Why are overhangs needed?

A roof overhang is the overhang of the roof that extends from the bottom of the roof. The recommended overhang width is 40 - 50 centimeters. Hemming of roof overhangs is a mandatory operation during the construction process. However, if you do not plan such a process, serious troubles may arise. The worst thing happens when a strong wind undermines the entire roof, passing through unlined overhangs. And the correct lining of the roof overhangs hides all the insides of the roofing pie and gives the building a finished look.

Important! Before carrying out lining work, you should complete the installation of the roof and also insulate the walls.

DIY cornice finishing

Sheathing the roof of a house is not difficult at all. This procedure is quite accessible to every home owner, but requires certain knowledge and skills. First of all, it is necessary to carry out preparatory work on decorating the roof frame with your own hands.

Actions are classified into:

- preparatory;

- protective coatings for protrusions.

Preliminary actions

Starting events are long-term, consisting of a series of tasks:

- Focus on material, hemming technology, ventilation.

- Organization of rafters, walls, tools, etc.

Types of overhangs

Structurally, overhangs are divided into only two main types: cornice and pediment.

Cornice overhangs

The lower horizontal part of the roof slopes is called the eaves overhang. It plays a key role in roof ventilation. The fact is that air enters through it, which either passes through the attic, as with attic-type roofs, or through the roofing pie, as with attic-type roofs, and then leaves through the ridge. Therefore, you cannot nail down the overhang tightly, because in this case air will not pass through.

A well-made sheathing should provide sufficient ventilation of the under-roof space Source interistroy.ru

There are several ways to ventilate your roof. Firstly, you can leave a gap between the wall and the lining material. It should not be too big, about one and a half centimeters. Secondly, the use of sheet materials when filing overhangs makes it possible to use ready-made ventilation grilles. Thirdly, if the overhang is hemmed with boards, we can simply make gaps between them. But in the case when the roof, for example, is based on bitumen, it is worth increasing the area of the ventilation holes compared to, for example, clay tiles, since the first does not allow air to pass through at all. It is also worth covering all openings with nets to prevent contamination of the roof or attic.

Gable overhangs

The side part of the roof overhang is the gable overhang. The list of its functions does not include ventilation, but its main task is to reliably protect the entire roofing pie. Otherwise, the systematic entry of moisture will nullify all the efforts of your insulation, which is located in the roofing pie, and the room will become noticeably colder. When it comes to front overhangs, the most important goal is airtightness.

The gable overhang looks more voluminous Source pallazzo.su

See also: Catalog of companies that specialize in roof repair and design.

Purpose of roof eaves sheathing

After covering the roof with roofing material is completed, there are areas on the gables and eaves that are not protected from moisture and wind. It is the covering of the roof eaves with one material or another that is the lining.

The main functions of the lining are:

Prevents the penetration of moisture from outside into the space under the roof. Since the lower parts of the rafters, which form overhangs at the eaves, are not covered by a layer of waterproofing and roofing, they can be subject to the harmful effects of rain or snow. Provides protection for the top of the building wall from getting wet and dirty

This is important because dirty water flowing from the roof drips onto the walls and spoils the exterior finish. It is a barrier for birds, which quite often like to make nests under the eaves. They not only destroy the roofing pie, pulling out the thermal insulation from it, but also create a lot of noise. From an aesthetic point of view, lining the roof eaves with wood completes its appearance and hides the internal frame.

How to trim an overhang edge

Each type of overhang will necessarily have uncovered elements, such as the end parts of the rafters, as well as the ends of the sheathing. You will definitely need to decorate them beautifully, protecting them from bad weather and all external factors. The choice of materials for lining roof overhangs directly depends on what you used as roofing.

Before starting work, you should cut off all protruding rafters and sheathing elements at the same distance from the wall. After this, you must cover them with a strapping board, to which the front board is then attached. It is necessary to cover all wooden elements with protective compounds and it is better to paint if it is made of wood. It is also necessary to provide attachment points for gutters. On the front overhang, you need to nail the end board to the cut parts of the sheathing, and only then use roofing materials to finish it.

“Skeleton” of the under-roof frame Source pinterest.com

Decorating a box for filing

The steps to create boxes on the roof with your own hands are carried out in strict order:

- Cut and pre-treat the material with antiseptics and paints and varnishes.

- Install and secure the board along the underside of the rafters.

- Nail the beam to the wall one centimeter higher than the front board.

- Arrange all the parts of the filing sequentially: fasten one edge to a beam mounted to the wall, the other to a board located on the side of the rafters.

- Alternate panels with ventilation grilles at equal distances or leave a gap of 2 cm or more between the parts of the filing.

- Fasten products with profile plates, screws, corners. Note! If the boards are long, at least three fastenings are necessary to avoid deformation.

- To form corners, mount the panels on both sides of the rafters or flat.

Options for filing overhangs

There are many options for filing overhangs, but the most common are the following:

- Finishing the overhang along the rafters . This method is the easiest of all possible, but it requires that all rafters lie strictly at the same level and in the same plane. It is suitable for roofs with a slope of no more than 30 degrees and an overhang of up to 50 centimeters. The sheathing material is attached to the sheathing, which in turn rests on the roof frame. It will be better and more convenient if the hemming strips are stuffed perpendicular to the rafters.

- Horizontal filing . Very fast and economical in terms of material, hemming the roof. In order to carry out this option, you must first assemble a box of two boards, and only then attach it to the rafters. The board covering the end should end slightly lower than the vertical one, so that water falling on it can easily roll down. If the width of the overhang is about 50 centimeters, then another longitudinal board will be needed in its middle. This is a ready-made frame for installing roofing materials. This method is well suited for roofs with a large slope.

An important point is that the frame is always assembled from beams and boards, and lining materials are already attached to them.

Sheathing materials are attached to the roof frame Source amwd.ca

Rafters

To prepare the rafters, you need to decide on the method of cutting the wood and installing the frame for the construction of the projections.

Sequence of activities when preparing rafters:

- Provide for their length to be 30-50 cm longer than planned.

- Form a protrusion that would correspond to the specified size.

- Cut the material and process the edges of the rafters: - vertical cut - for the purpose of filing along the rafters; - vertical and horizontal sections - during the creation of the box. It should be noted that if there is an unexpected increase in the width of the overhang before installation, the rafters must be lengthened using beams - “fillies”.

- Achieve a straight overhang line.

How to choose materials

If you are planning such an operation as lining the roof with boards, then coniferous wood would be better for these purposes. The board must be thoroughly dried, otherwise it will warp later. It is imperative to treat it with paint and varnish coatings to protect it from mold and moisture. This material can be hemmed parallel and perpendicular to the wall.

A good option is wooden lining . Its advantages over the board are that it is already processed. However, for such purposes it must be water-resistant, and it must also be dried and processed. When hemming with this material, you can use ready-made grilles for ventilation.

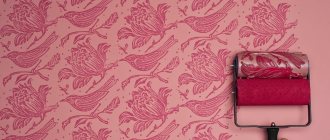

Good quality lining is a universal material, which is also used for lining roof overhangs Source stroyportal.ru

Polyvinyl chloride siding is another material option. Only waterproof material should be used for hemming. All accessories can be purchased in special stores. You should not attach such material along the wall, because over time it can bend greatly.

A very easy to use and affordable material is corrugated sheeting . It is distinguished by its lightness, strength and durability, as well as its affordable price compared to other materials. If the choice fell on this option, then when filing it is worth leaving ventilation gaps a little more than a centimeter.

Lining the roof with corrugated sheets looks very nice Source krovelmag.kz

You can also use sheets of waterproof plywood or OSB, as well as galvanized or polymer-coated steel, aluminum or copper.

Selecting material for hemming.

Which material to use primarily depends on the overall style of the house, taking into account the decoration of the walls and the type of tiles. An important factor is the price and, of course, the personal tastes of the homeowner. It is worth taking into account the practicality and durability of the material.

Wooden plank.

The tree requires special care. Before installation, it is treated with antiseptic and fire-fighting compounds, painted and varnished. From time to time you will have to repeat these operations, otherwise insects will appear in it, it will begin to become damp and deformed, and the appearance will noticeably deteriorate.

Coniferous species are chosen for lining the cornice. The board can be planed or edged, the permissible width is 2-25 cm, thickness 1.7-2.2 cm. When mounting the boards parallel to the wall, they are fastened in increments of 1 m, perpendicularly - on both sides of the board, with a wide overhang also in the center . For ventilation, leave gaps between the boards of 1-1.5 cm.

Wooden lining.

The material has already been processed, unlike the board. But, like a board, before installation it is advisable to keep it in the air under a canopy for 1 month, otherwise the wood may be too wet or dry, which will subsequently lead to deformation. Installed in a similar way. It is possible to install ready-made ventilation grilles, which are located at a distance of 1.5 m from each other. The lining costs twice as much as the board.

OSB and plywood.

The boards must be moisture resistant. Installation is quick, since the dimensions and rigidity of the material make it possible to install large sheets at once. For installation, a box of timber is erected, to which the slabs are screwed. Ventilation is carried out by inserting grilles. This type of filing is not durable and not aesthetically pleasing; painting is undoubtedly required.

Sheet metal.

It is rarely used, as it has a number of disadvantages: heavy weight, a special cutting tool is required, and anti-corrosion treatment of steel sheets along the cut edge is required. Mostly galvanized steel with a polymer coating with a thickness of 0.6 mm is used. The length of the product can reach 6 m. Rarely do they take copper or aluminum sheets. For ventilation, grilles or perforations are used.

PVC siding.

PVC panels are installed perpendicular to the walls, screwed in several places depending on the width of the overhang. For ease of installation, various additional elements can be purchased along with the siding. To finish the edges, “U” shaped strips are placed, the junctions of the panels are fixed with corners, and there are ventilation grilles. PVC siding is not recommended for installation along the overhang; it does not have sufficient rigidity and can sag. Siding is produced mainly in light shades, its cost is low. If you choose good quality material, it will last for quite a long time.

Profiled sheeting.

It stands out for its ease of installation and durability. Profiled sheet C8, C10 or NS 20mm is used. When designing the cornice, you should take into account the thermal expansion of the corrugated sheet and leave a gap of 0.6-1.2 cm. Fastening is carried out in increments of 1 m. Ventilation is carried out through specially designed grilles.

Soffit.

Soffit is a special siding for lining an overhang. Soffits are made of vinyl or metal. They have a varied texture and a large color palette. For example, wood-look metal soffits are very popular - they accurately copy the wood texture of noble wood species, such as cedar, oak, and maple.

But in comparison with natural wood, soffit does not require maintenance, does not require processing or painting, does not dry out or swell, is not afraid of moisture and temperature changes, and costs several times less. Soffits are suitable for all types of tiles and can be easily matched to any architectural style.

The kit includes all the necessary components, profiles and strips, which greatly simplify and speed up installation. Soffit panels can be of different types: single, double, triple, perforated or solid.

You can complete the overhang with soffit yourself; the installation procedure is very simple: the planks are cut along the width of the overhang and secured with grooves perpendicular to the walls.

Soffit is undoubtedly the most reliable and fastest way to frame cornices and is very popular among owners of private cottages.

Covering roof overhangs using soffits

Lining the roof using soffits is one of the most rational methods.

The soffits themselves are strips that are produced specifically for lining roof overhangs and are a very convenient and fairly affordable means. They can be made from any material from PVC to metal. Various colors and styles allow you to choose soffits for any home. Typically, this hemming material is sold complete with everything necessary, including fittings and fasteners.

Soffits are usually sold as panels, which can have one, two or three layers. Soffits can also be solid or perforated. This method of filing is very simple and relevant, since installing soffits on the roof eaves does not require special skills and abilities, as well as spending a lot of time.

Soffits are panels specially designed for lining overhangs Source krovelmag.kz

One of the most popular methods of lining roof overhangs with soffits is horizontal lining. When using this method, a sheathing is made and attached to the roof overhang. Then a profile cut to size is attached to the sheathing. Such a profile is usually cut with a grinder and attached to the sheathing with self-tapping screws. There should be two strips - one at the wall, and the other at the edge of the overhang.

Careful measurements are the basis of any construction work Source interistroy.ru

Then the plate is inserted first into a profile located near the wall, and then at the end of the overhang. The gable part of the overhang can also be covered with a soffit.

Final recommendations

To extend the service life of structures, it is recommended to paint over all open locations of metal fasteners or corresponding holes on steel soffits with special paints that match the main color of the soffits. The filing does not require special care, but a couple of times a year its surfaces are inspected and cleaned with a long-handled brush.

Abrasive or aggressive detergents are not used for these purposes; particularly contaminated areas are washed with water with minor additions of soap or regular washing powder.

Particular attention is paid to lining made of wooden lining or corrugated sheets. In the first case, the protective coating of the overhangs is periodically (once every 2 years or more often under unfavorable conditions) renewed; in the second, the surfaces are inspected to identify pockets of corrosion.

Regardless of the type and material of the overhangs, the operation and condition of the drainage systems are checked simultaneously with their inspection. Now you know how to line roof overhangs.

Common mistakes when working with spotlights

- If the work is carried out by professionals, then the filing should be neat and beautiful .

- Separate attention should be paid to the reliability of the fastening of soffit panels; fastening materials and fittings should never be saved, otherwise a strong wind can undermine the entire structure.

- the design of the external walls before filing .

Another important note: for filing overhangs, you should definitely get stainless fittings so that later rust does not spoil the appearance of the building.

Sheathing of overhangs, made in the same style as the façade of the cottage Source interistroy.ru

Types of roofing sheathing

The final cosmetic finishing of roofs is carried out in two options:

- Cornice filing;

- Finishing of the gable overhang.

The eaves overhang supplies fresh air to the roof cavities and attic space. If it is packed tightly or installed incorrectly, the “roofing pie” will not be ventilated and moisture will begin to accumulate.

The complete absence of cladding causes serious problems:

- Roof blown off by wind;

- Damage to waterproofing and insulation by birds, mice, insects,

- Rotting of rafters, important supporting elements of the structure;

- Leakage of the ceiling (when water gets into the cavities of the “roofing cake”, destruction of waterproofing) with its subsequent collapse.

The finishing of the eaves overhangs is always done not solid, but ventilated!

Types of spotlights

Soffits are used to cover overhangs. These parts are similar to siding, but differ in the presence of a ventilation grille. Soffits can have different designs. Manufacturers produce combined parts - solid at the edges and with a grid (perforation) in the central part.

Soffits are made of wood, vinyl or steel:

- Plastic soffits are lightweight, durable, reliable, and can withstand impacts and strong winds, which is important for roofing. They are not subject to rotting and are fireproof. Goes well with PVC siding.

- Metal soffits are made of steel alloy; galvanization protects them from corrosion. They are covered with a layer of polymer on top. It can be polyester, plastisol or pural. Polyester retains its color for a long time, plastisol withstands deformations and impacts well, pural is resistant to ultraviolet rays, heat and cold.

- Wooden soffits last a long time, but only if they are treated with an antiseptic.

Most often, plastic or metal soffits are used for filing overhangs. To install them, purchase the appropriate profiles. They are installed along the perimeter of the roof from the side of the gables.

Soffits are distinguished by a reliable locking design. Therefore, when compared to conventional siding, they last longer and withstand greater loads.

Types of spotlights and their design

The word “soffit” is translated from Italian (“sofitto”) as “ceiling”. These parts are panels made of metal, wood or plastic, and are intended for filing eaves and gable roof overhangs, as well as other horizontal surfaces. In terms of the functions they perform, they can be compared with such popular materials as siding or lining today. However, these panels have a number of differences that take into account their scope of application. And one of them is their width, which can even reach up to 800 mm.

Soffits are divided into types according to various criteria:

- according to design features;

- according to the material of manufacture;

- by area of application.

Design features of soffit panels

According to their structural structure, soffits come in three types: perforated, partially perforated and completely closed.

Perforation of soffit panels creates conditions for complete ventilation of the under-roof space, which is necessary to prevent the accumulation of dampness with all its negative consequences

- The perforated version consists of panels that are evenly covered with small through holes over their entire surface. This type of material is intended for hemming horizontal surfaces of overhangs that are not exposed to the direct action of precipitation. Perforation is capable of providing effective ventilation not only of the overhangs themselves, but also of the entire under-roof space of the roof structure. And constant air exchange must be provided here. This is necessary to prevent the accumulation of condensation, dampness, and as a result, the onset of putrefactive processes on the wood and the appearance of mold or mildew.

Perforated panels perfectly protect the space under the eaves from the penetration of birds and insects (for example, wasps) into these cavities under the roof, since the holes have a very small diameter.

Overhangs lined with partially perforated panels.

- Partially perforated panels do not have ventilation holes over the entire surface, but only on one or two sections of the profiled sheet. Thanks to such hemming materials, it becomes possible to regulate the air exchange in a unique way. Partially perforated soffit panels are used for lining the external horizontal surfaces of the house, as well as the ceilings of terraces, gazebos, verandas or porches. Therefore, this type of material can be called universal.

Gable overhang lined with non-perforated panels.

- The non-perforated version of the panels does not have holes on its surface, and is intended for cladding areas that are likely to be directly exposed to precipitation. Such areas may include overhangs on the gable part of the roof, as well as vertical walls along the eaves. In addition, soffits without perforation can be used to cover the vertical part of the pediment.

Vertical walls along the eaves, lined with non-perforated soffit panels.

All except wooden homemade soffit panels, both plastic and metal, have special locks with which they are secured to the eaves and connected to each other. After the soffits are docked and fixed to the overhang sheathing, the locks will not be visible.

Prices for soffit panels

soffit panels

Locking connections on standard soffit panels.

Standard sizes of vinyl and metal soffit profiled panels can vary in width from 300 to 800 mm, and their length is usually 3050 mm.

If the lining work will be done independently, then it is necessary to take into account that the wider the panel is chosen, the faster it is possible to install the soffits in place.

Types of spotlights based on material of manufacture

Based on the material of manufacture, as mentioned above, finished soffits can be divided into plastic and metal (steel, aluminum and copper) options. Sometimes natural wood is also used. To decide on the choice of soffit panels based on the material of manufacture, it is worth considering their characteristics in more detail.

Plastic (vinyl) panels

Plastic soffits are made from the same material composition as vinyl siding for finishing facade walls.

Inexpensive and very practical vinyl soffits

Expert opinion: Afanasyev E.V.

Chief editor of the Stroyday.ru project. Engineer.

The lifespan of such plastic in outdoor conditions declared by the manufacturer is 30 years or more, which, you see, is a lot. It is easy to care for - just clean it from dust periodically. The material does not require coloring, since it has a constant color - the dye is introduced into the structure of the vinyl at the stage of production of the plastic itself. Specialized stores offer a wide range of panel colors, which allows you to choose one that will harmonize with the shades of façade paint and the color of the roof. The panels are sold in packages of 16÷22 pcs.

The advantages of plastic soffits include their following characteristics:

- Vinyl is highly resistant to external atmospheric and mechanical influences.

- The plastic has good flexibility.

- Vinyl is easy to work with as it cuts easily, and this process can be done using a regular fine-tooth hacksaw.

- The panels are lightweight, so it will not be difficult to lift them to a height.

- Vinyl is completely inert to corrosion and does not serve as a breeding ground for parasitic microflora.

- The operating temperature range of this material is very wide. Vinyl easily withstands frosts down to -50 and heat up to +50 degrees. That is, finishing parts made from it are suitable for almost all regions of Russia, with the exception of the polar regions.

- Vinyl is characterized by resistance to the ultraviolet component of sunlight, so over time the plastic practically does not lose its original color and structure.

- Vinyl products can be used for covering surfaces outside and inside the building.

Metal soffit panels

The group of metal soffits includes panels made of aluminum, steel and copper. However, the most popular of metal panels are steel ones as they are the most affordable. Aluminum takes second place, and after it comes copper, but not because of low quality, but because of high cost.

Each of the metal options has its own disadvantages.

It has already been said that the most affordable of metal panels are steel soffits with an enamel protective and decorative coating. After cutting parts for hemming, the cut edges require processing, otherwise, with the inevitable exposure to moisture, they will become centers for the appearance and further development of corrosion.

Aluminum can also be damaged by oxygen corrosion, and to prevent this from happening, its cut must also be treated with a special compound.

Copper, although it has the highest cost, is also susceptible to oxidation. Therefore, the material for these products is often subjected to an oxidation process. True, oxidation of copper does not lead to structural damage. Therefore, such products are often considered as not having any limited shelf life.

Prices for plastic panel panels

plastic panels

Copper soffits in combination with a drainage system.

Copper panels become more expensive due to the fact that they are usually purchased complete with a drainage system made from the same material.

The positive characteristics of metal soffits include the following qualities:

- Wide range of color solutions for steel and aluminum soffits.

- The copper version of the cladding of eaves overhangs has a very presentable appearance, especially if it is combined with a copper roof.

- With appropriate processing of cuts, the material becomes resistant to aggressive atmospheric influences.

- Completely inert to the formation of fungus, mold, moss, and biological decomposition.

- The strength of the material and fairly high resistance to mechanical damage.

- Inert to ultraviolet radiation and temperature changes.

- The operating temperature range is very wide – from -60 to +100 degrees.

- The material is environmentally friendly and does not emit toxic fumes.

- The relatively light weight of the materials facilitates installation work. In addition, due to this quality of the material, it can be used on old buildings. Such decorative cladding does not significantly increase the load on the supporting structure.

- Easy maintenance of the created structure.

- Long service life, which should be at least 30 years for steel and aluminum. We have already said about copper - there are no special restrictions on the duration of operation.

Wooden soffits

Quite often on wooden and stone buildings you can see overhangs lined with boards or wooden planks. Home craftsmen most often make such soffits on their own. Another option is to order them from carpentry workshops.

Wide possibilities in filing eaves and gable overhangs open up when using natural wood. True, you will have to make the soffits yourself for this.

However, when choosing this material for lining overhangs, do not forget about the need for ventilation. To ensure this, gaps are often left between the wooden planks, and to prevent insects from settling in the under-roof space, a metal mosquito net is attached to the eaves before fixing the narrow boards.

Wooden soffit strips can be fixed along the eaves or perpendicular to it. Their location depends on the choice of the house owner, the overall design of the facade and the width of the roof overhang.

Additional design elements for lining eaves overhangs

When installing soffit panels, additional profile elements will be required, which play not only a functional, but also a decorative role. For soffits, fittings from a kit are used for cladding walls and other surfaces with siding or plastic lining.

- To frame and secure the edges of the panels, a J-profile is attached to the sheathing of the plumb lines, which can have different widths, depending on the model of the kit.

Siding prices

siding

The J-profile will hide the cut edges of the soffits, hold the panels in a given position, and emphasize the edge lines of the eaves overhang

- To decorate the upper edges of the panels fixed to the wind board, a finishing strip is used. It is the final element of the design. This element is fixed along the upper edge of the wind board and the edge of the panel is hidden in it.

This illustration clearly shows the installation location of the finishing strip

- The H-profile is necessary for joining individual panels in places where it is impossible to use locks located at the edges of the soffits. For example, you can’t do without it when decorating the corner areas of eaves overhangs.

H-profile - masks the joints of panels in those nodes where it is not possible to use standard locking connections between them.

Using the H-profile simplifies the diagonal installation of panels and masks their unevenly cut edges. In addition, the H-profile must be installed between the panels in cases where the eaves overhang has a length of more than 8000 mm. The connecting element will add rigidity to the structure and make it more reliable.

- To install soffit panels on the wall of a building, not only the J-profile, but also the F-profile is used. It is convenient because it fixes the panel not only from below, but also from its upper part. The panels are pushed into this profile, fixed along the wall line, and firmly held in one position.

The F-profile is convenient for attaching soffit panels to the vertical surface of a building wall

- The profile, called the outer or outer corner, is usually mounted at the junction of the lower edge of the wind board and the eaves sheathing, and the wind board cladding panels and eaves soffits are installed into it.

The external corner profile is not used so often when filing overhangs, but sometimes, in some areas, it becomes the optimal solution

. In addition, the external corner can be used in other areas of the cladding, where it is necessary to join two panels on a corner line.

- Internal corner - this profile will be necessary if the house has an L-shaped or U-shaped layout, as well as if the porch, veranda or terrace of the house protrudes beyond the main building.

If the house is finished with siding, then the internal corner profile is perfect for framing the transition from the wall to the soffit.

The internal corner is also suitable for joining soffit panels and siding boards or lining used for wall cladding along the wall.

J-bevel - excellent for facing the front board, while simultaneously creating conditions for attaching soffit panels

- A J-bevel is a wide profile with an S-shape at the bottom edge. It is designed to install the front edge of the soffit panel into it. This profile element can be used when installing soffits if there is a wind (frontal) board in the overhang structure. When choosing the size of this profile, you need to focus on the width of the wind board.

An example of using such a J-bevel is clearly shown in one of the illustrations above.

Additional fittings for installing soffits are selected depending on the design that the lining of the eaves overhang will have. Sometimes different profiles can be interchanged. For example, instead of an internal corner, two J-profiles are installed, turned in different directions. However, it is best to use the profile element that is directly intended for a particular area of joining or framing panels.

In order not to miss any of the elements for installing the structure when purchasing material, it is recommended to draw up a diagram in advance and measure the length and width of the surfaces of the overhangs and wind board. In a hardware store, according to the diagram drawn up, the sales consultant will help you decide on the size and shape of the profiles, as well as their length and quantity.

What are roof overhangs and why are they needed?

The roof overhang is the surface at the bottom of the roof, which is distinguished by its protrusion beyond the walls themselves. It is needed to protect the walls and foundation of the house from moisture getting on them during heavy rainfall. As a rule, the width of this part varies within one meter. Construction rules allow not to line this part of the roof.

But still, it is best if the overhangs are treated, since a strong wind entering through the holes in them can easily tear the roof off the building. In addition to the practical function, overhang sheathing also has a decorative function, since it is always better to remove the underside of the roof and aesthetically treat its edge.

Before making cornices under the roof, you need to complete the roofing work, finish the house and install the finishing material on the cornices last.

Lining the overhang with clapboard or board

It is more convenient to carry out this work from below, sitting on a stepladder or on scaffolding. Before making a roof lining, it is necessary to completely complete the external insulation of the walls, lay a vapor barrier and complete the creation of the roofing.

In the case of covering overhangs with clapboard, the rafters on the side eaves must not only have the same length, but also be parallel to the wall of the building. Wind strapping boards are attached to them.

One of them is attached to the wall vertically, and its edge should be located at the level of the edge of the rafters. The second board is fixed between the rafters and the first board along the lower edges - it needs to be parallel to the ground. The result is a base onto which the sheathing elements are fixed. Sheathing is mounted on the frame.

To ensure air movement under the roof when using lining along the entire perimeter, ventilation grilles should be installed at intervals of 150 centimeters.

When the roof frame is sheathed with boards, a slight gap must be maintained between them and the wall. Lumber must be smooth, of high quality and have a thickness of 1 - 2 centimeters.