Plasterboard sheets have become very popular when you need to get a smooth base that will last a long time. They are distinguished not only by their evenness, but also by the ability to hide heat and sound insulation behind them. Installation of sheets is not so complicated and can be done independently. But it is important to choose the right gypsum boards for certain operating conditions. The thickness of drywall for a wall can be different; the subtleties of choice will be discussed further.

What kind of plasterboard is best for covering indoor walls?

Which drywall is best used for walls is determined based on the type of room and the task at hand. If the work will be carried out in rooms where the humidity level is high, then moisture-resistant types are needed. To obtain partitions, the thickness of the gypsum plasterboard for the walls will be selected more.

It is also important to consider the type of base; different materials require different parameters from the finishing coating. If noise insulation work is carried out, the level of sound insulation can be increased by using thicker sheets.

Therefore, in order to make the right choice of what will be used, it is necessary to understand the types offered for sale. Then it will be possible to easily take into account all these points.

If noise insulation work is carried out, the level of sound insulation can be increased by using thicker sheets.

Calculation of the thickness of the structure

To do everything right, the main parameters must be determined at the preparation stage.

The most common options are:

- 75 mm. This indicator is the minimum, which is obtained from the thickness of the profile (50 mm) and two layers of gypsum plasterboard of 12.5 mm each. The corresponding type is S-111, for S-112 25 mm is added.

- 175 mm. Racks – 100 mm, 3 layers of plasterboard on each side – 75 mm. This thickness is typical for the S-113 design.

- The indicator for the S-115 variety must be calculated individually. With a profile thickness of 75 mm, the value is multiplied by two and the thickness of the gypsum board is added - 50 mm (12.5 * 4). Thus, the width of the wall is 200 mm. With 100 mm racks installed in two rows – 250 mm.

A more complex calculation is made for the partitions in which communications will be located. In this case, not only the dimensions of the profiles and drywall are taken into account, but also the parameters of the pipes with a margin.

Classification of drywall by purpose

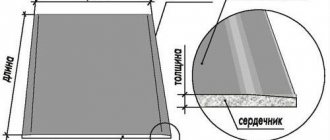

Before choosing plasterboard for walls, study the types of materials presented by manufacturers. Any type is based on a gypsum base, which is covered on the outside with thick cardboard; the sheets are distinguished by their strength and evenness. The following types of plasterboards can be used:

- Standard gray, low cost, suitable for working with structures made of steel or wood, you can create three-dimensional structures from them, but not applicable for conditions of high humidity;

- GKLV are distinguished by their water resistance; they are popular for use in bathrooms, kitchens, and toilets. The characteristic color is green, there is also a blue marking on the sheet;

- GKLO is a separate type, designed for rooms exposed to high temperatures. It is fire resistant, creates a gray tint with a red signature;

- GKLVO is the most expensive type, but it also has the ability to withstand high humidity and fire. Produced in green, marked in red.

According to this classification, it is clear that the choice should be made based on operating conditions.

Any type is based on a gypsum base, which is covered on the outside with thick cardboard; the sheets are distinguished by their strength and evenness.

How to choose correctly, according to what criteria

In addition to the type of gypsum board, when choosing, you need to take into account a number of features, otherwise you will be able to purchase low-quality material that will not be able to be installed. Experts make the following recommendations:

- You should not use the supply of sheets from small sellers; it is better to contact large companies and trusted stores that monitor the quality of products;

- Pay attention to how the goods are stored in the warehouse, whether conditions have been created so that they remain dry and are not saturated with moisture;

- Before purchasing, check the integrity of the sheets; there should be no flaws or separating elements;

- After delivery of the material to the place of application. They also check whether it arrived in good condition, and whether the exact batch that was ordered was shipped;

- Trusted manufacturers monitor the quality of the materials used, so it is better to read reviews about the brand in advance to make the right choice;

- They determine the type of structure and set the task of mounting the material to a wall or ceiling surface, or constructing an arch.

Before purchasing, check the integrity of the sheets; there should be no flaws or separating elements.

Types of frame partitions

A frame partition is a structure made of a steel profile or wooden beam, sheathed on both sides with sheets of plasterboard in one or several layers. To protect against excess noise, as well as for insulation purposes, its internal cavity is filled with insulating material. The German company KNAUF, a manufacturer of high-quality building materials, classifies interior plasterboard partitions into several types, shown in the table below.

| Construction type | Main settings | Main characteristics |

| S111 | The weight of 1 m3 is 28 kg, the height can reach up to 8.0 m. | The structure is a single frame made of galvanized steel profile, which is sheathed on both sides with sheets of GKLV - waterproof plasterboard - in one layer. The inside is filled with heat and sound insulation in the form of a mineral wool slab. It is used as an internal fence in rooms with low requirements for sound insulation and fire resistance. The minimum thickness of the C111 plasterboard partition depends on the width of the profile and HA sheets. |

| S112 | Weight 1 m3–53 kg, height from 4.0 to 9.0 m. | The single metal frame has a two-layer sheathing of plasterboard sheets on both sides. Filler – mineral wool. The type of construction provides higher sound insulation characteristics (RW index - up to 50 dB) and fire resistance (limit - 1.25 hours). It is used both for redevelopment and capital construction. |

| S113 | The height can be up to 9.5 m. Weight of 1 m3 is about 78 kg. | The steel profile frame has a “single” design and is sheathed on both sides with sheets of waterproof plasterboard in three layers. Mineral wool filling the “insides”, in addition to protecting against noise, perfectly conserves heat. By increasing the number of gypsum board layers, the sound insulation properties are increased. |

| C115.1. | Height – up to 6.5 m, weight 1 m3 – 57 kg. | Equipped with a double frame made of steel profile, which is covered with two layers of plasterboard. Along with strength and excellent fire resistance, it has high sound insulation characteristics. The thickness of the plasterboard partition depends on the width of the profile used, but even its minimum values allow the structure to be used both for repairs and for new construction. |

| C115.2. | The mass of 1 m3 is 69 kg. Max. height 9.0 meters. | In addition to the two-layer sheathing, the double frame is separated by an additional sheet of plasterboard (spaced frame). Due to this feature, the strength of the partition increases, as well as its noise and heat insulation properties. The inside is filled with mineral wool slabs. |

| S116 | Height from 4.5 to 6.5 m. Weight of 1 m3 is 61 kg. The minimum thickness of the C116 partition is 220 mm. | A special feature of this design made of a double metal frame, sheathed with gypsum plasterboard sheets in two layers, is the presence of space for communications. This type of partition provides the possibility of laying heating, water supply or sewerage pipes, as well as hidden installation of electrical wiring. Fire resistance limit – 1.25 hours. The sound insulation index of C116 is 50 dB. |

| S118 | Weight 1 m3 – 86 kg. Max. height – 9 m | Partition class “Protection of premises from penetration”. Made according to type C113 with a single metal frame covered with a three-layer plasterboard covering. A special feature of the product is galvanized steel sheets, 0.5 mm thick, inserted between the gypsum boards, which significantly increases the strength and fire resistance of the structure. |

| S121 | Weight 1 m3 – 32 kg. Max. height 3.1 m. | The frame is made of wooden beams, which have a moisture content of 12% and sheathed on both sides with one layer of plasterboard sheets. The minimum thickness of a partition made of plasterboard type C121 depends on the width of the timber and plasterboard sheets. |

| S122 | The mass of 1 m3 is about 57 kg. Height 3.1 m. | It is distinguished by a two-layer “upholstery” of the wooden frame with sheets of plasterboard. The insulating material of the partition is mineral fiber boards. Advantages: high strength and good sound insulation. |

Drywall used in the construction of partitions can be either ordinary, GKL brand, or water-resistant (GKLV) or fire-resistant (GKLO). Practical application, most often, has material in the form of sheets with a width of 12.5 mm. Regardless of their type and size, the surface can be finished in any way: painted, tiled, wallpapered, etc.

Back to contents↑

What thickness of drywall is best for walls, what will depend on

The thickness of the gypsum for the walls determines what load the structure can withstand, and will also affect the cost of the material that needs to be used in the apartment for cladding.

The main parameter that depends on the thickness of the coating is the reliability of the structure. For this reason, they decide in advance what loads will be applied during operation. For partitions, one- or two-layer or facing types can be used. There are special options for wall mounting.

Also taken into account when choosing the method of mounting sheets to the surface. Standard gypsum plasterboards are more popular, and standards have been created for installing them on metal profiles, determining their location so that the fixation is reliable. Excessively thin sheets will not be able to create a reliable structure.

For partitions, one- or two-layer or facing types can be used.

Which one is suitable for wallpaper and other types of decoration?

Painting and gluing wallpaper onto plasterboard sheets requires careful preliminary preparation of the base. These materials can highlight surface imperfections, so it is necessary to create a perfectly even layer.

When doing the work with your own hands, do not forget to carry out the preparation technology completely. Each stage is important to obtain a quality result. The thickness of plasterboard for walls under wallpaper is usually 12.5 mm.

Aerated concrete, brick and other materials differ in their properties, but it is not this parameter that is important, but the type of room.

For finishing materials, it is important to prepare the sheets with high quality so that they are not exposed to the negative effects of environmental factors and have high adhesion.

These materials can highlight surface imperfections, so it is necessary to create a perfectly even layer.

Types and technical characteristics

Modern industry produces several types of gypsum sheets. They all differ in their operational and technical characteristics. To choose the right drywall for a particular room, you should become more familiar with its properties.

GKL sheets

Purpose

- Standard drywall, also known as basic. It consists of a sheet of pressed gypsum, covered with cardboard on both sides, and is designated by the abbreviation GKL. The most common type of plasterboard sheet, widely used for finishing rooms with normal humidity levels.

- Moisture-resistant drywall (GKLV) is designed for use in rooms with high levels of humidity. The moisture-resistant sheet contains special water-repellent additives that reduce its hygroscopicity. In this regard, gypsum plasterboard sheets can be used for cladding bathrooms, toilets, and kitchens.

- Fire-resistant sheet - designation GKLO. Intended for finishing rooms with an increased risk of fire. Thanks to the treatment with fire retardants, such sheets are able to withstand the effects of open flames twice as long.

- Fire-moisture resistant plasterboard (GKLVO). It has a whole range of improved properties - it can be used in both wet and flammable areas. For example, it can be installed in kitchens with gas stoves.

Gypsum fiber sheet

Gypsum fiber sheets (GVL) are a special group of gypsum finishing material. GVL slabs are made from a mixture of gypsum and cellulose fibers in a ratio of 5 to 1. The distinctive quality of gypsum fiber sheets, compared to gypsum plasterboard, is their increased strength. Thanks to this, fairly heavy suspended structures can be attached to the wall.

One self-tapping screw screwed into a gypsum plasterboard wall can withstand up to 30 kg of load.

GVL can be installed either on a pre-assembled frame or directly on a leveled load-bearing base. In the first case, the GVL is attached to the wall using self-tapping screws, and in the second - using construction adhesives. GVL adhesive can be either silicone sealant or “liquid nails”, and sheets can also be attached to brick and concrete surfaces using cement- or polymer-based tile adhesive.

Thickness of plasterboard for walls used in interior decoration

When choosing the thickness of the material, you take into account where it will be mounted; there are several installation options - ceiling, wall, or creating arches. Also, thickness is taken into account according to the type of coating. The following options are available:

- For walls, 12.5 mm would be suitable;

- The ceiling covering is made from 9.5 mm sheets;

- Waterproof types are 12.5mm thick, this is the largest option;

- Fire resistant ones are made from 12.5mm to 16mm;

- For arches, the thinnest types from 0.6mm are taken so that they can be easily bent.

The ceiling covering is made from 9.5 mm sheets.

Material selection

When constructing interior partitions, it is important to choose the right products for the frame and cladding.

Drywall

For vertical structures, strength and the load generated are of great importance. The main dimensions of the slab are standard: width – 120 cm, length – 200, 250 and 300 cm.

Thickness of the plasterboard sheet for the partition:

- 12.5 mm. A classic indicator for creating ordinary and decorative designs.

- 15 mm. Such slabs are suitable for partitions that experience loads of up to 50 kg/m2.

- 18 mm. This material is used when the impact increases to 70 kg.

In situations where it is necessary to distribute more weight, a two-layer structure is used, which can withstand significant loads provided the frame is reinforced.

Depending on the type of room or area, a suitable type is selected: regular, moisture-resistant or fire-resistant. A special variation is universal - GKLVO.

When choosing plasterboard, in addition to the dimensions and withstand load, you need to pay attention to the level of moisture and fire resistance of the material; these parameters can be determined by the color of the plasterboard jacket

Important! Products must be labeled and have safety certificates.

Profile

Installation of plasterboard sheets occurs on a frame system, which is erected from CW rack parts and UW guides.

In domestic markings, the CW profile is designated as PS (rack-mount profile), and the UW model is marked as PN (guide profile)

The product size range includes several main variations. When determining the optimal width, you should be guided by the following recommendations:

- 50 and 75 mm. Such elements are used for the installation of simple structures that perform separating or decorative functions. Wooden beams are used for reinforcement.

- 100 mm. An excellent solution for creating a full wall with insulation and sound insulation.

- 125 and 150 mm. Professional profiles that allow you to create a structure that can withstand heavy loads.

There is a variety of UA that can be used as a load-bearing support when installing equipment and doors.

The minimum profile thickness for standard partitions is 0.5–0.6 mm, for those in need of reinforcement – from 0.7 mm.

Which drywall is best to use for walls in a wooden house?

In a wooden house, which drywall to choose for the walls is, first of all, decided based on the type of room. Is there exposure to constant humidity, or does it have a dry microclimate. Accordingly, either standard gypsum boards or gypsum boards are taken.

It is only important to correctly calculate the consumption, taking into account the size of the sheets; in small rooms it is better not to use large sheets, as it will be difficult to install them in them. Also, larger drywalls will require the work of at least two craftsmen due to their weight.

In small rooms it is better not to use large sheets; they will be difficult to install in them.

Features and Recommendations

Before choosing gypsum boards for leveling walls, you need to determine the manufacturer. Common ones are KNAUF, Volma. Before purchasing sheets, you need to check its dimensions.

Attention. The dimensions of the sheet affect the installation carried out indoors. When choosing the length of one sheet and making your own calculations, there may not be enough material. You shouldn't overpay either.

When installing thin sheets, it is necessary to limit the wall in advance from hanging any objects on it. Even creating a niche on such a wall can negatively affect the entire structure.

What happens if you choose the wrong gypsum board thickness?

When the selection for certain conditions and types of finishing is made incorrectly, the created structure will not last long. GCRs that are too heavy will fall from the ceiling. But the creation of partitions from thin types will not be reliable, and under small mechanical loads they can collapse.

If you use ceiling sheets for walls, they may not be able to withstand the objects that will be hung on them; not only the sheet will break, but also the object attached to it.

When the selection for certain conditions and types of finishing is made incorrectly, the created structure will not last long.

To obtain a reliable structure from plasterboard sheets, you must first select the right material, and then carry out a step-by-step installation, observing all operating principles. There are different types of gypsum boards, which makes it possible to create a durable structure for different operating conditions.