A house lined with metal siding. A wide range of materials, natural and artificial, are currently produced for the finishing of buildings. One of the most popular options is siding. There are many varieties of it in different shades and textures. Metal siding and shipboard are in high demand.

Subtleties of care

Both vinyl and metal siding do not require special care.

However, the surface must be periodically cleaned of dirt and dust. To do this, you can use a regular hose, from which water is supplied under pressure. You can also wipe the elements with a brush in cases where they are especially dirty. The application of varnishes, paints or protective compounds is not required throughout the entire operation process. All functions are performed by the factory coating. Due to the combination of properties and qualities, “ship plank” siding is widely used in all regions of Russia; consumers highly appreciate its quality and excellent appearance. The material is becoming increasingly popular for cladding houses and cottages and has pleased owners with its functionality for many years. Tips for siding are in the next video.

Types of material

At the moment, there are two main types of products with imitation ship planks on sale. Each option has its own characteristics.

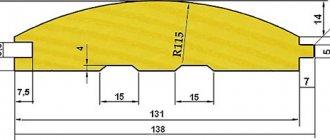

Configuration of the classic siding model under the board

Metal siding

This material is quite common and popular, which is explained by the coating, which perfectly follows the structure of wood. Panels of the desired shape are produced by rolling and stamping galvanized steel, after which they are treated with protective and decorative compounds.

Metal siding is considered one of the most durable coatings

Product advantages:

- Strength. The surface retains its structure even under severe mechanical stress.

- Decorative. Facade cladding gives the house originality and individuality. The front layer is resistant to ultraviolet radiation.

- Fire safety. The material does not support the spread of fire.

- Easy to install. Work can be carried out even at sub-zero temperatures. Houses that have not yet undergone complete shrinkage can be finished.

A significant disadvantage is the rather high price. Corrosion can also be a problem if it is damaged or improperly trimmed.

Vinyl products

Unlike the steel modification, plastic panels for boards have a more attractive price. For their production, PVC and special additives are used. The resulting mixture is molded and, after hardening, cut into parts of the required size.

Models simulating different types of boards

Advantages of the material:

- Resistance to precipitation. The panels do not rot, corrode, and do not contribute to the appearance and development of microorganisms.

- Ability to withstand various temperatures. The coating tolerates changes from – 50 to + 50 degrees, but in severe frosts the elements become fragile.

- Light weight. In this regard, PVC parts are significantly superior to the metal variety. This allows you to quickly finish the walls of the house and eliminates unnecessary load on the foundation.

Although vinyl panels have a uniform color, metal siding includes options with a more realistic imitation of wood. Also, plastic parts are subject to significant thermal expansion, which requires the creation of expansion gaps.

The color range of vinyl siding is constantly expanding

Appearance and dimensions

Externally, the profile of shiplap siding resembles plank cladding. Each panel has 2 waves. They are on top of each other. This allows you to create a surface that resembles overlapping boards. The special design enhances this impression. A person sees not a metal or vinyl product, but wood.

The form was invented for a reason. This design is characterized by high levels of resistance to mechanical stress, and also resists wind loads and removes excess moisture.

The standard dimensions of one element are 14x226 mm. Where 14 mm is the height, and 260 mm is the working width. The length of the panels reaches 6 meters. There is a separate material about siding sizes.

The color can be gray, ivory, oak and other natural types of wood. The cheapest panels are made in one color. Their board effect is much smaller.

Metal siding ship plank

Metal siding is a type of exterior siding consisting of long, narrow panels. They have a specific longitudinal profile, which makes it possible to join them into one sheet of any size.

The “ship plank” profile shape is one of the oldest; it appeared among the first samples of the material. Externally, it imitates a set of boards with a beveled edge that promotes water drainage, imitating the method of laying boards during the construction of a wooden ship.

The advantages of metal shiplap siding include:

- Easy to install.

- Light weight, no extra load on the walls.

- Relatively small size of thermal expansions (much smaller than vinyl analogues).

- A multi-layer protective coating reliably protects the panels from corrosion throughout their entire service life.

- Withstands large temperature changes, installation is possible at any time of the year and in any weather.

Disadvantages include:

- High cost of cladding.

- Possibility of dents from accidental physical impacts.

A feature of the material is the possibility of partial replacement (for example, one panel), but this will require disassembling the canvas to the desired area.

Metal siding is also divided into the following types:

- Under the tree;

- Under the beam;

- Under a stone;

- Under the brick;

- Under a log.

House with metal shiplap siding

Popular manufacturers

Siding made of galvanized steel such as shiplap, as well as vinyl, is in great demand among developers. Manufacturers took this nuance into account and included the model in their line of production. There are a large number of companies on the market producing this model, but there are those whose quality has been tested by time.

Ruukki

Ruukki is a world-famous company from Finland. The metal siding produced by it is valued by developers for its long-term use and excellent performance. The company produces models with matte and glossy finishes, as well as with a textured surface.

Alcoa

The company began its activities in America, and today is widely known throughout the world. It produces aluminum siding, which is highly valued for its combination of qualities:

- affordable price;

- wide choice of colors;

- lighter weight;

- different textures;

Consistently high quality attracts new customers around the world.

Corus Group

The concern has been operating for twenty years. Formed after the merger of British and Dutch companies. Produces high-quality metal siding from steel, which is strong and durable. The color palette includes more than 50 colors, and the price range will allow you to choose a material for the facade to suit every taste and budget.

Grand Line

A Russian company that produces a wide range of materials for low-rise construction. It produces shipboard metal siding as well as PVC panels. There are eight factories operating across the country that provide consumers with durable and visually attractive finishing materials. On the market for 10 years.

Metal Profile

A Russian company that has been providing consumers with high-quality metal siding for twenty-three years. Raw materials are purchased from leading suppliers. Siding from this company

- resistant to mechanical damage;

- economical during installation;

- temperature range from -30C to +70C;

- does not cause allergies;

- differs in fireproof characteristics.

Manufacturing takes place on equipment that makes it possible to maintain the correct geometry. The manufacturer provides a quality guarantee of 20 years in paper equivalent.

Types of block house: classification

All currently existing materials of this type can be classified according to only two criteria - the quality class and the material from which it is made. As for the latter, in most cases this is wood, to which quality classes mostly refer. They are as follows.

- Class “C” - as they say, the third grade is not a defect, but this class of block house for a log is still very, very far from the ideal. Such panels can be distinguished by a passably planed front surface, the presence of black, sometimes even falling out knots or holes from them. Also, in this class of material, the presence of mechanical damage, small cracks and even remnants of tree bark is acceptable. In general, not in good condition.

- Class “B” is not much different from the previous class of material. This block house is characterized by the presence of knots and holes from them, minor mechanical damage, cracks and chips.

- Class “A” is already a more acceptable material. Of all the defects described above, only the presence of dark and light knots that do not fall out is allowed here. This wooden house block has a perfectly planed front surface.

- Extra-class “E” - ideally selected material, without defects or damage. This is the most expensive type of material of this type.

This applies to the wooden block house, which, by the way, is considered a classic of the genre, and all other varieties, which we will talk about later, are classified as its imitation. They cost less than wood material, and sometimes even surpass it in their characteristics. Let's conduct a small comparative analysis of other types of block houses with the wooden original.

- Metal block house. Among all the substitutes, it can be called the best. This material has only one drawback - dents form on it quite easily. In all other respects, it outdid even its natural wooden counterpart. True, here everything depends on the metal from which it is made - if it is galvanized, covered with a protective and decorative layer, then it is not very well able to resist corrosion. But if it is aluminum, then this is a completely different matter - such a metal house block under a log can be called almost eternal.

- Vinyl block house. In some ways, it can be compared to vinyl siding - by and large, this is what it is, only with a slightly different configuration. It has many disadvantages - the only good thing about it is that it is not susceptible to corrosion.

- Plastic block house. Today, two versions of this material are produced - the first of them is some semblance of ordinary PVC plastic (it has exactly the same cellular structure, but differs in its curved shape like a log) and a plastic house block combined with polyurethane foam. The last option is already a serious product, which can even be ranked higher in its characteristics than its wooden counterpart. It is hard, warm, does not rust or rot, and does not require additional finishing or maintenance. The only thing wrong with it is that it can fade over time - this point depends on the quality of the plastic.

Among other things, the entire block house existing today, depending on the shape of the front surface, can be divided into a block house under a log and under a beam. In principle, both materials look great on the walls, and the choice between them depends solely on your personal preferences. And one more thing - a block house under timber is a little cheaper. This is due to less material consumption during its manufacture. In addition, timber material is often used indoors, and it is often called block house for interior decoration - this point is due to the less deep relief of the surface obtained with this material.

Sizes of different types

The dimensions of siding profiles are not regulated by state standards. Each manufacturer independently decides what size the panels it produces will be.

The dimensions depend not only on the brand under which profiles for external use are produced, but also on their type. It is important what type of finishing the profile is intended for. Thus, façade options are thinner than basement ones. The latter are intended to protect and decorate the basement of the building, which is more susceptible than others to moisture, road reagents, and mechanical damage. This is what determines the thickness of the plinth panels, which is 1.5-2 times the height of the standard profile for the facade.

Information about the width, length and height of the siding is necessary to accurately calculate the required number of siding packages, taking into account waste during the installation process.

Wood

It is durable and moisture resistant, but only if it is regularly treated with special compounds. The material is distinguished by good heat and sound insulation, unique colors and texture, and high cost.

Manufacturers are recommended to adhere to the following indicators when producing the material: length - from 2 to 6 m, width - no more than 22 cm, thickness - no more than 2.2 mm.

Cement

The material is based on cement mixtures and modifiers, and to ensure its strength, special cellulose fibers are added, which have reinforcing properties. The result is a durable monolithic material that is resistant to frost and high humidity. However, cement panels are not suitable for every type of foundation, as they add additional load to the foundation of the building.

The length of such panels can be from 3 to 3.6 mm, width - 20 cm, thickness - 0.8-1.2 mm.

Vinyl

This material is presented in the form of PVC panels. It does an excellent job of protecting buildings from wind and moisture, thereby ensuring the safety of load-bearing structural elements and the insulating layer. The affordable cost of facade vinyl siding, its attractiveness and excellent characteristics have made the material very popular and in demand in the field of cladding buildings.

Vinyl panels are produced by passing a molten mixture - a compound - through a profiling opening. The siding formed in this way cools down, maintaining the given shape. Using this method, two-layer panels can be produced. The top layer ensures color preservation and resistance to fading. The internal one is responsible for resistance to temperature changes, ductility and impact strength.

The thickness of the panels can range from 0.90 to 1.2 mm. If it is planned that the cladding should last at least 10 years, you should choose products with a thickness of more than 1 mm.

Imitation of logs or block houses is ideal for finishing country houses. This is one of the most popular materials for cladding facades in private construction.

The following are the advantages of vinyl siding:

- high ductility and elasticity;

- moisture resistance;

- anti-corrosion;

- shock resistance;

- fire resistance;

- affordable cost;

- does not require regular painting;

- easy to clean with water and non-aggressive detergents;

- does not emit toxic substances;

- easy to install.

The material is presented in the form:

- ship plank;

- Christmas trees - single, double or triple;

- block house.

Vinyl plank specifications may vary depending on the manufacturer.

Lamellas are produced:

- thickness – 70-120 mm;

- length – 3000-3800 mm;

- width – 200-270 mm;

- weight – 1500-2000 g;

- area – 0.7-8.5 sq. m.

The package can contain from 10-24 units of goods. Panel shades may vary depending on the manufacturer and product batch. Therefore, it is not recommended to purchase the material in parts.

Avoid purchasing recycled siding. These are low-quality products that do not meet the requirements for facade materials.

Purchase materials only from bona fide, trusted suppliers who are official partners of manufacturers - confirmation of this can be found on the company’s website. High-quality vinyl siding is supplied only in original packaging and has special markings. Among foreign manufacturers, the German one, Grand Line, whose products are produced today in Russia, has proven itself well, and the Belarusian one. Among Russian manufacturers we can highlight Altaprofil.

Ceramic

A ceramic profile made from clay and other natural components is environmentally friendly, and therefore can be used not only for external but also internal cladding.

Standard dimensions are: length – 3-4 m, width – 19-22 cm, profile height – no more than 1 mm.

Metal

Metal siding is a highly durable material that will honestly serve you for at least 30 years. The coating is absolutely waterproof and therefore reliably preserves the integrity of the supporting structure. It can extend the life of any building several times, so it is very often used when repairing dilapidated buildings. Metal siding has high fire safety characteristics. The low specific weight of the lamellas makes it easy to transport the material and simplifies the installation process. When installing a ventilated facade system, it is possible to install several layers of heat and waterproofing materials under the cladding, which allows for maximum energy saving. The surface of the sheet is coated with a special polymer composition. Thanks to this coating, the products are reliably protected from corrosion and exposure to ultraviolet rays - they do not fade or change color.

Advantages:

- Durability - manufacturers guarantee 30 years of service.

- Adequate cost.

- Wide range of shades.

- Simple assembly of the cover.

- Ensuring good ventilation of walls.

The products are presented in the form of lamellas with a width of 200-300 mm, a length of up to 6 m. Their weight reaches 5 kg / sq. m. The products are equipped with locking elements for connecting parts into a single fabric.

To design products, photo printing is often used, which allows you to apply any image to their surface. If desired, the customer can obtain an imitation of wood elements, brick or stone masonry.

Panels can be produced in the form of ship planks or logs. “Shipboard” has become the most popular variation of this product due to its cost-effectiveness.

Tsokolny

The base of the building is most susceptible to mechanical stress and needs reliable protection. Therefore, its cladding requires a material with increased strength. The thickness of polypropylene basement siding is 2-2.5 times higher than that of products for cladding the upper part of the facade. Due to this, its strength increases tens of times.

Base lamellas are produced by pouring a plastic composition into special molds. After this, the finished pieces are painted and thoroughly dried. During the molding process, the panels acquire mounting holes, locking protrusions and stiffeners. They give the panels excellent impact resistance and increased strength. Using a variety of shapes, manufacturers create panels with different textures. Imitations of rubble, natural stone, sandstone, brick, wood cannot be visually distinguished from natural samples.

Types of material

At the moment, there are two main types of products with imitation ship planks on sale. Each option has its own characteristics.

Configuration of the classic siding model under the board

Metal siding

This material is quite common and popular, which is explained by the coating, which perfectly follows the structure of wood. Panels of the desired shape are produced by rolling and stamping galvanized steel, after which they are treated with protective and decorative compounds.

Metal siding is considered one of the most durable coatings

Product advantages:

- Strength. The surface retains its structure even under severe mechanical stress.

- Decorative. Facade cladding gives the house originality and individuality. The front layer is resistant to ultraviolet radiation.

- Fire safety. The material does not support the spread of fire.

- Easy to install. Work can be carried out even at sub-zero temperatures. Houses that have not yet undergone complete shrinkage can be finished.

A significant disadvantage is the rather high price. Corrosion can also be a problem if it is damaged or improperly trimmed.

Vinyl products

Unlike the steel modification, plastic panels for boards have a more attractive price. For their production, PVC and special additives are used. The resulting mixture is molded and, after hardening, cut into parts of the required size.

Models simulating different types of boards

Advantages of the material:

- Resistance to precipitation. The panels do not rot, corrode, and do not contribute to the appearance and development of microorganisms.

- Ability to withstand various temperatures. The coating tolerates changes from – 50 to + 50 degrees, but in severe frosts the elements become fragile.

- Light weight. In this regard, PVC parts are significantly superior to the metal variety. This allows you to quickly finish the walls of the house and eliminates unnecessary load on the foundation.

Although vinyl panels have a uniform color, metal siding includes options with a more realistic imitation of wood. Also, plastic parts are subject to significant thermal expansion, which requires the creation of expansion gaps.

The color range of vinyl siding is constantly expandingTypes of ship siding

The finishing material, which imitates ship cladding, is available in two types.

Metal panels

Siding is made from galvanized steel sheet. The metal is covered with protective and decorative layers on top, which ensure moisture resistance and create the necessary texture. The thickness of the protective coating and the metal itself may vary among different manufacturers.

Steel siding structure

The following can be used as protection:

- purala;

- glossy or matte polyester;

- PVDF;

- plastoisol.

When choosing a color option, the standard RAL table is used.

Metal siding shades

Metal cladding has a number of advantages:

- It is durable and resistant to various mechanical influences.

- The planks have good geometry.

- Temperature range in which the finish can be used: -60…+80 degrees.

- The material does not support combustion.

- The coating has a low expansion coefficient.

- The decorative layer does not lose its external qualities over time.

- Siding is easy to install. Moreover, installation can be done year-round.

- Manufacturers guarantee a service life of the cladding of at least two decades.

- The coating is not subject to rotting and is not of interest to pests.

- The cladding is easy to care for.

- Variants of textures and color solutions offered by manufacturers make it possible to select the optimal option.

Why metal siding is convenient: the dimensions can be selected in accordance with specific requirements.

Lined country house

At the same time, there are a number of disadvantages that should be taken into account when choosing a finishing option:

quite high price; the large weight of the panels, which leads to an increase in the load on the structure of the building and to certain difficulties during installation; susceptibility to dents due to careless handling; the risk of corrosion if the protective layer of products is damaged; the labor-intensive process of replacing damaged planks.

When using metal siding to clad a building, it is imperative to carry out heat and sound insulation work.

Metal siding is characterized by:

- Steel thickness: 0.3…0.6 mm.

- Thickness of the protective and decorative coating: 25 microns.

- Profile height: 11.5…15 mm.

- Panel width: 255…263 mm.

- Length of slats: 0.8...6 m (the most common size is 4 m).

Some differences in the sizes of panels from different manufacturers (several mm) are not particularly significant, but you should pay attention to the thickness of the metal

Plastic panels

These coatings are made from PVC with the addition of additives that increase the functional qualities of the material:

- Vinyl siding protects the building well from the effects of precipitation and wind.

- It is biologically inert.

- The laminated layer helps protect the cladding from exposure to ultraviolet radiation and increases the material’s resistance to low temperatures.

- The material is lightweight, which makes installation work easier.

- The cost of plastic panels is significantly lower than their metal counterparts.

- Vinyl planks are available in a variety of colors.

- Siding is non-toxic.

- The lining does not burn, but only melts if the temperature reaches 400 degrees.

- The plastic is easy to clean with a wet sponge.

Palette of shades of plastic panels

When installing vinyl plastic cladding, a ventilated gap is created, which ensures proper circulation of air flow and reduces the possibility of condensation.

- Finishing buildings with vinyl requires the installation of a heat-insulating layer.

- Vinyl plastic is susceptible to damage due to careless handling. Replacing even one element is quite problematic, since it is necessary to dismantle the entire facing structure down to the damaged part.

- Another disadvantage of polyvinyl chloride coatings is thermal expansion, which entails the need to create expansion gaps.

- The appearance of plastic coverings is inferior in comparison to steel ship siding, since there is not such a variety of textures, especially those imitating natural materials.

Parameters of plastic ship siding:

- length of planks: 3.0…3.8 m;

- width: 23…27 cm;

- thickness of ship siding: 0.7…1.2 mm;

- profile height: 1.4…1.6 cm.

Metal siding panel design

The structure of the "ship plank"

"Shipboard" siding has a rather remarkable shape: each panel contains two waves overhanging each other, imitating the plank lining of a ship's side. This design not only provides the shiplap panels with mechanical resistance, but also promotes more efficient drainage . You can see a typical profile of such siding in the photo:

Metal siding profile “ship plank”

Note!

An additional advantage of the “ship plank” is its high resistance to wind loads.

Quite often, manufacturers offer the production of metal siding to the required dimensions - i.e. There is no need to trim the panels during installation. Like other models of metal siding panels, “shipboard” is produced on the basis of metal sheets using the stamping method. The multilayer structure of each panel provides it with high resistance to atmospheric conditions.

Panel dimensions

The classic “ship board” has a six-layer structure:

- Base – steel sheet 0.4-0.6 mm thick;

- Anti-corrosion zinc coating (minimum – 275 g/m);

- Passivation (second level of anti-corrosion protection);

- A primer that ensures reliable adhesion of the protective polymer to the metal base;

- Polymer protective coating;

- Varnish protective coating.

Each coating layer performs its own function, but the polymer protective coating plays a key role. It is the type and thickness of polymer coatings that, by and large, distinguish “ship plank” metal siding models from different manufacturers.

Metal siding panel structure

Polymer coatings

The following can be used as polymer coatings for shipboard metal siding:

- Polyester is one of the least expensive coatings. It is applied up to 25 microns thick and has a glossy sheen. The polyester coating is highly elastic and tolerates bending deformations well. Suitable for use in almost any climatic conditions, it practically does not fade under the influence of ultraviolet radiation.

- Matte polyester is a thicker (35 microns) coating based on polyester compounds. It is more resistant to fading and mechanical damage than polyester. The main feature is the matte surface.

- Plastisol is a polyvinyl chloride-based coating up to 200 microns thick with an embossed surface (wood embossing options are possible). Plastisol coating of metal siding is considered one of the most resistant and durable.

“Ship board” imitating wood

Note!

In the southern regions, shipboard siding models with a lighter coating are preferred.

- Pural is a polyurethane resin-based coating that recently appeared on the market, developed by Finnish engineers. The main feature of this coating is the preservation of performance characteristics over a wide temperature range.

- PVDF is a composite coating made from a mixture of acrylic and polyphenyl difluoride. It is durable, practically does not fade, and has self-cleaning properties. Metal siding of the "shipboard" type with a PVDF coating will be an ideal solution for finishing the walls of buildings located in aggressive conditions - for example, on sea coasts.

Accessories for additional elements for metal siding

Price from 150 rubles per piece Price is valid under certain order conditions Buy

| For proper installation and a finished look of the building facade, metal siding is completed with additional elements. They help to arrange all complex areas of the facade, maintain the tightness of the cladding and make it possible to easily design an architectural detail of any complexity. The component strips play an important role in the reliability, strength and durability of the cladding. Each element has its own purpose and technological location during installation. Without metal additional elements, it is impossible to ensure complete installation of metal siding and achieve high-quality performance characteristics of the facade. All components are made of hot-dip galvanized steel with a polymer coating of the same color as the metal siding or, at the customer’s request, in a color contrasting to the color of the main siding panels. |

| Additional elements are made from steel of the same thickness as the metal itself (0.45 or 0.5 mm). As a rule, two types of standard mounting strips are produced - simple and complex geometric shapes. They have different shapes and sizes, but their purpose and “seats” during installation are the same. It should be noted that for the block house and log siding profiles, we additionally produce our own metal components that are adjusted to the specific semicircular shape of this profile, especially for the internal and external corners, which consist of two parts - lower and upper. In addition, for each manufacturer, the dimensions of even standard components may differ. |

The standard length of all planks is 2 or 3 meters, but it is also possible to manufacture individual lengths to suit the customer’s dimensions.

| Our company has its own bending machine and can offer its customers any individual metal elements for the facade and roof - slopes, caps, ebbs, parapets, plinths and any metal elements (bending) of individual shape, size and color. The price of such products depends on the type of metal coating, its thickness and the size of the individual element itself. Production time is 2, 3 days. |

Attention! It is important. Standard metal strips from one manufacturer may not be technologically suitable for steel siding panels produced by another plant due to differences in the geometry of the products. Even a slight difference can make it impossible to install planks and siding from different manufacturers

However, the same mounting elements are suitable for different siding profiles (shipboard, herringbone, under the board, etc.) produced by the same manufacturer

Even a slight difference can make it impossible to install planks and siding from different manufacturers. However, the same mounting elements are suitable for different siding profiles (shipboard, herringbone, under the board, etc.) produced by the same manufacturer.

Material advantages

Metal and vinyl siding have some features that determine both the advantages and disadvantages of this finishing material.

The main advantages of metal siding panels are:

- the presence of very bright and quite resistant to external influences colors;

- guaranteed strength and absolute fire resistance of the material.

The vinyl finishing panels of the “Shipboard” series are characterized by the following advantages:

- beautiful appearance;

- no changes in color as a result of exposure to UV rays;

- ease of installation work.

As for installation, there are practically no fundamental differences between these two versions of the “Shipboard” series siding panels. It should be noted that both materials are durable and easy to maintain. In addition, in terms of performance characteristics, they are also almost identical.

Manufacturers have launched the production of all additional elements that may be required during the installation process. Such elements are necessary when decorating corners, eaves and ebbs. The color scheme of parts for metal and vinyl “Shipboard” siding is varied, which makes it possible to select the shade that best matches the color of the main panels.

Advantages and advantages of this material

The main advantages of metal siding are:

- cost is one of the main advantages of the material. Despite decent aesthetic and technological characteristics, the price of the panels is comparable to the price of good plaster;

- ease of operation - does not require painting or restoration work, can be easily cleaned of dirt using a watering hose;

- high mechanical strength and durability are ensured by a combination of high-quality materials;

- the material is non-flammable and resistant to high temperatures;

- resistant to temperature changes. Can be installed in any conditions;

Metal panels perfectly imitate natural boards

metal siding service life is from 50 years; does not require lengthy preparation of the façade before installing the panels. Can be installed on uneven walls thanks to the creation of lathing. The material can hide cosmetic imperfections of the facade, as well as technical communications; Installation of metal siding “Shipboard” can be performed without special skills. It is enough just to carefully and seriously approach the installation of key elements; metal siding is offered in a wide range of colors and sizes. At the same time, both a wide palette of uniform colors and a selection of textures of natural materials are available.

Installation of metal siding: video

This section presents a video of installation of shiplap metal siding. After watching, you can try to install shiplap siding with your own hands.

Typically, installation of shipboard (siding) includes the following steps:

- Preparatory work: if necessary, before installing metal siding, level the wall surface of the house using its lathing; if necessary, lay steam and heat insulation layers.

- At the very bottom of the wall of the house, marks are placed for subsequent fixation of the lower strip of metal siding, which should be positioned strictly horizontally;

- The next step in installing shiplap (siding) is attaching the outer and inner corners to the sheathing. At the same stage, according to preliminary markings, the strips are installed. They should be located at future joints of siding panels.

- Installation of frames for door and window openings using platbands or strips. They start by attaching the top part, then install the side parts, and then the bottom parts.

- Next comes the direct installation of metal siding from bottom to top. The lower part of the siding panel is inserted into the latch of the previous strip, and the upper part is attached to the wall using aluminum nails or large-head screws.

- At the very top of the wall, the finishing strip of metal siding is attached using self-tapping screws.

Panel installation

The panels are installed in a strictly defined order. First, a starting strip is installed around the entire perimeter of the building. It must be positioned strictly horizontally, which must be checked using a building level. The installation height depends on the size of the plinth.

When the starting strip is installed, proceed to the installation of corner and window profiles, and then you can begin installing all other panels:

- The first of them is attached at the bottom in the lock of the starting bar, while at the top it is fixed with self-tapping screws.

- The next panel should be located at a distance of 0.6 cm from the previous one. This condition must be observed to avoid the effects of expansion and contraction of the material as a result of temperature changes.

- The third, fourth and all subsequent strips are attached in the same way.

- The last row is installed together with the finishing strip, which prevents rain and melt water from getting under the skin.

Dimensions of components

Taking into account the dimensions of the panels and calculating their number, it is important to clarify the dimensions of the components. As a rule, they are similar to panels, but this is not always the case

J-trim strips are the same length as most siding panels, but they are not suitable for installation with Docke panels because they are shorter.

External and internal corners have a length of 3050 mm, the width corresponds to the width of the panel. Starting and finishing strips are available in lengths of 3660 mm. The hanging profiles and strips for decorating window casings are the same length, and the window slopes are 3050 mm.

Dimensions of the window strip

The width of the slopes is up to 18 cm. In the vast majority of cases, this distance is enough for the window strip to fit perfectly into the opening and the existing slope, connecting with the main siding along the outer perimeter of the window.

The small outer part of the plank is approximately three times smaller than the slope. This width is enough to hide the transitions between the siding sheets and the outer perimeter (up to the bevel) of the window opening.

The length of the elongated holes through which the window panel is attached to the load-bearing structure (along the perimeter of the opening) is no more than 2 cm. This, in turn, is rigidly fixed to the wall. The slotted holes - as on the siding sheets - are made in such a way to compensate for the bending of the window strip in the summer in the heat (or tension in the winter in the cold).

The range of sizes of the near-window profile is determined only by the manufacturer’s brand.

| No. (sub) item | Part length (in centimeters) | Width of the internal or slope edge (in centimeters) | External part (in centimeters) |

| 1 | 304 | 15 | 7,5 |

| 2 | 308 | 23,5 | 8 |

| 3 | 305 | 23 | 7,4 |

The window profile does not have dozens of variations in size. Houses built according to old standards are not always suitable for restoration: installing window panels without replacing the window is a difficult task. Having replaced the old Soviet wooden window with a new, metal-plastic one, it is adjusted in the opening so that the slope (including a vertical one, at 90 degrees) is obtained with a width of no more than 18 cm. A number of manufacturers also offer alternative versions of solving this issue.

What is this type of siding called “Shipboard”?

Classic looking profile. The surface sheathed with this material looks like a painted wooden covering made from eurolining. However, unlike wood, it has much more attractive performance characteristics.

It is most often used for finishing horizontal facade surfaces of buildings with both a small number of floors and taller structures.

“Shipboard” siding can be presented in two types:

Metal

It is made from galvanized steel sheets using cold rolling technology. On the outside, the material is covered with a protective polymer film, which allows maximum protection of the base from the harmful effects of moisture and, as a result, prevents the occurrence of corrosion.

Advantages of using metal siding

- A wide range of operating temperatures allows normal operation even in capricious climatic conditions;

- It is not a flammable material;

- Excellent impact and mechanical strength;

- Huge variety of colors;

- Installation of such siding can be carried out at any time of the year;

- Metal siding "Shipboard" does not rot and is also inedible for insects and rodents;

- Creating an airtight finish;

- It can be used for structures that were built not so long ago and have not yet shrinked.

Photo of a house with metal shiplap siding

Disadvantages of using metal siding:

- Steel elements have a significant mass, which makes it difficult to deliver and supply these finishing materials to the construction site;

- Finishing with metal siding requires mandatory heat and sound insulation;

- If damage occurs on the surface of the polymer protective layer, the likelihood of corrosion processes appears;

- Subject to bending deformations;

- Difficulty in replacing damaged elements.

- The material has low elasticity; if a dent or bulge occurs, it does not return to its original position.

IMPORTANT! It is worth noting that siding made of metal profiles perfectly withstands exposure to ultraviolet radiation, so that even over time the lined surface will remain in its original form and will not fade.