Articles

All photos from the article

Recently, metal facades have become increasingly popular not only when finishing public buildings, but also when cladding individual construction projects. Most often, profiled panels are used together with component parts to design complex areas, and metal siding under the timber deserves special attention.

The photo shows the building after finishing.

Features and benefits of metal siding

The main feature of metal siding under the beam is its shape, which imitates the wall of a log beam. Otherwise (except for technological nuances), the structure of this material is similar to other metal siding models. What is metal siding under timber :

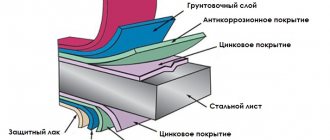

- The basis is a metal strip (0.4-0.7 mm), which is given a rounded shape.

- A zinc coating is applied to the stamped base, which is subsequently passivated and primed. This is necessary so that the metal is not subject to rapid corrosion.

- Next, the product is coated with one of the polymers: plastisol, polyester or polyurethane. The polymer coating performs not only a protective, but also an aesthetic function, giving the product an attractive appearance.

- Finally, the metal siding element is coated with a protective varnish.

We also suggest you read about how to adjust a plastic door.

Varieties

The production of L-beam metal siding includes two main types - premium and economy.

Economy L-beam is made of steel, with polyester on top, which provides decorative and protective functions.

For the production of premium siding, Korean steel is used, which has high strength indicators. A high-quality application of the top layer cannot be distinguished externally from natural wood by color and texture.

Siding installation

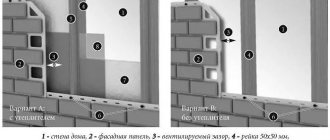

Like any other siding, this type of cladding is installed on guides. To install the profile, use brackets that are fixed to the wall with anchor bolts. The distance between the guides is from forty centimeters to a meter. Installation of siding panels, according to reviews from builders, can be done in any direction, both horizontal and vertical.

For insulation purposes, slabs of mineral wool, expanded polystyrene and other materials are mounted on the wall. A waterproofing membrane is placed on top of the insulation layer, which will not allow moisture to accumulate.

Wood siding is installed using standard self-tapping screws. The special system has a special geometry, so installation must be done from top to bottom. The first panel is fixed into the guide bar until it stops. It is recommended to start laying from a corner. A finishing strip is attached to the bottom of the structure, which is aligned with the guides and secured with self-tapping screws. If there are no holes for fasteners, you should make them yourself in advance.

Otherwise, the installation of L-beam siding is carried out using the same method as installation of any other type. Self-tapping screws must be screwed into the center of the perforation, at a distance of no more than forty centimeters.

This siding is ideal for walls made of stone, brick, wood and other building materials. Possessing excellent characteristics, it will transform any building into a beautiful, noble structure, shown in the photo. And after watching the video, you will be able to install the siding l beam yourself, without involving a team of specialists.

What are the advantages of metal siding under timber?

- This is a very stable material compared to plastic siding and wooden lining. It is less susceptible to deformation that occurs as a result of regular temperature changes. 50 years is the guaranteed service life of this material; at the same time, the external façade will remain attractive for a long time, maintaining freshness and novelty. A wall covered with it will not be visually different from a wall made of natural wooden logs.

One of the advantages of metal siding under the timber.

- Metal siding has high fire safety and corrosion resistance.

- The cost of metal siding that imitates timber compares favorably with the price set for natural material.

Additional elements

Each series of metal siding is completed with a set of special elements for decorating corners, door and window openings, as well as finishing and starting strips. offers additional elements, the front sides of which, in color, shade and texture, completely coincide with the main series of metal siding.

Depending on the selected series of metal siding, various fasteners may be required during installation. For example, the Woodstock series allows installation using simple self-tapping screws.

To create a load-bearing frame, you will need fastening brackets, and to fix sheets of metal siding and decorative elements, fastening clamps and screws. Depending on the selected series of siding and the length of the sheets, a different amount of fasteners will be required.

If the space under the siding is planned to be filled with insulation, then it is necessary to calculate its quantity, as well as fasteners for the heat insulator. Consultants or measurers will help you accurately calculate the required amount of a particular fastener.

The warranty on a metal profile can be up to 20 years, but the installation technology must be followed. If installation is incorrect, no warranty is provided; corrosion or destruction of the siding as a result of mechanical stress during transportation, installation, or operation is also not covered under warranty.

Euro timber - high-quality imitation wood

One of the latest innovations in metal siding construction is eurobeam, which is an imitation of the shape and pattern of laminated wood beams.

We also recommend that you read what a thermal curtain for the front door is.

A type of metal siding is Euro timber.

Advantages of Euro timber:

- does not fade in the sun and does not lose color brightness over a long service life;

- does not overload the foundation due to its lightness;

- practically indistinguishable from natural laminated timber;

- economical in consumption; after installation there is almost no waste;

- component panels are hidden and do not spoil the appearance of the surface;

- simple and undemanding to install;

- work with the material can be done at any time of the year, even in frosty winter.

Don't be afraid to install eurobeams yourself! This process does not require any special knowledge.

How metal doors are insulated is described in this article.

Eurobrus siding comes in two varieties:

- economy class euro timber , which is made of steel and covered with a decorative and protective layer of polyester;

- premium eurobeam made of especially durable Korean steel with high-quality PRINTECH coating, which perfectly imitates natural wood.

Upper layer

Polymer spraying is usually used as a protective coating. The service life of the material largely depends on its choice. A pattern that imitates a specific type of wood is usually applied to the surface.

Below are the color characteristics of some breeds:

- Birch is characterized by shades of yellow;

- oak has a distinct texture and a pinkish-brown color;

- maple wood is almost white;

- linden is usually presented in yellowish tones;

- the texture of aspen is weakly expressed, the wood is characterized by shades of white;

- Pine is characterized by yellow shades and a clearly visible pattern.

The surface differs in color and texture.

Note! If necessary, you can purchase panels that do not imitate wood texture, but are painted in one color. In this case, the coating resembles a wooden wall made of timber, treated with paint and varnish products.

Metal profile

Metal Profile is metal siding, which consists of stacked panels for facade cladding, complete with initial finishing and joining strips and internal and external corners. The presence of a wide range of additional (additional) elements in the kit is its main advantage and allows the use of metal siding for facades of any format and any complexity.

Metal Profile siding is especially often used in cladding the facades of large enterprises, but this material is also widely in demand in the private sector.

You can also read about entrance doors with good sound insulation at this link.

- high strength and resistance to external influences and fire;

- wide range and variety of color shades;

- high guarantee of durability.

You will be interested to know what types of locks there are for a metal entrance door.

The undeniable advantage of the material is its fairly light specific gravity. Domestic metal profile siding is considered a thin-sheet material (thickness is only 0.6 mm), which allows you to create a thin facade cladding without the use of additional fasteners.

This material will be a particularly good choice when finishing the façade of old buildings with weak foundations. The load on the walls and foundation will be minimal.

If you decide to cladding the facade with your own hands, then a metal profile is exactly what will suit you best. To install it, it is enough to have ordinary construction skills. Everything else can be found in the instructions for using the material.

Installation of vertical strips - corners and H-shaped connector

Corner strips have two types of design - complex and ordinary. Complex corner profiles have special recesses into which the ends of the panels are inserted.

They are installed strictly vertically along a plumb line, fastenings with self-tapping screws are made in increments of 0.2-0.3 m. Installation of complex corner profiles is carried out after installing the starting strip.

Simple corners are installed after installing the panels. It is much easier to work with them, since they simply cover the joint of the planes. Such corners are fastened with self-tapping screws or rivets. Experts recommend that everyone who independently installs siding on their home use this type of corner.

The joint of the panels along the length can be made with a simple overlap, but the connection with an H-profile, which has recesses on opposite sides for installing the ends of the panels into them, looks more aesthetically pleasing. The H-profile allows you to design the connection more accurately, on one vertical line, which improves the appearance of the house.

It is also installed immediately after installing the starting strip; the vertical is checked with a plumb line.

Installation of vertical strips - corners and H-shaped connector

DIY installation

So, you have decided to install metal siding without third-party specialists, that is, with your own hands. We offer step-by-step instructions for solving this problem yourself.

Scheme for installing metal siding with your own hands.

If you have basic construction skills and are not afraid of work, then facade cladding will be up to you.

Read here how to level walls with plaster.

Remember: before you start work, you should purchase not only metal plates, but also additional elements (to match the panels):

- internal and external corners;

- initial and final slats;

- connecting strip;

- brackets and platbands.

General rules for fastening metal siding

- Leave a gap of up to one and a half centimeters between the screw and the panel. When the temperature changes, the siding expands or contracts: the free space will facilitate the unhindered movement of the material.

- Self-tapping screws are screwed in without drilling.

- The panel is attached at each step of the sheathing.

- When installing additional elements, it is also necessary to leave a gap of up to 10 mm in order to prevent deformation of the siding under conditions of temperature changes.

Step 1: Preparing the facade for metal siding

- Carefully inspect the facade, tap the crumbling areas of the surface.

- Remove everything unnecessary from the walls: old putty, plants, various elements of drainage fastenings, roller shutters and other structures that interfere with the cladding process.

- Use a spirit level to check the surface is even. Walls with existing differences of more than 2 cm must be leveled using lathing, which will make the surface flawless.

Step 2: Installing the sheathing

Some people believe that installing the sheathing is an extra step that can be skipped. However, experts say that even if there are smooth walls, this part of the cladding process should not be ignored.

The grate can be made of wood, but a metal structure is still considered the best option - it is more reliable and durable. The pitch of the sheathing is determined by the width of the insulation. Usually it varies between 400-1000 mm.

The sheathing is installed in the corners, around doors and windows along the perimeter of the opening and at the junction of the panels.

Types, sizes, prices

Siding l timber can be of two types. “Premium” is made from steel that was produced in Korea. The cost of the material is from 400 rubles per 1 sq. m. "Economy" a polyester coating is applied to the steel plate. Its price is 300 per m2.

Each company sets its own siding sheet size. But basically the sizes are as follows:

- The length of the planks is from 0.8 m to 8 m;

- Width – range from 22.6 cm to 36 cm;

- Overall profile width – 26-39 cm;

- The height of the siding panel is from 12 to 15 mm;

- The thickness of the strip is 0.8-1.1 mm.