choose any shade. Matte brick varnish is often used for interior work. It helps hide visual defects in the wall. Excellent for application to artificial surfaces. Acrylic coatings are not affected by acetone and even gasoline. They penetrate the structure of the material, providing protection. The coating does not turn yellow over time. There are some minor restrictions. So, it is undesirable to use this product on facades.

- Solvent varnishes. These are compositions to which silicone resin and solvents are added. They penetrate deeper than others into the brick layers, after which the material will not crack. The disadvantage of this group of products is their increased flammability. When working with them, you should follow safety precautions.

- Polyurethane. This is the most versatile type among all solutions. It is used for almost any internal work, including external ones. When the varnish dries, a special film appears. It protects the surface from all possible damage. Dye can be added to the product to create the desired shade. Nowadays it is fashionable to create a “wet stone” effect - it is often used in country houses. Polyurethane varnish belongs to the category of waterproof. It perfectly protects brick walls from moisture and destruction. This type is considered the cheapest on the construction market.

Material properties

First, decide what effect you want to achieve? In the case when your goal is the usual protection of brick walls from atmospheric agents, then choose varnishes intended only for this. If, at the same time, you want to enhance the external attractiveness of the building, pay attention to varnish materials with a decorative effect. With the right choice, a brick wall under varnish can get a matte or glossy surface (up to the “wet stone” effect, popular among residents of our country, due to the use of special additives).

When wondering what varnish to coat a brick wall of a house with, first of all determine the area of the upcoming work. This determines which packages you will need to purchase the varnish in. This material is produced:

- In buckets with a volume of 10 to 15 liters.

- In cans with a capacity of 0.7-10 liters.

- In aerosol cans with a capacity of 200 to 500 ml.

When choosing a material, take into account the characteristics of the climatic zone in which the building is located. The greatest demand for paints and varnishes for brick walls, of course, is in areas with harsh climates. For owners of such housing, the following properties of varnishes come to the fore:

- Protection from moisture and ultraviolet radiation, as well as mold and mildew.

- Additional strengthening of the brick structure, which has a positive effect on the service life of the building.

- Resistant to temperature swings (as well as extremely high and low temperatures) and aggressive chemical substances (solvents, etc.).

In addition, varnished bricks show less soiling, since the additional coating of the building material repels dirt.

Varnish is a truly universal material; it can be used outside and inside (for decorative purposes). When applied, it lays down in an even layer, regardless of whether work is being done on horizontal, vertical or inclined surfaces.

Application Tips

If a person decides not to use the services of specialists, but to apply the product himself, then he should study a number of tips. There are certain rules for applying varnish to bricks for interior work.

The coating should be applied in a thin layer so that several approaches can be made. With this technique of use, drips will not appear. For brightness, it is permissible to paint the seams in a different color (more contrasting). Many useful tips can be found in the instructions for brick varnish for interior work.

What to look for when choosing?

It is important to understand for what purpose you are choosing a product and in what work it will be used. You should first study what is suitable for a particular material - in our case, brick.

The varnish must be moisture resistant. On the market you can see products from different manufacturers of brick varnish for interior use. There is a chance that you will find an option that is suitable in price and quality. The composition will improve the appearance of the brick - it will be brighter.

More and more often you can find colored varnish on bricks for interior work. It is used to add brightness and harmoniously combine the colors of the interior. Some people want a rich red brick color or matte white when decorating a loft-style room. These coatings look great and are of good quality. It is also important to pay attention to the expiration date of the solution.

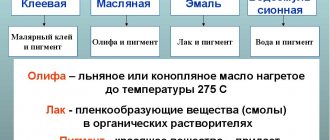

No. 2. What are the composition of varnishes?

Brick varnish is a universal product for protecting the brick base. But in order for the varnish to lie evenly on the material and fully perform its functions, it is necessary to select it correctly, paying attention to its composition.

Polymer varnishes

This is the most popular type of paintwork. The demand for this product is explained by the versatility of its use. It can be used when working with brick and concrete foundations. Polymer varnish can be applied at sub-zero temperatures and in rooms without heating. It is easy to apply, dries quickly and reliably protects the material from scratches, cracks, moisture and dust. The mixture can be used to protect interior and exterior walls. Due to the ease of application of the polymer composition, it can be used by both professional craftsmen and beginners. Polymer varnishes are affordable.

Silicone acrylic varnishes

This type of coating is suitable for application to interior walls. The silicone-acrylic mixture can be used to coat not only brick, but also concrete, ceramic tiles, drywall, and metal. The composition is often used for application to decorative elements.

Thanks to the presence of special polymers in the mixture, the varnish can be of different shades. In addition to the protective layer, a wall treated with this composition can be transformed into any color, depending on your wishes.

Silicone acrylic varnish protects the base from alkalis, acetone, and oils. The only disadvantage of such mixtures is the price, which is significantly higher than their polymer analogues.

Polyurethane varnishes

This is a universal product that can be used to cover external and internal walls. It is polyurethane varnishes that create a “wet” effect on a brick base. They have excellent moisture-repellent characteristics, which is why they are most often purchased for treating external walls. The popularity of polyurethane varnishes is also explained by the fact that they can be used to treat not only brick, but also concrete bases.

Heat-resistant varnishes for fireplaces and stoves

This is a separate category of coatings, which differ in the characteristics of heat resistance and fire resistance. They are designed to prevent condensation from forming on the walls of stoves and fireplaces. Due to their high moisture resistance, such paints and varnishes are also purchased for decorating and protecting building facades.

Solvent varnishes

These compositions are based on silicone resin and solvents. When they penetrate the material, they create a strong protection, preventing cracking and loss of color. But at the same time, such varnishes are easily flammable, and it is necessary to work with them extremely carefully, observing safety rules.

Impregnations

In order to strengthen any paint and varnish, you can use special sealing impregnations. They are made on the basis of silicone and acrylic resins with the addition of aromatic, aliphatic solvents. Due to this composition, maximum protection of the paint and varnish for the brick base is ensured. When using impregnation, deep penetration of paintwork into the building material is guaranteed.

In addition, sealants create an additional protective layer from seasonal precipitation, chemicals and UV rays. Many manufacturers also offer decorated options with a “wet stone” effect. The negative side of such impregnations is that they can only be used for external or internal walls; they cannot be used when working with stoves and fireplace installations.

Foreign or Russian

The buyer of brick varnish for interior work always faces a choice of which manufacturer to choose. Some purchase exclusively imported varnishes. There are advantages here: they do not have a strong odor and dry quickly. Also, imported materials are better in operation.

The most popular coatings and varnishes among the population are those produced in the USA. They are produced by Pufas and Petri. These manufacturers have established themselves as successful and reliable suppliers. They have a wide range of products, which are regularly supplied to Russia.

The domestic production of varnishes is also not standing still. Usually universal formulations are created. They are suitable for brick, stone, and are also good at working with concrete. The price of locally produced products also pleasantly pleases the potential buyer, especially when large quantities are purchased. The disadvantage of Russian varnishes is a strong, unpleasant odor that does not dissipate for a long time from the room where the work was carried out. They are not recommended to be used or stored near children. Over time, they began to produce good quality varnishes that perfectly protect brickwork from external damage.

One of the best products is Neomid. It creates a high-quality protective film that even fights the appearance of fungus. Unlike most coatings produced in our country, Neomid does not have a sharp or unpleasant odor. They can easily handle elements located in a small room.

Types of varnish for bricks

Polymer varnishes

In first place in demand among consumers are polymer ones, consisting of alkyd resins and acrylic copolymers mixed with several additives. Such varnishes give a decorative “wet stone” effect and increase the resistance to aggressive weather conditions and the wear resistance of the brick. An undoubted advantage of polymer paints and varnishes is that they can be worked with in the cold season at temperatures down to -10 degrees.

Polyurethane varnish

A multicomponent substance consisting of polymeric materials and organic solvents. This type of varnish was created for use in aggressive environments and has increased wear resistance; as a rule, it is used to cover frequently used surfaces, in particular road surfaces. Resistance to moisture and abrasion allows the use of polyurethane-based brick varnish for outdoor use.

Solvent varnishes

In second place in the consumer rating are solvent varnishes based on silicone resins. This varnish creates a coating that:

- It is characterized by increased strength.

- Not subject to cracking.

- Maintains a presentable appearance throughout its entire service life.

The disadvantages of this type of varnish include their increased flammability. Therefore, when working with solvent-based paints and varnishes, it is necessary to strictly follow fire safety rules.

Acrylic varnishes

If you want the varnish to be used in a range of exterior and interior applications, acrylic mixtures are the right choice. These are one-component organic-based varnishes. They saturate the brick well, preventing the formation of cracks and other microdamages, as well as the appearance of fungus. As a rule, one of the key advantages of these varnishes is the absence of odor or its rapid disappearance during the polymerization (drying) process.

Impregnations

Any of the above types of brick varnishes can be strengthened with sealing impregnations. As a rule, such “amplifiers” are made on the basis of acrylic and silicone resins with an admixture of aliphatic and aromatic solvents. All together ensures maximum wear resistance of the paint coating for the building material.

Impregnations also ensure deep penetration of the varnish into the brick. Additionally, they provide protection from sunlight, rain and snow, reagents and chemicals. Most impregnations provide a decorative “wet stone” effect. Their disadvantage is that they cannot be used when varnishing a brick oven.

And this means that we have gradually approached the fourth type of paint and varnish materials for brickwork - “fireplace” or as it is also called “stove”.

Heat-resistant varnishes for bricks

Specialized heat-resistant and fire-resistant varnishes are designed to prevent the formation of condensation on the walls of stoves and fireplaces. Another purpose of the heat-resistant brick varnish used in stoves is to decorate places with open and closed combustion.

Among oven coatings for bricks, we highlight special fire-resistant varnishes KO-85 and KO-815. They are not only suitable for decorative covering of fireplaces, but can also be used for covering facing bricks on the facades of brick buildings.

High-temperature heat-resistant brick varnish can be used to strengthen the internal surfaces of fireplaces, stoves and fireboxes. Its fire-retardant composition enhances the heat resistance of bricks, strengthens stove seams and masonry in general.

Advantages of varnishes

It is worth noting the advantages of using brick varnish for interior work:

- You can advantageously emphasize the texture of a brick wall. The surface will become brighter.

- Perfect for those who want to add color to the interior with varnish.

- There are options to choose from - make the surface glossy or matte.

- You can coat a horizontal surface with varnish. They are also comfortable working on a vertical wall.

- Helps the brick remain intact for a long time. The composition penetrates into the material, preventing it from collapsing. Mold will not penetrate into the brick if the room is damp.

You can see what brick varnish for interior work looks like in the photo.

The surface is glossy and looks beautiful in daylight. Under artificial lighting it shimmers and has a shine. The wall or floors look quite aesthetically pleasing and rich.

Types of varnishes and their application

To improve the performance characteristics of gypsum tiles, they should be varnished. The following products are considered the most popular on the market and in construction stores:

- oil-based varnishes;

- yacht varnish for gypsum surface;

- protective acrylic coating.

Oil based varnish

The composition of oily varnishes includes a solution of artificial resins and a collection of plant herbs. The substance is brought to an oily consistency and combined with additional materials, which as a whole form a varnish. Due to its texture, the coating forms a thin film on the surface, which, after complete drying, protects the gypsum tile from physical and mechanical damage.

Oil varnishes can be transparent (colorless) and are also available in a variety of shades. Therefore, when purchasing, compare the color of the original material and its future coating. To give the surface different effects, you can purchase glossy or matte varnish. It should be noted that if you varnish (even colorless) a plaster surface, it may become slightly darker than it was originally.

When covering a wall decorated to look like stone, try to protect your body and face from getting paint and varnish. Wear protective clothing, gloves, goggles and a respirator, as the composition has a specific pungent odor.

On video: varnish for stone.

Acrylic composition

When purchasing varnish for gypsum tiles, most builders want to get a material that will combine “two in one” characteristics. That is, initially it is a protective coating, and only then performs a decorative function.

All desired requirements will be met if you cover the tiles with acrylic varnish. In construction stores or on the market you can purchase ready-to-use material, which, when applied to the surface, forms a durable thin film.

Acrylic varnish is a “protective shield” for artificial stone. It is moisture resistant, reflects UV rays, and is resistant to various detergent compositions and temperature changes. The material has no toxic odor, dries quickly, and if excess needs to be removed, this can be done using a special solvent. If the acrylic varnish is too thick in consistency, it can be diluted with plain water.

Acrylic coating is divided into three types:

- matte;

- semi-matte;

- glossy.

If you use matte acrylic varnish to cover the plaster, the imitation of rough stone will be preserved down to the smallest touch. After application, the composition penetrates into all existing cracks and recesses, and as it dries it takes on a transparent matte texture.

Semi-matte plaster varnish has similar characteristics to the previous material. The coating has only one drawback - after drying, you can notice a light light coating on the finish. Of course, if you choose a varnish that matches the tone of the tile, this effect can be avoided, but colorless compositions can present an unwanted surprise.

When choosing a glossy finish, keep in mind that in a brightly lit room the surface will be very shiny. Consequently, the interior decoration will be distorted due to glare.

If, according to the designer’s plan, the gypsum tile will be painted with water-based paint, then for better adhesion of the material to the surface, add acrylic varnish to the solution. The paint should be applied with two salts, and after complete drying, open with one layer of varnish.

Yacht varnish

The most durable material for treating gypsum surfaces is yacht varnish. Based on the name, you can guess that this material is used to cover wooden surfaces on yachts. Its composition will give gypsum tiles 100% waterproofness.

Before applying to the surface, the product must be thoroughly mixed with solvent. The solution is distributed on the tiles with a thin brush or roller, and the surface should be evenly exposed, avoiding smudges. The material dries in about 24 hours, depending on the room temperature.

To achieve maximum protection, decorative gypsum stone is coated with 2 layers of varnish. But before application, minor cosmetic errors should be carefully sanded with sandpaper. The second coat will take about the same amount of time to dry. After this treatment, the relief surface of gypsum tiles is easier to keep clean. To do this, you just have to wipe it with a damp cloth.

Care after applying varnish

After treating the surface with brick varnish, it becomes easy to care for. The wall practically does not get dirty, dust does not settle on it. If there is a fireplace or other appliances nearby, the surface does not become hot. This coating is not afraid of water, it does not wear off for a very long time. During cleaning, it will be enough to wipe the surface with a damp cloth. You can even do without cleaning products. This wall can withstand many washing cycles.